How to choose and install a circulating pump for heating?

Pumps operating in a variety of places have significant features. So, circulating systems must be ready to work with hot water and to increased pressure. They have other unique features depending on the particular species.

Special features

The technical features of the circulating pumps for heating are determined by their main task - maintaining the desired rate of water pumping through the pipes. Contrary to popular opinion, the increase in pressure during the operation of such pumps is small, and it is only an indirect result of the main effort. To really increase the pressure in the system, you need a completely different booster type.

Inevitable contact with hot water is characteristic of both species, but the narrowness of the task of booster devices does not allow creating such a large variety of models. Circulating devices are designed to maintain the water flow with the given parameters continuously.

Device

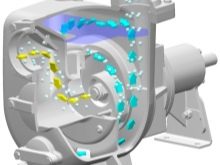

Pumping systems are divided into two basic groups - with a dry and a wet type of a rotor. Each subtype has its positive and negative sides.

The dry variant is characterized in that the coolant contacts directly with the impeller, and the rotor is prudently placed in a hermetically sealed housing. For the greatest protection from getting wet, it is additionally covered up immediately with a chain of sealing rings. The advantage of this option would be excellent efficiency (from 80%).

As for the drawbacks, the owners of dry machines do not like the strong noise and the need for systematic maintenance. The ingress of solid particles deposited from water on the sealing rings inevitably damages their tightness. Therefore, it is necessary to correct this problem at an early stage. Summarizing, we can confidently say that these characteristics do not allow to consider dry pumps as a rational choice for a private household.They are used mainly where savings in energy consumption overlaps these disadvantages.

The wet rotor is in direct contact with water. Only the electrical infrastructure of the pump, including the starter, is covered by impenetrable metal walls. Despite the efficiency in the region of 50%, such systems are considered to be the best output for a private house. No maintenance at work is required, and the time of use can be 2-3 times longer. The exact time of operation depends on:

- technical nuances of a specific model;

- heat carrier quality;

- practiced mode of application.

The use of a well-chosen circulating pump will not only accelerate the passage of water through pipelines, but also reduce the need for fuel or electricity to a reasonable minimum. This circumstance far covers the cost of the purchase, installation and use of equipment. In addition, the occurrence of air "traffic jams" is drastically reduced, which will be more efficiently removed with the active movement of water.

Important: the selection of the pump, which will be built into the existing heating system, should be even more careful than when creating it from scratch.When selecting a modification, it is worth choosing the ones that will be able to stand in their dimensions in the place where the coolant has the least heating.

Often, circulation pumps are supplemented with an uninterruptible power supply. After all, the slightest failure on the power line is able to block the heating system. And only the reservation is able to protect against the adverse effects of this kind. The UPS turns on automatically as soon as the mains supply stops. It gives the energy accumulated in the normal mode to the pump. Switching from emergency to storage mode is also done without the participation of people and even in their absence.

Considering the increased demands of the pumps on the quality of the incoming current, the uninterruptible power supply must produce the purest possible sine wave. For a complete set of solid fuel boilers emergency power supply is made more capacious, so that they can work for a long time without mains power. Double-conversion UPS are additionally stabilizers and have at least three batteries in the case. High practical characteristics naturally mean a very solid price.

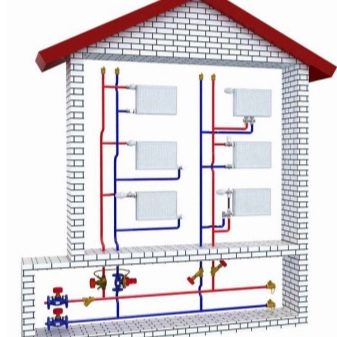

An open heating system in private homes is practiced much more actively than a closed one. In such an installation necessarily provides an expanding tank. It is placed in the highest place of the system and directly communicates with the home atmosphere. Pumps embedded in such systems should provide the movement of the coolant at a speed of 30-70 cm per second. This is sufficient for an optimal level of heat release; it will be possible to make the distance from the heater to the batteries quite large.

How to calculate?

To guarantee the normal operation of the circulation system is possible only with a preliminary determination of the necessary characteristics of it. You will not be able to take the required parameters in the finished table, you definitely need a competent calculation. It will have to be fulfilled, starting at the same time from the total heat demand of the house, and from the total resistance of the planned elements. If you overestimate the required figures, the pump will absorb too much electricity, and if you underestimate it, it will constantly be subjected to excessive load, which can lead to an early degradation of the equipment.

The need of a private house of an insignificant area is assumed to be 100 kW of heat energy per 1 square meter. m. For apartment buildings, this figure is somewhat less - only 70 kW. In industrial buildings and in the presence of high-quality, well-designed insulation, the energy consumption for heating 1 m2 is taken from 30 to 50 kW. Hydraulic resistance is calculated according to special schemes, in most cases, its value is taken from the technical documentation for the heating system. A typical heating boiler often has a resistance of 1 - 2 kPa, a thermal valve - 5 - 10 kPa.

Selection criteria

The choice of circulation pumps is determined by a number of factors.

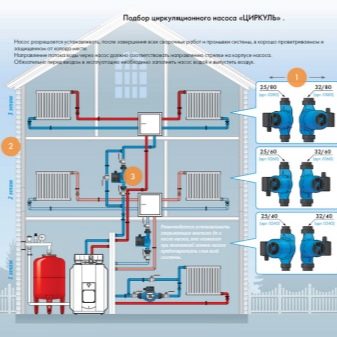

It is recommended to choose a device whose speed is regulated.; This allows you to improve the heating of the air in the room. Most of the existing models have two or three speeds, four-speed vehicles are rarely available. For private homes, in the opinion of experts, electric centrifugal circuit pumps are preferred. In them, the liquid, having entered the centrifugal wheels through the inlet opening, is soon removed via the side nozzle.

If the rate of rotation exceeds 1.5 thousand revolutions per minute, the system is considered as high-speed. Pumps that develop less than one and a half thousand turns in 60 seconds fall into the category of low-speed ones. The importance of this parameter is that the volume of fluid supplied to the system is strictly proportional to the torsion speed of the impellers.

We must not forget that the change in power consumption equals the change in head multiplied by itself. And it also coincides with the cube of changing the frequency of the torsion of the motor shaft.

The same proportion works strictly when performance drops. Usually a small pump power makes it more profitable. Even the increased initial price of a low-speed system and the complexity of its design result in low electrical current consumption.

For your information: for the most money-saving, it is worthwhile to select a pump with stepless switching of the shaft speed. Depending on the amount of water passed per hour, pumping systems are divided into productive and non-productive.

Some installations can pump up to 15 m3 of water in 60 minutes. With regard to the pressure, the most powerful household systems come with a wet rotor, they can supply water 17 meters up.More productive devices are designed for industrial use, differ in very large dimensions and are too expensive. Massively used pumps can work with water heated to 110 degrees, but some modifications allow pumping the coolant, the temperature of which reaches 130 degrees.

With everyday use, do not forget about the noise level. The quietest are the systems with a wet rotor, the sound they produce when working is limited to 40 dB. This roughly corresponds to the volume of a quiet conversation a couple of meters from the audience. In a private residential building you can find heating lines up to 1 ½ inches, connection to them is carried out using threaded connections. Typical lengths of circulating pumps are now 13 and 18 cm; additionally take into account the diameters of the inlet and outlet nozzles.

According to the latest international standards, the heating circulator has a protection category of IP44 and higher. Without going into purely engineering details, you can see that this means that solid particles larger than 1 mm in diameter cannot penetrate into the body.At the same time, electrical components are impenetrable for any drops and splashes of water, regardless of their speed, intensity and angle of flight.

Installation

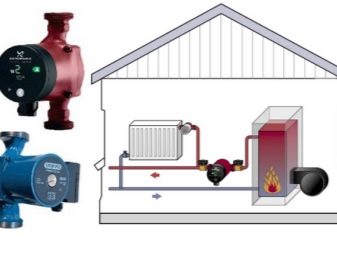

Installing with your own hands interests many people. And it is worth noting that there is really nothing phenomenal in it. It is not recommended to use pumping systems of excess capacity, there is enough reserve in 1/10 in comparison with the previously calculated value. As practice shows, this is quite enough in almost any case. And if not enough, it means that the calculation itself was wrong.

Before starting work, it is worthwhile to buy a complete set of equipment in which there will be detachable threads. In the absence of such parts in the supplied kit, you can always buy them additionally, but it is better to choose the most compatible ones. And also for the normal operation of the circulation pump, it is impossible to do without filters of enhanced cleaning and without check valves.

When choosing a place where it is better to install the pump, it is necessary to focus on areas that will make it easier to maintain the entire system without help. If the pipeline is made according to the falling scheme, the device is attached to it in the area of the tank.

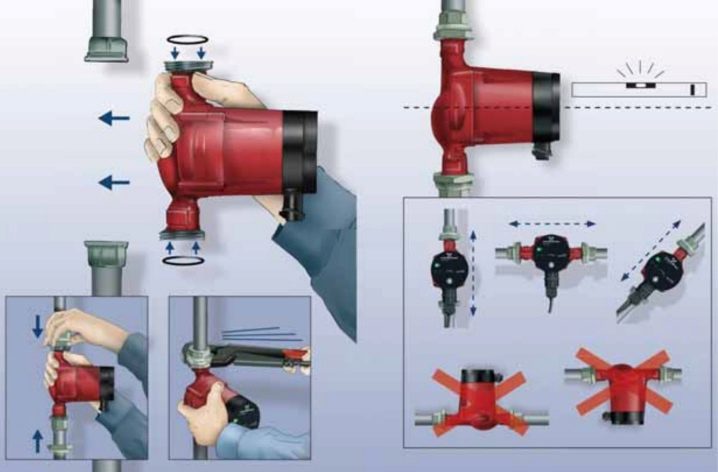

Before attaching pumps to the bypass pipes, it is recommended to check whether the device will be able to withstand the effects of an intensely pressing liquid heated to high temperatures. If you plan to connect a warm floor, the installation site, experts advise to choose a site where water is supplied. AT such a system accurately eliminates the risk of air bubbles. Before and after the pumping part, ball valves are installed to dismantle the device during various operations. The pump must be preceded by a filter that prevents debris and dirt from affecting the gentle technique.

In order to periodically discharge air, it is necessary to install an automatic or manually operated valve in the upper part of the bypass. All equipment is placed horizontally, it helps to avoid breakdowns of the "wet" pump, inevitable with partial immersion in water. The terminals are mounted at the top. Plumbing pads in advance soaked with sealant. The outlet to which the pump is connected should be grounded.

There are some differences when installing pumps in existing heating systems. In this case, doing the right job means:

- remove all water and clean the system, while if the equipment has been used for a long time, you will have to repeat this manipulation repeatedly;

- install the pump in the place that corresponds to the plan, taking into account the direction of the coolant;

- fill the pump with water;

- conduct a practical test of the system and identify any problems immediately and completely eliminate them;

- throw air out using the central screw (the operation ends when the water is released);

- start the pump when it is filled with water and will be connected through an automatic fuse.

The connection of the second pump is made so that it is connected to the relay or parallel to the first. Installation on the water return pipe increases the uniformity of the coolant wiring and reduces the operating load. Because the total time to use the pump will increase significantly. The diameter of the bypass pipes should be made smaller than the diameter of the pipes in the heating pipe. When installing the motor shaft, the box is rotated slightly along the axis, and the force should be negligible.

All connections, including the point of connection of the circulation pump to the valve, are treated with a sealant. This will make the system much more reliable and stable.

To reduce the time for parts selection and installation, it is more practical to choose complete sets ready for work.

For every 80 m of pipeline one pump should be installed. By following these rules and regulations of specific companies, you can guarantee yourself complete peace of mind.

Tips

Among the leaders of any rating of pumping equipment for domestic needs, brand products are invariably Grundfos. All experts agree that this equipment is definitely worth the money charged. On the market there are models with both wet and dry rotor. The second type is complemented by a special fan and is notable for increased noise, designed mainly for boiler rooms.

It is recommended to give preference to products from the “Alpha 2”, “Alpha 3” and “Comfort” lines (the first two belong to the premium category).

"Alpha 2" is different interface friendliness, the settings can be left and the factory - they are ideal for most tasks. Only in exceptional cases, experienced installers decide that it is better to change the modes of operation. As for the shortcomings of German products, it is worth mentioning the high price - but it is fully compensated by stable and uninterrupted work for a long time.

The developers promise that the pump will start exactly, even if its rotor has been inactive for a very long time. Excellent thermal protection and compact design - also testify in favor of this version; you will need to buy wires to connect to the network, as they are not included in the kit.

Representatives of another German company - Wilo - do not miss a chance to also say about the unsurpassed quality of their products and their adaptability to Russian conditions of operation. And this statement is not far from reality. At least, the period of use of such systems (Star RS) before applying to specialists for repair is 10-15 years on average.

Installers mark the convenience and ease of installation of such models, the ability to adjust the power in accordance with their needs. The common shortcoming of the “Germans” (as well as any other means of circulation, however) is dependence on the incoming electricity.

Much depends not only on the selected model, but also on the elaboration of connecting it to the system. Since the circulation will be provided at any time, you can save money using pipes and fittings of a smaller section.Moreover, the reverse approach (attempts to do without pumps, increasing the diameter of the connected circuit) does not justify itself economically. In most cases, non-specialists can perform only the most approximate calculation of the required characteristics of the equipment. After all, you need to analyze:

- how complicated is the layout of highways;

- how many radiators will need to be installed;

- what valves will be installed;

- how powerful the boiler is;

- Is the water quality in the pipe good?

- what material the pipes are made of and so on.

All these factors can be studied competently and fully only by professionals. But also their actions are required to be controlled, for this it is worth knowing a number of obligatory nuances. So, models with automatic mode switching are noticeably more expensive than simple ones - and yet the price difference fully pays off. If only because the setup of such equipment without the involvement of consultants is very easy. The design pressure for the pump is assumed to be equal to the distance from the input of the return into the boiler to the top of the highest radiator.

Wherein Of course, they take into account the thickness of interfloor overlappings The figure obtained as a result of measurements can be quite increased (rounded to the nearest integer value in meters). "Wet" pumps are mounted by tapping into the pipeline, a two-way threaded connection is made. More powerful dry-type apparatuses are mainly fixed using flanges. In any case, there should be a valve on the bypass.

Repair of the circulation pump in most cases, it is possible to make their own hands, without turning to the masters of service centers. But it would be even more correct to take care of the prevention of failures. Thus, it is prohibited by technology to start circulation when the pipelines are drained. We'll have to carefully monitor the compliance of the pumped volume of liquid and passport characteristics. It is recommended during long periods of inactivity for any reason to start the pump for at least 15 minutes every 30 days.

This technique will significantly reduce the risk of oxidation of moving parts and their destruction. Even if the instructions allow, it is better not to take risks and do not feed water hotter than 65 degrees into the pipeline. Stronger heating can break moving parts of a vehicle or cause accelerated wear on it.Once a month you need to inspect the circulation pump and check whether it works properly. The test procedures for initial and subsequent starts are about the same.

Immediately after launch, it is assessed on the standard operating mode whether there is any extraneous noise and excessively strong vibration. The generated head should not be more or less than the passport values. A normally working and properly installed motor should not get very hot.

The next step of the test will be to check the lubrication of the threaded flanges and the test for grounding the gap from the housing to the terminals. Be sure to look for possible leakage during the inspection, primarily at the junction of pipes and housing.

If these checks give a positive result, or problems are fixed, you need to check the tightness of the bolts and gaskets, the terminal box (fixing the wires in it). But it is important to understand that even deep, high-quality prevention does not fully guarantee the appearance of serious problems. The hum of a pump that does not spin is most likely due to the oxidation of a long idle motor shaft. You need to act like this:

- disconnect the device from the network;

- drain water, including from adjacent pipes;

- remove the screws and remove the engine with the rotor;

- rotate the rotor manually or with a screwdriver, making sure it is in close contact with the notch.

A similar approach will help solve the problem of contamination of the pump with foreign bodies. If the circulation apparatus fails, it is imperative to check the quality of the power supply and the voltage level in the network. The pump, which is very noisy at start-up, suffers for the most part from the presence of air in the heating circuit. Without releasing this air outside, the problem cannot be solved. When the device not only makes noise, but also vibrates, you need to increase the pressure at the inlet to the pump; weakened head can be corrected by increasing the level of coolant.

But it would be much more correct to deal with the real cause of the weakening of pressure, that is, with the wrong connection of the equipment phase. Sometimes the pressure weakens due to excessive viscosity of water, which is difficult to overcome by the impeller. You can resolve the problem if you clean the filter on the inlet pipe, check the cross section of the pipeline. According to this section, the pump itself is regulated.An abrupt halt immediately after starting is usually triggered by incorrect connection of the wiring phases inside the terminal box.

And also this problem occurs when the fuse density is insufficient, which needs to be removed and cleaned. But still competent for the normal operation of the heating system is competent selection of equipment and installation of it. For example, to prevent the occurrence of noise with an increase in hydraulic resistance from switching thermal valves can only pump with electronic adjustment of revolutions. Before installing the circulation pumps, it is worth reading the instructions, not relying on your own knowledge, on the advice of professionals and even on personal experience with similar devices. Only strict adherence to regulations ensures minimal risk.

A common mistake is the incorrect placement of the pump in relation to the horizon line. It leads to air traffic jams, and this is still a relatively mild consequence. More serious problems are poor cooling and insufficient lubrication of the bearings. Regardless of the quality of these parts, this mode is unnatural for them, and quickly leads to wear.It is also worth looking carefully so that the pump is not set “on the contrary” with respect to the flow of the fluid, because it is easy to mix up the same-looking flanges.

The filter at the pump inlet is a standard mud cleaning device for water supply. In appearance, it resembles a fragment of a pipe with a tap at an angle. The straight segment is equipped with a metal mesh that stops the flow of debris. A twist off end cap allows regular cleaning of the system.

Important: it is necessary to mount the pump only after the expansion tank, because this tank normally works only with calm water.

Terminal boxes are most often equipped with watertight gaskets, you should not neglect this detail. If the heating system is filled with water heated over 90 degrees, the pump must be connected with a heat-resistant cable. But even in this case, it is recommended to conduct such a cable so that it does not come into contact with the case or pipeline. The circulation pump must necessarily be grounded, even if with a typical European plug, so long as the ground line is connected to the supply socket. For the most security, it is worthwhile to place an additional disconnectautomatic machine next to a working outlet.

Manually operated pumps are free from air before each start to work. Devices of the "dry" format are mounted for the most part on specially prepared platforms or brackets. In some versions, a socket is created where you can put a pressure gauge. The impeller of the fan, which removes heat from the electric drive, should be covered from above with a cover. Almost all pumps are connected to the 220 V network, but there are models that violate this rule, so you need to be careful when choosing.

Getting acquainted with the technical documentation on the pump, we should not confuse the mention of metric and inch measures. With regard to the characteristics of specific brands of equipment, you need to remember the different requirements for the coolant. Some manufacturers claim that water can be used in a mixture with ethylene glycol (up to a 1: 1 ratio). But no firm extends its official guarantee for systems operated in this way. The instructions often say that the load on the system with this approach increases, and you need to buy pumps with increased power.

On the other hand, even those companies that do not mention this in the accompanying documents always notify consumers that when the glycol concentration is from 1/5, it is necessary to check the performance of the pump. You should not choose products from the most famous brand or the one that is offered without explanation, declaring “the best”. It is more correct to focus on the availability of service, especially when buying an imported pump. The longer there is a manufacturing company, the better. For every 10 m of the length of the heating pipeline, there must be a 60 cm fluid pressure.

When the pump is connected to the peak load unnecessarily, a discouraging result can be obtained. Too fast moving water will not be able to warm up in the heat exchanger to the desired value. At the same time, the cost of heating the room and the intensity of fuel consumption are unnecessarily high. The overwhelming majority of systems on the Russian market have an installation size of 18 cm. It is very important to find out whether a particular sample can switch from day to night mode or not.

Among Russian companies, it is worth mentioning such a manufacturer as the Insel PTK. A quarter of a century in one of the most unpredictable and volatile markets definitely deserve attention from consumers. If we talk about international suppliers, you can not ignore the company Neoclima. The company has been present on the Russian market for almost 20 years, and all this time it has been working to improve its products, to improve its appearance. This last moment is important, because the circulation pumps will inevitably come across the eyes of the owners and everyone who comes into the house. And because it is worth buying just such a model that does not disappoint emotionally.

For relatively powerful pumps, three-phase electric motors are required.

If the special mechanical force for pushing water through the pipes is not needed, you can do with a single-phase product. The choice in favor of the “wet” scheme is also optimal in those cases when the simplest correction of problems is required. These devices are now assembled on a modular basis. And because the vast majority of problems are fixed by simply replacing the problem parts.

To find out how to install a circulating pump for heating, see the video below.