Vortex pumps: device and principle of operation

Today, thanks to a large number of instruments and devices, it is much easier to perform various kinds of tasks and processes. Such units as pumps have long been widely used in various fields of human activity. This also applies to vortex aggregates.

Special features

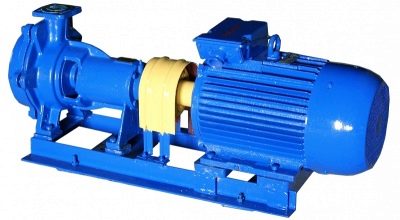

Such equipment acts as an assistant in solving many everyday issues, since, due to its configuration, it has inherent technical characteristics that favorably distinguish the devices of this line from other analogs. To vortex pumps include dynamic units, in which, thanks to special blades located on the impeller, the fluid circulates.

Due to its design, the device is operated for pumping various liquid substances, whereby these types of pumps are widely used not only for domestic purposes, but also in the production area.

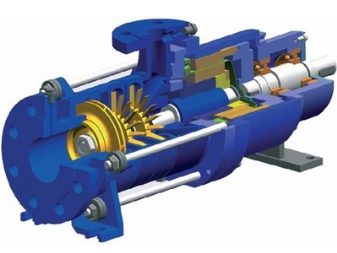

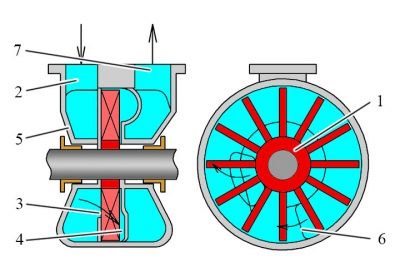

Today in the market, manufacturers offer the consumer various types of vortex pumps, which have differences in configuration as well as in principle of operation. However, one feature that unites all commercially available types of apparatuses is the presence in the design of the impeller of special elements in the form of blades, which can be located both in an inclined and radial position. The main part of the unit is the impeller, its rotation occurs inside the chamber of the cylindrical type, where the distance between the walls and parts of the blades has a minimum value.

Water or other liquid medium penetrates into the apparatus through a special inlet, and then, thanks to the operation of the blades, it moves along the internal capacity of the pump. Fluid exits through the outlet.

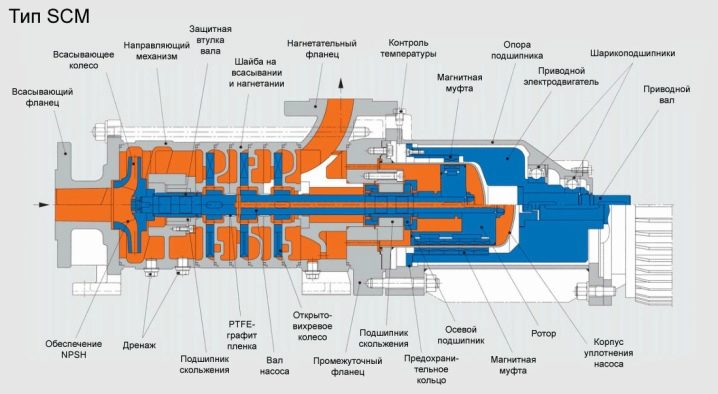

In its configuration, the device impeller is a disc made of stainless steel.Around the entire circumference of the parts, using milling, special notches were made, forming the blades. The receiving and output openings are located on top of the unit.

The internal part of the vortex pumps has a drain channel. To separate the cavities of the impeller device, a special jumper is used.

Compared to centrifugal devices, vortex pumps are capable of pumping seven times more fluid, creating much more pressure, since the main feature of their design is the ability to function as a self-priming mechanism that can work with a liquid and gaseous medium.

The device has a number of positive characteristics related to the operation:

- due to the ability to work with large volumes of liquids, the pump capacity can be about 12 liters of the pumped substance per minute;

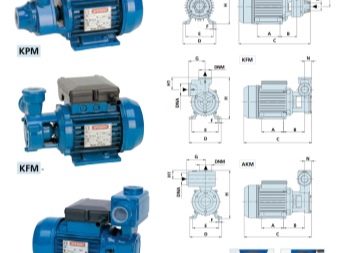

- the device has small dimensions, due to which its installation is facilitated, and also it becomes possible to locate the equipment in small-sized rooms;

- due to the self-priming capability, the device can be started even in cases when there is no liquid in the inlet pipeline;

- design features of the vortex pumps allow the use of units for working with liquid substances, as well as with mixtures of different types, which may contain gas;

- in the case of operation of the device in wells, devices of the vortex type can work with a fluid that is in the well even at a depth of about 20 meters;

- surface devices are not inferior in their power devices, the operation of which is recommended in the industrial field;

- vortex pumps are allowed to be used as a device capable of pumping and transporting volatile liquid mixtures, which include liquefied gas or gasoline.

Like any other equipment, the vortex pump has some drawbacks, among them it is necessary to highlight the following nuances:

- due to the low efficiency of about 45%, the use of high-power aggregates of the vortex type is impractical from an economic point of view;

- equipment can work only with pure liquid medium, pumping dirty liquid is strictly prohibited;

- besides, with the liquids having a viscous consistence, the vortex pump cannot work.

It is necessary to highlight the main areas where vortex pumps are operated:

- industrial plants are pumping alkali, various acids and other non-aggressive substances;

- With the help of vortex aggregates, volatile liquids are transported, therefore the device is necessary for the functioning of different types of filling stations;

- the device is used to work with dissolved gases;

- the device is present at many pumping stations operating in automatic mode;

- equipment of vortex type is widely used in public utilities;

- similar devices act as vacuum pumps instead of water ring compressors;

- Quite often, vortex pumps are purchased for arranging mini-boilers.

Based on the features of the device, we can conclude that the operation of the devices is justified in the case when you need to pump over the liquid medium with the supply of an average level, but with a large head.

Kinds

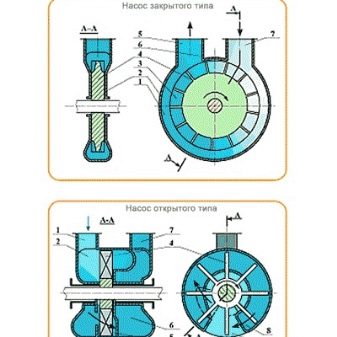

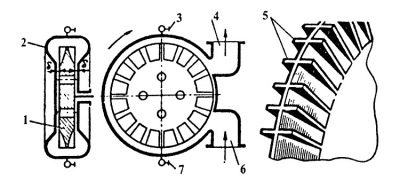

Taking into account the device of the vortex pumps, they can be divided into two groups:

- open-vortex type devices;

- closed-vortex machines.

The first type of pumps is distinguished by the following characteristics:

- the impeller blades of the device are characterized by an elongated shape

- the impeller has a small diameter;

- the annular valve is connected to the pressure port.

The second type of pump has the following design features:

- blades of the device differ in smaller size in comparison with similar parts of devices of open-vortex type;

- the diameter of the impeller is equal in parameters to the cross section of the inner region;

- annular channel combined with the receiving pipe and the outlet pipe.

The differences between the units are not only in the individual features of the assembly of devices, but also in the scheme of their work.

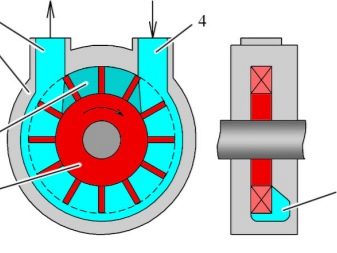

Open-vortex devices function as follows:

- fluid enters the inner chamber;

- the medium is captured by the impeller and enters the annular channel;

- a fluid flow is formed, which under pressure passes through the structure to the outlet of the pump.

Based on the structural features of the closed-vortex apparatus, in the course of working with a liquid medium, it immediately enters the annular channel from the inlet, in which a pressure flow is formed.

You can also classify products, given its location:

- stand out devices that are lowered into the work environment;

- devices of surface type, which are located near the tank with a liquid medium.

In addition to the standard configuration devices, there are combined type devices on the market.

- Devices free swirl destination. Such pumps differ in the positive characteristic allowing the device to work with the polluted liquids. That is why such devices are operated as drainage and fecal pumps, as well as for the arrangement of mining enterprises.

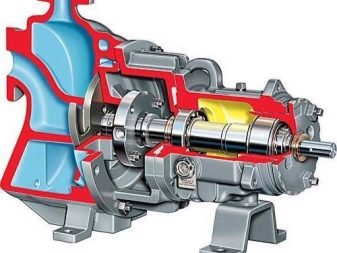

- Centrifugal-vortex units are notable for the possibility of working with liquids whose temperature can reach 105 ° C. The devices have two impellers, which contributes to a high level of efficiency.

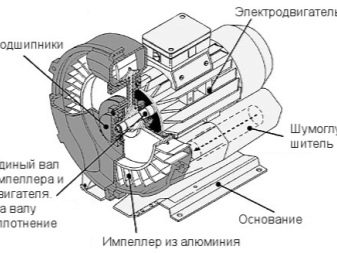

- Vacuum devices are characterized by the ability to pump air. Devices have a simple configuration, so it is very easy to work with them. Most often, such combined devices are used in the form of a heat apparatus that ensures the transmission of air in a heated or cooled state.Vacuum pumps are purchased for drying glass containers or for aeration of various types of reservoirs.

How does it work?

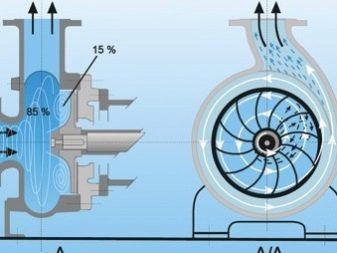

The principle of operation of VCS devices is quite simple. During the rotation of the fluid and the impeller centrifugal forces are formed, due to which the contents under the pressure goes into the nozzle. In comparison with a centrifugal pump, vortex units have some differences in operation.

It is worth noting the main features of the unit:

- during the rotation of the impeller, a certain amount of a liquid medium enters the nozzle, where it moves along the slots of the rotational mechanism;

- the liquid medium entering the grooves makes its movement from the beginning of the unit to the center;

- working fluid when exposed to centrifugal force moves along the grooves in the opposite direction;

- due to the rarefaction of the air, which creates the blades of the moving parts in the pump, it becomes possible to suck the liquid medium inside.

It should be noted that the vortex aggregates for one complete rotation of the impeller carry out the suction and ejection of a liquid or gaseous medium several times, thereby increasing the energy of the flow, and as a result - the pressure increases.

Installation

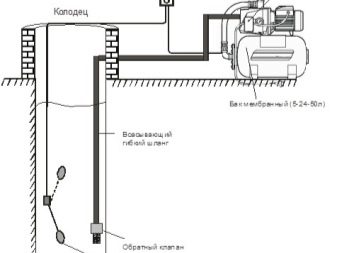

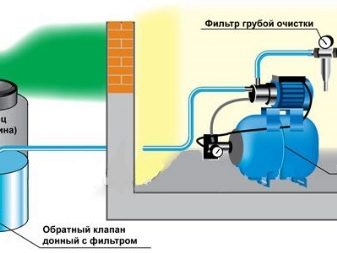

Thanks to the competent and professional installation of the vortex devices VKS or VC, the device will be able to perform its functional tasks as efficiently as possible.

Therefore, first of all it is necessary to choose the right place for installation. In this case, the choice will come from where the source is, a reservoir or a well with a liquid medium that should be pumped out. The pump must be installed as close as possible to this place.

Installation can be done by hand, it is enough to adhere to the installation scheme.

- First, you need to build a rigid foundation for the device. It is best to pour the foundation of concrete, or to place reinforced concrete slabs as a foundation. The strong and equal platform will allow to put the equipment correctly. In this case, the level of installation of the pump is very important, since even a slight bias can negatively affect the operation of the machine.

- The device must be protected from the effects of atmospheric factors. To do this, it is necessary to make a canopy in the case of temporary installation of a load on this place or to build a special building, inside which the pump will be permanently.If you plan to build a stationary station, do not forget about the heating of the building, since negative temperatures can damage the equipment, resulting in the question of the need to repair the device.

- A very important point is the stabilization of the voltage of the electrical network, due to which the vortex pump will function.

- At the final stage of installation of the device, it is necessary to check the tightness of all available joints and connections in the apparatus, as well as to make sure that the water head corresponds to the parameters that are specified in the technical documentation for the product.

Tips

To make the right choice of the vortex pump, with the purchase it is worth remembering that the device must perform two main tasks - to supply liquid medium from the designated place and have a reliable design.

Almost all models of aggregates on the market meet the stated requirements. But, Adhering to the recommendations of experts, you can choose the optimally suitable device.

- An important nuance is the power level of products.Based on the needs and technical characteristics of the devices in this or that case, the decision to purchase a pump is made.

- The volume of fluid in the well should not be less than the minimum consumption of the device.

- You should pay attention to the calculation of pressure. This indicator is influenced by the depth of the tank and the location of the pipelines. The above values are indicated in the technical documentation for the device.

- Also important is the warranty period of the device.

By focusing on such important features of devices, you can accurately choose a model of equipment that can satisfy your needs to the maximum extent, as well as meet all the requirements of the water supply system.

In the next video you are waiting for the disassembly and repair of the surface vortex pump.