How to repair a pump station?

Pumping stations are usually used in order to organize an autonomous and high-quality water supply in a private house. They can also be used to improve the quality of the plumbing in the apartment. Of course, like any other device, pumping stations can break. However, if there is a desire, even without a lot of experience, you can repair the equipment yourself without any problems.

Special features

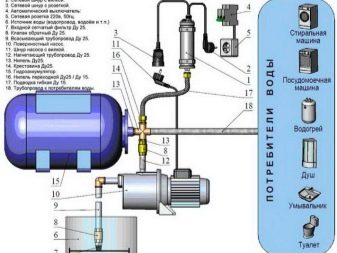

Pumping stations often consist of a water pump, a hydraulic accumulator, a pressure switch and a pressure gauge. Their main task is to automatically draw water from a certain source and deliver it to the house.Also, the station allows you to make the water pressure in the water pipe better, protect the water system from water hammer and organize a water supply if you suddenly have problems with the water supply.

Mostly used surface pumps. For the installation of pumping stations in a private house most often allocate a separate room with good sound insulation. They can also be put in caissons.

Pump power should be enough to raise the water from the well and deliver it to the house. One of the most important parts of the station is a hydraulic accumulator, its storage tank should contain from 20 liters. The accumulator allows maintaining constant pressure in the pipelines of the station. The most successful battery model is a metal bottle, inside which there is a rubber membrane. When the station is working, the membrane is stretched, and at rest it occupies the same position.

The pressure switch turns the pump on and off depending on the water level in the tank. Water enters the tank until it reaches a certain maximum level, and then the pump is turned off.As water is consumed for a variety of needs, the pressure decreases. When the pressure reaches the minimum mark, the pump will turn on again and water will flow into the tank. A pressure gauge is needed to determine the level of pressure in the water supply system.

Each element of the pumping station can work both by itself and as a single system. You can pick up a fully finished pumping station as well as assemble it yourself, taking into account your own needs. Pumping stations can safely provide water not only for the house, but also for the bathhouse and other buildings on the site. When the principle of the station is clear, it is easy to identify and fix many breakdowns.

Causes of failure

As with any device, pumping stations can have various malfunctions. Among them there are the most common, you should learn a little more about them.

Pump turns on too often:

- If at the same time the water goes jerky, the cause of this malfunction is often the non-working automation unit, in particular, the pressure gauge.

- If the readings of the manometer will decrease sharply, then it is then that the water will go in spurts.This is due to the unsuitability of the pressure accumulator membrane, which changes its size based on the volume of water. To determine this failure, you should click on the nipple that makes access to the membrane. In that case, if you can hear how air is oozing out of it, then everything is in order. If water is pouring out of it, then the serviceability should be eliminated by replacing the accumulator.

- Accumulator volume too low. When choosing a pumping station for a country house, many want to save money by choosing a low-capacity hydroaccumulator (24 liters or less). Such a volume will be very small, as the hydraulic tank eventually collects only 50 percent of the water from its total volume. Thus, in a 24-liter tank, there will be about 7 to 12 liters of water in total, which is quickly consumed. As a result, the pump has to turn on often. To eliminate it, it is recommended to additionally install one more accumulator.

Incorrect setting of pressure switch. The difference between the pressure at which the pump is turned on and off, you just need to do more. Moreover, it is important that the pressure at which the pump will turn on should be set at 0.2 atmospheres less than the pressure in the accumulator.The pressure in the accumulator is checked by connecting the pressure gauge to the nipple. The optimum pressure is 1-1.5 atmospheres. If necessary, it must be set off or pumped up using a pump, for example, an automobile.

- The check valve is clogged. In the event that the valve does not work and the water leaves the system, the pressure decreases and the pump is turned on every 10–20 minutes. Often just enough to clean the valve, but sometimes it needs to be replaced.

- Damage to the spool, which is located in the upper part of the accumulator. Eliminated by replacing the nipple.

- Unsealed pipeline or its connections. As a result, air enters the system and water flows from it.

- The pump pumps water along with the air. This is due to the reduction of the water mirror. Solve this problem is necessary by lowering the pump or pipe below.

- Malfunction of the plug, socket, cord, burning or oxidation of the contacts in the place where the electrical cable is attached to the motor.

- The pumping station does not turn off: Lack of water at the source, the so-called “dry run”. This malfunction can lead to combustion of the pump, since it does not cool due to the pumped water.To prevent this breakdown, it is best to use sensors that show the water level. They are electric or float.

- Suction line resistance value is too high. Most often this happens if the length of the line is too large or the diameter of the pipes is too small. To check it is necessary to immerse the suction inlet in a container with water near the pump. In the case of a normal increase in pressure, it is necessary to look for the cause in the route. For example, lay pipes with a large diameter, lay the pipeline in a straight line, minimizing the number of elbows and connections.

- Air suction in the main occurs due to poor connections (non-tight). Detected by monitoring the pressure gauge after the station is in the off state. In that case, if the pressure does not decrease, then everything is in order with the system in terms of tightness, and if it decreases, then a leak should be sought in the system.

- Check valve or pipe filter does not work. They must be removed, cleaned and reattached.

- Faulty pressure switch. Sometimes the pump cannot build up the required pressure due to the fact that the pressure valuewhen the pump is turned off, too large. In this case, it is sufficient to adjust the cutout limit. Also, the relay contacts may be damaged. In this case, they form a dark patina, which is cleaned with sandpaper. The pressure switch may stop working due to salt, which is deposited on the adjustment springs or clogged inlet.

- Impeller erased. This often happens when the pressure at which the pump is turned off is set much lower than the maximum pressure. In this case, it is often enough to simply replace the impeller.

- Low mains voltage. In this case, it happens that the pump is working, but the pressure switch stops. The solution may be a voltage regulator.

The motor works, but the water does not go:

- The impeller does not rotate. This can be due to both a low line voltage and a blown capacitor in the terminal block. The latter is checked using a tester.

- There is no water in the well or the well.

- Filter or check valve clogged.

- Jammed impeller. In this case, you can try to turn the shaft with your hands, which can be covered with salts.If it was not possible to manually scroll through it, then you should remove the protective cover and unlock the impeller.

- The pump does not take water. The reason for this failure may be the lack of optimal pressure in it.

- Water flow is uneven. It happens that the pump is stable, but the water flows in uneven volumes. The main cause of this fault is the air in the pipeline. To eliminate it, it is advisable to check the water level in the well or well, and, if necessary, to correct the position of the water intake hose.

How to fix?

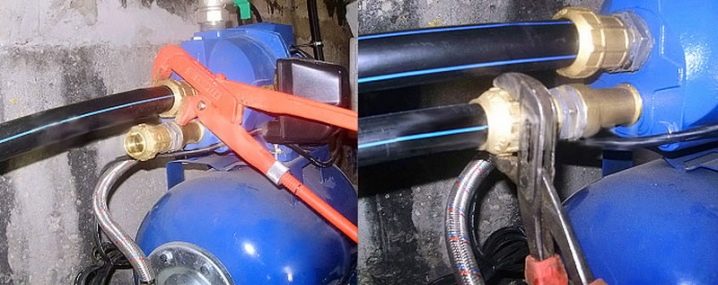

Do-it-yourself pumping station repair is quite a feasible procedure. However, it must be remembered that before troubleshooting and restoring normal water supply, all water should be drained and all elements should be disconnected, including the expansion tank, pressure gauge, pressure switch, and so on. If the engine does not work, the first thing to start with is to check the supply voltage. Then it does not hurt to check the entire wiring diagram of the station. It can also happen due to contamination of the pump, which means it should be disassembled and cleaned.It is advisable in this case to install an additional filter. If a fuse fails, it must be replaced. The fan impeller should scroll freely. If not, then the engine is jammed. In this case, the motor cannot be started until the problem is resolved.

It is worth checking the contacts of the pressure switch. Also, it would be useful to check the terminal capacitor. If there is no water in the device, it means that you just need to fill it in there and reduce the height of the suction, if it is no more than 7 meters. In the intake manifold, make sure that there is no suction and clean the check valve. Next, you need to adjust the voltage stability, reduce the resistance in the discharge pipe, clean the pipeline or lay a new one along a more direct path (without sharp bends).

If the engine is running, but does not supply water, you need:

- check the water level for the intake;

- eliminate air leakage into the pipeline;

- clean the feeding part of the pipeline;

- pour water into the system to remove the airlock;

- eliminate the reasons why the equipment is working "dry".

Insufficient water supply is eliminated as follows:

- clean the pump and pipeline;

- eliminate pipeline leakage;

- remove the slightest leakage of air in the intake section of the pipeline;

- in case of significant corrosion, replace the intake section of the pipeline.

If there is an excessively frequent on / off of the pumping station, then you need:

- Replace damaged accumulator membrane or hydraulic tank.

- If the pressure of compressed air is low or there is no compressed air in the tank at all, then it is possible that a damage has been formed in the tank due to corrosion. It should be removed, and then pumped into the tank air to the required pressure on the gauge.

- The third-party item blocked the check valve and it cannot close. In this case, it is necessary to carry out actions to unlock the valve.

Pumping station does not provide normal pressure:

- The pressure switch is set too small values, they are adjusted.

- The inlet of the pressure switch is clogged, it must be cleaned.

- If there was a blockage of the supply pipe or the working body of the pump, you should turn off the power.Then clean the pipeline and pump.

- If there is air in the pipeline, check the tightness of the connections; it is advisable to make as few connections and bends as possible.

If the pumping station is working, but not shutting down, then the pressure switch is set to a very large value and must be adjusted.

Manufacturers and reviews

On the market you can find pumping stations from various manufacturers. Of course, they all have their own characteristics. However, the choice is to rely on real feedback from users. For example, pumping stations Pedrollo have a beautiful view, high performance and low heat, if used for a long time. But among the shortcomings worth noting low-quality rubber, the taste of which you can sometimes even feel. Automation also proved to be not the best way, as the body of cast iron.

Stations Espa work fine the first 2.5-3 years. Any obvious flaws pumping stations of this manufacturer do not have. Practice shows that as a household device, devices show themselves as high-quality and reliable.The only thing they need is the right conditions of use (humidity, temperature, and so on). Unipump pumping stations are fully consistent with the stated characteristics and practical in operation. Great for country houses, as easy to use and fully automated. Rarely for several years of use there are minor breakdowns.

Manufacturer "Watercolor" I invested a lot of advantages in my stations. These pumping stations carry voltage drops, work even with low water quality. At the same time the small weight and compact dimensions allow them to be removed at any convenient time. Another advantage is the affordable price. Users of Karcher BP 3 Home pumping stations are mostly dissatisfied with unstable pressure. For country houses this is not the best choice. In addition, they require a special installation location, as it is very noisy.

Stations from Sterwins have good quality. Of the special advantages should be noted compactness and low power consumption. The station also works very quietly and in practice has shown itself as a trouble-free unit. Hammer pumping stations are one of the few with almost no negative feedback. Differ in reliability, a good pressure, the compact sizes.At the same time, they also work quietly.

Pumping stations Leo great fit for use. Full automation, low cost, compliance with the stated characteristics make them almost ideal device for domestic use. The only thing that is necessary for the normal operation of stations is a check valve. Manufacturer CMI has invested a lot of advantages in pumping stations. Despite the low price, the stations work quietly, give excellent water pressure and automatically maintain pressure. Among the shortcomings of these stations, it is worth noting the lack of automatic protection against working "dry." Users characterize pumping stations Elpumps as powerful, durable, high-quality and corresponding to the declared parameters.

Tips and tricks

To pump station worked for a long time and without interruption, experts advise to adhere to some of the recommendations. To prevent compression, you must use PVC pipes with high rigidity, metal pipes or reinforced hose. At the same time, smooth installation of pipes is important in order to avoid any deformations.At the junction should be carefully sealed. During inspections for the purpose of prophylaxis, compounds for leakage should be carefully examined.

The check valve is best installed on the water supply hose. A filter should be used to protect the pump from contamination. Hose leading to the pump should be immersed to the depth recommended by specialists. To install the pumping station it is necessary to prepare an even and solid base. Also useful will be rubber gaskets, absorbing shock from vibration when the pump is running. It is recommended to install a pump station in a room where the temperature varies from 5 to 40 degrees and the humidity does not exceed 80 percent.

To prevent the pump from running dry, use a special circuit breaker. If the water level falls below the set mark, it will turn off the pump. Check the status of the pumping station is necessary every three months. Special attention during testing should be given to the readings and settings of the pressure switch. If this knot is adjusted incorrectly, a serious damage to the station can occur.As a preventive measure, it is recommended to vent air released from the water and filling part of the volume of the hydraulic tank. Large tanks are equipped with a special crane for this. Excess air is removed from the membrane of a small tank by filling and completely draining the water several times in a row.

How to repair the pump station with your own hands, see the following video.