Borehole adapter: what is it?

The most important moment in the preparation for the operation of the cottage or suburban area is the water supply. In the absence of trunk communication systems, an excellent solution is to install a water well, and if it is already installed, then half the work is done. Now you need to properly provide automatic water supply. For this purpose, use the adapter for the well.

Special features

The downhole adapter has appeared recently, but it is already successfully replacing caissons in the wells, because this mechanism has a number of positive characteristics. A downhole adapter is an installation that connects the well exit to a plumbing system that goes into a dwelling.The device is located in the casing at a level below the freezing point of the soil. Thanks to this installation, the functionality of the well and the design of the autonomous water supply of the dwelling in winter is achieved, even in extreme cold. The need for thermal insulation works for the plumbing system is automatically eliminated.

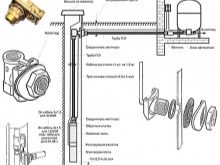

The device consists of two parts: external and internal. The first element is a fitting that is installed in a pinhole, prepared in advance in the casing. On the part of the nozzle that remains inside, a recess is placed for fixing both parts of the downhole adapter. On the outside is a threaded connection for connection with a water pipe, auxiliary sealing parts to protect against leakage and ingress of ground water, as well as a cap nut, which firmly secures the entire system in one position.

The second element of the downhole adapter is placed inside the casing. It is a modernized knee, one end of which is connected to a hose remote from the pump in the well, and the other with a part, which was described in the previous paragraph.For this, the part is equipped with a dovetail thorn and a rubber sealing ring, which makes the joint tight.

To facilitate the installation procedure, the upper part of the inner part of the downhole adapter is equipped with a blind threaded microhole. A mounting tube is screwed into it, through which the product is immersed in a water well. There it is installed in the groove of another element of the adapter. After that, the installation pipe is simply unscrewed and pulled out. You can make such a mechanism yourself.

The borehole adapter has the following advantages:

- reasonable price of products. If you compare with the cost of the caisson, the adapter is 5-7 times cheaper. If the budget is not enough, you should pay attention to the data mechanism;

- the fluid at the mouth of the well does not freeze through;

- easy installation Installation of such equipment can produce anyone who knows how to hold a drill;

Installation of the adapter can take several hours, thereby saving time.

- compactness. The casing pipe with an adapter does not occupy any storage space, nor will it be a structure that spoils the whole look of the manor.Indeed, only a cover of a water well with a diameter of 30–40 cm will be located above the ground;

- possibility of installation near the communication system;

- possibility of the hidden installation of the pumping mechanism;

- aesthetic design. The well in the suburban area is practically invisible, which is very good for owners who fear theft;

- reliability;

- possibility of use at high levels of groundwater;

- 100% tight system. Even with spring floods, the water remains clean. This condition is satisfied if the correct installation of the equipment and further maintenance of the system has been carried out;

- if the water system does not need to be used for a long time, the downhole adapter allows you to drain the water. It is enough to disengage the connection of elements, and all the liquid will drain.

In addition to the positive characteristics, the adapter has negative sides, such as:

- a rubber part (compactor) may fail over time. But it depends on the manufacturer of this design and the quality of the manufactured product;

- joints may become oxidized; in order to avoid this, it is necessary to lower and raise the pump 1-2 times a month;

- the cable that lifts the pump does not hold it in the working position. This function is performed by the adapter. Perhaps premature wear or excessive sealing of the connection from the constant vibration that comes from the pumping mechanism;

- Often there are problems with the gasket, which is located between the soils and the outer walls of the device. It may dry out, causing a seal failure. As a result, groundwater will get into the mechanism, in the future there will be a destruction of a water well;

- there is no possibility to connect additional sources of water intake from a well, for example, for watering a vegetable garden, for a detached outbuilding.

The only way out of this situation is the installation of a tee.

Kinds

The designs of different types of adapter are quite similar to each other, even if they are made by different manufacturers. Symbolically, they can be divided into groups depending on the special material from which they are made.

- Brass. Service life is 8-10 years. During the work, this material releases copper and zinc compounds into water, therefore it is recommended to use a filtering mechanism.Such a mechanism is characterized by an acceptable price of the product.

- Bronze. Bronze adapters are characterized by high cost. But it pays off with a long operational period, which is up to 25 years. In many countries it is prohibited to use such material due to the high percentage of lead in bronze. Adapters from such materials appeared at the end of the twentieth century. Today, it is rather difficult to find such a mechanism for sale due to a rather high price.

- Stainless steel. Adapters made from such materials are distinguished by their heavy weight, durability, and long operational life span, which reaches 30–40 years. Stainless alloys are highly resistant to rust and oxidation, rarely fail.

- DZR. This material with such an abbreviated designation is a brass-based alloys, which are food, and also they are resistant to the formation of rust. Brass mechanisms are popular in Europe and the USA.

Manufacturers

When choosing an adapter for a well, you need to pay attention to the manufacturer, since the performance of the mechanism depends on it. It is worth considering the most popular manufacturers of downhole adapters.

- Debe pumpar manufactures adapters that meet European quality standards. Such mechanisms have a body that resists the appearance of rust for quite a long time, and can also be equipped with thermal protection, through which you can install the adapter above the level of soil freezing.

- Baker manufactures stainless steel downhole adapters that are mainly used for drinking water piping systems. Such a mechanism is considered high quality, which allows the use of fittings for domestic water structures.

- Vinkell engaged in the production of high quality bronze products. The smallest diameter of the pipe to which the adapter can connect is 12 cm. It is possible to install near the sewer system or inside the foundation.

Dimensions

Borehole adapters are available in various sizes. They differ in the diameter of the connecting thread. The most sought-after installations are 1 inch thread size. With this dimension often used pipe HDPE, whose diameter is 32 mm. And there are also adapters with thread sizes of 1¼ and more.

With parameters 1¼, it is recommended to use a pipe with a diameter of 4 cm. For a 2-inch thread, a pipe with a diameter of 7.3 cm.

Installation

If it is decided to use such a mechanism for a well, it is necessary to find out in what situations the installation should be carried out, namely:

- next to the plumbing system are communication lines;

- if you need to quickly complete the installation of equipment;

- it is planned to freeze the well for a certain period;

- There is no opportunity to get an expensive caisson.

Install the adapter to the steel pipe. Since the pump is attached directly to the adapter, it is regularly affected by vibration. This affects the operational life of the casing. To install the adapter on the well with your own hands, you must prepare the following tools:

- drill bit with a special crown, which allows you to make a hole in the casing;

- wrench required to connect both parts of the adapter;

- pipe size adapter;

- submersible pump.

The caliber of the cutter must match the size of the nozzle of the product. If you do not follow this rule, the tightness of the structure will be broken. The adapter is mounted in several steps such as:

- first, the level of soil freezing is checked;

- you need to make a groove for the casing and the groove, which will install water pipes. For year-round use, the supply pipe must be laid in the ground at 1.7 m;

- a hole is made on the casing from the side of the living space. To prevent contamination from entering the source through this hole, parts are connected through a double seal;

- The first part of the adapter is inserted into the hole, after which the connection is made to the water pipe;

- the part of the adapter, which is located in the inside of the casing, is connected to the submerged pump;

- The adapter parts are connected with a wrench. During work, rubber seals are laid between the parts of the adapter. Such seals are able to protect the structure from the ingress of groundwater;

- then the safety cable is pulled out and fixed. It performs the function of unloading the adapter, which the equipment experiences from the mass of the pump.Thus, the risk of damage is reduced, and the life of the adapter is extended;

- after that, it is allowed to connect the pump and check its operation.

Tips

Experts recommend guided by the following tips when using a downhole adapter:

- it should be remembered that the pump should be collected in a dry place. After that, electrical cables and hoses are connected to the pump. This procedure will not allow different types of contaminants to enter clean water;

- Before choosing components for a well, it is necessary to pay attention to what material they are made of. If there is an opportunity, then it is better to acquire mechanisms from steel. They are capable of quite a long time to carry the load that occurs when the pump is running on the downhole adapter;

- reviews of homeowners in suburban areas say that with constant lubrication of parts of the described mechanism, the operational period can be extended to 10 years;

- When a borehole adapter is installed, the pump should be set to the pressure switch. It is important that the minimum and maximum pressure in the water supply station be established;

- a heavy downhole pump, water pipes (the pipe is filled with liquid), an electrical cable and a safety cable - all this together has a large mass, which is a serious test for the strength of the downhole adapter.

Therefore, it is not recommended to install it with a pumping mechanism lowering depth of more than 70 m, because two small metal parts will not withstand such a load.

Installation of the borehole adapter is shown in the following video.