Circulation pumps: the principle of operation of structures

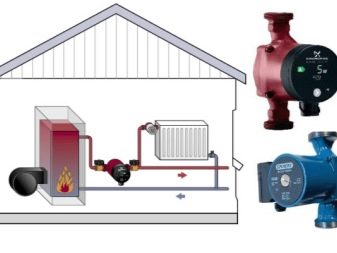

The heating system consists of a set of elements, one of which is a circulation pump. Such a device saves heating costs by about 20-30%. This is due to the fact that the coolant returns to the boiler faster because it circulates forcibly, and its temperature remains slightly higher than usual.

Thus, it will not be necessary to spend a lot of energy to reheat the coolant. That is why heating systems with a circulating pump have become so popular now.

Especially well such equipment is suitable for maintaining a comfortable microclimate in large country houses.

Special features

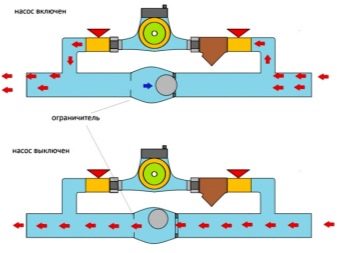

Circulation pump - one of the main components of the heating system, the coolant of which is hot water. It is a small-sized device that has pumping and suction functions. The device is mounted in the pipeline itself. The main task of the pump is to ensure the constant movement of fluid in a circle, as well as in the opposite direction. Due to this, a much faster and more uniform heating of the room is achieved in comparison with the conventional natural circulation system.

This device increases the efficiency of the boiler and all heating equipment to the maximum value. In this case, the pumps operate stably and reliably.

Regulatory requirements

Any circulation pumps must strictly comply with the requirements specified in the relevant regulatory documents. Here are the basic parameters of the device, according to GOST and JECD 2:

- type of pump;

- feed (m3 / s);

- head (m);

- inlet pressure / design pressure (MPa);

- coolant inlet temperature (K);

- design wall temperature (K).

Wall temperature is:

- MCP - 1,975; 51.4; 12.22; 13.71; 543; 608;

- MCP 5.5-93.0 - 5.5; 93.0; 15.30; 17.62; 573, 623;

- MCP 6.95-73.7 - 6.95; 73.3-100.5; 15.30; 17.62; 563; 623;

- MCP - 9.72; 100.5-114; 15.30; 17.62; 563; 623.

There are several limitations to the listed parameters:

- The deviation from the values should vary from + to - 4%.

- The tolerance on the head includes errors in accordance with the characteristics.

- The minimum pressure at the inlet to the existing pump is determined separately, according to the type of device and the temperature of operation.

Any circulation pumps must be manufactured in accordance with the state standard for a particular heating system, and also comply with the rules for the safe operation of such appliances. The design of the unit must assume the possibility of its movement in the horizontal direction. This is due to the fact that the pipeline inevitably expands under the influence of high temperatures. The force for such a movement is determined at the design stage of the unit and individually for each device.

Also, the design of the device must assume the possibility of compaction due to the coolant or a special system that locks the water.

Water for cooling pump parts that are in contact with the coolant must meet the following parameters:

- inlet pressure — up to 0.587 MPa (6 kgf / cm2);

- inlet temperature is from 283 K (10 ° C) to 318 K (45 ° C).

The pressure of the device must have a falling characteristic when applying more than 80% of the nominal. At the same time, its working part should be in the zone of 90-130% of the nominal feed. As part of the transmission system, the device must be provided with purified water, with a temperature of at least 70 degrees Celsius. The proportion of impurities should not exceed 0.03 g / l.

The maximum leakage from the seal in any operation mode is 2 m3 / h. Free draining of locking water - maximum 0.05 m3 / h. Leaks - no more than 1.0 m3 / h. It is also important that the design of the pump was designed for seismic effects.

In addition, GOST imposes the following reliability criteria for these devices (medium):

- the time between repairs is 16,000 hours;

- duration of service - 30 years;

- mean time to failure - 18000 hours;

- storage period - at least 2 years;

- the total operational complexity of planned (unplanned) maintenance - a maximum of 250 people / h;

- specific consumption of pumps - 5.35-5.8 kg / m3.

Specifications

On the modern market there are several models of circulating pumps.Each model assumes specific performance characteristics, in accordance with certain functional features. All this is reflected in the technical passport that each device has.

There are 3 main parameters that are worth paying attention first of all:

- performance;

- head;

- consumption.

The rules for calculating each individual indicator are different.

Head pressure

Sometimes this indicator is referred to as “pressure”. It is measured in atmospheres or “water columns” and is indicated on a special tag that is attached to the pump body. If there is no such tag, then information should be sought in the technical passport of the device.

There are rules for choosing the optimal indicator of pressure:

- Calculate the head for each room separately.

- Eliminate significant hydraulic losses in pipes and their connections.

- Analyze the graph of power pressure, which is listed in the data sheet.

- Determine the required pressure.

- Find the sum of all the bends and turns of pipes, tees and other hydraulic resistances of the system.

In this case, the calculation of resistance is performed without taking into account the height of the structure.

Since the height of the rise of water is not very important.This is especially clearly manifested in a closed system, where the height of the water column and the falling line are in equilibrium. If calculations are carried out for multi-storey buildings, then the resistance there is 0.2 - 0.4 atmospheres.

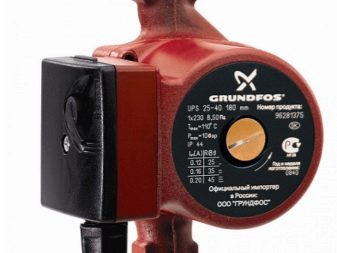

To make it easier for you to understand how the calculations are made, we consider them in more detail using the example of a circulating pump from the well-known Grundfos brand, UPS 25-40. Numbers are not just ordinal numbers, they enclose certain information. So, 25 in the marking is necessary so that you can determine the appropriate diameter of the heating pipes. It is 25 millimeters.

The second number - 40 - indicates the height of the supply and rise of hot water. It is 4 meters (0.4 atmosphere). Knowing this option, you can accurately select the size of the pump for this system.

Consumption

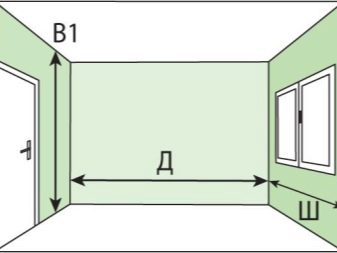

Correctly determine the magnitude of the load on the heating is very important. It is best to use a special program for this, which helps to calculate the amount of heat by heat loss or general indicators. For Russian homes, this figure is 120 or more watts per square meter, and for European homes - 100 watts per m2.This is due to the climatic features of the regions.

You can also calculate the optimal flow rate using the formula: G = (Q / (t2- t1)) х103where:

- Q is the heating load, which depends on the amount of heat you choose;

- G - coolant flow rate in the heating system;

- t2 t1 is the inlet and return flow parameter, respectively.

As a rule, the temperature in the circuit t1 is from 60 to 70 degrees. The value of t2 is in the range from 90 to 95 degrees. Such indicators are indicated in a special temperature chart. Using this formula, it is impossible to achieve a perfectly accurate calculation. However, it is enough to identify the optimal parameters.

If you do not want to work with formulas and tables, you can use ready-made rules. So, for a room of 10 square meters (the height of the room can be any) you need to take 1 kilowatt of boiler power. 1 section of the battery or radiator is taken as 200 watts. As a result, it turns out that a radiator with 5 sections (- / + 2 sections) is necessary for heating a room of 10 m2.

Then you need to add the volume of sections in all rooms, it will be equal to G + 3-5%.

Performance

Calculate this parameter can also be using the formula.However, mathematical calculations have one significant disadvantage - they do not take into account the impact of external factors. therefore it is necessary to adjust the calculations taking into account several factors:

- Ambient temperature Air temperature significantly affects the efficiency of the heating system. If it is too low, the device will work much worse.

- The diameter of the pipe. This is one of the most important parameters. The larger the pipe size, the higher the performance of the device. However, for overall pipes need an appropriate pump.

- Coolant viscosity. Heat carrier is always more viscous than water. Therefore, the characteristics of the coolant affect the power of the pump.

- The frequency of circulation. Be sure to consider how often the pump will be used. If the frequency is small, then you can opt for a pump of low power. For systematic use should choose more productive and wear-resistant models.

- The presence of a double heating circuit. If the circulation pump is installed together with the natural circulation system, then the load on the device will be quite large.So, you should choose the most powerful and reliable design.

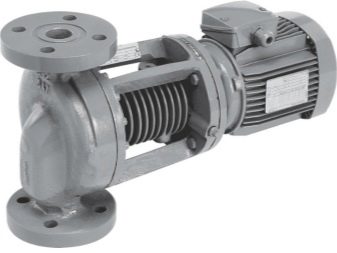

Device

There are 2 types of pumps for heating systems: “wet” and “dry”. The device and the principle of operation of each of them has its own characteristics, which should be disassembled in more detail:

"Wet"

The design of this type of pump does not imply contact of the pumped water and the rotor, since the pump is separated from the electric motor by means of o-rings made of metal or ceramic. During operation, these rings rotate relative to each other, and an almost imperceptible layer of water film forms between their surfaces. It is he who ensures reliable sealing of the connections due to the pressure difference in the heating system and the total atmospheric pressure.

This type of circulation pump does not lose its performance for at least 3 years. This is due to the fact that over time, the sealing rings even more rubbed together, so the reliability of their connection only increases, and does not decrease.

Also, the pump is characterized by complete noiseless operation, compactness, long continuous operation, cost-effective energy consumption, ease of repair and use.

Depending on the power, the “wet” structures are equipped with single or three-phase electric motors. Cooling and lubrication of engine parts is provided by the coolant. Also, the design of this pump provides for a flange connection or thread, which greatly simplifies and speeds up the installation of the structure.

But, despite all the advantages, these pumps have a significant drawback - low efficiency. It is less than 50 percent. This is due to the fact that it is impossible to attach a rotor of large diameter to it, since in this case there will be no sealing of the connections. Therefore, such devices are most often used only in domestic conditions.

"Dry"

The main difference of this type of devices from the previous one is performance. The efficiency of the "dry" pump is at least 80%. However, the device is characterized by a high noise level, so it is best to install them in rooms with high-quality sound insulation.

In addition, this type of pump must be kept perfectly clean. This is due to the fact that during their work air turbulence is formed, which can attract dust particles.This provokes a violation of the tightness of the seal rings. Therefore, it is important to carefully clean the dust in the room where the pump is installed, as well as monitor the quality of the coolant.

There are 3 types of dry-type pumps:

- Horizontal. They are also called "console". Their design involves the horizontal location of the engine, the presence of the injection and suction nozzle.

- Vertical. The engine in them, respectively, is located vertically, and the nozzles are mounted in one axis.

- Block Variants consist of separate blocks.

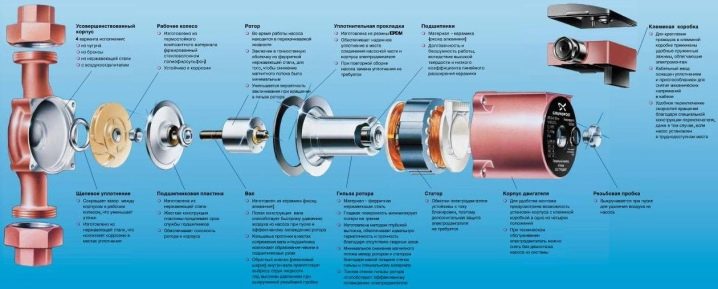

Now consider the elements that make up the circulation pump:

- Housing It is made of metal elements that are reliably protected from corrosion: steel, cast iron, bronze, brass. Also on the body there is a so-called "snail" - an important element that is used to connect the device with pipes.

- Rotor. This is the main working steel, which is made of alloyed or ceramic steel.

- Shaftequipped with a wheel and blades. It performs the process of circulation of the coolant: sucks water and moves it around the circuit.

- Electric motor (UPS).

Its power depends on the specific model of the device.

Scope of application

Most often circulating pumps are used in heating systems. But this is not the only sphere of their use. Here are a few more options for the use of such devices:

- Hot and cold water supply. Thanks to the pump you can achieve a stable temperature and good water pressure. You do not have to wait long for the hot water to go, pouring tons of cold into the sewer. It saves not only your money, but also natural resources.

- Innovative heating systems. Circulating devices are also indispensable when installing geothermal or solar heating systems. Such technologies have not yet become widespread in the modern world. However, they are a great alternative to traditional heating.

- Air conditioning systems - Another direction for which devices are successfully used.

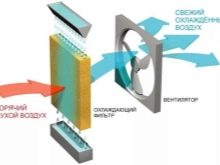

- Heat recovery systems. The recuperator is a special unit that is able to heat the incoming air at the expense of outgoing air.The device is necessary to ensure the circulation of ethylene glycol in the system.

- Warm floor. Stainless steel circulation devices do an excellent job of pumping air and fluid in modern floor heating systems.

- Air cooling systems. Some types of pumps are used to “treat” air to the required temperature in the range from -25ºС to + 110ºС.

Also, the device is used for installation in swimming pool systems, towel warmer, aquarium.

Economic benefit from use

Installing a circulation pump helps not only to make the heating system more functional and reliable. This solution will also provide you with economic benefits. For comparison: a conventional pump for heating consumes about 500-800 kW over 1 year. At the same time, about 200 kilowatts per year is spent on regular TV work, about 200 kilowatts on a washing machine, and 450 kilowatts on an electric stove. It turns out that a large part of all electrical energy is spent on the continuous operation of the pump, while modern circulating pumps consume only 50 kilowatts in 1 year.

Therefore, the installation of such a device will help you save about 90% of the electrical energy - this is a huge indicator. At the same time, such efficiency does not affect the efficiency and service life of the device.

Also, modern appliances can make the house completely autonomous.

This is achieved due to the fact that the heating system can be equipped with an additional uninterruptible power supply (UPS). Thus, failures in the work of electricity or an accident at power plants will not affect the operation of the heating system in your home.

In addition, modern pumps have a long service life and do not require expensive repairs, which means that they are a profitable investment of funds.

How to install?

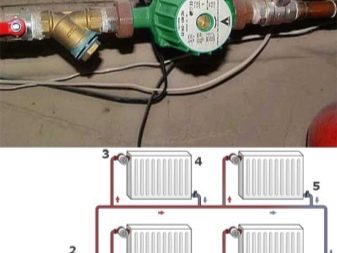

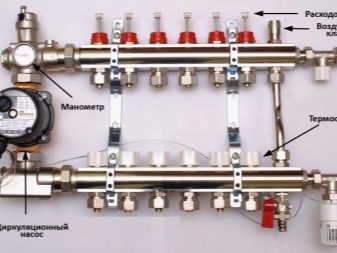

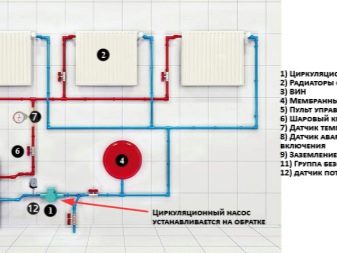

Before you start installing the device, you should correctly choose a place for it. Experts recommend to put the circulation pump in front of the boiler. This is necessary so that access to the pump for its maintenance is always open. Also, the position of the device ensures a uniform supply of coolant to the heating system, prevents the formation of air plugs in the boiler, prolongs the life of the pump.

First option

It is better to entrust the pump installation process to professionals. However, it’s realistic to do the installation yourself. To do this, remember the basic rules for working with a circulation pump:

- Place the equipment near the boiler, on the reverse type line. This should be the place with the lowest temperature. If the area of the room is more than 200 square meters, we can neglect this rule. In such houses, the length of the pipeline will be quite large, which means that the temperature of the coolant will not be very different in the area of flow and flow.

- Pay attention that the arrow on the body of the device being mounted coincides with the direction of movement of the coolant. Then bind the pump with a coarse filter, 2 shut-off valves, and a non-return valve (if there is a accumulator).

- Treat all threaded connections using suitable sealant.

- Generate an additional bypass. This is necessary in the case when the pump is installed in the heating system with a combined circulation. A bypass is a section of pipe with a stopcock. It must be placed parallel to the pump.Thanks to this device, you will have the opportunity to carry out the work of the heating system in the mode of natural circulation in the repair process.

- Place the pump in a horizontal plane and fill the device with a suitable heat transfer medium.

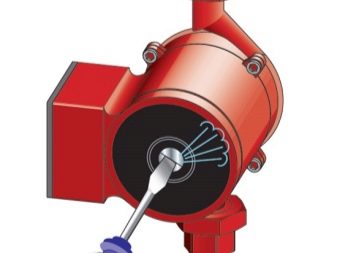

- Open the center screw to remove excess air.

The impeller of the device is installed only horizontally and functions under the bay.

The bypass size must be smaller than the main line of the check valve. It is also important that the bypass be removed if necessary.

Second option

We will list all the main points that are important to remember in the process of installing the pump. We now turn to the stages of work on the second installation scheme:

- Select a site for mounting the pump and weld an additional piece of the P-shaped pipe to it (you cannot mount the pump directly into the heating pipe). In the center of the additional pipe and the circulation pump will be mounted.

- A tap must be installed on the main surface of the heating pipe. Its function is to regulate the direction of movement of the coolant or water in the system.When the device is functioning, the tap must be turned off, then water or coolant is forcibly sent to the device. If you need to repair the device, this tap is simply opened. Even then, the coolant or water circulate freely in the wiring due to natural thrust.

- Also in the wiring, you must install a filter to reduce the number of instrument breakdowns.

- Now it is necessary to attach a special valve to the welded bypass. It is necessary in order to release the excess air from the pipes in manual or automatic mode.

- Be sure to ensure that the apparatus is surrounded on all sides by taps to de-energize the coolant. This is useful if the device will need to be repaired.

- Do not forget to carefully handle all connections and threads with a special sealant.

If you are not sure that you will cope with the installation of the device yourself, then it is better to seek the help of professionals. Only competent installation and timely high-quality maintenance will help to achieve proper and continuous operation of the system.

For information on how to properly install the circulating pump, see the following video.

Manufacturers

The choice of the manufacturer is also one of the most important points. To date, the most popular products have become the following companies:

- German: "Wilo", "Halm";

- Danish: Grundfos;

- Polish: AlfaStar;

- Italian: “DAB”, “Lowara”, “Ebara” “Pedrollo”.

No less demanded brands: Taifu, Unipump, Dzhileks, UPS 25/80/40, as well as Wester.

The latest brand is Wester - is the most popular among buyers. According to reviews, it is he who is considered the best combination of price and quality. There are also many positive reviews about brand devices. Grundfos.

Such pumps are far from the budget cost, but their durability and practicality fully justify the money spent.

The most common models of pumps from this manufacturer: Alpha, UPE, UP, UPS and Comfort. In Russia, the UPS series is in the greatest demand. They are distinguished by a minimum consumption of electrical energy, are almost completely silent during operation, and are also equipped with a special protective relay.

Also, the design of this type of devices implies the presence of ceramic bearings, which ensure a long service life of the device without breakdowns and accidents.Such pumps are successfully used for heating single-and two-pipe systems, for air heaters, hydraulic accumulators, underfloor heating.

Another worth noting economical model UPS 25-30 180which consume only 55 W, weigh 2.6 kilograms, supply a pressure equal to 3 m, pump 3 cubic meters of heat carrier or water in 1 hour. And the UPS 32-100F pump is recognized as the most productive model of this company. It consumes 345 watts, weighs 6.5 kilograms, creates a pressure of 10 meters and delivers 11 cubic meters of coolant.

Brand devices AC204-130 They are also a popular economical version of the circulation device. At its service takes only 62 watts. The weight of the device is 3.4 kilograms, it creates a pressure of 4 m, delivers 40 liters of liquid within 1 minute. Also, the unit is equipped with a protective relay and has 3 modes of operation.

Known company Dab has long established itself in the market of similar structures. The company produces devices for various purposes:

- VA-VB-VD - for domestic heating;

- VS - for hot water supply;

- VSA - for small heating systems for collective use.

And this is not the whole range of the company. The model DAB VA 35/130 is in great demand today.It is great for indoor or outdoor heating, air conditioning systems. The device weighs 2.6 kilograms, creates a pressure of 6.3 m, is characterized by a power of 0.56 W, has 3 speeds of work and a capacity of up to 3.3 m3 / hour. The special design of the engine protects the device from overloads.

The most convenient way is to select the appropriate pump from the catalog in the online store. So you will have time to compare the characteristics and cost of all models without spending a lot of time on it. We have not included Russian companies in the list of brands, since they mainly produce only industrial pumps. Domestic production of domestic appliances is very small.

However, some pumps of Russian production still worth mentioning.

LLC “Company“ Host ” occupies a leading position among domestic manufacturers of circulating devices. The plant is located in the city of Podolsk. Brand products are affordable, their cost is much lower than that of well-known European brands. Also, the devices are characterized by a long service life and excellent energy savings.

In particular, the most economical and affordable version of the Russian pump is the Master device 4.25.180. Its power is 7 W, and the maximum pressure - 4.2 m.With the help of such a device, it will be possible to pump about 3 cubic meters of water or heat carrier per hour. Such a device is perfect for heating systems or floor heating in country houses.

Pump model The owner of 8.32.180 is the most powerful of this line of products. The power consumption of such a unit is 270 watts. With its help it is possible to pump over the heat carrier up to 9.6 m3 / hour. The pump head is 8 m. The device is quite versatile, but the coolant is not suitable for it, whose temperature exceeds 110 degrees Celsius.

"Dzhileks" - another relatively popular domestic manufacturer. It produces devices called "Compass". Among them are quite economical models, for example, the Circular 25/40, as well as a more productive version - the Circular 32/80. The pressure of structures is from 4 to 8 m.

Today, circulating pumps are used very actively. Therefore, hundreds of companies specialize in their manufacture. Such a variety greatly complicates the choice, so we list only those manufacturers whose products really deserve attention.

Tips

When choosing a circulation pump, be sure to pay attention to the following parameters:

- area and temperature in the room;

- temperature difference;

- functional characteristics of the heater;

- head power

- network feature;

- coolant characteristic.

You should also remember that there are special formulas for calculating the optimal ratio of all these parameters. So, in order to find the performance of the device depending on the temperature difference, it is necessary to divide the power of the heating boiler by the differential. A pipeline length of 10 meters requires 0.6 m of head.

For a particular pump, the size of the water column is indicated in the data sheet.

Coolant flow directly depends on the power of the boiler. Boiler 25 kW can heat 25 liters in 1 minute. Therefore, a 5 kW radiator needs a flow rate of 15 l / min. And in order to determine the correct diameter of the heating pipes, it is necessary to correlate it with the cross-section of the pump connecting pipes.

If as a heat carrier not water is used, but a more viscous substance, then a more powerful pump will be needed.

In the case when the heating system assumes that there is only 1 pump, it is important that it has a power reserve.

If you are not sure which pump to choose, it is best to purchase a device with several modes of operation. So in practice you will be able to understand exactly which device is most suitable for your heating system.

Use the listed recommendations, select and install the circulation pump correctly, and you will not need to change it for many years.

How to calculate and pick up the circulation pump, see the following video.