Whirlwind Pumps: Product Specifications

Currently, pumps are widely used in construction. Most often they are used for water supply. Today we will talk about this production company "Whirlwind".

Special features

Today pumps of the Whirlwind company are one of the most qualitative and reliable for consumers. This manufacturer specializes in well materials. Such products are used, as a rule, to provide the necessary water resources for residential premises.

Submersible pumps manufactured by this company have a fairly powerful power plant. This allows uninterrupted supply of water resources from wells or deep wells.It should be noted that the company "Whirlwind" also produces some other types of pumps (surface, drainage).

It is also worth saying that borehole pumps are divided into several types depending on the type of working body.

- Screw pump unit. He is a universal model. Such a device is able to pass water with a solids content. It consists of an electric motor fixed in the upper part of the body, a working chamber, a special eye with a cable and an electrical cable.

- Centrifugal submersible machine. This type of pump consists of a working chamber of the engine compartment, which are combined in the housing. His working chamber is a special cochlear diffuser, inside which a wheel with blades rotates. These elements capture water and rotate it in a circle while the device is operating.

- Vortex deep pump. This type is similar to the centrifugal view of the device. But at the same time, the diffuser vanes may have shorter elements of the open and closed versions. During operation of the pump, these blades capture water and disperse it in a circle.It should be noted that the vortex immersion device also has a special strainer that does not allow large particles to pass through.

It is worth noting that the pumps of this manufacturer have certain characteristics. So, they can boast a fairly high volume of water supply. It can reach 60-70 liters per minute. But they also have considerable power, most often it is 800-1000 watts. The maximum immersion depth for these structures is 50-60 m.

It must be said that quite often Vortex company manufactures its products with a special controller, it is intended for automation of parts. This element turns on the pump when the pressure in the system decreases. And turns it off when the cessation of water consumption.

Kinds

Currently, the brand "Whirlwind" produces a large number of different pumps. Each of them has its own unique qualities and properties. The most popular types include the following models:

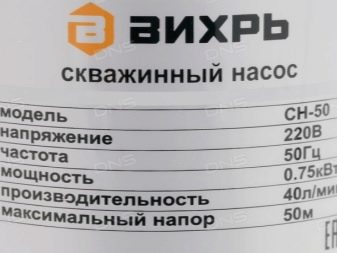

- CH-50;

- CH-60;

- CH-80;

- CH-90B;

- CH-50R;

- CH-60B;

- PN-370;

- PN-900;

- VN-10B;

- VN-10N;

- FN-250;

- CN-25-4;

- CN-25-6;

- FN-1100L;

- FN-1500L;

- DN-750.

Consider in more detail each of them.

- CH-50. This drainage pump is made with a special feedthrough condenser that boasts good conductivity.According to most professionals, he can easily withstand even a lot of pressure. It is important to note that the pushers for this model are created with special linings.

- CH-60. Such a fecal pump is produced together with a condenser box. It should be said that the pushers for this sample are quite compact. But at the same time they are quite easy to cope even with large loads from the plates. The power of this model can be 400-450 watts.

- CH-80. This type of pump is produced together with a special condenser box. An adapter for this model is most often used at the terminals. It should be noted that the rotary unit in this sample is missing. Its power is 300-350 watts. Pads for pushers of this element are made of steel, so that they are erased much more slowly.

- CH-90B. This sample is made with a special adapter for the capacitor unit. According to most experts, the pushers at such a pump will be able to withstand considerable pressure. In addition, the device 90B can be easily used even at great depths (30-40 m). It is important to note that this model has a heavy-duty case made of brass, therefore it is rather difficult to damage it.

- CH-50P. This pump is different from other models of high-quality condenser unit. According to some experts, it has a high power, which is 500-650 watts. Pushers of this sample can easily handle even heavy loads. It should be said that often these elements are used in large hydropower stations.

- CH-60B. Such a borehole pump is designed for pumping water from wells and wells of small diameters (70-75 mm). It is most often used for irrigation and irrigation of suburban areas or for water supply of residential premises. The case of the device SN-60B is made of stainless steel, so it is completely not susceptible to corrosion and reliably protects the device from mechanical damage.

- PN-370. This model is a surface pump. It can be used even at great depths (30-35 m). The maximum water supply of such a sample can reach up to 45 liters per minute. Its power, as a rule, does not exceed 370-400 watts. It should be said that PN-370 has a low price, so it will be affordable for almost any buyer.

- PN-900. This surface pump is used to move water resources. Quite often it is used to irrigate large plots of land.The device PN-900 has a convenient handle and special legs, the base, so they are comfortable to use. The case of such a unit is completely made of plastic. It can pump at least 60 liters of water per minute.

- VN-10B. This pump experts refer to the submersible (deep) type. It is equipped with a special ten-meter network cable. And also this device is equipped with a wear-resistant vibration motor. Often VN-10B is used in irrigation systems, irrigation of land and individual use. It should be noted that this sample has an upper water intake, which does not allow silt, sand, stones and other debris to clog the pump.

- VN-10N. This model is a submersible pump that is equipped with a lower intake and a ten-meter network cable. But also it should be noted that this unit has a built-in thermal protection. It allows you to automatically turn off the engine with a strong temperature increase or in the absence of water.

- FN-250. This type refers to fecal pumps. Often it is used in large suburban areas for pumping heavily polluted wastewater.This unit consists of a main pumping unit, a powerful electric motor and a float switch. It should be noted that the electric motor model FN-250 has a special stator. It ensures that the water device is turned off when the temperature of the windings rises.

- CN-25-4. Experts refer to such a device as circulating pump types. It is used for heating systems and provides water circulation. This type of unit differs from other samples in that it is able to work almost silently. In addition, it boasts a long operating life and simple installation technology.

- CN-25-6. This pump also applies to circulating devices. It is important to remember that this type of unit is suitable for pumping only clean water. And also it should be said that, like the previous model, the TsN-25-6 works almost silently. At the same time, this model of pumps has a rather low cost, it will be affordable for almost any person.

- FN-1100L. This unit also refers to the fecal type of pump. This model is used for pumping heavily polluted water.For this purpose, this device contains a special grinding blade. It is important to note that such an apparatus is often used in cases when it is necessary to extract excess moisture from cellars, basements and garages.

- FN-1500L. Such a unit is a highly efficient device for pumping highly contaminated water. Like the previous model, the FN-1500L also has a special cutting blade made of steel. The electric motor of this model is equipped with a stator with a thermoprotector, which automatically turns off the device when the temperature of the stator windings rises sharply. This avoids damage to the device due to overheating.

- DN-750. This drainage pump is equipped with a 750 W power engine. This sample has a special sensor that protects the unit from overheating and breakage. And it is also worth noting that the device automatically turns off at a critical water level. Disconnection occurs by means of a float mechanism.

Spheres of application

Pumps manufacturer "Whirlwind" today found a use in many construction fields. So, well elements are especially important.After all, they are able to pump large volumes of water even from deep wells. It should also be said that some models of this company are designed for wells of small diameter, so with the help of their water you can pump out almost from any opening.

It should be remembered that if water is pumped out of mine wells or from boreholes in which the depth is greatest, it is best to take a submersible pump. It is lowered to a great depth below the water level. This allows the device to raise considerable volumes of water, even with gases and other substances dissolved in it.

Many samples of the Whirlwind pumps are fecal. Such models are designed for pumping polluted water. As a rule, such devices are produced with water intake, which prevents solid particles and other debris from entering the unit and clogging it. In addition, a special durable blade embedded in the mechanism, allows you to quickly grind fibrous debris, which simplifies the operation of the device.

Quite often, pumps "Whirlwind" is also used in country houses and on land. After all, they can serve as an excellent system for irrigation and watering the garden. Such models are quite easy to operate.They pump water from wells or wells and deliver it directly to the dacha area. And also often the pumps of this brand are used in residential buildings as a water supply system. They do not require too complex installation technology. They just need to connect to the necessary devices in the room and attach in the well or in a natural pond. After that, water in the right amount will flow into the room.

Tips

The vast majority of specialists strongly recommend the use of pumps with special water intake. Even if it was not in the same set with the device itself, it is better to purchase such an element separately. After all, it protects the device from the ingress of all kinds of garbage, which can lead to serious damage to the unit. Water intake can be purchased at almost any hardware store. In addition, it should be noted that such a detail will not be expensive, it is affordable for almost every person. Many people believe that such an element should be installed only for faecal pumps, but it is not. It should be put on any type of device.

And also many experts advise as little as possible to disassemble these devices for cleaning.After all, if such procedures are carried out too often, then this can lead to violations of the tightness of the body of the product. And this may subsequently lead to serious malfunction of the pump.

If you still find a breakdown or malfunction in your pump unit, then it is best to take it to the workshop. It is not recommended to repair such devices by yourself. Since you can damage the device even more, which can permanently disable the device.

But also Often, consumers and experts advise buying a controller for pumps separately. Such an important detail protects the unit from idling. It automatically turns off the device in the absence of water resources. This allows you to significantly save energy consumption required for the operation of such units.

Reviews

Currently, on the Internet, you can find a considerable amount of consumer feedback on pumps manufactured by Whirlwind. So, many people have noted the high level of quality of this product. And also the majority of users separately noted that devices of this brand are capable of pumping out water at a considerable depth (40-50 m).

A considerable number of consumers spoke of a good built-in protective system of such pumps. It allows you to avoid breakdowns and malfunctions of the device. After all, the devices of this brand are automatically turned off when there is no water or with sudden temperature fluctuations; they are not clogged with debris when pumping water. And also similar products are reliable thanks to the heavy-duty and tight case which is almost not subject to damages.

But despite the large number of positive reviews, some users still noticed the disadvantages of the Whirlwind pumps. So, consumers expressed that the bolts on the steel case began to rust quite quickly, which happened after two years of operation. And also many buyers said that the product's hairpins are also rapidly rotting and losing their former appearance.

In the next video you will find a review of the pump Vortex FL-250.