Well cleaning rules

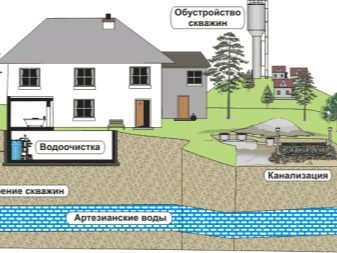

The organization of water supply for living quarters is an important element of the life of a modern person. If it is impossible to connect the water supply system to the centralized water supply, the house owners can make an individual water source. Specialists will not only help you to install equipment in accordance with technological norms and standards, but also tell you how to carry out maintenance work and repair of pumping equipment for long-term uninterrupted operation of the system.

Special features

A well is a source of water supply not only for a private house, but also for the summer cottage. In regions where there is no centralized water supply, an individual source of drinking water will not only ensure quality water supply of residential premises, but also provide an opportunity to irrigate agricultural land. To obtain high-quality water in the required quantities, the hydraulic structure requires regular maintenance and repair work.

Experts identify several signs of water source clogging:

- a significant decrease in the volume and pressure of the water being raised;

- frequent pressure drops in the system;

- the presence of sand and silt particles in the water;

- lack of water in the well.

Before starting work on cleaning the well, it is necessary to determine the cause of the occurrence of faults and take steps to eliminate it.

There are several reasons:

- violation of technological standards in the performance of drilling and well installation;

- irregular use of the aquifer system;

- natural movement of underground layers of the earth;

- changes in the movement of underground sources;

- installation of low-quality protective structures against the penetration of contaminating elements from the surface;

- clogging of water filtration equipment;

- poor pumping unit operation;

- irregular preventive maintenance.

For high-quality well cleaning, experts recommend taking into account the following parameters:

- soil type;

- well depth;

- casing size;

- aquifer productivity;

- availability of power supply systems;

- availability of pumping units and the necessary tools.

What are we cleaning from?

In order to choose an effective way to clean a well and quickly fix the problem, it is necessary to accurately determine the type of contamination. Experts note several types of pollution, each of which should be found.

Dusting

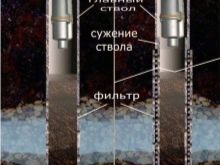

This is the main problem of small sand wells in which water passes through a layer of sand and gravel.

The reasons:

- an unpressurized structure that allows sand to pass through the soil;

- large cells in the filter;

- deformation or breakage of the filter;

- lack of tightness of the casing sections;

- corrosion of metal pipes;

- poor-quality installation of the structure (the thread is badly twisted, violation of the technology of welding of the structure).

Remove internal problems well is almost impossible. Sand will always be in the pumped water. For high-quality installation of equipment and elimination of errors during installation, it is necessary to consult with experts.

Silting

Contamination of pores in the aquifer and filter cells with particles of clay, rust, sediment and calcium deposits with occasional use of the well. Silting leads to a decrease in the volume of water, and after a short period of time to a complete drying of the source. Regular pumping of water makes it possible to use the wells for several decades, and timely cleaning of filters from sludge will increase the volume of water and prevent clogging of the water supply system.

If the well is silted, it is necessary to carry out work as soon as possible to eliminate the possibility of a complete cessation of water flow.

Special attention should be paid to the buildup process. The buildup is the cleaning of the bottom of a well after drilling from lime and rusty water.The first water from the well contains a high level of contaminating elements and unsuitable for drinking. Failure to clean the source will lead to silting. Professional pumping will remove all particles of sand and silt from the aquifer. The minimum amount of time required for this process is 14 hours and depends on the type of soil.

Errors when cleaning a new well:

- wrong location of the pumping unit;

- discharge of dirty water near the well;

- thin cord for pump.

Ways to solve the problem

Experts identify three principles of cleaning wells:

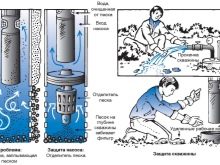

- Pumping - A simple way to flush the well with a pump. The use of this method is possible only when a layer of sand has not completely covered the horizontal parts of the filter.

- Flushing with circulating fluid - water supply through the hose into the well under high pressure. The sand and clay under the action of the jet erodes and rises the surface through the production pipe. Disadvantages - the possibility of damage to the filter, a large amount of circulating water, the release of large amounts of sand.

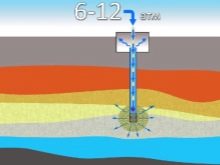

- Compressed air purge - rough cleaning system, carried out by airlift. Airlift is a special apparatus consisting of a compressor and a hose through which air is fed into the well under pressure from 10 to 15 atm. A high pressure is created in the barrel, pushing particles of silt and sand. This method is suitable for wells with a depth of 30 to 40 m.

These principles are the basis for a large number of methods for cleaning wells.

How to clean your own hands?

There are several methods for cleaning the well using your own resources. Consider the most effective of them.

Pumping by the vibration pump

Simple, but long and inefficient method of cleaning that does not require physical effort. To perform this type of work, a vibration pump is better suited than a circulation pump, due to the ability to pump water of any quality and the presence of water and small stones in it.

Before starting work, it is necessary to consider the high content of abrasive particles in the pumped water.which can disable the check valve. Pre-prepared part for replacement will help to perform work in a short time without downtime and delays.The ingress of small stones under the installation membrane can impede the movement of water; the apparatus can only be released by pulling it to the surface.

This method of cleaning will help remove sand from the casing and is suitable for shallow wells with a size of no more than 30 meters. For effective sand stress, the pump should be as close as possible to the sand layer. In the process of work, the sand layer will decrease, and the pump must be lowered below.

To prevent combustion of the pump unit, the time for continuous work should not be longer than 20 minutes.

Flushing pump installation from the surface

An effective method of removing sand, rust, deposits from the casing and cleaning the surface of the filter. For high-quality well cleaning it is necessary to organize a closed cycle of flushing from the surface. Do not use water from open water sources. Water for work must be placed in technical tanks, the volume of which corresponds to the full capacity of the casing.

The working fluid will move between the well and the reservoir., at the bottom of which contaminating elements will accumulate.To prevent re-entry of debris into the well, the tank must be cleaned. To improve the quality of the removal of dirt in the water, you can add chemicals that remove rust and calcium deposits.

If there is a centralized water supply system near the site, the well can be cleaned with its help, having equipped a drain for dirty water in advance. The flow of water down through the hose, lowered to the bottom of the well.

Two pumps

Effective method for cleaning wells more than 50 meters deep. The superficial and deep pump is used. The downhole pumping unit supplies water to the well, lifting all debris, and the submersible installation pumps water with sand and stones to the surface. The pump, which is in the well, can perform the function of water supply down. The negative impact of sand and sludge on the parts of the pumping unit increase their wear rate and can lead to a breakdown of the apparatus.

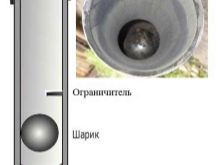

With the help zhelonka with ball valve

The method is used to remove sand, stones and pressed sediments from the casing, but does not clean the filter and soil from sludge.The construction of the yolk is a steel pipe with an integrated valve on one side and a lever for the cable on the other. To clean the well, it is necessary to drastically lower the shell into the empty casing. From hitting the bottom of the valve opens, and particles of debris fall into the cavity zhelonka.

Lifted to the surface of the device must be cleaned of dirt. This cleaning method requires great physical effort and a long period of time. Sharp lowering of the bark can damage the surface of the filter; therefore, work should be stopped when a layer of contamination is reached at least 10 mm.

Using a water hammer

This method is used to remove sludge deposits from the surface of the filter and the nearest soil. This method is used if the sand from the casing has already been removed, and the volume of water in the well has not increased, and a muddy plug has formed.

The principle of the method is the sharp dropping of a special projectile in a casing filled with water. The device consists of a pipe section with a small diameter with one side welded and a cable attached to the other side. To effectively remove contaminants, you need to add a special acid to the water. After 4 hours of operation, the pipe is filled with water and washed.If necessary, the action can be repeated.

Gas mixture

The combined and safe method with low productivity and the long period of work. Sparging provides an opportunity to clean wells and filters from sludge and sand with minimal risk of damaging the pumping device. This method allows to protect even old and worn equipment from damage.

The principle of operation is to supply compressed air to the nebulizer located at the bottom of the well. Air bubbles, rising outward, lead to the movement of particles or sand. To ensure the constant movement of water in the well, it is necessary to ensure regular supply of water from the surface or create a circulation of water in a closed loop.

If it is not possible to clean the well yourself, it is necessary to call the fire brigade itself with equipment that will clean the well with the help of a fire hose with water pressure.

Work time will be no more than 15 minutes. This method is costly. Purging the well with high-pressure water will help remove all debris, sand, sludge and turbid water, but can damage filter elements and disrupt the integrity of pumping system components.

Tips

For long-term use of wells in the city or at the cottage Experts recommend to follow a few simple rules:

- observe drilling technology;

- install only centrifugal pumps;

- preserve the integrity of the filters and the tightness of the pipe;

- after drilling, rinse the water source until water appears without contamination;

- make a structure above the well to protect against penetration of groundwater and other contaminating particles;

- accurately calculate the depth of the submersible pumping system, taking into account the amount of water in the well;

- Do not use vibration pumps, which facilitate penetration of sand and soil into the source;

- conduct regular water intake without long downtime.

In case of violation of the integrity of the water supply pipe, it must be replaced. Work must be done very carefully, trying not to damage the casing.

To raise the pipe to the surface will help automotive crane or jack. New pipe should be made of plastic or metal. Asbestos-cement pipe not only has low resistance to mechanical damage, but also emits substances harmful to health.

For effective cleaning of filter elements, technological standards and rules allow the use of chemical compounds that facilitate the removal of all types of contaminants and deposits. After applying chemical reagents it is forbidden to immediately use water for cooking, it is necessary to pump the wells several times and remove all elements that may damage health. For mechanical cleaning of filters use large brushes made of metal. Work should be carried out carefully, trying not to damage the elements of pumping equipment.

Preventive measures to avoid breakage of the pumping equipment of the water supply system:

- regularly check the integrity of the pipe;

- periodically inspect and repair the pump unit;

- monitor casing tightness;

- clean the sludge and sand filters;

- install devices that stabilize the voltage in the electrical network;

- carry out regular flushing of the hydraulic tank.

Regular diagnostic work will help not only to avoid the breakage of a well, but also to reduce the financial costs of repairing the water supply system.If a pumping equipment breaks down or if the quality of drinking water is reduced, experts recommend that you carefully study all the methods of cleaning the well, determine the causes of trouble, and only then begin to independently perform this type of work.

Special organizations involved in the implementation of this type of work will not only quickly and efficiently clean the well, but also give recommendations on further operation of the water supply system equipment.

In order to avoid repair of the well, it is necessary to detect all failures in a timely manner and correct them quickly, carefully and carefully use the water supply source.

See the next video for a simple and effective way to clean a well.