Caisson for a well: subtleties of selection and installation

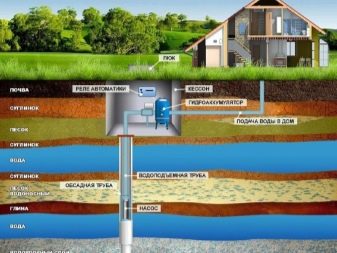

During the construction of cottages and country houses, each owner faces the problem of communication systems. This concerns not only gas supply, but also water supply. For their installation using various systems and equipment. Today we will talk about such details as caissons for wells and consider in stages how to properly install them.

What it is?

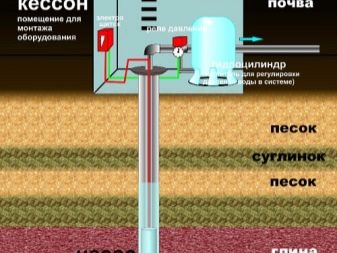

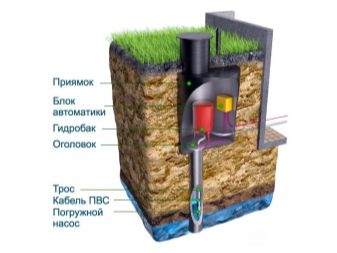

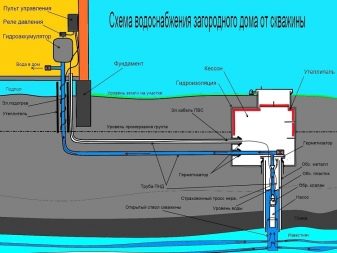

The caisson is a special chamber that is designed to equip the wellhead at a level below the surface of the earth. Such elements are installed above the water intake in order to achieve the most convenient access, as well as for the further installation of special equipment designed for the water supply of the house / cottage.

Special features

Initially, caissons were intended for various works under water. They were a closed chamber, which did not penetrate water. The shape of such objects, as a rule, was round or square. Currently, the main feature of the caisson, which consists in its water resistance, has remained unchanged. However, today the range of its application has become wider. For example, caissons are rightfully recognized as useful elements of autonomous water supply.

If you want to use water from your own well all year round, you cannot do without a quality caisson. (or a special downhole adapter). Its installation is possible to do it yourself, although it is not as easy to make as it may seem.

As a rule, homeowners turn to specialists for this. However, if you decide to do everything yourself, then it is extremely important for you to follow the instructions and not to neglect any of the installation steps.

Caissons are leakproof, which protects the wellhead from groundwater. This feature plays an important role as it protects households from the flow of fluid from the neighboring sewage system when the faucet is turned on.This is due to the fact that the end of the casing of the well does not intersect the ground surface, but is located at a depth of approximately 2 m. In this place there are ground waters.

Such a depth of the wellhead is due to the freezing of the soil (its depth is approximately 2 m). Of course, in this matter a lot depends on the area in which the house is located. In addition, the appropriate depth of the tip is also necessary in order that in winter time the water would leave the taps without freezing. The equipment itself with such a design is also reliably protected from destructive freezing.

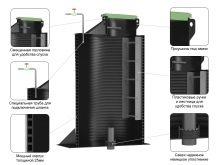

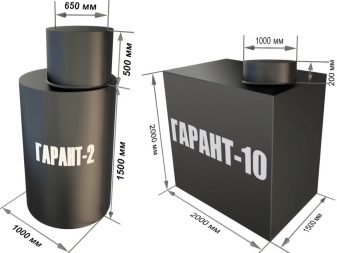

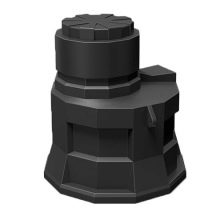

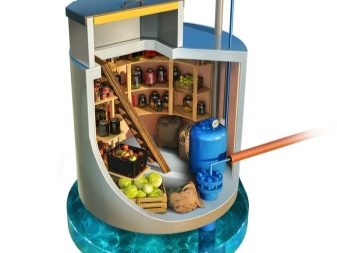

Externally, the caisson is similar to an ordinary barrel made of iron or a box with a neck. Meanwhile, the neck of such elements is closed with a special manhole cover, complemented by warm foam sheets.

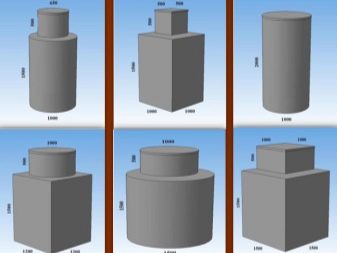

Common in our time are caissons of a round shape. Such products have a diameter of 1 m and a height of 2 m. The dimensions of these objects are explained by the fact that the well is located at a depth of 2 m, and to access it, the hatch of the caisson is carried to the ground.

Today, caissons are made from different materials, but the most common and reliable options are made of iron.Such units are not afraid of mechanical damage or temperature extremes, but are susceptible to corrosion, and therefore require high-quality protective treatment. In addition to iron, there are also brick, concrete and plastic models of caissons. Each of them has its own distinctive features.

Device

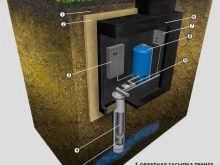

The device of the caisson is quite simple. This element is an airtight container made from one of the suitable materials. At the bottom of this unit is the entrance to the casing of the well, and laterally the caisson, as a rule, has inlets for water supply pipelines.

In the upper part of such items is a special hatch, which is necessary to provide access to repairs and maintenance of equipment present in the inside of the tank.

In an atmosphere of changeable and harsh Russian climate, high-quality caissons, supplemented with warming materials, are particularly relevant. It can be not only the above-mentioned foam, but also a foamed polymer.

The usual design of the caisson is a cylinder, characterized by a cross section of 1 m and a height of 2 m. The last parameter is due to the fact that it is optimal to protect the internal filling of the caisson from the effects of low temperatures.

As for the wellhead, it, like the entrance for the pipeline, should be located at a level below the soil freezing. As mentioned above, it is on this parameter that, first of all, the suitable depth of placement of the bottom of the unit depends. The diameter of the caisson must be such that all the required components fit seamlessly in its interior and there is additionally room for certain work stipulated by the regulations.

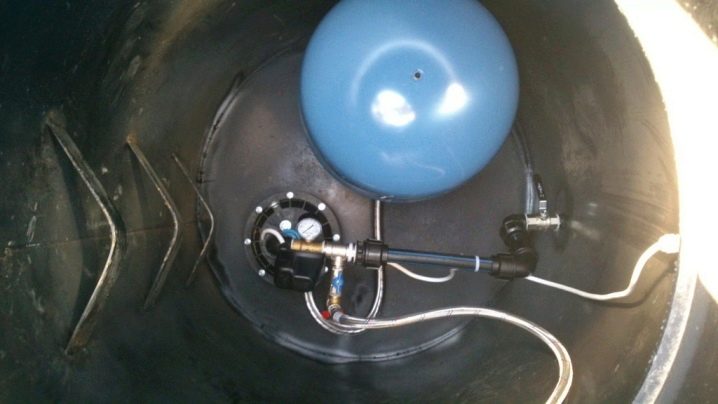

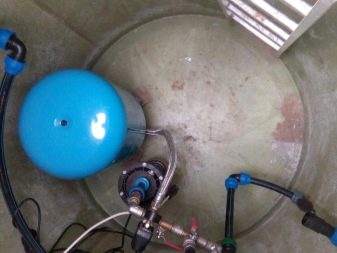

Inside the chamber are the following components:

- pump and its automation;

- stop valves;

- expansion tank;

- filter;

- pressure gauges.

Materials

Caissons are made from different materials. Different instances have different performance characteristics and features. Consider them in detail.

Metal

Units made of metal are particularly popular with consumers. In fact, such a device is a large metal box with welded bushings for the passage of communications.As a rule, the caisson is made from sheet material - its optimum thickness should be 3-4 mm. Experts recommend to give preference to reliable and durable stainless steel aggregates. If you do not want to buy a steel caisson, then you can purchase an aluminum construction.

Metal caisson units are famous for their reliability, durability and durability. - these characteristics explain the demand for such models. In addition, both specialists and home craftsmen claim that such caissons are installed fairly quickly and easily.

It is possible to make such a unit by hand, but for this you need to have suitable tools and also have certain skills. If you are not confident in your capabilities, it is better to turn to experienced specialists.

Despite the fact that the welds in most cases are of good quality and are reliable, they can undergo cracking if the metal is deformed. For this reason, even those caissons, which are made of high-quality stainless steel, must be further waterproofed. There are devices made of ferrous metal.They are also very important to waterproof waterproofing. However, it should be borne in mind that even if the insulation was fixed as tightly as possible and does not allow moisture, it cannot be regarded as a full waterproofing protection of the unit.

The quality and service life of the caisson is largely dependent on the thickness of the metal from which it is made. So, inexpensive devices with thin walls can be installed only on dry soil. As for a more complex heaving soil, a model with walls having a minimum thickness of 5-7 mm is suitable for it. Otherwise, the caisson may be crushed.

If you decide to install a steel caisson, then you should consider that it has an impressive weight, so installing it alone will be problematic. It is recommended to hire a crane for this.

Brick

According to experts, brick caisson is one of the most successful and practical options. Most often, home-made craftsmen turn to this design, who alone design these units with their own hands. Of course, in the construction of this unit is also quite complicated, but its durability will pay for all the cash and energy costs of the home master.

For the construction of brick need to fill the foundation. It is recommended to prepare the tape base, as it will fit most. The future foundation is not necessarily filled with concrete - it is possible to fill dug brick trenches with splinters, crushed stone or sand-cement composition.

Plastic

No less popular today are caissons made of plastic. According to many people, such units are not the most reliable and durable. However, this does not apply to sewage and sanitary installations that are present in today's market.

Currently, caissons are made of plastic such varieties:

- polyethylene;

- PVC;

- fiberglass;

- polypropylene.

Plastic caissons are popular because they have many positive qualities, including:

- Plastic models do not require complex and regular repairs. In service, they are also malleable.

- Plastic caissons are characterized by a long service life (on average 50 years), despite their apparent lightness.

- Such units are distinguished by good insulation performance. They are not afraid of temperature drops. In a cold region, such models need only be supplemented with a warming shelf.

- These devices are inexpensive.The price of plastic itself is not high, so products made from this material are available for most consumers.

- During the entire service life of plastic caissons do not lose their quality characteristics. Moreover, this factor is not affected by any significant loads on the system or harsh environmental conditions.

- Characterized by these units and increased tightness. During the installation of such caissons there is no need for coating and fixing waterproofing materials.

- Plastic structures are lightweight, which makes them lighter and more flexible in terms of installation.

- These designs have a body without seams, which makes them more reliable and durable.

The main disadvantage of plastic caissons is their susceptibility to deformation. Such defects may appear if the tank is on the ground with a high groundwater storage.

To protect the plastic unit from damage, it is recommended to supplement it with concrete. To do this, a concrete ring is arranged around the container, having a thickness of 10-15 cm.

Of concrete rings

More recently, caissons made from concrete rings have been the most popular.Such structures are made quickly and easily, and the result is reliable and durable, as evidenced by reviews of homeowners. Caissons made of concrete rings are good and that they are assembled at a specific place from typical materials, therefore the home craftsman will be able to cope with them. Variants of concrete rings are not afraid of heaving soil. Of course, much depends on the correctness of the installation work. In case you made mistakes when constructing a similar caisson, the soil can move concrete parts over time.

It is also worth taking into account the fact that such erections require high-quality waterproofing., because by itself the concrete passes through a capillary moisture. In addition, impressive mass structures can shrink over time.

Dimensions

Currently, metal and plastic constructions are considered the most popular, since they have good performance characteristics.

So, popular metal tanks are produced with the following parameters:

- 1200х1200х2000 mm, while the wall thickness of such products is 3-10 mm;

- 2000x1000 mm with walls having a thickness of from 3 to 8 mm;

- 4000х1500х2400 mm with a metal thickness of 3-10 m.

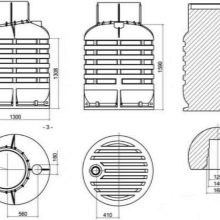

Plastic caissons for wells have other dimensional parameters:

- 950x2000 mm - the wall thickness of such models is 10 mm;

- 1240х2100 mm / 1500х2500 m with walls of 25 mm;

- 2000х2500 mm - the thickness of the walls of such options is 40 mm.

The choice of a well construction of suitable dimensions depends on the distance of the water intake from the house, as well as the availability of free space in the existing area. Today models of caissons under the name "Triton-K" and "Triton K-1" are in great demand. Such products are produced in the mini format and are made of low pressure polyethylene.

Installation

Independent installation of a caisson cannot be called a simple process - not everyone will cope with this. However, this does not mean that it is impossible to do such a work with your own hands. Below we will consider step by step how to install various caissons for the well. The procedure for installing caissons from different materials is about the same. However, it is very important to take into account some features and nuances so that the installation of the tank is successful.

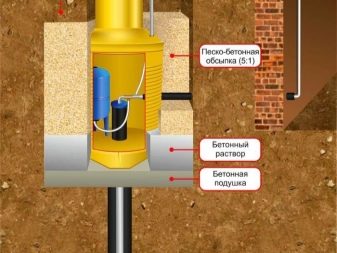

The pit for this container should be more than the caisson itself, not less than 30 cm. Thanks to this, the unit will be able to deliver more accurately. In this case, it will be possible to correct the coincidence of the well pipe and the liner for its passage. In addition, in this way you can additionally warm the walls of the apparatus or make them stronger, which is necessary for plastic containers.

Consider the fact that the casing should be cut to the subsequent level of the height of the chamber floor. The bottom of the pit should be covered with a pillow of sand (the thickness of this layer should be not less than 20 and not more than 30 cm).

Sand backfill must be equipped under water for additional compaction. On a pillow of sand it is necessary to pour a concrete slab with steel reinforcement. It is permissible to pre-install anchor bolts in it in order to secure the caisson with their help. However, in this situation, the probability of errors is high. It is better to first set the container to the right place, and then drill holes for fixings on the plate.

Currently, self-expanding and wedging types of fasteners can be found in stores, so you can easily get suitable options. Next, we consider in more detail how to establish the popular variations of caissons, taking into account their features.

Of concrete rings

The installation of this design is in many ways similar to the installation technology of the well rings, only in this case there is less depth. The concrete rings are fastened together with special steel plates. Such details are necessary in case a ground shift occurs. As for the seams remaining between the individual rings, they are blocked with a cement composition or iron (that is, they are coated with a special cement mixture without sand and other additives).

Concrete will pass water, even if not too much. For this reason, it is extremely important to engage in waterproofing the walls of the building in time. For this you can use materials such as roofing felt or polymer film. But experts recommend contacting reinforced gidroizolu or stekloizolu.

Concrete seamlessly tolerates low temperatures and does not undergo freezing, but its standard properties are not enough, so the construction will need additional insulation. In this situation, it is important to bear in mind that the insulating material should not absorb water. Otherwise, it will be absolutely useless.Also, the insulating layer must resist the pressure of the soil, since too soft raw materials can be compressed by them.

Experienced craftsmen recommend insulating caissons with more dense and plate materials. For example, it may be foam glass, but it is very expensive, so it is rarely chosen. If you want to buy a more affordable option, then you should look at extruded polystyrene foam. The cheapest insulation for concrete caisson will be foam. He is malleable in his work, and flammability will not affect his qualities in any way while he is in the ground.

It is necessary to warm not only the walls of the concrete caisson, but also its overlap. Do not be afraid of this work - it is easier to hold. It is only necessary to remember that the insulating material should not go beyond the perimeter of the tank. Otherwise, it may break during shrinkage due to the weight of the structure.

Some people argue that concrete caissons do not need a bottom (that is, rings should be placed immediately on a pillow of sand and drainage of gravel). Thus, in case of accumulation of condensate, it will pass into the ground. It is also possible not to close the joint between the lower ring and the base of concrete with the cement mixture - so the condensate can escape.

However, it is necessary to take into account that this technology can not be addressed in far from all cases. Such a scheme will work only if there is a dry and high ground on the site. In other situations, a 2 m dredge will cause the caisson to be flooded annually.

The problem with condensate can be solved by installing high-quality insulation. Some masters do more cunning - set in the design of ventilation like a cellar.

Under the rings must be a concrete base. In addition, the intersection of pipes through the walls of the structure should be isolated, as well as the inputs through the foundation of the dwelling - cement mixture, as well as bitumen mastic.

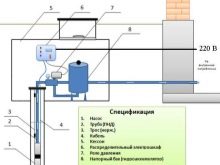

Metallic

Installation of metal structures as follows:

- First you need to dig a pit for the tank.

- Then the foundation is prepared in the form of a pillow of sand and a slab of concrete.

- Next, the well casing is trimmed to size.

- Over the dug pit on the bars and channels put the caisson itself. It is necessary to carefully set it up to coincide the pipe wells and sleeves.

- After that, the structure is fixed in place.

- Then additional trenches are dug, for examplefor holding water to the dwelling.

- Connection of communications is carried out.

- The warming material and a layer of a waterproofing is established. At the end of the caisson closes ground.

Plastic

Such types of caissons are installed in the same way as steel aggregates. The only difference is that when sealing the articulation of the casing with the liner it is not necessary to weld, but a special adhesive compound for polyvinyl chloride. Also, the passage of pipes through partitions should not be carried out on threaded bushings, but through special couplings — they are subsequently sealed with covers.

It is necessary to take into account one distinctive feature - such caissons do not need protection from moisture and insulationBut just need protection from excessive pressure from the ground. Arrangement of such is carried out by filling the concrete solution of the space between the walls of the pit and the structure itself. To do this, do not need a high strength composition. A simple solution in the ratio of 5 to 1 (5 parts of filler, 1 part of cement) will suffice. For filler, you can use sand and crushed stone.

Tips

- If your site has heaving soil, then around the caisson is necessary to fill the "shirt" of reinforced concrete.

- Steel caisson must be treated with an anti-corrosion agent.Otherwise, it can cause destructive rust, which is almost impossible to get rid of.

- Steel tanks should be insulated from the outside. Otherwise, you may encounter a problem of condensate accumulation on the inner walls of the structure.

- The presence of an additional pipe in the design makes it possible to connect a hose to it, which can be used for watering garden and garden plantations.

- During the installation of the caisson, it is necessary to wait until the concrete is completely dry before proceeding to the next step. Otherwise, all work will have to be redone.

- A large number of welds in the structure will adversely affect the durability of the product, since the seam is a potential source of the appearance and spread of rust.

- If your site has a high level of groundwater, then the installation of the caisson should be abandoned. In this case, it is worth referring to a less demanding adapter.

- If you have any problems during the installation of the caisson, you do not need to save on the dimensions of the pit, it is more important to ensure access and convenience when working with the structure.

- Even if the structures are supplemented with stiffeners, this does not mean at all that it is sufficiently protected from contractions when the soil expands in frost.

- If you want to install a special hydroaccumulator in the well, then it is better to make the hole for casing installation not in the center, but closer to the side.

- Experts advise to dig up the cellar at the construction stage of the house / shed, because the caisson will require a pit.

- Insulation is especially important for metal structures, since they rarely maintain the desired temperature regime.

- Note that the water from the well is not always crystal clear. For this reason, it is recommended to install special fine filters at home.

How to install a caisson on a well in stages, see the next video.