What is the best drill for the well to choose and how to do it yourself?

When building a private dwelling house or a comfortable comfortable cottage, it is necessary to consider a water supply and drainage system. The main component of the system is a source of clean water. If the water supply is not supplied to the building, a well will have to be drilled in the territory of ownership. This procedure can be performed independently in the presence of a drill.

The tool will drill into the soil neat, even holes of the required size. It is impossible to perform such work with a standard shovel. The choice of tool should be taken very seriously. Here it is worth considering the characteristics of the soil, the estimated depth of the aquifer and other points.

Special features

The drill is designed for digging vertical holes of a large depth of small diameter.In this case, the efforts of the person are reduced to a minimum. The beginning of the well on the surface layer of the soil is called the mouth, the walls of the well along the entire length form the stem, the end of the well is called the bottom.

The main components of any drill are:

- lower support tube;

- tip;

- cutter or incisor part;

- handle;

- drilling nozzles;

- auger (auger part of the drill).

The screw part of the drill destroys the layer of soil in which drilling takes place and brings the soil upwards. The shape of the tip is sharp, but slightly rounded to quickly penetrate deeply and enhance the stable position of the tool. If necessary, the handle is easily removed, and an extension pipe is attached to the drill, which allows you to dig a well to a great depth. The use of boers is extensive: from the manufacture of wells and the strengthening of pillars for hedges to planting shrubs and trees.

Kinds

The most commonly used manual borehole drills. There are several types of them.

Screw

It performs drilling by cutting the soil layer with specialized plates that are the basis of the design. The plates are welded at a 90 degree angle.So the soil is partially removed from the wellbore, so cleaning it is carried out manually with a shovel. In the case of boers with knives-plates welded at an angle of 30 to 70 degrees, all the soil easily comes out. Such tools are suitable for the drainage system.

Crown

The design of such a product includes a pipe and a crown, which is located in the lower part. The crown is made of highly durable material in the form of pointed incisors. This makes it possible to maneuver.

Coring drill drilling is possible only if there are other additional tools: chisels, rods, fasteners. When drilling in this case, the chisel is first used, and only then the drill.

So that the walls of the well are not destroyed, use water. If the drill is not long enough, it is instructed by the addition of rods. High-quality care only improves the technical characteristics of the instrument.

Shock rope

This is an unusual large-sized tool consisting of a pipe with a sludge. To use this type of drill you need a tripod. It is installed at an altitude of about 2 meters.

With this type of drilling, the task is to manufacture a well. From a height a great weight pipe with a sharp end, tied with a thick rope or rope to a tripod, is thrown into it. The soil layer is loosened and falls into the pipe. Then it is removed to the surface with a winch and cleaned from the ground. Only one person can be engaged in such work.

Lozhkovy

It includes a long metal rod with a cylinder at the end. In the cylinder there are 2 components that are located along or in the form of a spiral. At the bottom of the cylinder is a sharp cutting edge. While drilling a well, the cylinder is filled with soil, then it is removed to clean it. Such type of the drill is adapted for territories with the dense damp soil which are not inclined to fall. This tool is often used for the manufacture of wells under water.

Spiral drill or serpentine

It is used for drilling on dense clay and loamy soils, which contain pebbles or small gravel. The elements of such a drill are: a cut head, spiral turns with blades and a rod. Work such a drill slowly, quietly turning it deep into. The soil sticks to the turns, with their full filling, the drill is taken out and cleaned.

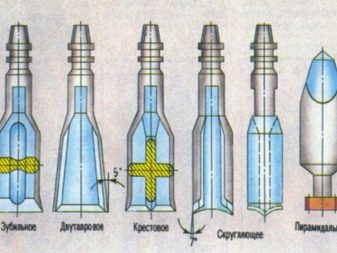

Chisel chisel

This option is great for dry clay or loose sandy and sandy soils. To create it used a piece of steel. Drilling is carried out by the method of impact with the subsequent rotation of the tool by 15-20 degrees. Also chisels are used for crushing small stones.

Push rod

Rotary or percussive drilling can also be performed by a sucker drill. For its manufacture requires pipes with a length of 1 to 3 meters.

Diamond

In particularly solid foundations (concrete, stone), drilling is carried out using diamond drills. They are of two types: electric and hydraulic. A small tool is drilled using an electric tool. They require an electric current. Certain samples of electric diamond drills run on gasoline or diesel fuel. The use of hydraulic requires the use of a special pump for making large holes.

In the description of the technical capabilities of each type of Boers you can find the following data: maximum drilling depth, borehole diameter, tool weight. The ease of work performed by the drill is directly dependent on its mass.The bigger and harder it is, the harder it is to work with it.

How to make a drill with his own hands

Any craftsman can independently design a unique drilling machine from his materials and available tools. However, the assembly requires at least the basic metalworking skills and plumbing skills.

Making a simple drill under water

The easiest to manufacture the drill, which does not have a screw spiral, is made of a handle and blade for drilling. The role of the handle can be played by a pipe made of metal with a diameter of not more than 3 cm. If there is no metal pipe, a wooden element can replace it. A strip of steel is needed for the blade.

A loop-tip is attached to the working part of the strip. On the other side of the slot is formed for the handle. When drilling, the tip-loop is clogged with a small amount of soil, which is pulled to the surface. Then the action is repeated. To obtain a well of the desired depth, several bands join and rotate the structure.

There is another production option. Take a strip of steel with a length of about one and a half meters, a width of 5 to 10 cm, a thickness of about 1 cm. Make an indent from the edge of the strip of 8 cm, cut a slit 150x2 mm.Bend the other end of the strip into a circle to insert a lever handle.

The working edge of the metal must be unbent from the gap in different directions, forming an oval. The tape around the tip needs to be cut to make the point. It should be sharpened and bent in the opposite direction. Next in the ring should insert the lever handle. It will give the device the opportunity to make rotational movements.

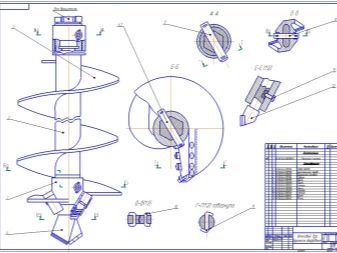

Making auger drill

For the manufacture of the apparatus of this type will require a pipe with thick walls, a steel disk with a diameter of a future well and a thickness of at least 6 mm. If there is no steel disc, it can be replaced with a disc from a circular saw of the same size.

A sharp steel tip is welded to the pipe; in its absence, the tube edge is simply sharpened until sharpness is obtained. Then the disk is cut in half. The edges of these halves are eroded to obtain teeth.

Both parts of the disk are welded to the pipe, retreating from the pointed edge of the pipe from different sides by 13 cm at an angle of 65 degrees. The angle between the resulting screw parts should be equal to 40 degrees.

If during the assembly of the drill, mistakes were made and a very large angle between the blades was set, then the ground would fall down from the drill and additional efforts would be required to extract it.In the upper part of the pipe, the coupling is mounted to increase the bar length (if necessary).

The screw apparatus is more complicated to manufacture. Here you will need steel strips that are attached to the pipe with coils.

Assembling a spoon drill

If you plan to drill a well on moving soils with soft soil, it is best to use a homemade spoon drill. In this case, the loosening of the soil layer will be carried out by the bottom and side surfaces of the structure.

First of all, you need to prepare the drawings and everything you need. For the manufacture of a drill of this type are needed: thick-walled pipe with walls more than 5 mm, welding machine, metalworking tools.

A wide cut is cut along the longitudinal side of the pipe. The width of this cut directly depends on the type of soil. The less friability of the soil, the cut should be wider, and vice versa. The pipe line and expand, giving it the shape of a spoon. Work is carried out with a hammer and scrap. Edges grind, the drill is attached at the bottom of the construction. In the upper part of the pipe, a bar is installed with a shift of 1 cm to the axis of the pipe.

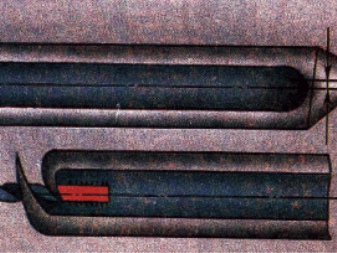

Production of the shock and cable drill

In the percussive method of drilling a well, two tools are used: a sharp pipe and a shell. For zhelonka need a strong alloy, resistant to damage and deformation. Steel and cast iron are best suited. Such drills are suitable for the development of aquifers with a depth of up to 10 meters.

To construct a pipe, a length of about 85 cm and a diameter of 6 cm, a ball of steel with a diameter of 4 cm, a washer, and a metal grill of rods will be required. The washer is tightly fixed at the end of the pipe. The size of the saddle must match the diameter of the ball. A grate is welded on top of the pipe. It prevents the ball from falling out. Here is attached an arc of metal to install the zhelonka on a cable or durable cord. To make the construction more durable and efficient, teeth can be attached to the lower part of the yolk to loosen the soil.

Tips and tricks

A simple and convenient device in the form of a drill will facilitate your work in the country.

Skilled craftsmen advise to choose the necessary tool quietly, not hurrying so as not to be mistaken in the purchase.

- When choosing a coil should pay attention to the spiral purchased product. The steeper it is bent, the greater will be the speed of drilling.

- If you want to drill a small hole-slot, choose a structure with a flat spiral. Such products are less susceptible to wear.

- The product with "self-sharpening" will save you from frequent sharpening of knives, since they will sharpen when rubbing against layers of soil.

- The metal from which the apparatus is made must be so thick as to withstand a certain load and not rust.

- The well-known brand testifies not only about the high costs of purchasing the instrument, but also about its high quality. Over time, spending pays off.

If the choice is stopped on a storm with a motor, compare the cost of fuel and maintenance of the structure.

It is also worth considering the recommendations on the use of the tool.

- The speed of drilling should correspond to the speed of the drill. Excess can lead to rapid wear of parts and bringing the tool to a non-operating state.

- Before drilling, check the operation of the machine at idle, make sure that all parts are working properly.

How to choose a drill for wells, see the following video.