The subtleties of drilling small-sized installation

Currently, many dream of their country house or cottage, but one of the problems in the construction of their own home is water supply. This problem can be solved with the help of a personal well, which will allow you to have a constant source of water.

If you plan to purchase an already equipped section with all the necessary buildings, it is possible to make water supply using a small-sized drilling rig. Drilling with the use of MBU is performed according to the same rules as drilling with large installations, there are also small-sized mechanisms for the shock-cable, auger type of drilling.

Special features

There are certain rules and requirements that must be followed in order to carry out the construction of a high-quality autonomous water supply system.For example, one of the most popular wells with a depth of 15-30 meters can be equipped in 1-2 days, which will save a lot of time. In this case, strict adherence to technology is required, a responsible approach to the choice of a site for the well and the quality of the work itself, which will increase its service life to 15 years and more, preventing its rapid clogging with groundwater.

The staffing of the MBU depends on the terrain conditions, the characteristics of the geological sections and the type of soil (sandy, clayey, loamy soil, except stony soils).

MBU is of 2 types:

- self-propelled (drilling equipment made on the basis of a wheeled trailer);

- stationary (modular modular equipment that can be used for work inside buildings).

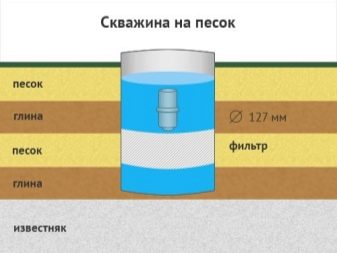

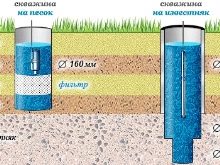

Depending on which aquifer is being drilled, there are 2 types of wells - limestone or artesian and sandy. Since these horizons are placed at different levels, when you contact specialized organizations, the price of work varies considerably. To choose the best option for your site, it is necessary to analyze all the disadvantages and advantages of each type of wells.

Advantages and disadvantages of wells

A well in the sand has several advantages, including:

- low cash costs due to shallow sandy aquifer;

- installation does not require a long time (collection and preparation for operation 1-2 days);

- a small amount of dissolved iron, which significantly improves its properties;

- there is no need to obtain special documentation that is needed when drilling artesian wells;

- productivity is greater than at wells (1-1.5 m3 / hour);

- the expediency of using MBU in a limited space, as well as in basements and rooms where the car does not have access;

- no serious damage to the backyard landscape;

Sand wells have drawbacks:

- it happens that when a well is being developed there is no sandy aquifer;

- service life is 6-10 years subject to periodic cleaning;

- not always high-quality water, when used, it becomes necessary to filter;

- with a 135 mm casing caliber, the water supply is limited to 500 liters.

The main pros and cons of the limestone well:

- high productivity compared to the well on the sand;

- the service life is 50-60 years;

- does not silt, therefore constant cleaning is not required;

- the location of the well in the garden is not important, as the aquifer is everywhere;

- the depth of the aquifer is significant, so the development of a well is expensive;

- installation requires a longer time (collection and preparation for operation at least 3 days);

- high content of dissolved iron, which impairs the properties of drinking water.

Small-sized installation is the most practical way to drill a well on the sand, but there is an opportunity to perform a deeper drilling. A water well on a sandy aquifer can be to a depth of no more than 40 meters and a caliber of 125-135 mm. It does not have strong differences from the artesian source, except that the inside of the well on the sand is always made from a single pipe (usually plastic, PVC). In order to protect the PVC shell from the pressure of the soil at a great depth, a protective sleeve is made of metal in artesian wells.

Statistics show that the number of individual wells developed on a sandy aquifer is more than 60%.

MBU device

By type of drive MBU is divided into electromechanical and hydraulic. Electromechanical characterized by the presence of an electric motor, it works either from the mains or from a generator of a certain power. Feedback on such an installation is generally only positive.

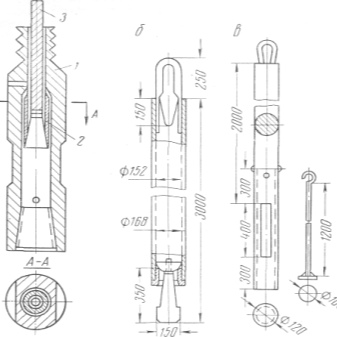

Compact electromechanical equipment consists of several elements.

- Electric motor and gearbox. The gearbox converts the torque generated by the motor and sends it to the drilling tool.

- Swivel - constructive unit designed to fix the drilling tool. For the absence of vibrations and backlash when using the installation it is necessary to monitor the reliable operation of this mechanism.

- Winch - a mechanism that is used for lowering, lifting, moving and feeding pipes into wells, as well as in case of an emergency, extracts a drilling tool.

- The drilling mechanism has a chisel and a rod, and in some equipment a screw column. As the depth of the well increases, new sections are attached using a thread.

Depending on the type of soil and its hardness, an appropriate drilling mode is selected, for which the frequency converter is responsible.

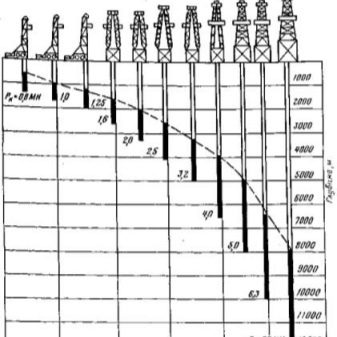

The speed of the small-sized installation depends on the hardness of the soil (grades 1-6) and the type of soil:

- sand, sandy - up to 20 m / h;

- clay, loam - up to 15 m / h;

- solid soil, soil with a large number of stony inclusions - up to 5 m / h.

For the machine, the maximum caliber of the bit should be up to 300 mm, the auger up to 200 mm, and the size of the working mechanism with a caliber of at least 75 mm. Depth of the well drilling depends on the equipment of the mechanism in the installation. If a chisel is used, then the maximum drilling depth will be up to 200 m, with mandatory hydrotreating or blowing of the bottom hole device, if a screw is used in the installation, the drilling depth does not exceed 30 m.

Drilling methods

Another way to obtain a well without the use of heavy special equipment is hydro-drilling - the use of the force of the water itself under strong pressure.

This method has its advantages:

- small dimensions MBU allow you to freely move it between sites, to mount and dismantle;

- operation of the device is possible without special skills and knowledge;

- possibility of renting MBU without additional costs for the purchase of the installation;

- performance of work on drilling a well using one’s own resources without attracting qualified workers.

The disadvantage of this device is a small capacity, and therefore the ability to equip wells with a depth of 30-100 meters.

Hydraulic drilling allows making wells where the layers of soil are dense and compacted, as this technology uses a special flushing fluid that softens the soil and reduces the friction force of the drill.

Compact drilling rigs for water drilling consist of the following elements: frame, engine, swivel, rods for drilling various caliber, heads for drilling of various types (petal or exploration), also hoses required for pump bundle with swivel, a set of fittings for connecting the drilling fluid to the pipeline. Not all small-sized mechanisms are equipped with winches, so it is better to immediately clarify. In the future, when arranging the mine, casing and a pump will be needed.

Manufacturing jobs

To get started, one of the methods of drilling is necessary:

- choose a suitable place for the well;

- mount the frame and attach the winch, engine and swivel to it;

- assemble and secure the first knee of the drill rod, pulling it with a winch to the swivel;

- mount the pipe parts on the threaded lock;

- equip tanks to accommodate technical fluid (number of 7 pieces), for this purpose it is necessary to dig out sumps with a size of 1 x 1 m and tie them in shallow trenches;

- combine clay with water and place the mixture in a mini-well system;

- apply the solution to the drilling area with a pump.

During drilling, the flushing fluid enters the swivel and then into the rods. The waste material is in the trench near the working area, later on it moves to the nearest pit after it has settled. As the rod deepens into the soil on the bracket, the engine, swivel and gearbox descends along the frame. After obtaining the necessary depth, the mechanism is pulled out with a winch and another wheel of the bar is mounted to it.

The process is repeated until a hole of the desired depth is obtained. To set the drilling angle and adjust the inclination of the frame, the rod must be centered with a gage bracket. With the help of remote control changes the speed of rotation of the drill.

There are several signs by which it is possible to determine the aquifer:

- in the first pit there is a clear, washed out soil;

- three layers of soil, two of them more dense and one more porous;

- drilling speed drops;

- reducing the water level in the resulting well.

The small-sized drilling rig is removed after the aquifer has appeared. This is done with the help of technical fluid, which is pumped into the well, and it softens the soil, and then draws the drill rod with a winch. Following the dismantled equipment, a special casing string is installed into the well (the pipe walls must be covered with perforations and wrapped with geofabric).

It is recommended to use asbestos, cast iron or polymer pipe. (unplasticized polyvinyl chloride - NPVH, polyethylene - PE, polypropylene - PP) and electrofusion couplings. The diameter of the casing can be 120-150 mm, and the wall thickness of 6-7 mm. Pipes that are suitable for drinking water (not for sewage), is a pipe made of PP or PVC. At the bottom of the pipe have a filter, which is equipped with a stainless steel mesh with a length of 2-3 m. Pipes on the threaded connections are lowered into the well in parts of 3 meters. In order for it not to fail, it must be held with two pickups.

The final stage of work is strapping and mine arrangement.

The well is cleaned before the appearance of light water, then a hose with a submersible pump is lowered, the tip is attached to the shaft so that it is sealed with a pipe, and the pipeline is led to the room.

At present, it will not be difficult to purchase a small-sized installation for drilling water wells., since all the necessary information can be found on the Internet. The main thing when choosing and buying MBU is to cooperate with large and reliable manufacturers, because they can offer a more loyal price for a drilling rig. Depending on the type of soil on which the well is planned to be installed, it is necessary to choose the correct modification of the drilling mechanism, pay attention to the engine power, rotational speed of the drilling equipment, torque, drilling caliber, warranty period.

To learn how to properly drill a small-sized installation, see the following video.