How to drill a well on the water?

If there is no water on the site - this is very bad. Broaching a water supply system is sometimes extremely expensive and difficult, especially if the distances to sources or to stretched highways are already large. The solution may be to use the well, but first you need to understand its specifics and eliminate possible errors.

Special features

Quite a few companies offer water wells, however, the quality of their services is not always acceptable. That is why it is important to understand the intricacies and nuances in advance. Non-professional approach can not only impede the supply of water, but also provoke a local environmental disaster.Saving on installed equipment, on casing strings and on auxiliary infrastructure is unacceptable. Such performance of work by contractors sometimes indicates their lack of preparedness or unwillingness to comply with technological standards for the sake of revenue.

Regardless of the practical nuances of the well water should be protected from the sewage, as their penetration leads to serious irreversible consequences.

When choosing the right technology, you should pay attention to the following key points:

- type of well being created;

- the desired mass of water;

- its target quality;

- features of the aquifer.

Often interested in whether it is possible to make a well on the water manually. This is perfectly acceptable, even in basements. Manual wells are made temporarily with the active development of the site or constantly, when the need for water is small. But shallow deepening increases the risk of drying out on hot days. And if it rains, any contaminants will seep into the well.

Kinds

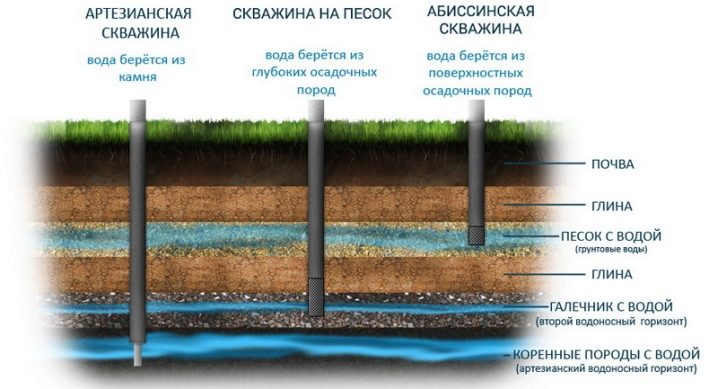

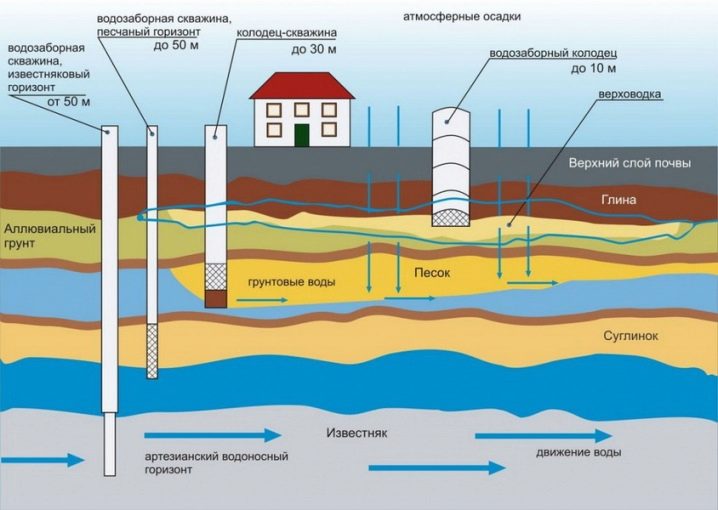

There are a number of varieties of wells for water, which differ in practical indicators and capabilities.If you want to save money, it is recommended to use the Abyssinian format. It runs as a narrow pipe (1 to 1.5 inches). At the bottom of this pipe is equipped with a filter that is attached by soldering. Following the filter is mounted a pointed tip.

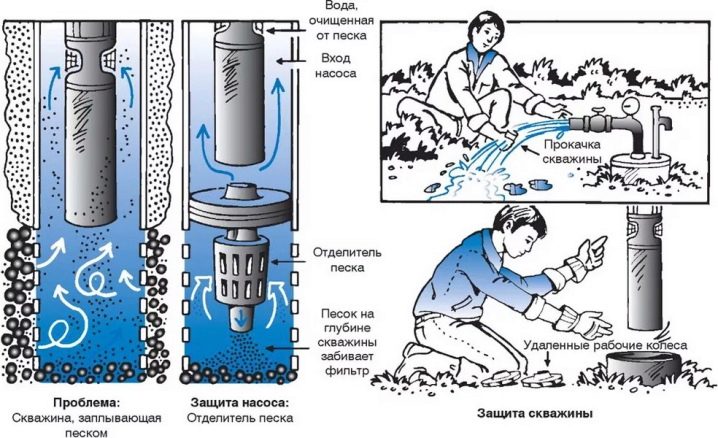

As a result, the prefab design resembles a large needle, ending in a spike. When a well is drilled or a pipe is driven in, such a “needle” very quickly penetrates the soil and reaches the required depth. As soon as the flow of water begins, it passes through the filter and is brought out under the action of a surface pump. It is worth noting that driving the pipe can threaten with the destruction of the couplings or the shift of filters to the side. Much safer is considered full drilling.

A typical Abyssinian well reaches only the aquifer closest to the surface. As a rule, it is located at a depth of 400–500 cm. If the sand in the upper layer is extremely fine, drill further. According to technical standards, it is supposed to bring the well to the formation with particles of medium grain size. Otherwise, the sludge supply and accumulation will be too intense.To compensate for the excess thickness of fine-grained sand can be added to the cavity of marble chips.

A needle well is drilled in 240–600 minutes, and specialized equipment is not required. At the disposal of professionals there are small drilling machines with a height of up to 2 m. Thanks to such equipment, it is possible to get water in built-up areas without driveways for large cars. The exclusion of contact with the installation at observance of technological requirements is fully guaranteed. Especially good is the decrease in the concentration of substances that have a detrimental effect on health.

A surface well cannot be equipped at a site where the ground is composed of stones. The maximum flow rate is 3 cu. m per hour, which does not cover the needs of a large household. This solution is certainly not suitable for the supply of animal husbandry. To use the channel all year round, will have to form a pit. A hand pump at such a water source only works during the warm season of the year.

Much more common is the so-called well on the sand, confidently coping with stony soil, and with the passage of a layer thicker than 8 m.Such a device reaches 14–40 m, the exact depth is determined by the geological properties of the soil. The casing is formed from pipes with a diameter of 12–16 cm. Usually, a puncture is brought to the nearest layer of sand with the inclusion of water. Important: making the casing string is required strictly from pipes of the same diameter.

At the very bottom is placed a pipe with perforation, which allows you to collect the water contained in the sand. The filter with small cells helps to eliminate the ingress of grains of sand. To lift the water using a submersible pump of the vibration type, which is quite resistant to the action of sand. The use of centrifugal devices is unacceptable. Their internal filters will be filled with hard deposits in seconds.

It is recommended to drill a well in the sand with a large grain, the layer of which is divided into two parts by gravel. Theoretically, good water can be obtained on fine-grained rock, but the period of normal operation of the passage is noticeably reduced. A surface sand well will give only 1.5 m³ of water per hour, which is not enough to supply households with pools, fountains, extensive gardens and vegetable gardens.In addition, the quality of the extracted fluid is lower than that of the Abyssinian product. Despite the absence of iron and hazardous minerals, it is necessary to thoroughly combat the penetration of top water and industrial, agricultural effluents.

The surface sand well is 10–15 years old, but with the only condition that it will be applied continuously. Insufficiently intensive use leads to the accumulation of sludge and the loss of water of its beneficial qualities. In the summer months and in other dry periods, the sandy layers will give very little or, in general, lose it. No one can guarantee that water will be found in a particular place. And this is not only a fee for empty work as for exploration, but also additional costs for new drilling.

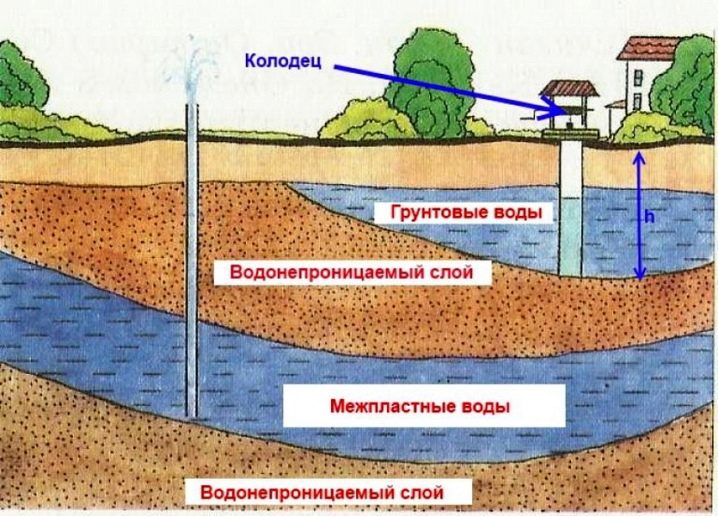

The artesian type of wells deserves special attention. Such channels extend deeper into the layer of limestone, which, thanks to its porosity, allows liquid to flow through superbly. Despite the considerable depth (40–200 m in most cases), water under pressure will lift violently. The impossibility of infiltration of soil water to such depths allows not to be afraid of clogging.The strength of limestone makes it possible not to be afraid of penetrating sludge into the well, even if it has not been used for a long time.

It is necessary to take into account that artesian water contains a lot of iron and mineral salts., sometimes more than acceptable sanitary standards. Therefore, before food, and sometimes before technical use, it will still have to be filtered. The rise of the fluid is provided by submersible pumps, subject to the technology, the source will meet the needs of at least half a century. Unfortunately, artesian drilling is ten times more expensive than penetration of surface layers.

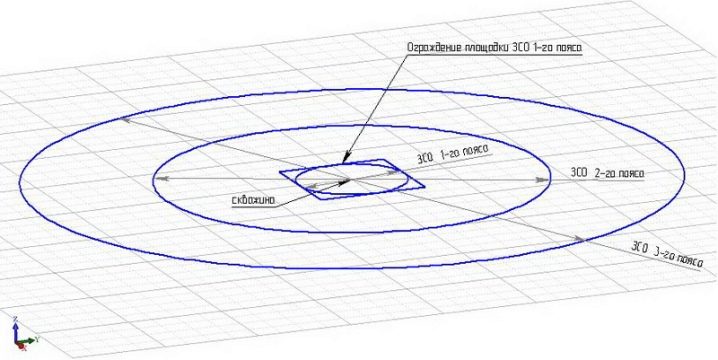

In addition to the actual drilling, you will have to pay for registration of state registration documentation. Within the settlements, the necessary equipment may not be deployed everywhere, especially after the completion of the development of a particular site. Equipment for an artesian well should be exposed on a flat rectangle with sides of 4 and 12 m, and there should be no electrical wires nearby. The sanitary radius around such a source is 30 m, within its limits it is impossible to plant trees, build anything and do without external perimeter fencing.

All artesian waters in the Russian Federation have the status of national ownership. A deep well can be broken only in accordance with the project that has been approved by the subsoil use department. No commercial organization without its permission will not send equipment and specialists to the objects, it does not need problems with the law. When the source is ready and equipped, it is registered in the water cadastre, and only then you can begin to use. Therefore, artesian wells are drilled for the most part for a large enterprise or for the needs of a separate cottage community.

Device

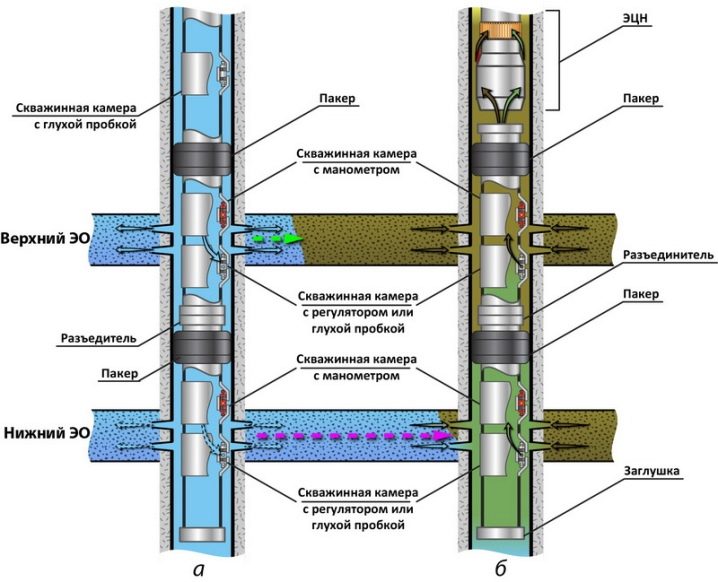

Any of these types of autonomous water supply is organized very difficult. It is not enough even to drill a well, it is required to equip it thoroughly and to supply it with additional working parts. The source drilled “on the sand” can be used only after thorough chemical and bacteriological analyzes of the incoming fluid. Otherwise, safety cannot be guaranteed. An artesian well with a one-pipe scheme implies a coincidence of the casing and the exploited channel brought to a limestone formation.

In most cases, the casing is formed from pipes with a cross-section of 15.9 or 13.3 cm. Water will rise to ½ the total depth, the pump is immersed by 2/3, that is, approximately to the edge of the casing. The two-pipe scheme is distinguished by the use of an auxiliary casing in the area of dry calcareous rock. When the metal channel reaches the limestone, inside it there is a pipe made of polyvinyl chloride, overcoming the layer of rock and reaching the aquifer itself. The operational plastic channel has a diameter of 13.3 or 11.7 cm.

Important: when the limestone is completely unstable, the casing of the inner tube is made to the bottom of the borehole channel. If there are fluids in the upper parts of the earth, an artesian well is made with a so-called conductor that is wider than the casing. Its purpose is the external protection of the base structure against the pressure that arises. It is recommended to connect the conductor with the so-called caisson. The telescopic version implies the use of several different sized casings at once.

This solution is practiced if the ground is very dense or not sufficiently stable.Metallic passing element has the largest diameter and reaches the reservoir where the boulders are located. Through it lead to the first line of limestone. When limestone contains clay, another pipe is pushed through it — already plastic — to a pure aquifer. These requirements may change if experts discover an atypical state of affairs.

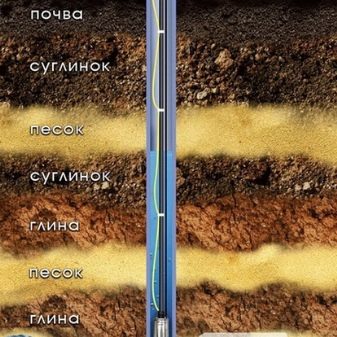

A well on the sand consistently pierces the following layers:

- ground on the surface;

- top sand;

- clay;

- sand containing water.

It is this chain of layers that is most often present, although in certain areas they can be mixed or diluted with other inclusions. Fluid saturation of the aquifer determines whether the well should be drilled to the middle part or to its lowest point. The filter apparatus at the bottom prevents the crushed rock particles from entering the technological area. There are both external and internal cleaners in relation to pipelines. Above them in any case put a tank for settling.

The pump unit, as well as in the well of the greatest depth, is placed approximately in the middle of the column.The pump installation of the deep sample goes down into the water source. Therefore, it is made in the form of a narrow cylinder. Surface structures are placed in caissons or in houses. It is recommended to install the weakest pumping units in the caisson, which will help simplify the production of liquid.

Submersible pumps should be freely moved inside the casing.therefore, a gap of at least 0.3–0.5 cm should remain up to its walls. If this gap can be increased, this is exactly what needs to be done. In most cases, pipelines are made of reinforced hoses that are certified for food use. Often take sleeves from plastic or silicone. There are other parts of the well construction.

It is extremely difficult to pass the barrel and mount the casing with your own hands, even when the well is shallow on the sand. It would be much more correct to seek help from specialists. But the external improvement of any homeowner can perform on their own, and it does not even require excessive effort. The pipe coming out with a hose attached to it is highly questionable from an aesthetic point of view.Moreover, in such a system, clogging will occur continuously, during the winter months such a circuit is inoperative.

The first step in the arrangement of the well outside is the installation of the caisson. So called impermeable to water and laid insulation layer capacity. The purpose of the use of such a tank is the uninterrupted operation of the water supply system.

In most cases, the surface pump is placed inside the caisson, and the following elements can be placed there:

- the locking fittings;

- automation;

- end filters;

- measuring systems.

Caissons can be made of a wide variety of materials, but plastic, steel, and reinforced concrete are still the most practical. Plastic passes very little heat, except for particularly severe frosts, it is possible to avoid hardening of the liquid. But the rigidity of the plastic is too small, it is recommended to shed concrete solution along the entire perimeter. Steel housings are most common, they are even made independently of sheets with a thickness of 0.4 cm. But the necessary durability of the structure is guaranteed only after anti-corrosion treatment.Strength and long-term use is a characteristic feature of reinforced concrete.

Once such products were used almost everywhere. The decline in their demand is caused by excessively high prices and the weight of the blocks being formed, therefore in living conditions almost always metal coffers are used. Under them dig holes, which in all planes by 0.2–0.3 m more than the mountable structure. The depth is calculated so that the neck of the caisson is 150 mm above ground level. Then comes the turn of work with the casing liner.

A recess is cut in the bottom of the tank and a sleeve, previously cut from the pipe, is welded to it. The length of such a part is 100–150 mm, and its diameter is somewhat larger than that of the casing itself. When it is finished, nipples are mounted in the wall that serve to drain the water circuit. Before installing the caisson, it is required to cut the casing at the surface level, only then put on the container. The orientation of the tank in the pit should be perfectly vertical with fixing bars. When this work is done, tighten and attach water pipes. The final step is the decoration of the surrounding space, which is performed according to a randomly chosen scheme.

Technology

No matter how carefully approached the arrangement and design work, you first need to still drill a well according to all the rules. The first step is to carefully select a suitable site where you can get water and place pumping equipment, connect the pipelines. It is worth considering where to put the drilling rig and additional devices. Experts recommend immediately calculate the necessary working area and the space where the process water will be removed, the space to accommodate the stored things. The pipe should be introduced no closer than 3 m from any buildings. After the completion of work with a well above it, it will not be possible to build anything.

Traditionally in Russia, water well drilling with flushing is used. Clean water or clay solution is driven into the formed channel under pressure. Pumps help to increase pressure and pump fluid in conjunction with small rock out. Raised solutions are placed in a sump, where solid inclusions settle down. The settled water can again be used in the technical cycle.

The penetration of insufficiently strong layers is carried out with the supply of the clay solution. At the first stages of drilling, when they go through layers of clay, they can be supplied with clean water. The role of the clay mixture is not only to evacuate the crushed masses, but also to strengthen the outer perimeter of the well, to prevent its collapses. The passage of wells in durable layers, such as calcareous rocks, involves washing with process water. When it reaches the aquifer, it begins to be absorbed, and therefore does not return. This circumstance helps to stop drilling operations in time.

In household construction electrical destruction, thermal or explosive crushing is used extremely rarely.

The cleaning of the borehole channel, in addition to flushing, can be performed using the following elements:

- boers;

- augers;

- squirrels;

- a jet of compressed air;

- several options listed at once.

To strengthen the walls of the channel, plastic casing and asbestos-cement pipes are increasingly being used. Metal structures are found in three main types - threaded, welded, seamless. The ousting of even these common decisions by modern materials is due to their low profitability.It is not recommended to use galvanized steel, as it adversely affects the nutritional characteristics of water. Plastic liner has a positive effect on the life of the well and on its practical, technical parameters.

It does not matter whether manual or mechanized drilling is underway, the final step is pumping out the fluid to obtain a transparent flow. Be sure to check the level of incoming water to calculate the required parameters of the pumps. You can manually pierce only wells on the sand (and even then not all). In most cases, they are still involved in the work of specialized equipment. This means that you need to think about the organization of arrival. It is useful, which is important, and later, when it comes to repairing a drilled well.

Returning to manual drilling, it is impossible not to mention that compact installations are divided into four fragments: frame, control system, electric motor, winch. Additionally, use disassembled drilling hoses. When using such devices assembly is made with the most complete observance of the instruction. After the completion of drilling, all the equipment used is washed from the accumulated soil (most often clayey in origin).

Auger drilling is no less effective than the above-described solutions with classic drills. Such a measure is needed if you want to go through the soil containing a lot of sand and gravel masses. Special drilling equipment is equipped with a head part and augers that divert the soil. The processing of the soil separated from the slaughter is not performed. The auger approach eliminates the need to flush the shaft.

The technological process is divided into key stages such as:

- soil destruction mechanically with heat removal from working parts;

- lifting crushed mass;

- pressure on the inner walls to give them maximum strength.

Auger drilling copes well with soft earth, which needs to be penetrated to a relatively small depth. The speed of work and the ability to continuously raise the ground will delight all builders. But apart from the limitations of the deepening, it is important to remember that the screw machine should spin strictly under pressure. To make the chisel last as long as possible, it is made stronger by cutting tools made of hard metal. The chisel should be 2.1 cm wider than the auger. Due to this, the system is able to guarantee the free torsion of the apparatus when overcoming loose soil.Depending on the designers' intent, the screw mechanisms can be made with a column, single screws with a crown, sometimes there are ordinary columns or columns containing a cavity with a bit to be removed.

Initially, a geological survey is always carried out. First, dig a pit that is removed to 1 m from the main point of development. In this excavation to dump the waste soil. The size of the soil collector is dictated by the depth to be drilled. Usually take the ratio of 1 m³ per 10 m of penetration. Screw drills are mounted on special guides, which should guarantee the excellent retention of working mechanisms.

Since soils are mobile, it is necessary to prepare bearing positions for the chassis. It is necessary to fix and hold the augers or columns of augers with a rotating pipe. Many screws are equipped with an internal cavity, which helps to collect the cut rock.

A chisel of 2 or 3 blocks is placed at the bottom, which is responsible for the following:

- fault;

- grinding;

- pulling rocks to the transport mechanism.

Overcoming of soft masses implies the orientation of the working blades of the bit at angles from 30 to 60 degrees relative to the vertical.When it is necessary to pierce the soil containing a lot of gravel and pebbles, they are mounted strictly perpendicular to the drilling plane. As soon as the first drill came, it was lifted and installed in the initial position. This solution helps to avoid clogging of the working mechanism of the breed. Then the structure is strengthened, the bracket is pushed with a hammer, the rotational tube is raised to install and fix the new column.

Appearing outside the rock is thrown shovel into the pit. Then the boring machine will have unhindered access to all parts of the working platform. It is recommended to choose a rotational tube 50% more powerful than the technical characteristics of the bit. The chisel itself can be made of hard alloys, which is relatively cheap, or with a diamond part, while the equipment runs faster and better. Reducing the diameter of the column augers increase the rate of penetration and vice versa.

Very carefully should pass the granite masses. The drilling mechanisms going through them can break, which slows down the work process. When the design depth is reached, the auger should be removed by all the rules.First, the column is raised so that the uppermost drilling unit is above the ground, and installed after it - 15% rise above the surface. Then parts of the pipeline are fixed on a channel, mounted under the spiral part.

Remove metal hardware mounts and remove the drill unit itself. The pipe with brackets attached to the borax. Again and again, these actions are repeated, seeking a final rise of the bit to the surface. Casing cling to the lift, lowered into the mine and, gradually moving down, attach the following pipe. In order for these parts to be firmly connected, it is recommended to use an electric arc.

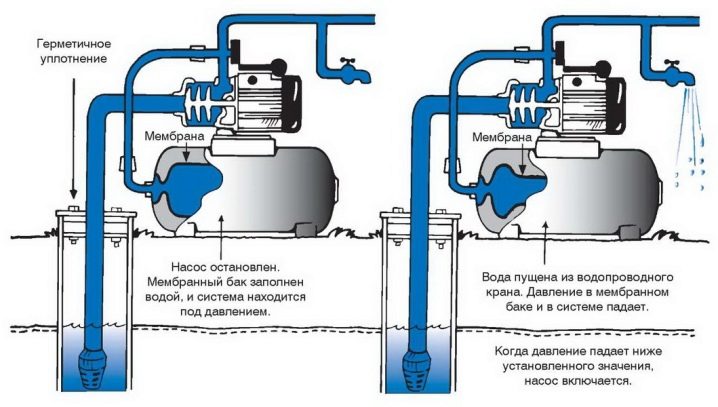

Whatever way of drilling and the type of pipes the customers choose, they need to think about another important point - the automation schemes for the well. Their importance is due to the fact that, for example, the cost of individual blocks can vary tenfold. Such significant differentiation is due to practical characteristics and target parameters. The easiest and most economical solution for well automation is the use of a mechanical regulator.When water presses insufficiently inside the capsule, the contacts of the circuit that starts the pump close. After the valve is closed, the pressure increases, the electric circuit is broken, no power is supplied.

There is another option, as the use of a pressure switch with a sensor and pressure gauge. In the simplest devices, a relay can do without these additional components. The relay is allowed to be installed at any point of the line, since the pressure in it is the same everywhere. Simplicity turns zero protection from dry running. The relay will “drive” the pump even if there is no pressure in the well until it breaks.

To compensate for this drawback, the addition of a hydraulic accumulator to the circuit helps reduce the frequency of pump start-ups and dampens the blows that occur when the taps are turned on rapidly. To create a battery used ferrous metal or (more often) stainless steel. Most models are painted on the production in blue color, capacity varies from 5 to 500 liters. If water consumption is high, batteries with a volume of less than 50 liters often cannot prevent pressure surges.

Inside there is a membrane designed for a pressure of 2 atm. External pressure must be greater than this mark, otherwise the device will be inoperative in principle. When the pump is active, water flows into the expansion tank and squeezes the membrane. After shutdown of the pumping system, the pressure is balanced. When the tap is opened, draining the water from the tank gradually leads to a drop in pressure to the value set by the relay settings for starting the pump.

There are more serious automatic devices that are many times more expensive than the simplest relay.

The fee is not accidental, because the consumer can receive in return the following:

- comfortable adjustment of the lowest and highest pressures through the liquid crystal display;

- dry motion prevention;

- blockage of pumps seizure;

- programming a specific interval for automatic start after errors occur.

Even the most advanced automation does not give reason to think that you can do without a hydraulic accumulator. But here it can be reduced to the minimum value, which only allows to extinguish the arising blows.The most expensive regulating system is the frequency converter, which is most convenient in terms of water use. He will definitely be able to maintain the required pressure in the circuit. Therefore, the main parts of the pump will wear out more slowly and reduce the consumption of electrical energy.

Where there is a frequency converter, the equipment works smoothly and measuredly. In addition, the system recognizes how large the water flow is and whether it is necessary to pump it as intensively as possible. Manufacturers of such equipment consider it necessary to supplement it with expansion tanks of 1 or 2 liters, so that small leaks do not provoke a restart without end. In any case, you should take into account all these subtleties before buying additional equipment. The practical superiority of frequency regulators turns their increased price, which significantly reduces the popularity of this choice.

Location selection

Breaking a well, either with the help of professionals or with your own hands, is a very expensive business. Consumers are forced to spend tens of thousands of rubles for each attempt to reach the aquifer.In order for water supply in a country house or at the cottage not to become “platinum”, you need to carefully select the appropriate point to start work. Initially, they study the general plan of the site, where all the objects located on it are reflected, including even minor buildings.

For your information: do not invite operators of the vine. The performance of their work is no different from random guessing, and the board is very large. Where better to seek help from professionals in hydrogeology.

For the passage of the wellbore trying to choose the highest point to avoid flooding.

You should also consider the following:

- maximum removal from contaminating objects within the suburban area;

- approaching water bodies, because it is there that chances are higher stumble upon underground water;

- terrain relief;

- soil structure.

The technology of drilling for water allows the arrangement of wells even in the lowlands. A prerequisite for this is the minimum risk of flooding and ease of execution. Water horizons are usually located where the terrain drops off or often changes the terrain.It is useful to be interested in the depth of the nearest wells or boreholes. On completely empty terrain, a reference point is often a section of vegetation or a wet corner that lasts the longest of the hot summer.

Pollutants are not only septic tanks and poultry houses, but also houses, garages, storage rooms, baths and so on. It does not matter whether they are built on a particular plot or from neighbors.

It is recommended to move the well away from the following objects and structures:

- from the house - on 5 m;

- gas station, industrial enterprise, railway - 100 m;

- sewage wells, pits, storm sewer - 50 m;

- household septic tanks and ordinary toilets - 25 m.

Where cars often drive or there is a constant source of vibration, it is impossible to guarantee the normal operation of the well itself, casing pipes, hoses and pumps. It should be remembered that sometimes during drilling the installation raises the mast to 10 m in height. Drilling vehicles are 3 m wide, which imposes strict restrictions on the choice and installation of gates. The construction of a well or digging a well on a slope should be carried out with reliable protection from rain and melt water.In advance, they think through all the measures to strengthen the structure and protect it from vandals.

How to do it yourself?

It’s quite possible to drill a well in the water. Begin by digging a hole of 1x1 m at a depth of 0.6 m. The pipes are taken from a length of 2 m, and thread is prepared at their ends. Entering the pipe into the soil, the second pipe is attached to the sleeve. This operation is repeated until the desired depth is reached. The teeth on the working side of the first pipe make a grinder, the opposite end equip thread.

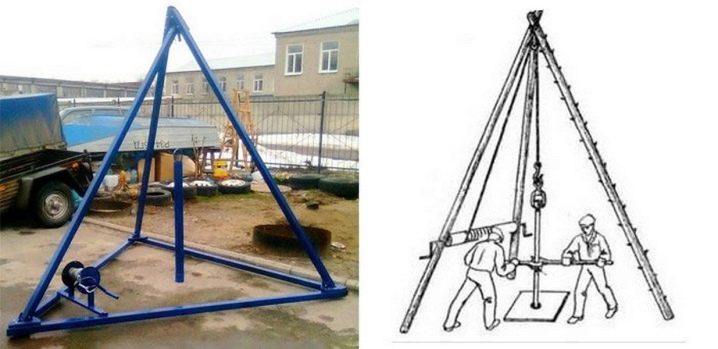

First of all, an adapter having an end block for the hose used is threaded to the thread. The use of 4–6 m long pipes helps to reduce the difficulty of unscrewing the adapter. In addition, such structures under their own weight go into the soil much more effectively. The three-legged construction made of bars, placed above the recess, is complemented by a roller block, and a rope is pulled out through it. Attention: it is recommended to fix the prepared product, tying in the lower part and in the very middle of its support with the help of a bar.

Then they fix a drum made of metal, like a well, and then with its rotations they give movement to the pipe.A pit is placed on the ground near the pit and placed on the floor raised to the edge of the first barrel. In the second tank, drilling the bottom, put a pipe segment with a valve. The barrel is filled with dried grass, on which a metal net is laid out on an incline to help remove large soil particles. The lower barrel is equipped with a pumping apparatus, the turbid suspension after cleaning, being pumped into the upper tank, fills it. This method will deepen the pipe without excessive mechanical effort. All that is required is to throw the ground aside and see if the desired level is reached or not.

Regardless of the subtleties of the technique, you should definitely pay attention to piping the well to the water. The dacha scheme, which is designed for water intake only during the warmest months, is mostly formed by own hands. All that is needed is to mount a surface pump and supplement it with a hose through which the fluid will rise. It is more difficult to “tie up” the well, which is planned to be used year-round. The pit is made in the form of a recess, the volume of which is equal to the volume of a typical reinforced concrete ring with a cross section of 1 m.

The lowermost plane of the sump deepens by 50 cm under the freezing line in a particular area, and the pipeline is also brought to the same depth. It is required to dig a hole for a caisson before the start of drilling, but it should be equipped strictly after the completion of casing and grouting manipulations. In most cases, the walls of the pit are covered with concrete, only occasionally with bricks. In cold and particularly harsh climates, it is recommended to use keramsit concrete or well laying with filling of the internal cavity with loose thermal insulation. The perimeter of the caisson is supposed to close the layer of hydrophobic impregnation. The base of the pit cannot be concreted, it is only concentratedly rammed and covered with a mixture of gravel and sand, then accidentally broken through the torrents will definitely go down.

When high soil waters, the caisson is undesirable to equip the equipment. A hydraulic accumulator is then more correctly placed in the house. To do this, select the appropriate layout. Be sure to take all measures to reduce the risk of the bay pit. The walls of monolithic concrete are saturated with plasticizers, which make the masonry impermeable to moisture.

The subject of a separate concern of zealous owners is the cementing of the drilled well. The displacement of the drilling fluid cement (cement) significantly increases the strength and practicality of the water source. For 113 years, cementing casing in one stage has been used. This method has undergone only minor improvements. The work must be carried out according to a specially designed scheme, which is based on technical calculations.

It makes no sense to take on them until such geological parameters are clarified:

- how large is the reinforced gap;

- what is the design of the borehole;

- how good is his condition.

Skilled builders always figure out in advance what is the practice of cementing in a certain area. Sometimes the mixture is fed directly, it goes inside the casing. Reaching the shoe, cement seeps into the space behind the pipe, going upwards. In serious industrial projects, wells are cemented in a straight line pattern. Pushing the solution to a greater depth helps work in two stages, with the help of a cuff, a part of the stem is isolated temporarily from the plugging mixture.

Arrangement

If the well has a relatively small depth, it is recommended to equip it with a low-cost, easy-to-install and service surface pump. It is desirable that the bundled membrane type and automatic equipment, selected individually, be included with it. One of the pipes leads to the well, the other will be pumped into the water supply system. Pre-set filter for coarse cleaning. No matter how good the condition of the well and its internal filtering, it is unwise to rely only on these moments.

Tips

Reviews about specific brands of automation, about pumps and hoses, about the types of wells in a particular area, it is extremely important to consider for informed choice. Equally careful is the selection of firms that are entrusted with commercial drilling or maintenance of a finished well. You should always check licenses and certificates. From plastic pipes, preference should be given to products based on HDPE, since they have more flexibility. With independent performance of work, the shock-cable drilling method becomes the most universal solution.

To learn how to drill a well in the water with your own hands, see the next video.