Bile: varieties of product for cleaning wells

The construction of wells requires the use of special equipment and devices. In addition to drilling rigs, a device such as a shell is used in the course of drilling or cleaning wells.

Special features

It is a fairly simple tool related to the line of drilling products, with the help of which private sources of water are cleaned from accumulated bottom contamination. In addition, using the sink, you can drill the source under water.

Such a well will require minimal investment, and independent production of the tool will not significantly affect the budget.

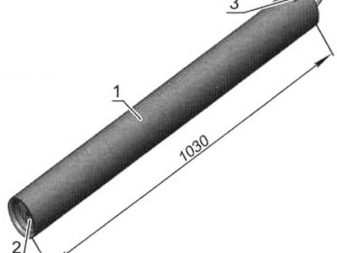

Based on the design features, such a device is made of a pipe whose length is about 2 meters. The lower part of the shell has a valve and a shoe, in some cases, teeth with different sizes are attached to the end. Such sharpened elements help loosen the soil, which most often contains silt, sand and other soil layers.

On the top of the pipe there are usually eyelets into which a metal cable is passed. In addition, a protective net made of thick wire is fastened at the top. It acts as a damper that prevents the release of soil components in the valve.

However, the main scope of the zhelonka is to clean the sources and wells from the accumulation of a large amount of contaminants. Such situations everywhere arise in cases when the pumping equipment has not been functioning for a long period, as a result of which the source has been silted up or a lot of sand has accumulated in it. This leads to a decrease in well production, as well as pump clogging. In such a situation, it is removed from the well and the source is cleaned with the help of a choke with the method of tarting.

The basis of the functioning of the device is the gravitational principle. A rather heavy tool is sharply immersed in a shaft from a great height, sharp edges begin to loosen the soil, and excess deposits are collected in the opened bottom valve, and the cement slurry remains in the well. After that, the valve is slammed down, and the bowl with the contents is lifted to the surface.

For maximum effect, such work is performed several times, the valve reliably holds all deposits inside. After complete purification of the source, the scum is cleaned from collected sludge and sand.

Drilling with the help of a can is to be carried out in loose types of soil, and the resulting well, made in this way, will be suitable for operation.

Views and their device

The device has a different configuration, on the basis of which it is possible to classify the product. Products on the market today have a different valve system, which differ in the principle of operation and device. This specificity of the fells should be considered when making the device with their own hands.

Based on the type of valve, it is possible to distinguish the following bits for wells:

- products with petal valves;

- products that are equipped with ball valves.

Elements of the petal type are the simplest, taking into account the manufacture.

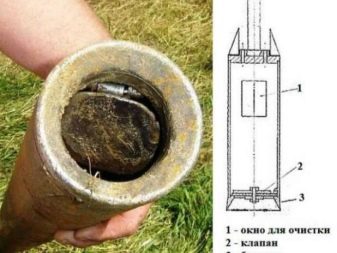

However, the valve with this type of valve has a high level of efficiency during operation. In appearance, such a valve is an ellipsoid plate, which is fixed in the center of the pipe. In some models, a sealant is attached to the valve walls, which increases the tightness of the part. It is usually made of rubber or leather.

Most often, these valves are made from polymer materials or from thin springs made of steel. According to the scheme of work, they act as an analogue of the “blinds” in the small bowl - that is, the pollution penetrates only in one direction. Under the pressure of water, the edges of the plate open up, due to which the soil and other contaminants get inside. What is reflected in the productivity and speed of cleaning wells.

However, along with the positive features of the configuration of petal valves, they have some drawbacks - this concerns the short life span of such a system. The movement of the elements and the mechanical load wear out the valve rather quickly.

For the type of petal valves for zhelonka can be attributed to the valve on the spring, which is responsible for closing the element. This type of valve is widely used for cleaning sources as well as for drilling wells.

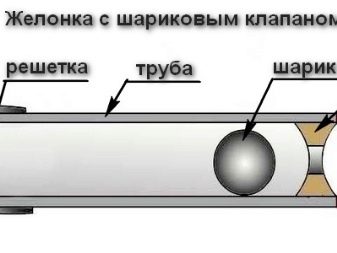

Adaptations with a valve having a spherical shape, according to experts, are considered the most reliable for working with wells.

According to its configuration, the ball valve is a funnel, in which the mouth is closed by a ball, the selection of which is based on the size of the hole. Such products are manufactured on lathes or are purchased in stores. The ball must have an impressive weight, and also effectively close a funnel with a large diameter. Some craftsmen make a hand-made ball using various available tools, including waste from metal.

How to do?

Sink for pumping wells can be done independently. To perform such work should be familiar with the drawings of the product. To make the shell, you will need the following materials:

- metal pipe, which will act as a housing;

- valve;

- welding machine;

- metal cable and durable wire.

When choosing a pipe, one should proceed from its diameter; the size of the well casing will be used as a guideline. For the productive functioning of the stalk, the distance between the source walls and the base of the cleaning device should be about 2-3 centimeters. That is, it is necessary to subtract this value from the internal diameter of the pipe in order to obtain the required pipe diameter for the manufacture of the element.

The distance between the wall of the shaft and the cleaning device can be different, but the size of the shells depends on its size. Too much clearance will adversely affect the progress of the well cleaning process. And a small distance, in turn, can lead to damage to the walls of the well when it is dipped or the zolon leaves the source shaft. In some cases, the pipe may jam at all, it will be very difficult to remove it. Since there is a risk of damaging both the product itself and the wellbore.

The most acceptable length of the pipe is considered to be 80 centimeters, but this value can vary between 60-150 centimeters. It is necessary to choose the optimal size of the broom based on the size of the well, since too short a device will touch the walls in the process of work,and the long element can be very heavy. Such a product will be difficult to immerse, and in particular, to raise when the shell is filled with silt or another blade. Long products will be more efficient when drilling.

The thickness of the pipe should be about 2-4 mm in order for the finished product to have an acceptable weight to work with.

The combination of the above parameters will directly affect the course of cleaning activities. Therefore, the weight and size of the products must meet the following requirements for the shells:

- provide explosive penetrating inertia, which allows you to quickly remove contamination from the well;

- the mass of the element itself, together with the formations collected from the bottom, should allow the shell to be taken out of the source independently or when using a winch.

In order to make a strong and functional shell, you will need to connect with the pipe several more components of the product. In the absence of a welding machine, the shell can be made from a pipe 0.6 m long, with a diameter of 70 mm. At the top is to attach a wire handle.

For mounting at the base of the pipe, holes are made and wire is threaded through them.In the lower part have a valve. The petal element can be made from a plastic bottle; for this, an ellipse of the required size is cut out of the container wall.

Fix the valve with a 6 mm bolt, however, it should be noted that its length should not be more than the outer diameter of the pipe. Under the bolt drill two holes in the pipe. The valve with the bolt is fixed with a wire, its thickness should be about 3 mm. From it form two rings. The valve bends and slips into the interior of the yolk. Then pass the bolt and wire rings. The bolt is tightened with a nut.

At the final stage of manufacturing the element, it is necessary to sharpen the bottom edge. It is better that the hydro vacuum sheath is unilaterally sharpened from the inside. To prevent the edge from being erased, it is better to heat-harden it.

In the presence of a welding machine, pointed pieces of metal can be welded to the edge, such a configuration will ensure more effective loosening of the soil.

The fastening for the metal cable to the top of the pipe must also be welded. The vertical position of the loop will allow you to keep the squirrel in the same position.The absence of distortions in the design will eliminate the jamming of the installation and the possibility of damage to the walls of the well shaft.

When using a ball valve, a mesh is welded at the top of the pipe, which will protect the ball from being accidentally ejected when the element is dipped into the source. After attaching the cable to the pipe, you can start working.

To facilitate the descent and elevation of the yellowcone above the well, it is better to install a frame with a block. The cable gets for the block and carry out manipulations with adaptation. This greatly facilitates cleaning and working with the scrape in the absence of an automatic device control system.

Before you immerse the pit into the shaft, you should make sure that there are no irregularities or damage on its walls, such precaution will prevent the risk of breakage of the new cleaning element.

Tips and tricks

As a cleaning tool, the slug will need to be used to clean wells several times a year. To avoid the occurrence of various kinds of difficulties associated with the process of self-cleaning of wells, it is worth monitoring the condition of the walls of the well.

Drilling with the help of zhelonka is recommended to perform only on a specific type of soil. Piston model is better to use on soft, sandy soil. In all other cases it is better to entrust the work of specialized equipment under the guidance of specialists.

There are a few tips for working with the smalltalk:

- in the sandy soil device should be immersed no more than 10 cm;

- performing drilling it is necessary to feed water into the barrel to strengthen the walls of the mine;

- in order to collect too wet sand with the help of a zhelonka, it is worth using a special chisel;

- the bowl must be lifted every half meter to avoid the maximum filled body of the element;

- when working with soft types of soil it is not always necessary to use a valve, because most often the rock already accumulates in the device.

To facilitate the work of lifting and cleaning the bile filled with rock from a clogged well, it is worth optimizing the operation of the device. The modernization scheme consists in a small addition of the case with details.

The reverse side of the pipe body is tightly welded, retracted, and a special fitting is placed there that will be used to drain the hose. The pump is connected to the hose.Use a device model designed to handle contaminated liquid media.

With this principle of operation, all collected pollution will be pumped out of the pump, thereby eliminating the need to raise the shelf for cleaning each time. A cleaning device with a pump will simply lift and submerge in order to move the fluid and collected rocks along the body. Such optimization will be effective in case of severe contamination and silting of the well. For normal regular cleaning use of the pump is not mandatory.

How to drill a hole, see the video below.