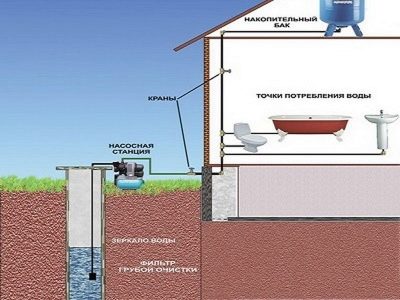

Water supply scheme of a private house from a well

Arrangement of its own water supply system is an important moment both for the house already built and during its construction. To provide water to a private house, it is necessary to choose an acceptable water supply scheme, which primarily relies on the level of groundwater.

Next, you need to drill a well and equip it with a caisson, purchase a set of pipes, pumping equipment, and automation. Then follows the installation of the entire plumbing system, taking into account the subtleties of each stage. To fully understand the specifics of the arrangement of an autonomous water supply system, it is necessary to delve into the issue in detail.

Special features

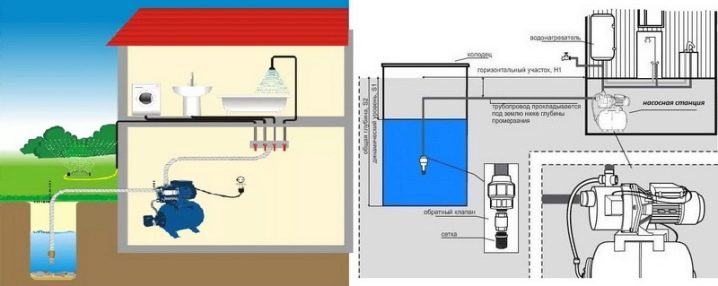

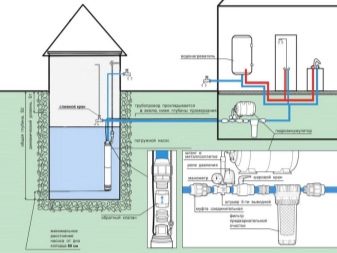

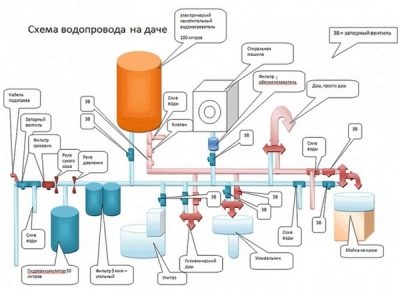

The autonomous water supply system of the house consists of three main parts:

- water source;

- pumping station - consists of a pump and a hydroaccumulator (storage tank);

- pipeline - provides the movement of water from one node of the hydraulic system to another until the entrance to the house.

When building a house, the fresh water system and sewage system are considered and designed together due to the complexity of their implementation separately. In addition, for normal operation, the main nodes must be supplemented by the following minor ones:

- caisson - performs the protective function of the well and equipment;

- cleaning filters;

- water heating equipment;

- control automation.

Designing an autonomous water supply is the initial and one of the main stages, since the system has a complex structure and many features of operation. To draw up a project, most often they turn to specialized companies or to private experts. A plan consists of many elements: the necessary documentation, planning the placement of all nodes, the correct choice of water source and calculations that combine everything into a single system.Also, the project may include a system for further water distribution inside the house. Ultimately, it is drilling and installation of all necessary equipment.

Summer house in the country or a private house in the villages may well receive water supply from the well. You can use a small-sized construction or you can apply a homemade borehole model. Just do not forget about the insulation of the structure, if you decide to hold it with your own hands.

For carrying water supply is often used mini-drilling installation. With it, the procedure of deferrization can also be carried out.

Kinds

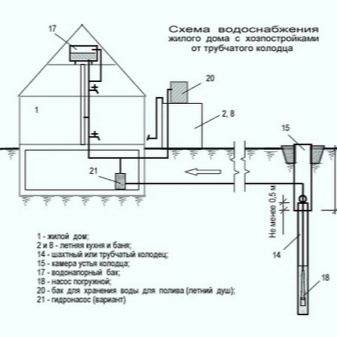

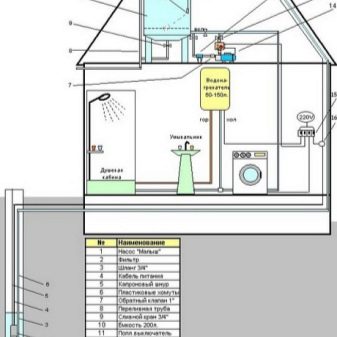

The main feature of the system with a pressure tank is a tank that is placed at a high altitude and thereby creates pressure in the system. For these purposes, an attic can be used, but in the absence of such, a pressure tower is constructed. Also capacity can be installed on a nearby high hill. In the future, from this tank is distributing to all points of water intake in the house.

The operation of a pressure tank system can be described as follows:

- Water is pumped into the tank from a well or well through a pump.The water level in the tank is controlled by a float, which, when filled, turns off the pump and turns it on again when empty.

- The height of the pressure tower determines the pressure in the system. The higher it is, the more pressure. This feature allows you to provide water to all points of water intake without using a pump in continuous mode.

The system with a pressure tank has several serious advantages:

- Saving electricity, as the pump only works to inflate the pressure tank, where its power is used to its full potential.

- Even with a power outage, the tank will provide water in the faucet. If there is a hill next to it or a house is located on its slope, you can put a large tank, which will make the use of the hydraulic system as energy efficient as possible.

Also, this system has its drawbacks. If the tank is located low above the water intake level, the pressure will be low. Also, this indicator is affected by the number of simultaneously open cranes. In such conditions, some household appliances may not function, for example, an automatic washing machine, an electric water heater, a dishwasher, independent heating, etc.

If the tank is located on the roof of the house, then if the automation fails, there is a chance of flooding the building with water. To reduce the damage, an emergency drain system is used, which, according to the principle of operation, resembles a drain in a bathroom or washstand - a pipe is welded at the top of the tank; when filling the tank with water to its level, all the excess flow into the pipe. They can merge into the garden or sewer. It is important to come up with a system that signals an overflow tank to know about the breakdown.

For normal operation of such a system, a tank of impressive size is needed, which is not always possible to locate in the house. In this case, the tower is the best option, but you need funds for its construction.

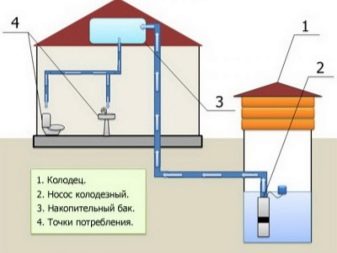

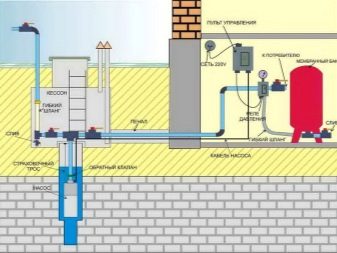

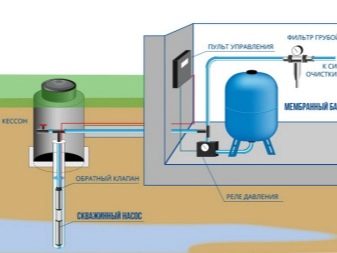

The system with the pump and the hydroaccumulator has a feature - constant pressure, which can be adjusted at its discretion. The pump is used in the same way as in the first version, but it pumps the water not into the pressure tank, but the hydroaccumulator, which serves as an indicator for the operation of the automation. Such a node is called a pump station. A hydroaccumulator is a tank divided into two parts by an elastic membrane, on one side is gas, and on the other is water.When the tank is filled with water, the membrane stretches, presses on the gas, it contracts and creates pressure in the system.

In short, the principle of operation of this system can be described as follows:

- The pump pumps water into the hydroaccumulator. When it is full, the sensor shuts down the pump. Due to the compressed gas in the system pressure is maintained, so you can safely use water.

- When the water at the opening of the tap begins to be consumed, its level drops and with it the pressure in the system. When the specified minimum is reached, the sensor turns on the pump and restores the supply of water in the hydroaccumulator.

The system with a hydroaccumulator has its advantages:

- easier to install and less dependent on the circumstances - a large tank at a height, as in the first system;

- pressure can be adjusted as desired;

- higher water quality, but it’s a double-edged sword.

Also, this system has its drawbacks:

- need more funds for the arrangement;

- higher power consumption;

- higher water quality requirements;

- need to use a filter;

- a smooth-walled pipeline and a more powerful pump are needed to ensure uninterrupted water supply and the necessary pressure;

- when the light is turned off, the system does not work;

- if a well is used as a source, it should have a good debit - the rate of filling with water, for this reason such a system is more often used with the well.

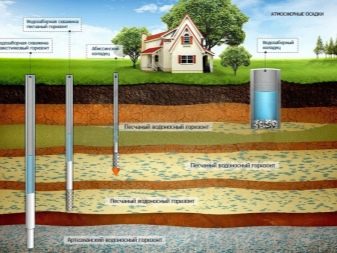

Location selection

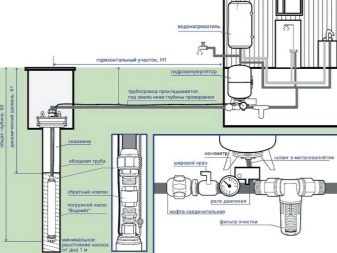

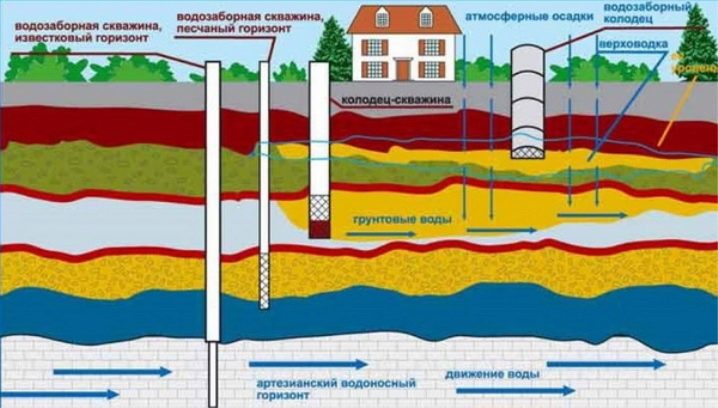

A very important factor that will further determine the parameters of the entire water supply system. Depending on the choice of the type of well, the type of pumping equipment also depends. At the occurrence of water at a depth of 9 meters, a pump station with a surface pump is used; if the well is deeper, an immersion unit will be required for operation. All these factors directly affect the financial issue, and not only in terms of developing a deeper well and the equipment used.

To discover the location and depth of the water, several different actions can be done:

- ask the geological bureau about the aquifer maps in the area or get them from another source;

- pay for a water search at a site in a company engaged in drilling wells or similar activities related to the search and development of water;

- find out from the neighbors about the specifics of their water supply system, in particular, the well.

Such data have minimal accuracy, but an approximate understanding of where you can start looking for water can be obtained, which will reduce costs when contacting a company to search for water.

Device

Not all pipes presented on the building materials market are suitable for creating an autonomous water supply system. Therefore, when choosing them, first of all you need to look at the marking. Water pipes have approximately the following designations - PPR-All-PN20, where

- "PPR" - abbreviation, abbreviated name of the material of the product, in the example it is polypropylene.

- "All" - the internal aluminum layer protecting structure of a pipe from deformation.

- "PN20" - this is the wall thickness, it determines the maximum working pressure of the system, measured in MPa.

The choice of the pipe diameter is based not so much on the diameter of the threaded inlet on the pump and on the automated pressure control system, but on the expected volume of water consumption. For small private houses and cottages, pipes of 25 mm in diameter are used as standard.

When selecting a pump, consider the following points:

- If water from a well is used, the vibration unit cannot be used; it will damage the casing and the filter element. Only a centrifugal pump is appropriate.

- The water from the well quality must meet the requirements of the pump. When the well “on the sand” in the water will fall grains of sand, which will quickly lead to the breakdown of the unit. In this embodiment, it is important to choose the right filter.

- Automatic from dry run. Selecting a pump, if the choice fell on a model without built-in protection against "dry running", it is necessary to additionally purchase automation of the appropriate purpose. Otherwise, in the absence of water that performs the cooling function for the motor, the pump will overheat and become unusable.

The next step is drilling a well. Due to the complexity and high labor intensity, this stage is better performed with the help of a specialized brigade with the necessary drilling equipment. Depending on the depth of the water and the specificity of the soil, various types of drilling are used:

- screw;

- rotary;

- kolonkovy.

The well is drilled to reach the aquifer. Further, the process continues until the impermeable rock is found. After that, the casing is inserted into the opening with a filter at the end. It should be made of stainless steel and have a small cell.The cavity between the pipe and the bottom of the well is filled with fine gravel. Next, you need to flush the well. Most often, this procedure is performed by means of a hand pump or a submersible pump, lowered into the casing. Without this action clean water can not wait.

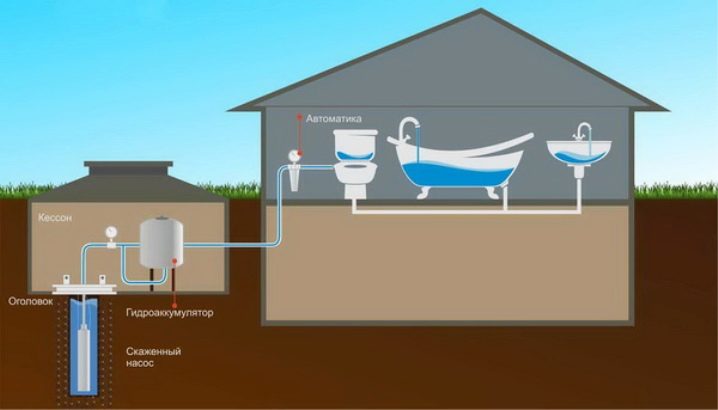

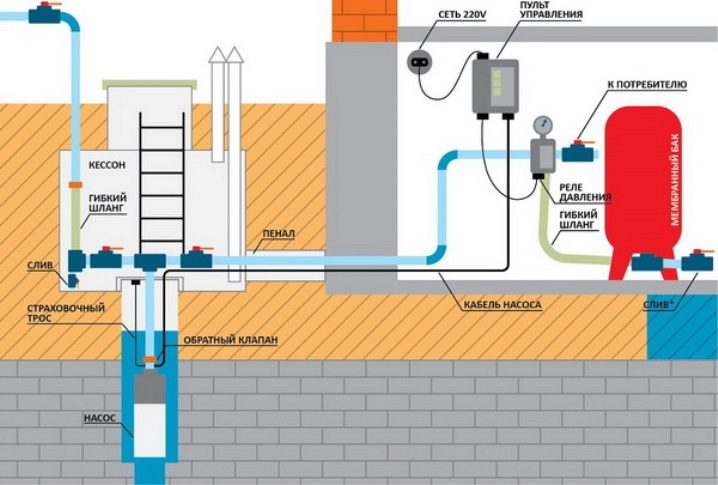

The caisson serves as protection both for a well, and for the equipment lowered in it. From its presence directly depends on the service life of the pipeline, as well as convenience in the maintenance of units, immersed in the well.

Caisson depending on the material used may be as follows:

- metal;

- cast of concrete;

- lined with concrete rings with a diameter of at least 1 meter;

- ready plastic.

Cast caisson has the most optimal qualities, during the creation of which all existing specificity of a well can be taken into account. Plastic caisson has low strength and needs to be strengthened. The metallic look is susceptible to corrosion. Concrete rings are not very spacious and maintenance or repair work in such a caisson is very difficult. The depth of this structure is determined by the level of soil freezing in winter and the type of pumping equipment used.

For clarity, consider an example.If the depth of soil freezing is 1.2 meters, then the depth of the location of pipelines leading to the house is about 1.5 meters. Taking into account the fact that the location of the well head relative to the bottom of the caisson is from 20 to 30 cm, it is necessary to pour concrete about 100 mm thick with a gravel bed of about 200 mm. Thus, we can calculate the depth of the pit for the caisson: 1.5 + 0.3 + 0.3 = 2.1 meters. If a pumping station or automatic equipment is used, the caisson cannot be less deep than 2.4 meters. When arranging it, it is worth remembering that the upper part of the caisson should rise above ground level by at least 0.3 meters. In addition, a natural ventilation system is necessary to prevent the accumulation of condensate in the summer, and frost in the winter.

Required tools

To perform work on the arrangement of the water supply of a private house you will need the following list of tools:

- shovel;

- adjustable and gas keys;

- welding machine for polypropylene pipes;

- roulette;

- pipe cutter;

- knife;

- saw "hacksaw";

- silicone and sealant and gun to them.

For electrical work you will need:

- screwdriver;

- tester;

- wire cutters and other electrician tools.

Since the drilling of the well itself is extremely not recommended, the tools for performing these works are also not listed in this list.

Installation

Submersible pump is installed directly into the mine. The phased execution of works is as follows:

- A check valve is installed on the output coupling of the pump. It is necessary to prevent the discharge of water from the working chamber after the pump is turned off.

- An additional cup-shaped filter is installed in the water intake of the unit, preventing the ingress of small particles of rock into the pump.

- From the second side of the pump is attached pipe from the highway leading to the house.

- To protect the electrical connection to the standard wire of the pump, a waterproof clutch is used. Throughout the wire is fixed to the pipe.

- The safety cable is attached to the designated place on the pump.

- The free end of the pipe is passed through the tip of the well, the cable is passed through a special hole, and the safety cable is fixed to the tip.

- The design goes down into the casing.

- The cap is fixed to the casing, the electrical cable is connected to the mains.

Upon completion of the installation of the pump comes the turn of the pipe wiring. For this, according to the existing plan, trenches are dug up taking into account the depth of soil freezing. Further, the following actions are carried out:

- If water is diluted in several buildings, and not just in the main house, automatic equipment is installed in the caisson to control pressure, and trenches are dug in all directions of pipe laying and settled down according to the same principle.

- Then pre-insulated water pipes are laid. After that, they are sprinkled with a layer of sand, which is spread on the surface and shed with water to ensure uniformity of the sealing layer.

- In the same trench fit cable power for pumping equipment. To ensure its integrity, it is placed inside a polypropylene or polyethylene pipe and is placed on top of the sealing layer of sand. An additional hole is drilled in the caisson under it.

- Further trenches are buried. After 20-30 cm is to put a special tape, signaling the occurrence of electricity and water supply.

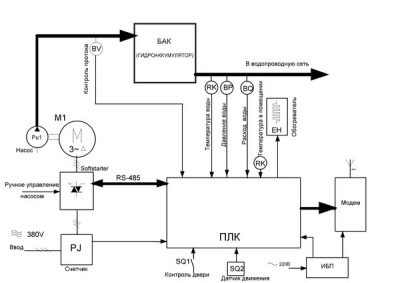

Automation for water supply systems makes the greatest contribution to the process of its operation. The main directions of its activity are:

- maintaining constant pressure at the established level throughout the water intake;

- maintenance of the most gentle mode of operation of pumping equipment;

- prevention of unit breakdowns due to overloads and minimization of power consumption;

- emergency shutdown of power supply in violation of the integrity of the pipeline.

For these purposes, various types of automation are used. In total there are 3 generations of devices that differ in their functions. - from the minimum set of tasks in the first, using the mechanical principles of control, and to the third, equipped with electronics, which controls all the processes occurring in the hydraulic system. Such systems can be assembled from individual nodes independently, but this requires some knowledge in electronics.

More often, a different path is chosen with the purchase of a ready-made automation system, and since its choice is wide enough, it is possible to choose an option that is best suited for specific conditions with many nuances. To install any automation, except for the first generation, advanced knowledge in electronics is required and the call of a specialist is recommended.

The final stage is the installation of water intake points inside the house. With an existing house or cottage, it is more often carried out by the open method - pipes are laid on the surface of the lined walls. During the construction phase of a new building, the closed method is often chosen when the pipes are laid either in the cavities of the walls or under a layer of finishing materials. In the second version, pipes with markings denoting suitability for the food industry should be used.

It should also be mentioned that the use of metal-plastic type pipes is not allowed when the pipeline is closed.

The most successful is the use of so-called "brazed plastic". It guarantees full waterproofing in all joints, has a high resistance to destruction, and consequently, durability, and does not need any kinds of maintenance.

Tips and tricks

In the process of arranging the water supply for a private house, there are a lot of small moments, accounting for which will help simplify the installation and further operation of the entire system. These include the following points:

- When laying pipes, their intersection with building structures should be avoided.If it is necessary to lay the pipe through the wall, this is done through a special “glass”.

- Taking into account that the pipes may have to be repaired or changed, it is not necessary to place them directly near the wall, it is better to indent, even if it is only a few centimeters.

- Near the outer corners of the pipe are at least 1 centimeter apart, near the inner corners - by 3-4.

- For mounting products on the surface of the wall is to use single and double clips. The interval of their use in straight sections should not exceed 1.5-2 meters between them. Corner joints are fixed.

- For joining polypropylene products, special fittings are used, tees that allow joining pipes of equal or different diameter.

- Drain valve for accumulator MGBU mounted with a slope in his direction.

Charting a private home water supply from a well is quite difficult, but the above recommendations will help you with this. Thanks to them, you will do the job much faster and better.

How to make a well with your own hands and take the water into the house, see the next video.