SonoPlat panels: modern soundproofing methods

Types of insulation materials and products can be classified in various ways, for example, by their structure they consist of fibers, granules or cells; in form or physical nature. The latter feature distinguishes plant, mineral and synthetic insulation products. The most popular plant insulation material is wood.

Features and composition

As insulation, wood was mainly used to create various types of fibreboard. For the first time, fibers were used for the manufacture of construction boards in the early 20th century. Most panels are available in large sizes, and their width is from 10 to 30 mm. But they had drawbacks: they were sensitive to heat and moisture, bent and expanded, reacted to chemicals, thereby losing their original qualities.Modern developments have allowed a new look at this type of sound insulation.

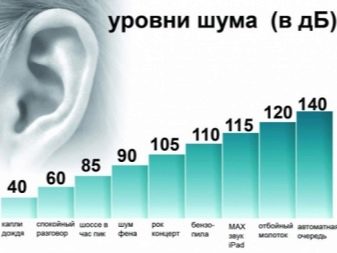

Sonoplat is a wood fiber panel. The properties and structure of the panels allow them to fulfill the task in a quality manner. The material saves from noise, reduces air corridors and creates the necessary level of comfort inside the room. All this makes SonoPlat effective in combating various intensity pi noise. It is indispensable in apartments that are close to the airport or the metro. Today SonoPlat is an integral part of the modern city.

Panels have a small thickness and weight. Sound insulation is 38–42 dB. The special structure allowed to create a product that is distinguished by its multifunctionality. The material helps to reduce the vibration of the walls and eliminate sound corridors. The structure is multi-layered and corrugated, which forms a rigid frame with wood fiber at the base. The sound absorbs the quartz filler, and the rigid substrate allows to simplify the installation process.

Among the main advantages of the material are the following:

- no debris during installation;

- the ability to qualitatively absorb sound waves;

- universality;

- saving of useful space;

- environmental Safety;

- ability to keep a microclimate.

Like any building material, SonoPlat has several disadvantages:

- Hygroscopicity. This is one of the reasons why the product should not be used in rooms with a high level of humidity, including the outside of the rooms. The main storage place should be a room where the material is placed only horizontally on a flat surface.

- Weight. The panels are quite heavy, installing them yourself is very difficult.

- Cost The complexity of production determines the price of the goods.

Kinds

Products that are designed and designed to absorb indoor echo are soft and light. They are designed to reduce echo in the space under consideration. Products designed to block sound are almost always inside the wall, and this is their hallmark. These products are heavy, dense in structure, bulky and most often one side has no hard contact with the surface. Some acoustic plates better absorb the echo in the room,others succeed in blocking the penetration of sound into the room, but there are also materials that can fulfill both requirements.

SonoPlat is available for sale in several versions. On the market you can find the plates "Standard", "Standard Plus", "Profi" and "Combi". They all have distinctive characteristics. The SonoPlat tape is also on sale.

- Panels "Standard" have a three-level corrugated structure, between each level there is quartz sand. The Standard Plus model differs only in the increased dimensions. On average, the cost of such a sheet of sound insulation on the market is 650 rubles.

- Material "Profi" perfectly absorbs sounds and has a small thickness. It has a peculiar structure, in each cell there is quartz sand. It is used for the ceiling and floor. Price per sheet begins with a mark of 1 thousand rubles.

- Model "Combi" - it is a combined product, inside of which there is a multi-chamber frame of increased rigidity, fine sand as a filler and a substrate made of MDVP.

Dimensions

Fiber and chipboard panels can be sawn or drilled as natural wood products.The plate SonoPlat has the following technical characteristics:

- weight is 13.5 kg;

- density - 18.8 kg / m²;

- dimensions - 1200х600х22 mm;

- thermal conductivity of 0.17 W / (m * K);

- area - 0.72 m².

Scope of application

The main field of application of SonoPlat panels is sound insulation in the room regardless of its purpose. The material is used in such structures as:

- interior partitions;

- installation directly on the wall is allowed;

- placed under the finishing trim on the floor;

- used in the construction of wooden houses;

- soundproof screens;

- premises with noisy industrial equipment;

- room for acoustic installation.

Excellent insulation has become one of the main reasons for the demand for material on the reviews. The consumer receives a lot of advantages, using sound-proof plates indoors. For example, in some cases, excessive noise in the offices can be a serious problem, because office workers are very difficult to perform everyday tasks in an uncomfortable atmosphere. Extraneous noise can make it difficult to work during customer calls. If the conference room is not private, then information about confidential business transactions and other matters may go beyond the walls of the room.

Soundproofing office provides a better working environment.

Getting the best acoustics is very important in music halls. Fortunately, the sound insulation of such a room allows you to achieve high results without spending large amounts of money. This is an ideal option for those who have to realize their creativity in the apartment. Material is also considered indispensable in the framework of industrial production, when turbines, large-sized engines and other mechanisms must be located indoors. Unfortunately, the noise in the equipment room can be an obstacle to normal operation, especially for those who need to communicate with each other in order to ensure that tasks are performed on a daily basis.

Installation Tips

You can optimize the search for suitable soundproofing panels for industrial and home use. Each space is different, so before you buy a product, final goals are necessarily taken into account. If you need to prevent noise, soundproofing products are ideal. It is necessary to determine where the installation of the material. This will allow you to value space and plan costs.

Sometimes, in order to achieve a proper result, it is enough to isolate just one room, thereby saving on expenses.

Installation can be quick and easy, especially when recruiting professionals. A professional installer will offer recommendations based on the available data and tell you about each step. Attracting a qualified specialist is a guarantee of the correct consumption of material and future results. The choice of a suitable type of sound insulation panel can be made independently or entrusted to its master, who understands all the intricacies. When choosing, it is necessary to take into account not only price and quality, but also important factors in order to choose a suitable sound insulation material for walls and ceilings, including:

- thickness;

- efficiency factor, for example, a brick has a coefficient of 0.05, carpet and cork - 0.2, soundproof walls - 0.7;

- degree of flammability, toxicity in case of fire.

Non-combustible materials are mineral wool, cork, self-adhesive sealing film, polyurethane foam, vinyl.

For high-quality installation is not enough to have on hand only the required amount of sound-proof material, it is important to stock up with plastic dowels.Useful tape from SonoPlat on a sticky basis, which will protect the cuts, and sealant. The panels must be acclimatized, which means that the product is kept for at least three days in the conditions of the room where it is planned to be installed. If the humidity does not exceed 40%, then two days are enough.

Plates are laid inside ten pieces in piles.

If, prior to installation, works on plastering or screeding have been carried out, it is not possible to install sound insulation plates. This is exactly what the technology of work and the manufacturer's instructions require. When the humidity in the room is above 60%, the room must be forcibly dried.

Laying material in such conditions is contraindicated according to technical standards.

Among the main features of the installation should be the following:

- if the frame technology is used for fastening, then the guides should correspond to the dimensions of the plates;

- accurate marking is the main condition when it comes to cutting the panel, the cut is made with an electric jigsaw;

- the cut line is always glued with adhesive tape, and the space from which the sand has spilled is filled with sealant;

- self-tapping screws or dowels that can be put on glue are used for fastening;

- if the frameless method is used, the surface is treated with a primer and dried;

- if the panel is damaged during transportation, the cardboard layer is sealed with a special tape, after which it can be used for its intended purpose;

- the plates are mounted with a staggered shift, the existing joints are treated with a sealant.

You can learn how to make soundproofing of the walls using SonoPlat panels with your own hands by watching the video below.