How to build a house made of logs?

For many centuries in Russia they built houses of wood, but even today such material does not lose its popularity. The rounded log, which is a more modern analogue of the traditional log house for the construction of houses and has only positive feedback from the owners, is in special demand.

Structural features

The main feature of this material is that the log has an ideal cylindrical shape, the same diameter along the entire length, as well as clearly defined parameters of the longitudinal grooves and the landing bowls.Thanks to this, the finished building looks as smooth and tidy as possible - it becomes more stable, resistant to torsion, and easy to assemble.

To make an ordinary round log, it is calibrated on industrial woodworking machines under production conditions. As a result, the trunks get the same diameter along the entire length and smooth surface. Then docking bowls and longitudinal grooves are created, which are necessary for connecting the logs together. Thanks to such manipulations, the construction of a house from a rounded log becomes much easier and faster.

However, it is also necessary to be able to work with this material. If you make a mistake in the construction of mezhventsovyh seams, then the material can be spoiled. Therefore, it is better to trust the construction only to professionals in this field.

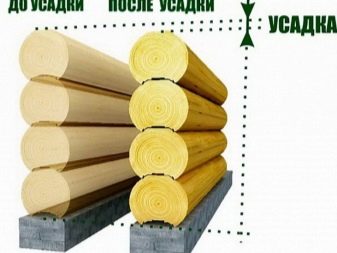

The most important thing to consider when working with a wooden log house is its natural shrinkage. Such a phenomenon cannot be completely excluded, therefore, when constructing a structure, special gaps are created in the structural elements and nodes. They are made in the window and door openings, at the roof, stairs, as well as in other structural elements.On the ground floor, such gaps are made much wider, since it is on the ground floor that the greatest load falls.

The lumens are filled with suitable insulating material, vertical grooves are created at the ends of the openings, pipe fixings for the chimney are left mobile, otherwise the structure may be deformed or even destroyed.

In connection with the shrinkage of a house from a log, it can be settled no earlier than six months after its construction. In this case, the house will still sit down for at least another year at an active pace, and about a few more years passively. For these reasons, the interior of the house do not earlier than 2 years after completion of construction. In the first winter the house is not heated to a temperature that exceeds 20 C. Also one year after the construction of the house from the rounded timber, it is necessary to additionally caulk the intergenital joints and eliminate the existing defects.

In the future, it is necessary to carefully take care of the house, conduct a systematic inspection. Care must be taken to avoid excessive moisture, mold or fungus. In a certain season, you will need to clean the roof from snow, and the gutter construction - from fallen leaves and dirt.

Causes of shrinkage

Shrinkage is called natural, because such a physical property is inherent in any wood. The thing is that wood is a natural material, which contains a large amount of moisture, because it grows and develops due to water. Over time, the felled tree dries. On average, it can decrease from 240 to 220 mm, which means that the height of the house can decrease by about 7% (it all depends on the humidity of the air and weather conditions). Also, the material can be deformed due to the fact that it has a large load.

The time of year in which the timber was cut and procured directly influences the degree of its drying in the same way as its breed. For example, Arkhangelsk pine has a high density and does not crack under any conditions. It should be noted that the percentage of shrinkage of a log from a rounded log is much lower than from the usual option.

Advantages and disadvantages

Like any other material, a rounded log has certain advantages and disadvantages. They differ depending on the quality of material processing and some other parameters.

Below are the main advantages of the material.

- Environmental friendliness. It is the main advantage of any house of wood. Natural material does not cause allergies and is absolutely safe for health.

- Natural ventilation. The house does not form condensate, dampness, fungus or mold from a rounded log.

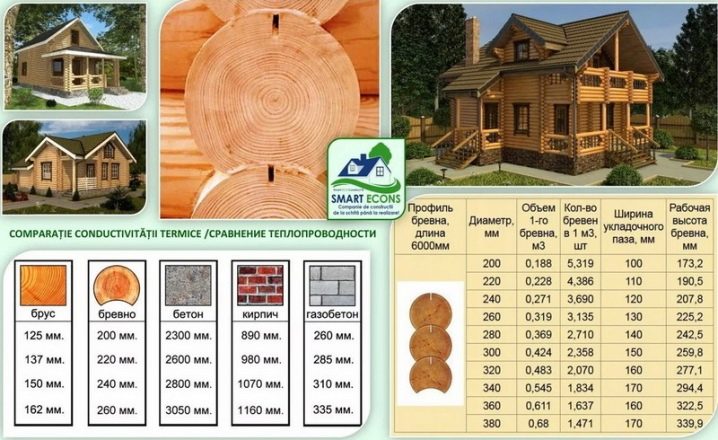

- Optimum thermoregulation. It is always comfortable to be in such a room: in winter it is warm and cozy enough, and in summer it is cool. Due to the correct shape of the logs, they fit snugly together, and the building does not need additional warming and conditioning. In addition, the wood itself has a low thermal conductivity.

- Pleasant atmosphere. Wooden houses give a person a special mood, a feeling of comfort and tranquility. Pleasant smell relaxes and brings great pleasure.

- Attractive appearance. Structures made of logs look very neat and attractive in appearance, but the internal look is not worse. Due to the fact that the material has already been processed, you can even neglect the interior decoration of the room - the interior will benefit from this.

- Easy to assemble. The correct design of the already prepared and fitted elements to collect much easier and faster.If this work is done by professionals, the result will be great. On average, the construction of a house from a rounded log takes from 5 to 30 days - it depends on the type of layout and the area of the building.

- Durability and reliability. Creating a wooden house, there is no doubt that it will serve its owner for many years. At observance of all rules of construction service life can be estimated in centuries. The design turns out very strong and practical.

- Economic benefits. Of course, the rounded log is more expensive than usual. However, with the correlation of the cost of processing and preparation of the material, as well as time for the construction of the house and its quality, the price becomes fully justified. Choosing a rounded log, we can say that a person makes a profitable investment.

In addition to all the listed benefits, the house of the round timber has its drawbacks. Basically they apply to all structures of wood. They can also be avoided or minimized if the structure is correctly mounted and regularly maintained.

The main disadvantages of wooden buildings can be described in several paragraphs.

- Shrinkage. This is a natural feature of the tree, which cannot be excluded. The only option to build a house of wood, which allows you to minimize shrinkage, is a frame construction. A round log building shrinks a little more. But if you take a break from work for about half a year, choose a sufficiently dry material, use jacks during operation, strengthen the joints of the logs, you will be able to optimize the construction to the maximum and reduce shrinkage.

- Flammability Wood, unlike, for example, from brick and stone, is subjected to burning. It cannot be called an easily flammable material, it does not instantly flare up from a spark of wiring and does not ignite by itself. However, this property should be taken into account in the construction process.

- Cracking. It is also a natural and inalienable property of any tree. But you can almost completely eliminate the appearance of cracks, if properly follow the structure. For example, in time to put it into operation and properly heat the room in the winter.

- The need for care. Rounded timber is a fairly practical material with an attractive appearance, however, it will also have to be regularly maintained.From time to time it is necessary to fill gaps and cracks, to protect the material from the effects of adverse environmental effects. If you do not run the house and regularly engage in such works, then they will seem even enjoyable.

Wood selection and processing

The process of choosing a quality rounded log is a fairly important undertaking, because the durability and performance characteristics of the house directly depend on this. First you need to determine the requirements for the manufacturer of the material. They are described below.

- The manufacturer must strictly adhere to the technical standards and requirements for the manufacture of a rounded log. He must clearly understand what are the features of a particular type of wood, which may appear defects. If the supplier does not provide such information, then it is likely that he is working with low quality raw materials.

- The manufacturer must use modern equipment and advanced processing technology. If the production of the material used old machines, then a first-class result is not worth dreaming. The latest technology makes it possible to achieve high accuracy and quality results.

- The manufacturer must process the material with special formulations. These include, for example, antiseptics, which help to protect the log from the adverse effects of the external environment, mold and pests. This will significantly extend the life of the material, increase its reliability and resistance to wear.

Also, the manufacturer must necessarily inform the buyer, in which region and when the wood was harvested, because its quality directly depends on it.

Experts note that the highest quality is a log from the northern regions. This is due to the fact that at low temperatures the tree grows more slowly, and hence the distance between the annual rings will be small. This makes the material more robust and resistant to stress.

From this it also follows that the cold season will be the optimal time of year for procurement of material. In winter, the tree is characterized by minimum humidity relative to summer, therefore, the shrinkage of the log house will be small, which is an important factor when choosing a material.

Also, when buying a round log, you should pay attention to the points described below.

- Presence of mold or traces of fungus on the surface of the material. These manifestations suggest that the tree has an increased level of moisture. This will adversely affect the performance of the tree. You should also check whether there are traces of insects on the log - wood dust and specific surface damage indicate this.

- Clear fit. Rounded logs must meet the specified parameters of length and width, since it is for this reason that many buyers prefer to choose such material.

- The correctness of the grooves. They should be made according to a common standard, without visible deviations from the specified parameters. It is important to check this immediately to avoid problems during the construction of the house.

- The presence of large cracks. If there are small, barely noticeable defects on the surface of the log, then you should not attach much importance to this, because this is characteristic of natural material. However, the presence of large defects, for example, cracks of sizes up to 1.5 mm, is a serious reason for refusing to purchase such material.

You should also make sure that the log lacked the longitudinal deformation of the fibers, the so-called screw, since such a flaw can significantly complicate the construction process.It is necessary to check the entire log house, not the individual components, so as not to miss the defect.

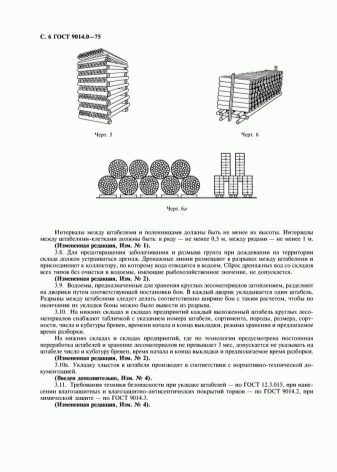

Be sure to note that when you buy a log may not be defects on it, but they may appear due to improper storage of wood. If you do not plan to start construction the next day after the purchase of the material, then you should remember a few important rules.

- When storing, place the material under a roof, shed or film to protect it from the adverse effects of external factors. At the same time, the tree should not be completely covered to prevent the accumulation of condensate and excess moisture.

- The log should be laid in stacks, the longitudinal direction of which corresponds to the direction of ventilation. Stacks should have a strong base to prevent the logs from contacting the ground.

For the best effect, you can further treat the material with an antiseptic. If you follow these simple rules, the log will be stored without harm to its characteristics.

Manufacturing

The rounded log is created from several tree species: Karelian and Arkhangelsk pine, cedar, fir, spruce and larch.The processing of the material is carried out by different methods, and the final result depends on the requirements of the client. Below are the features of the manufacture of OB

Ways

The cylindrical shape is given to the log by two methods: manual and machine.

- In the first case, the barrel is processed using a hand-cutter, and bowls are also created. This method is suitable if you need to create a log house for a traditional Russian izba.

- In the second case, the ideal geometry of the log is achieved by machining the barrel on a special machine. Modern equipment allows us to achieve not only a top-notch form, but also precise cutting of grooves and bowls.

To dry a tree also two methods are used: natural and artificial.

Most of the material on the market is dried in a natural way. This avoids additional costs and does not increase the total cost of building materials.

Thermal beam is a more advanced product. The material is subjected to high-temperature drying in airless space, which significantly reduces the time of preparation of the material, but increases its price.

Technological process

The OB production process consists of several successive stages, which will be discussed below.

- Selection of initial logs by size.

- Processing in the cylinder machine.

- Removal of the top layer. From the original log remains only the middle part, which is durable and gives the least shrinkage in the construction process.

- Minimization of the difference in diameters of the material - it should be no more than 4 mm.

- Sorting logs in accordance with the specified parameters.

- Natural or forced drying.

- Creating a compensatory cut, if there is such a need.

- Cut to standard length. This item changes if an order is made to make a kit for the house. It is a set of parts for assembling a house that are already prepared in length and marked. Working with such material makes the process of building a house as fast and simple as possible.

- Skewer This process involves cutting the seats for laying the crowns of the log. In a rounded log, two kinds of bowls are made: longitudinal and transverse. The process is performed in the same way as in the case of the profiled bar.

- Creating grooves.The dimensions of the grooves should not exactly coincide with the dimensions of the log - there should be a slight difference so that there is a place for laying insulation. If the curvature of the grooves and the logs are the same, then after shrinkage the log will touch the other not the whole surface of the groove, but only its central point. So, you will need an additional caulker structure.

- Facing

- Edge processing.

- Application of antiseptic. Substance covers the entire area of the logs, including the longitudinal cup and grooves. Due to this, the log becomes resistant to adverse external factors. At the same time, the antiseptic does not clog the pores of the wood, which means that the process of drying the material does not stop, which speaks of saving time for shrinkage of such a log.

- Transportation and storage. The sellers often take on the transportation of the material - they know all the rules for unloading and storing logs, and also give the necessary recommendations for the proper storage of the material, because the house is not built in one day. They know how important it is to properly save wood until the end of construction.

Slot types

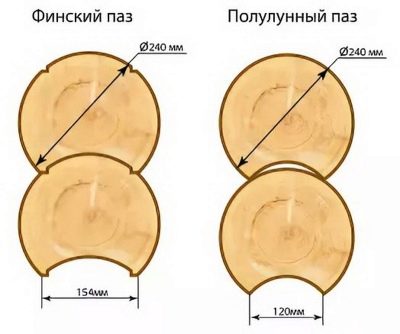

The grooves are necessary for the maximum fit of the structural elements to each other. There are two most common types of grooves for OB.

- Lunar. It has not round, but semicircular shape. This approach has become widespread due to the simplicity of the device.

- Finnish. Differs more complex installation system - ridge. Its design implies the presence of special cuts, due to which the insulating characteristics of the joints are increased. The use of such a groove eliminates the caulking of the walls and minimizes the damage caused by the natural shrinkage of the structure.

Technical requirements

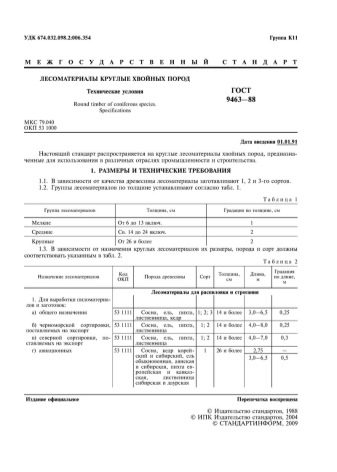

There is no general regulatory document in accordance with which it is necessary to produce a rounded log. However, most manufacturers develop their own standards, which contain all the necessary data on the dimensions of the material, its quality, possible defects and storage rules. However, there are several state standards that regulate some rules for the manufacture and storage of rounded wood. These are GOSTs under the following numbers: 9462-88, 2292-00, 22279-76E, 9014.0-75, 2708-75.

In accordance with GOST 9463-88, a rounded log (pine, spruce, fir larch 1 and 2 varieties) must have the following characteristics:

- nominal length - 3-6.5 m with a gradation of 0.5 m;

- deviations from the nominal length - from +0.03 to +0.10 m;

- diameter - 14-24 cm;

- rot and bitches are not allowed;

- curvature deflection arrow - 1-1.5% of the length of the log;

- depth of mechanical damage - 0.1 cm;

- the height of the branches from the bark is 2 cm;

- bevel cut - no more allowances in length.

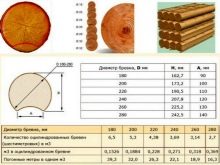

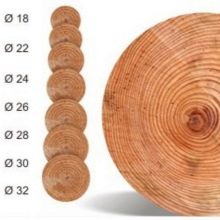

Standard log sizes:

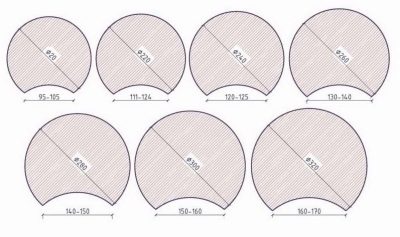

- Diameter (cross section). It ranges from 160-320 mm. 240 mm - the most common diameter used in private construction. The choice of the optimal size depends on the purpose of the building and its location. For example, the optimal diameter of a log for summer cottage in the southern region is 160–180 mm, while a house for year-round living in Western Siberia needs to be built from a log of 280–320 mm.

- Length. The standard length of the OB is 6 meters. Depending on the characteristics of the order, it may increase up to 12 m. The longer the length, the higher the price of the goods.

- Width. If the diameter of the trunk is 220 mm, then the moon groove will be 110 mm, and the Finnish - 140 mm. Sometimes the moon groove may be 20 mm larger.

- Propyl. The depth of cutting to reduce internal stress and to prevent cracking is about 15-20 mm.

- Volume This parameter depends on the type of groove, diameter and length of the log.To calculate the amount of material needed in cubic meters a person will need to know the total cross-sectional area of the trunk. Then multiply the result by the length of the log and round the resulting amount to an integer value.

Specifications

- Thermal conductivity. The freezing temperature of a log directly depends on its diameter. For example, 160 mm - -36С, 220 mm - -54С.

- Soundproofing. Due to the structure of the natural material, you can always enjoy peace and quiet in a log house, as its sound insulation characteristics are at a height.

- Strength. Wood is considered one of the strongest and most durable natural materials. Resins in its composition provide guaranteed reliability.

- Dimensional stability. If the OB is made on high-quality equipment, then its geometry and dimensions are ideal.

Design Stages

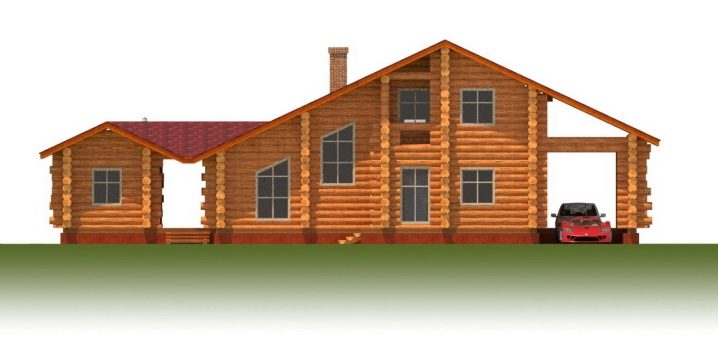

It should be the most responsible approach to the issue of creating a project of the future home, because it depends on the quality of construction. Below are the main stages of the construction of the house of the ABOUT. Length distribution It is important to properly use the length of the logs to prevent too much waste.You can use a standard log length for a building of 6x6 m, but then the choice of architectural solutions will be very limited. If it is required, for example, to build a two-story house with a garage or extensions, it is better to order an OB of up to 12 m from the manufacturer, their diameter will be 30-40 cm.

It is important to think through all the joints of the structure and create an optimal design depending on the size of the trunks.

Diameter selection

The optimal diameter of a log for private construction is 28-40 cm. The choice of a specific size depends on the type of cutting, walls, the number of window and door openings. You can choose a log of a larger diameter, which will lead to a decrease in the number of crowns and structural cuts. The optimal time. Shrinkage of the house depends on the chosen time for construction.

- The main shrinkage is about 60% and occurs during the first one and a half years after construction.

- Full shrinkage is about 95% and takes from 3 to 5 years. Residual shrinkage takes place throughout the entire period of operation of the building.

The best time to create a design is winter.

Erection

After an individual project is developed or a model is chosen, you can begin the process of building a one-story or two-story house. Foundation.In order for the structure to be strong and reliable, it is important to pay special attention to the foundation, because it is the foundation of the structure. For houses from the OB most often used shallow-foundation, which is ideal for construction on heaving soils. The design of such a foundation eliminates deformation and is characterized by a long shelf life.

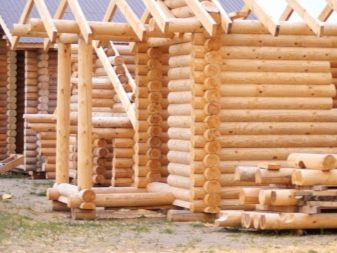

The principle of its creation: the tape bases of all the walls of the house are combined into one common system, which forms a rigid horizontal frame. Due to this, all uneven loads on the foundation, which could lead to the deformation of the structure, are corrected. Assembly and installation. After the foundation is ready, you can proceed to the construction of walls. This work must be performed in strict accordance with the project documentation.

The rounded log is folded into the finished box is very simple, however, and here you should be careful not to make mistakes. It remains only to cover the finished structure on top and perform the interior trim.

It is worth reminding once again that it is important to process logs with antiseptic prior to construction., and the laying of logs should be carried out along the axes in accordance with the woodworking and laying of the layer of inter-material insulation and mounting the dowel rods. It is important to stack logs in a checkerboard pattern on pre-cut transverse bowls. Interfloor overlappings. For the construction of beams in a log house usually choose the same ABOUT or timber.

It is important to correctly calculate the cross sections of the beams depending on the distance between them and the width of the span.

Roof

Before you begin to install the roof, you need to install rafters. For the house from OB it is accepted to use "the sliding" rafter system thanks to which the felling sits down correctly. Then you need to connect the ridge bars, girders and fights with the help of corners, linings and cuts. After that, you can begin to install a drainage system and waterproofing windows in the attic.

The shape and cover of the roof depends only on the preferences of the owners. Most often, natural, bitumen, metal tiles or ondulin are used to cover the house.

Insulation and finishing

As mezhventsovy sealant walls, built of logs, used lnovatin, flax jute cloth, felt and other similar materials.To finish inside the house you can start no earlier than 3 months after the construction of the house. At this stage, install window sills, windows and doors. Aesthetic decoration depends on the wishes of the owners.

Many builders prefer not to cover the walls with decorative materials in order to preserve comfort and a special atmosphere in a wooden log house.

Expert advice

In order for the house from a rounded log to serve as long as possible, not to deform and not lose its characteristics, it is necessary to take care of it regularly. Below are a few recommendations from professionals.

How to care?

To follow this recommendation, you should follow some simple rules:

- it is necessary to check regularly whether there is no mold or mold on the surface of the material;

- it is necessary to make timely painting of the facade and coating of logs with protective compounds;

- should annually clean the drainage system from the leaves and dirt;

- snow must be removed from the roof to prevent excessive moisture from getting onto the wood;

- use only high-quality decorative coatings for facades, so as not to spoil the quality of wood;

- regular caulking of walls should be made to prevent heat loss.

Possible mistakes

To avoid common mistakes in the process of building a house from OB, you need to carefully study them.

- Unreasoned project. No need to spare time for thorough development of detailed planning of the building - it’s better to hire a professional for this. This approach will avoid many unpleasant consequences in the future.

- Wrong time for construction. Construction of the house in the winter will reduce the time for shrinkage of the building and get excellent construction quality, which is not the case for the summer period.

- The choice of poor-quality material. Base material may shrink too much, deform strongly. It has low rates of heat and sound insulation, so you should not save on a good log.

- Unsuitable foundation. Improperly sized basement can lead to a misaligned wooden structure.

- Inadequate quality control. Any, even minor errors in the construction process should be immediately eliminated, otherwise in the future they will surely make themselves known.

- Processing house after construction. Cover the material with protective and antiseptic substances should be before the construction of the house, and not after, because the pre-treatment allows you to fully process the material, and after construction will be inaccessible place for knocking. After all, there may be a fungus later.

- Early commissioning. It is strictly forbidden immediately after construction to start finishing and laying communications. It is also impossible to heat the house in the first year after construction - a sharp overheating will lead to a sharp drying of the tree, which will entail the appearance of cracks and deformation, deterioration of the insulating characteristics.

Beautiful examples

This is an incredibly beautiful and unusual house from ABOUT. His project is quite complicated and expensive. However, given the durability of the structure, you can afford such a profitable investment.

This option of the building is no less attractive from the outside. The design involves two floors, a small veranda and a multi-level roof.

Here is the interior of the house from the rounded log. There is no interior decoration in it, only the material has been polished,as well as applied paintwork, but this already gives comfort and color to the house.

Another example of a cozy and beautiful veranda of the house from ABOUT.

This is a simpler project log house. Such a structure can be used for both seasonal and permanent residence.

To learn how to competently build a house from a rounded log, see the following video.