Houses from a log: how to build a high-quality and warm dwelling?

Natural wood is an eco-friendly, durable, inexpensive, aesthetic material. The log for construction is used very much for a long time and does not lose the popularity and today. Today, when people make a choice in favor of natural and environmentally friendly products, log houses are becoming particularly relevant.

A large number of companies are engaged in the construction of turnkey wooden houses. Most often they are also engaged in logging. The final price of the finished home will depend on not only the size of the house, but also the quality of the log, its diameter and the method of production.

Build a house with your own hands is two times cheaper. In this article we will consider step by step how you can build a house from a log yourself.

Special features

Wood has the properties to give moisture.It is much more pleasant to live in such houses than in stone houses: it is warm in winter and cool in summer. Wooden construction is lighter than concrete or brick, therefore, the foundation will be cheaper.

Compared to a bar, a log house will be much more expensive and take more time to complete the construction process, but its unique color and high performance characteristics easily compensate for these disadvantages.

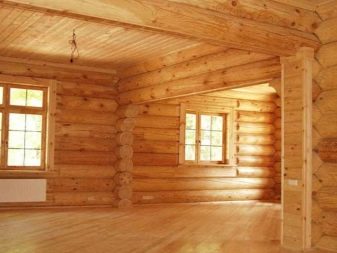

One of the important points is the preservation of the wood structure in the interior. The interior design of a wooden house from a log can be made in a rustic style under a hut with a Russian stove or, for example, Provence.

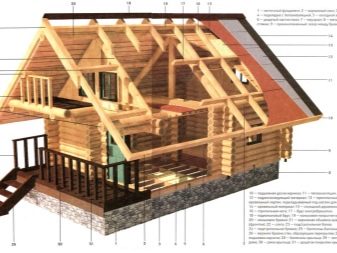

Despite the emergence of new technologies in the construction field, log houses continue to be erected in traditional ways. Logs are laid in a horizontal structure that forms the walls. The crown is each designated row, and the lowest one is called the crown. The log house, which consists of 4 walls, is called the four wall, where the logs are tied at the corners. If there is an internal partition - pyatistankom.

Advantages and disadvantages

The log house has several advantages. Specialists of the construction industry and owners of log houses note the following advantages:

- Environmentally friendly material. Such houses are built from natural wood, which allows preserving the natural qualities of the material. In such a home will always remain a pleasant woody aroma and cozy atmosphere.

- The most important thing for which they love wood is its excellent thermal insulation properties.. For example, a house from a 20-centimeter log is much better insulated than a similar house made of brick. Therefore, building a log house, you will save on heating.

- Weight a wooden house will allow you to lay any type of foundation.

- Structure wood allows the house to "breathe." In such a house is comfortable to be.

- From a material point of view wood is an affordable building material. Building a bare box of a log house will cost you a small amount for which you would never put a brick house. Also, due to the cheap foundation and the lack of decorative processing of the walls, a house made of wood in the end is much cheaper.

- The tree is natural. Pleasant appearance allows you not to finish it additionally, neither outside nor inside.

- Wood possesses high strength and resistance to stressthat allows you to build a house of several floors.

- Ability to assemble and disassemble if necessary, allows you to transfer the house to a new place.

- The project of wooden houses represents simple drawing design, which will be clear to anyone reading.

In addition to the advantages, there are also disadvantages of such buildings:

- susceptibility to decay with time;

- complete shrinkage of the log house occurs after three years, although you can settle in six months after the end of construction;

- Although special treatments reduce fire risk, the risk of a fire is still high.

Wood selection

In preparation for the construction of an important step is the choice of material. The main requirements for wood as a building material are resistance to the effects of external aggressive factors, aesthetic appeal, accessibility, durability, heat and sound insulation.

It is also important to understand that whatever quality wood is, if the construction technology is broken and the technical instructions are not followed, the durability of the building is not guaranteed in this case.

Usually the choice of wood is made between larch, pine and spruce.

Larch

Larch is a coniferous tree that is distributed throughout Russia. The most suitable for construction is larch from Siberian regions.

This type of wood has many advantages. It is durable, durable, does not rot and is not exposed to the fungus.

Materials made of larch are not subject to swelling and are not deformed even in rooms with high humidity.

Larch has a beneficial effect on humans, bringing great benefits to their health. The price of products from this material will be available to every customer. In addition, larch does not require additional processing, unlike other species, which can also significantly save.

In the process of cylindering the logs, very narrow sapwood is removed from the larch, as a result of which the logs will not turn blue in the future.

Logs of this breed do not need additional processing. The resin of the tree itself acts as an antiseptic, disinfecting and preventing the tree beetles from developing.

Larch is more fire resistant than other species.

Spruce and pine

Both breeds are actively used in the production of building materials. These are the main competitors in the consumer demand rating. The timber from these breeds is distinguished by durability and strength.

Spruce and pine are identical in physical indicators, but the fir-tree timber is looser, but that is why it is warmer than pine.

Both breeds are similar in strength and chemical properties, but pine is more susceptible to blue-colored sapwood, which can initially be prevented by special means. As a prevention, it is recommended to use antiseptics. Over time, the color of the wood in spruce does not change.

The natural humidity of both breeds is 12%. Logging for spruce and pine falls in the winter season due to the fact that deformation is possible in the summer during shrinkage of logs. Pine logs of large diameter are preferred for the construction of large buildings.

There are also differences in fiber structure: in pine it is expressed and has a certain pattern, spruce also has a homogeneous structure.

When choosing a material, an important factor is its flammability. But this can be dealt with using wood flame retardant compounds for wood treatment.

During the construction of wooden houses use different types of logs.

A rounded (calibrated) log is obtained by machining on an otsilindrovochny machine. The advantages of this type of raw material are high quality, the ability to form a profile of any complexity, low cost and high speed of the construction of the log house. Houses made of round wood look beautiful and do not need additional processing.

Planed log is a more suitable option for a warm and durable log house. It is processed by an electroplane, while all the irregularities are removed. Such logs turn out equal and smooth. The price of a house made of planed logs is significantly higher compared to houses from a different type of wood. A log is the most durable, even without special treatment. And with additional antiseptic, a log house from this type of log can last for more than a hundred years.

Minor processing helps the debarked log to retain all the protective properties, which significantly increases its service life.

Glued log combines the advantages of profiled glued timber and beautiful rounded logs. Differs in the increased durability in comparison with an array. The main advantages of this type of log: does not crack and does not change its shape over a long service life, and also has a slight shrinkage of only 1-2%.

Requirements

There are certain standards and requirements that must be considered before starting to build a house.

For example, first you need to get permission to build housing on your site. When it is received, the following documents are checked: certificate of title to land ownership, permission to use land for country house construction or individual housing.

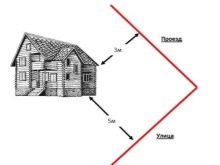

After obtaining the necessary permission from the administration you need to start planning the site. As a guideline for the location of the future house are selected neighboring buildings and a fence. The distance to them should be at least 5 m.

There are also requirements for building materials: the absence of cracks, defects, curvature.In solid timber and glued indications may vary. For example, in solid, the appearance of cracks up to half a log depth is allowed, and in glued one, their permissible depth is only 1/3. The curvature of the laminated timber can be up to 10 mm, and in the case of solid - 17 mm.

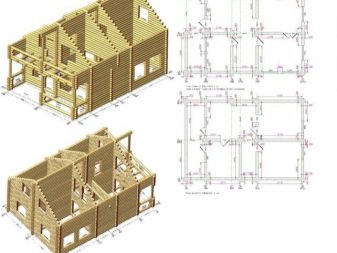

Design

Any house is an architectural and engineering structure that cannot be built without a project that will require certain calculations. When designing, it is best to turn to experts or select a ready-made project.

It should be borne in mind that a two-story house of 50 m2 will cost a little more in terms of financial costs than a one-story house of the same area due to the fact that costs are reduced due to the foundation, engineering systems and roofing.

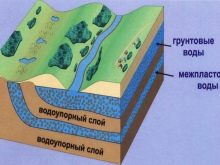

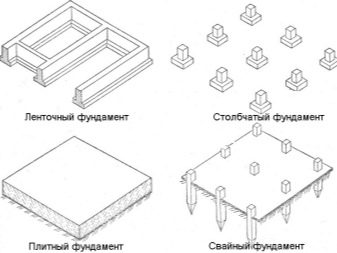

Before starting the design, it is important to conduct a geological survey of the area, which will give an idea of the properties of the soil and groundwater. This information will help determine the choice of the type of foundation.

To begin with, the total weight of the future house is calculated, according to which the type of foundation is selected. Then the layout of the rooms, as well as the design and appearance, are thought out.It is necessary to think over in detail at this stage of preparation, since later it will be impossible to make any changes, since the partitions in the chopped houses intersect with the crowns of the outer walls.

The next step is to calculate the number, place and size of windows and doors.

Next, select the type of roof. Before designing a roof, you need to consider that the simpler it is, the more reliable it will be in the end. After that, a sequence of works is developed, as well as a phased assembly of a log house. At the end of the design, the installation of all engineering communications is considered.

Do not forget to think about the storage of building material on the site. For this, a canopy is usually constructed, where logs are laid with obligatory re-placement of thin wooden bars.

Important nuances:

- pre-determine what type of timber will be built;

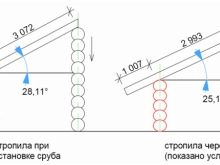

- Do not forget to calculate the effect of shrinkage on the roof;

- choose the place where the house will stand, given the 5-meter distance from the boundary lines of the site;

- do not design windows openings on the roadway, in the future it will be noisy in the rooms.

It is recommended that the water intake point and the sewer risers be in the same place, thus you can significantly save on their installation and operation in the future.

Projects for country houses and houses for permanent residence will differ in some details. For the latter option, a more solid monolithic foundation is chosen, installation by communication, thorough insulation and special sound insulation are taken into account.

A typical project is the most frequent type of design that does not require special modifications. The most important thing in this version is to take into account the features of the site for future construction.

The sketch project is a drawing in which only the facade of the house is shown without calculations.

An individual project is developed taking into account all the wishes of the future homeowner.

Training

Today the house is not just a place to stay or spend a weekend, but also investing money. Therefore, before you start building, you need to thoroughly prepare. Errors in the design, in the choice of materials, installation can lead to further serious consequences.

Forging for construction consists in the following actions:

- If you are already a happy owner of a land plot, before construction you will need to think over the design, obtain technical specifications from the bodies servicing communication systems, and also obtain a building permit.

- If there is no electricity and water on the plot, it is necessary to take care of this during the preparation stage. The question of water supply is solved by drilling a well, and in the absence of electricity, it is necessary to stock up at least with an electric generator.

- To prevent outsiders from entering your site and preserving building materials, it is advisable to protect it.

- It is also necessary to install a small economic unit, which will simultaneously serve as a place for storing tools and shelter from the weather.

Then you need to level the area under the foundation, uproot stumps, tree roots, clean the place of construction from debris.

Stages of construction

After completing the preparation, design, procurement of materials, you can proceed to construction.

When building a house with your own hands, it is important to observe the phasing of actions.

At the first stage, the foundation and the basement are erected.Trenches or excavation are digging depending on the type of foundation. For log houses are usually chosen tape, pile-grillage or slab version of the foundation. At the same stage communications are laid, drainage is arranged. The foundation of the house is better to lay in the warm season.

After the delivery of the marked log to the site, the walls are constructed and floors are overlapped, as well as the installation of the stairs and internal partitions. The assembly takes place on the technological maps of the walls in the development. All crowns are fastened together in staggered order.

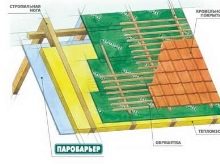

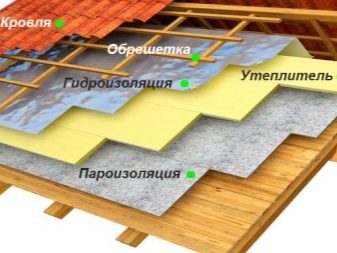

The next stage - the construction of the truss system at home. It is very important to follow all the necessary technological rules. When building wooden houses, rigid attachment of the rafters is not used due to the fact that during the shrinkage, the entire structure may break. The most popular roofing coatings are metal tile, corrugated flooring, soft roofing, and ondulin.

The next stage is the grinding of walls and insulation. During shrinkage cracking is possible, therefore it is very important to inspect the house and, if necessary, to repair the cracks. Walls after grinding can be covered with special tinting solutions to change color.

Then doors and windows are installed, leaving gaps for the insulation.Conducted engineering work, installed heating system, stairs. At the end of all work is the exterior and interior.

Warming

A tree house is considered to be warm and pleasant to live in due to the fact that the walls breathe, keeping warm. However, not always the thickness of the logs can withstand severe frosts. In this case, it is best to conduct external and internal insulation of walls, roofs and foundations. Insulation at home will help reduce heating costs, as well as reduce heat loss.

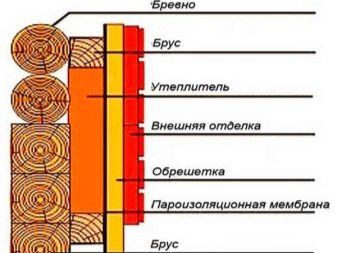

Vapor barrier film must be present in any type of insulation of the house, whether external or internal.

The film is installed between the wall cladding and the layer of heat insulator. Vapor barrier helps not to get wet with the main insulation.

Outside

The owners of log houses need to take into account that not all materials are suitable for outdoor installation of insulation.

Ecowool, granulated sawdust and mineral wool are well suited for log objects - these materials do not interfere with water evaporation, are resistant to burning and increase the thermal insulation parameters of a log house.

Before installing the outdoor insulation in a log house, it is necessary to treat the facade with antiseptic agents to prevent damage to wood by rot, mold and insects. Also, the structure must be carefully prokonopatit, that is, to conduct a study of all walls for the presence of damage and cracks.

The cracks can be easily detected by the help of a candle; to do this, it is enough just to move a burning flame next to the wall. If it deviates, it means that there is a gap in this place that needs to be repaired. When caulking use jute or tow.

After that, the crate is mounted in the form of horizontal and vertical guides with a pitch equal to the thickness of the insulation. A vapor barrier film is first laid on top of the sheathing with a stapler, and on top of it is insulating material. Over it the waterproofing film which will protect a heater from a moisture lays down.

Finishing in the form of siding or lining is made at the very end. This veneer will provide protection from wind and weather, as well as give a beautiful look to your home.

It is advisable to warm the house during the dry season and only a year or two after the start of its operation.

For outdoor insulation, in addition to the heat insulator, you need wooden bars for the frame, a vapor barrier and a hydro-barrier, fasteners.

It should also be noted that the work on the insulation outside are the best compared to other types of insulation.

Inside

Insulation from the inside can sometimes reduce the living space, so many people choose outdoor insulation. However, if the outdoor version of the insulation is not suitable, but it is still necessary to protect the home from the cold, then this can be done from the inside. But it should be remembered that this method can create a threat of rotting of the walls, especially in baths due to the constant high humidity.

Before insulation, it is necessary to cut, seal all cracks and cracks with tow, foam, or felt and treat the walls with a protective solution. Next, create a "pie", consisting of several layers. At the beginning of a vapor barrier film. Then a frame is made of timber 5 * 5 cm, after which a layer of insulation is applied to the frame and is closed with another layer of vapor barrier film.

You should never rush to any finishing work, if the room is not yet warmed.It is important to insulate not only the walls, but also the ceiling and the floor. Popular materials for this are mineral wool and glassine for ceiling and floor; glass wool, polystyrene foam and ecowool - for walls.

It is possible to insulate the building from the inside no earlier than one year after the construction of the house, in which case the insulation will last a long time. External insulation of the roof is quite a laborious process, consisting of several steps. First you need to conduct a thorough waterproofing of the entire roof space. In this case membrane membrane is most often used, which is easy to install and affordable. Next is the flooring of insulation, and in the end fit the roofing material.

For insulation inside the attic most often trimmed with sheets of fiberboard, which create additional sound insulation, as well as create a beautiful view.

As an external insulation for the roof, bulk and liquid heaters are often used, which must meet the following requirements: have low thermal conductivity, low weight, high vapor permeability, good sound insulation properties, be fire resistant and have a high density.

Warming of the foundation is also possible to carry out from the inside and outside. The most optimal time to warm the foundation is before the start of wall construction. If you are not planning a basement, then the whole space should be covered with expanded clay to the level of the future floor. To create this type of insulation it is necessary to make formwork around the perimeter of the inner walls, while using durable materials (boards, slate). Then, claydite is poured inside, and the subfloor is covered with a hydromembrane layer and mineral wool.

The outer walls of the foundation must be treated with special sprayed insulation.

Installation of partitions

In addition to load-bearing walls, wooden houses have interior partitions, which can be made of various materials, but in a log house they are usually made of wood, in harmony with the log walls. They are mounted, as a rule, after shrinkage.

With the help of interior partitions you can divide one large space into several small rooms to your taste. However, they do not carry any load, but are responsible for noise insulation. Such partitions can be moved from place to place without the assistance of outside help.

When designing a house, interior partitions are usually placed so as not to create a large number of passageways. Today there are a lot of modern programs where you can create a three-dimensional model and immediately evaluate the future layout.

Partitions should be made of high quality wood, treated with antiseptic, and have lightness, reliability, rigidity and heat and sound insulation.

There are several types of interior walls.

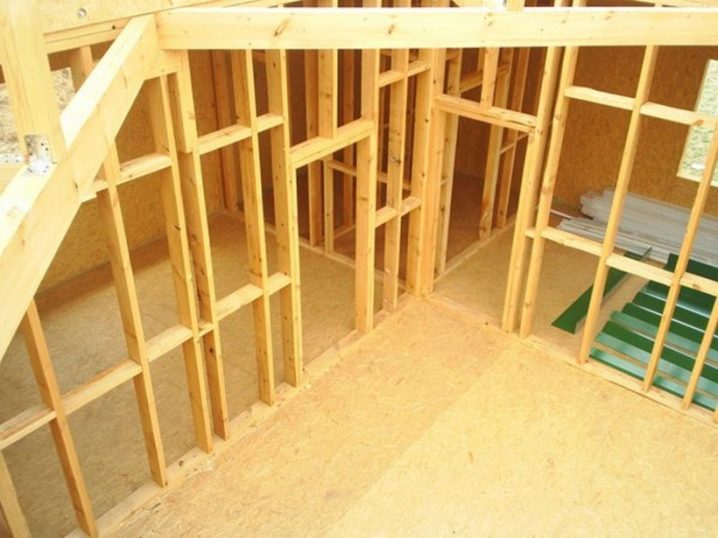

Frame and shield

The most popular and economical option that can be done easily with your own hands. They are constructed from log beams, which are interconnected by horizontal strapping. Such binding gives durability and reliability. Warming of frame-shield partitions can be made of mineral wool, while on both sides of the wall it is necessary to impose any material for vapor barrier.

Frame-shield walls are considered the best in sound insulation compared to other types. Also, the surface can be sheathed with plywood sheets to give a perfectly flat surface.

Solid

This type of partitions is made of the same material as the load-bearing walls, but the top is sheathed with fiberboard. Above and below the solid partition is fastened with bars, and on the sides - with nails.

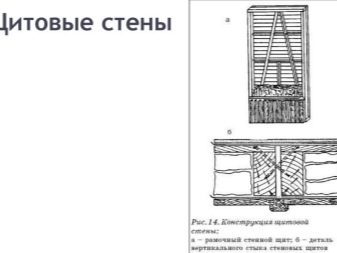

Shield Walls

Made of several layers of boards that fit into the ligation, it is a rather heavy construction with a thickness of 6 cm and a weight of about 80 kilograms.

Partitions are placed after the shrinkage of the log house. For their manufacture you will need a hammer, a hacksaw, a screwdriver, a chisel, a screwdriver, an electric drill and a jigsaw.

Common mistakes

Possible errors during construction:

- Sloping foundation. When erecting a foundation, horizontal deviation is possible by a maximum of 20 mm, otherwise it may lead to incomplete support of the house against it. Also not allowed are the protrusions of the reinforcement, the influx of concrete and other defects. Lack of ventilation holes under the foundation can lead to accumulation of water vapor, which further leads to the formation of mold.

- The thickness of the walls should be at least 28 cm, which corresponds to the minimum diameter of the acquired logs. In the opposite case, large heat losses are possible.

- In the absence of gaps in the window and door openings in the future there will be wall distortions and cracks in the double-glazed windows.

- The best quality are logs, felled in winter - they do not shrink much and do not crack. Summer logs with increased sap flow and moisture are most susceptible to cracking.

- Poor processing of gaps between logs can lead to drafts and an unfavorable microclimate in the house.

- In the absence of processing logs and logs with fireproof impregnations and insect repellents, the durability of the building is significantly reduced. Processing must be done before assembling the house, since if this is done afterwards, the surface of the logs under the joints will remain unprotected.

- The use of dowels during the drying of the log will help to overcome the axial twisting.

- It is unacceptable to use nails in the corners of the log connection, since in the future they will lead to the formation of rot.

Professional Tips

It is worth knowing the following:

- Before ordering an individual project, look ready. In this case, you can save financial resources, since individual design costs much more than a typical one.

- After complete drying of the material, it is advisable to grind before decorating the house.

- Hard illiterate control of workers and foremen will not give any result. If you are trying to intervene in the construction process without knowing the necessary knowledge and understanding technical terms and the work process, while making incorrect comments, this may lead to the creation of an inoperative situation at the facility.

- The foundation of the house must be laid in accordance with technical standards. Errors in its construction over time can lead to cracking or shrinkage.

- Painting the house inside and outside can be done with varnishes, paints or enamel. Choose only environmentally friendly and harmless materials for decoration.

- Pay due attention to the process of drying logs and their treatment with protective agents.

- Make a thorough interior layout even when designing a house. For example, the dimensions of the stairs to the second floor and the place of its installation should be planned in advance, since after completion of construction it will be too late to change anything.

- You will need electricity on the plot for work. Take care of this issue in advance.

- It is not recommended to heat the house in the first year after construction, as this can lead to a dramatic drying of the tree, which is fraught with cracks and deformations.

- Design the landscape in parallel with the construction of the house. This will create a beautiful and harmonious look for your private ownership.

- Many wonder what time of year to start building. Many firms for the construction of wooden houses offer their services year-round. However, it is better to lay the foundation in summer, but a house made of timber, built in winter, will be more durable.

A cheap house is a house that was built right away at once, on the first try.

Observing all the rules and recommendations, not saving on materials, in the end you get a good house that will serve you for many years. Alteration of poor-quality construction leads to financial expenses in excess of the amount for the construction of a new house.

Interesting examples

Log houses are a continuation of the traditions of Russian wooden architecture. The more technologically the life in megacities, the more with pleasure people flee to the country and build stylish wooden houses and cottages.Beautiful log finishes, associated with a mountain chalet or a Russian hut, are now very popular.

Many people do not realize that houses from a log can be made not only in the style of a peasant dwelling, but also in a high-tech style. Such wooden buildings are increasingly attracting fans of modern trends in architecture.

Projects made of stone and timber combine the advantages of two durable materials. Such combined buildings will be ideal for permanent residence.

Houses from a glued bar unite in themselves reliability, heat, comfort and beauty.

For decoration of the exterior of a wooden house can be a lot of styles. However, country music is the most common.

Two-storey country wooden houses are reliable structures with a modern approach to comfort.

Wood is a natural material that has been used for centuries for interior decoration of houses. The dwelling from a tree is filled with warmth and a cosiness. To create a special atmosphere, you can add natural materials for decoration, a Russian stove, furniture with openwork patterns, to decorate the walls with a board with the effect of antiquity.

In wooden houses, a combination of stuffed animals with an old samovar, semi-antique carpets with a four-poster bed looks good.

A detailed review of the house of logs, as well as what mistakes should not be made when it is built, see the video below.