Single-storey log houses: advantages and interesting projects

Today, many dream of their own summer cottages. Some prefer single-storey houses. But at the same time, not everyone can decide what material such a structure can be built from. Today we talk about log buildings.

Features of buildings from the 1st floor

To date, some are building for rest or permanent residence one-story log houses. According to many experts, such residential buildings will be able to serve their owners for many decades.But at the same time it should be remembered that it is necessary to precisely plan the space, because all the necessary residential areas should be located on one tier.

Comparison with a two-story option

It is worth noting that, in contrast to two-story buildings, the construction of one-story buildings does not require too much effort and time. After all, there is no need to mount the stairs. Besides, This type of construction can significantly save on building materials.

Single-storey buildings do not require a heavy-duty foundation, which is needed for two-story houses. After all, they do not have too much load on him.

It should be remembered that such a house will take a fairly large area of land. The roof in this case should be wider.

Advantages and disadvantages

Single-storey log buildings have several important advantages.

- Efficiency. During the construction of one-story wooden houses cost the owners quite cheap. After all, this material does not have a high price. In addition, compared with the two-tier options, you need significantly fewer items.

- Easy to disassemble. If you suddenly need to move facilities to another place, you can easily do it. After all, one-story log houses are fairly easy to understand.

- Low weight design. Single-tier structures made of logs have a small mass, this allows you to build them even on soft ground.

- Simple construction technology. Unlike two-storeyed options, single-level log buildings are much easier to design and build.

Despite all the advantages, single-story log buildings have disadvantages.

- Can only be built on flat surfaces. In contrast to the two-story single-story buildings can be erected only on a completely flat area without relief.

- Occupy large areas. In order to accommodate all the necessary living areas in such a room, it will have to be made quite spacious, which will require a lot of land.

Construction requirements

One-story houses do not require superstrong foundation, they can be rebuilt on ordinary structures. But at the same time the base should be almost perfectly flat. Only in this case, the facility will be able to serve its owners for many years.

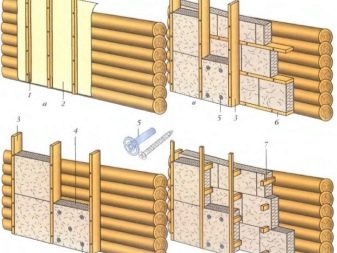

It is important that in the construction of single-storey houses, special attention should be paid to insulation. Indeed, in such cases, the design is most susceptible to temperature fluctuations. Often, experts recommend in such variants to lay insulation in several layers at once.

Building material

Currently, a considerable number of different materials for the construction of one-story houses can be found on the building materials market. The most popular of these is the treated log. Many experts today prefer just such a basis.

Wood selection

It should be said that today the logs for the construction of premises are made of various types of wood. Most often, pine is used for such purposes. After all, it has almost flat trunks, so it is easy to process.

And also often used and spruce. After all, she is able to keep warm. Some prefer larch, but remember that this type of wood is not cheap. Many experts advise when building a dwelling to take a cedar. True, because of the expensive delivery, he too will be affordable for not everyone.

We should also note that if you plan to build a bath on your land plot, then you should use aspen or linden.

After all, these types of wood are the most resistant to high humidity. These types of wood can be called resistant to sharp temperature fluctuations.

Manufacturing methods

Today there are a considerable number of different technologies for the manufacture of logs for construction. Experts identify several basic types of wood processing:

- rectangular timber;

- chopped log;

- round log;

- glued laminated timber;

Rectangular timber

Quite often, for the construction of various structures wooden square or rectangular beams are used. It is pretreated, removing strong irregularities. This material is the cheapest option of all the others. But it must be remembered that the house, built from it, must be additionally warmed.

Chopped log

It is a tree trunk that is cleared of knots and bark.In this case, it is necessary to make special grooves on the logs, with the help of which the logs are connected to each other. However, it will be possible to enter this dwelling only after the process of natural shrinkage has passed.

Round log

In this case, the trunk of the tree is first carefully removed from the bark. Then it is passed through a system of cutters, which gives the log a smooth, rounded shape. Such material does not need finishing. After all, it is not only a building material, but also a decorative coating.

Glued laminated timber

Consists of several boards glued together. Since the portage of such boards have different directions, the bar is durable. Houses built from such material will be able to serve their masters for many decades. But it is important to remember that the cost of this wood is not cheap.

Optimal size

Logs for the construction of premises can be of different sizes. So, a rectangular timber is most often produced with dimensions of 150x150 mm. It is quite enough for thermal insulation of the building.

It should be remembered that this material is better not to take with large dimensions.After all, such a product will be subject to natural deformations.

If you want to build a structure made of chopped or rounded wood, then you should take logs with a diameter of at least 25 cm. Glued laminated timber can be of different sizes. Most often you can find such products with dimensions of 180x200 mm, 160x200 mm, 200x200 mm.

Design

Today, experts can offer a considerable number of different projects of single-story log houses of various sizes. Before starting work it is necessary to make a detailed drawing of the future structure. However, he must include the dimensions of the structure.

When designing it is necessary to consider the shrinkage of the logs. Therefore, it is necessary to provide for log height tolerances. It is worth paying special attention to the foundation. When developing a plan, include in it a high foundation.

Such a base is necessary so that the wooden structure does not come into contact with the soil and does not absorb moisture. Otherwise, the structure will collapse.

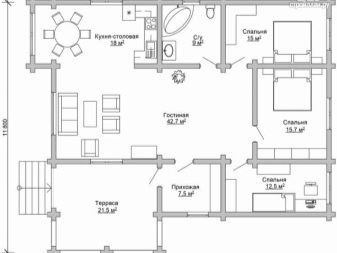

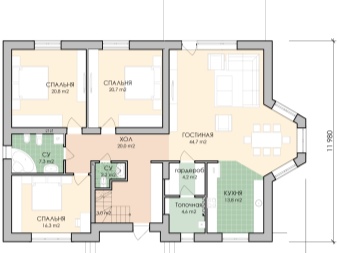

Log house projects can be of very different sizes. Today, experts offer many options for such dwellings with an area of 100, 150 square meters. mThis scale is considerable, so it is possible to place all the necessary zones in such a room.

The project should include all residential areas. In the area of 100-150 square meters. m can include several bedrooms (2-3), a kitchen, a hall, a small corridor and a place for a bathroom. After all, this scale is enough to accommodate all these spaces.

Often, when designing such houses, people make only one bedroom, but leave the remaining space for a more spacious kitchen, dining room, pantry, and a large bathroom. The number of rooms in the house and their size depends on the preferences of the owners, the number of family members.

The drawing of the future house a person can make on their own or seek the help of professionals.

Stages of construction

- Before the direct laying of a single-story log house it is necessary to construct a foundation. For its construction most often take brick or block posts, which are fixed in a sand-gravel pillow. From above the construction is connected by strong beams.

- After that, you can proceed to the construction of walls. To do this, the log must be cut into two equal parts and lay them on the foundation with twoopposite sides. Then they need to be fixed exactly on the base. The remaining logs should be laid intact. In this case, they need to make special grooves, with which the products are attached to each other.

- After building the walls you need to make a roof. Its laying should start with gables, which are created from logs "pyramid". To connect a design use special runs. After that, the structure can be covered with a finishing finish.

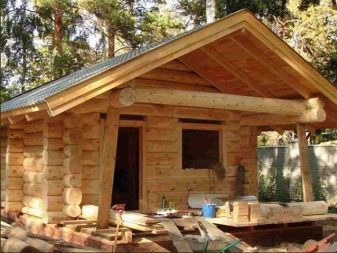

Beautiful examples

Today, designers can offer many options for large and small wooden houses. Log buildings are often made with a terrace. Such houses made of light wood look effectively.

At the same time the roof, window and door openings should be made darker. The terrace can be made in even lighter colors. Stairs at the same time it is better to do in the same color with the house.

Review the log house in the next video.