Choose slopes for plastic windows

After the installation of new glass units, the window opening does not look the best - foam is sticking out everywhere, fragments of plaster and in some places material of the walls is noticeable. All this "beauty" can be closed slopes, which are made from a variety of materials.

Special features

Nowadays, it is quite difficult to imagine an apartment or house without plastic windows, but installing them is only half the battle. After installation it is necessary to trim the slopes on the windows. Many believe that on the slopes can be saved - it is enough to zapenit them outside and inside and insulation will already be effective. However, this is a common misconception.

Foam readily absorbs moisture, so if it is not protected, then under the influence of water, as well as temperature drops, the sealant will begin to break down, nullifying the entire insulating effect of plastic windows.In addition, after installation of glass packs, rather unsightly seams remain that do not add to the general appearance of the window opening of attractiveness - this problem is successfully solved by the slopes that make the window neat and beautiful.

Properly equipped slopes provide effective thermal and sound insulation, which contributes to the formation of a favorable microclimate in the room, and in addition, prevent glass misting and condensation inside the living space. However, this is possible only if the installation of windows and slopes was carried out correctly in compliance with all technological requirements. If the slopes were installed with violations, then through them will leave up to 40% of the heat from the rooms.

From a technical point of view, the slopes are called the part of the wall opening between the window and the corner of the wall, and the inner part of the wall is called the inner slope, and the outer part, respectively, the outer slope (outflow).

Approximately until the mid-90s. last century, all the arrangement of slopes was reduced to their plaster and finishing painting. However, progress does not stand still; every year more modern materials appear, and windows are no exception. In place of the usual plaster came plastic slopes and slopes from the plasterboard.

New materials are more efficient and durable, they are easy to install with a minimum of dust and debris, in addition, they are affordable.

Kinds

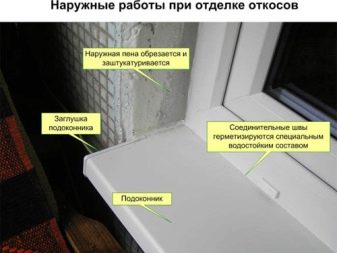

As already mentioned, the slopes can be internal and street, while it is very important to install them from two sides, only in this case the protective elements will be durable and wear-resistant.

After installing the external slope, it is imperative to carefully seal the gap between the frame and the wall, otherwise the moisture begins to absorb into the mounting foam, and through it goes to the walls, causing the appearance of mold and fungi. This not only destroys the walls and impairs the appearance of the premises, but also causes dangerous diseases of the broncho-pulmonary system.

External slopes can be performed in any shade, it allows you to focus on the original stylistic decision of the facade and emphasize the conceptual design. The internal slopes, as a rule, are made in white, this gives the rooms a bright and sun-filled look.

Materials

Installation of slopes is a complex of finishing works, the neglect of which will lead to the fact that the windows will not be able to perform the tasks that are assigned to them by the manufacturer.Slopes are usually trimmed using a variety of technologies, which in many respects differ in quality, degree of durability and cost.

To choose the best option, you need to take into account several recommendations:

- the slope should last for a long time;

- the material should be resistant to high humidity and temperature extremes;

- special attention should be paid to the tightness of the structure;

- since the slopes are mounted inside the dwelling, they should be made only from environmentally friendly raw materials;

Slopes should be easy to maintain and should be easily cleaned with the most standard detergents.

Consider the most common materials that are used for the manufacture of slopes.

Plaster

Now the popularity of plastering has declined, but, nevertheless, admirers of such slopes have remained to this day.

Advantages of plaster:

- low cost of materials;

- ease of installation;

- the ability to arrange slopes in cases where the windows are installed close to the walls.

But a lot of drawbacks:

- plastering is only a part of the finishing process, in any case it is not a finishing coating, which means that you will have to spend additional money, time and energy on puttying and painting;

- any works with plaster leave behind a large amount of rubbish and dirt, which is not so easy to get rid of;

- plastering makes it impossible to install additional thermal protection of mineral wool or foam;

- plastering requires at least minimal skills in construction and finishing;

- such a coating has a rather short lifetime, after a few years it begins to crumble and leave a lot of dust around itself.

Obviously, the minuses of the plaster as a base material for the design of slopes are much more than advantages, because it is the right way to give preference to other materials.

Drywall

This is a fairly common lining material, without which it is difficult to imagine any repairs. It is used everywhere for interior decorating due to its quality and durability, and because of the ease of installation it has become widely used for slope design.Of course, the novice wizard may face some difficulties, however, unlike the version with plaster, there will be much less of them.

Advantages:

- relatively low price of materials and works;

- small amount of waste after installation;

- the ability to sheathe slopes on their own without recourse to specialists;

- the ability to equip the additional insulation of the foam;

- any damage can be quickly eliminated with your own hands;

- slopes installed with the observance of technology, can serve for many years.

Of course, nothing perfect has yet been invented and drywall is no exception. GCR have drawbacks that need to be mentioned:

- making plasterboard slopes requires a large amount of additional materials, such as corners, profiles, wooden bars and paint;

- GKL is sensitive to water, so you should not use the material for the design of window openings in the bathroom, bathroom, in the kitchen and other rooms with high humidity;

- GKL necessarily requires insulation using foam, otherwise condensate will accumulate under the coating, which over time will destroy the structure of the slope.

Plastic

This is a modern and stylish material for the design of slopes, which in recent years has become very popular among the owners of apartments and houses. Benefits:

- ease of installation;

- no dust and dirt after work;

- material resistance to humidity and temperature extremes;

- the possibility of mounting a heat-shielding layer under plastic;

- smooth structure that does not require pre-alignment of the surface;

- ease of care - plastic is easily cleaned from household pollution with the most standard detergents;

- no need for finishing;

- mold and fungi do not develop on plastic:

- walls keep room temperature, which reduces the amount of condensation;

- wide selection of colors and textures of the material.

Plastic soffits trimmed with siding look very stylish and aesthetically pleasing, they organically fit into any interior, make the overall look of the window opening neat and well-groomed.

Cons are also available:

- installation without foam will lead to rapid freezing of slopes and their destruction;

- the installation process uses corners or profiles, in the second case the installation is significantly complicated,since the panel has to be inserted into the profile, which is often not so easy;

- in case of damage, it is necessary to change the entire slope.

Obviously, the advantages substantially exceed the disadvantages, which is why the material has now become number one in the difficult task of arranging effective slopes.

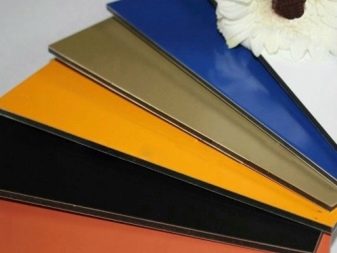

Sandwich panels

Another popular modern option for finishing window slopes. In essence, the product is the same sheets of polyvinyl chloride, between which is placed a layer of insulating material. That is why such slopes are considered a reliable obstacle in the path of moisture and cold entering the house from the outside.

Metal

In recent years, metal panels are gaining more and more popularity when finishing slopes, which ensure maximum tightness of the entire window design and thereby significantly reduce the degree of heat loss. The undoubted advantages of metal slopes include:

- esthetic appearance;

- reliable hydroprotection;

- resistance to temperature extremes;

- ease of installation and operation;

- durability.

The only disadvantage is the high price - such materials are much cheaper than their counterparts.

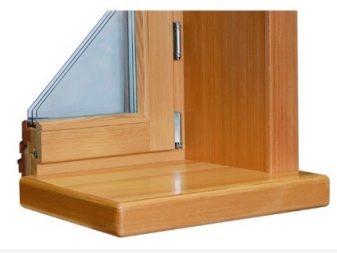

Wood

Wood is used as a basis for trimming slopes in the implementation of the eco-house concept, when all materials used for construction are of natural origin. Wooden slopes look very stylish and perfectly harmonize with wooden windows.

At the same time, this is a rather expensive material that requires constant maintenance, and the installation itself is not as simple as it may seem - only specialists should be engaged in its manufacture and installation.

Quite rarely, but you can find slopes that are made of cellular plastic. This is an economical solution, but this fragile material is characterized by low resistance to mechanical damage, besides, it burns out in the sun.

Quite trivial look slopes, made of stone. The most commonly used artificial. Such material is usually trimmed with external slopes, which gives the facade a very expensive and truly luxurious look. However, it is impossible to conduct such work on your own, since the stone is difficult to process, and the cost of a stone, even an artificial one, will be several times higher than any of the above materials.

Some do much easier - paste over the slopes with wallpaper. This option, of course, is good for its budget, but you can’t call it practical because the wallpaper does not create the necessary heat and water protection, and this coating deteriorates under the influence of moisture pretty quickly. Laminate board is also often used for the arrangement of slopes, with its help you can get a rather non-standard finish, which easily fits into any interior.

Corkwood is very popular, it can also be used to create a stylish and modern window opening. In addition to exceptional decoration, cork has another important advantage - it has good noise absorption and high thermal protection. Cork panels can be fixed with any glue, but this material should be coated only with special varnishes with high elasticity.

The fact is that the cork is a springy material, which, under mechanical action, easily bends, and then returns to its original position, so the usual lacquer can quickly crack and become covered with ugly cracks.

And finally, the mirror canvas is a modern trend of the “window fashion”. Using a mirror tile allows you to visually enlarge the windows, as well as improve the degree of illumination of the room. Therefore, the option is optimal for rooms with small window openings.

Device

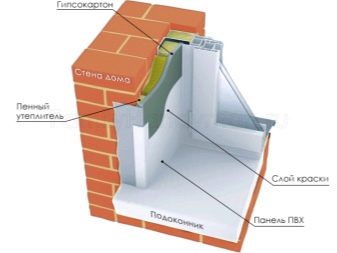

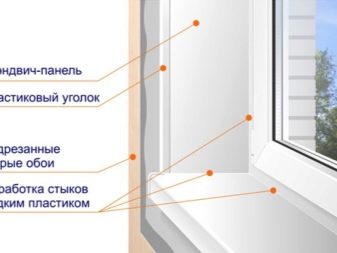

If we talk about the structure of the slopes, then the greatest complexity of the composition differ in devices made of plastic and sandwich panels. Their components:

- foam insulation;

- minwat;

- rail;

- self-tapping screws;

- plaster layer;

- PVC corner;

- back panel

External slopes consist of:

- plaster layer;

- foil vapor and waterproofing;

- silicone sealant.

How to choose?

To begin with, all types of slopes are conditionally divided into 3 categories;

- insulated;

- decorative;

- plastering

Before you understand when using each method of finishing, you should focus on the very concept of “quality slope”. A good slope should be durable, its service life should be commensurate with the period of operation of the PVC window itself - agree, it is unlikely that someone will like to regularly redo them.

The slopes should be decorated in a single stylistic concept with windows.

High-quality slopes not only protect and preserve, but even significantly improve the consumer properties of PVC windows themselves and under no circumstances reduce them. Modern windows have a rather thick glass package - 40-47 millimeters, while its heat transfer rate is 0.5-0.8, that is, they are quite warm, and in addition, new generation windows have efficient fittings and quality seals that reliably protect from wind and cold.

To date, the only weak point of the windows are junction points, so the slope should strengthen the functionality of these nodes. It is obvious that the plaster slopes do not meet this requirement. However, they do not meet any of the listed requirements.

Cracks and deformations always appear on the plaster near the frame, since plastic and it are completely different materials with different thermal expansion, moreover, the industry has not yet created a single sealant that has the same high adhesion with plastic and plaster, so avoid cracks it does not work out, moreover, over time they appear not only near the frame, but also near the window sill.

The second point to remember is that even the highest quality plaster cracks, and there is no such master who will make slopes that can stand in its original form for at least 3-5 years, and the paint, which the plaster is covered with, will eventually turn yellow, and after three the coating will turn completely yellow. It does not matter what paint you used, its appearance will deteriorate in any case - the glossy starts to glare and peel off, and the matte is so stained that it will be impossible to wash it even with the most powerful detergent.

In addition, the plaster slopes do not have a special plugging contour along the perimeter, so the inhabitants and guests of the house will see the cut edges of the wallpaper, and this very edge will constantly peel off whenever it comes to your mind to clear the slopes.

Any plastic frame has two contours protruding from above and below, the main glass unit is “sunk” in them, and when during the wind the door hits the slope, then the main impact force falls on these two places. Thus, even a small wind will enough to damage at least both areas on the plastered surface.

And finally, in order for the window frame to look aesthetically pleasing when using plaster for finishing slopes, there is a need to reduce the thickness of the foam layer, otherwise it will stand ugly and spoil the appearance. However, it is strongly recommended not to do this, since foam is already a weak link in the whole window construction.

In no case should the seam be made thinner, on the contrary, for greater tightness and thermal insulation, it should be maximally thickened, which is not compatible with the principle of plaster slopes arrangement.

Does it make sense to use the plaster for the slopes, only if you consider such an option as temporary in a limited budget. Now we will stop on decorative slopes. They do not improve the consumer characteristics of windows, but significantly improve their appearance. Let's see when it is possible and even necessary to mount decorative slopes.

First, they are used as frontal partitions. However, in this case we are not talking about windows in the full sense of the word, but about partitions with a branch, for example, in an office.Well, the second option is to finish the balcony block or loggia. In this case, the use of slopes of the decorative type is also allowed.

In all other cases, insulated slopes are mounted. They must meet the following requirements:

- they must be very firmly fixed so that they will not be squeezed out by the pressure of the assembly foam;

- the slopes and profiles themselves must be made of plastic;

- it is imperative that there is a plug loop that will give the coating a finished appearance, as well as protect the edges of the wallpaper;

Insulated slopes are a more modern and practical option, it allows you not only to decorate the window beautifully, but also to make it more durable and functional. Insulated slope contributes to the formation of a healthy microclimate in the room and increases the life of the walls.

How to set your own hands?

The lining of slopes is the last but mandatory step of installation of plastic windows, directly in front of it you need to install a window sill, and in case you are doing a general repair, besides finishing the latter, you should also finish the design of the walls and ceilingsotherwise, you risk damaging new slopes.

To make installation works with your own hands, you need a set of tools:

- building level;

- roulette;

- pencil;

- hammer;

- pliers;

- tray and pliers;

- screwdrivers;

- screwdriver or hammer drill;

- construction stapler;

- jigsaw or hacksaw;

- putty knife;

- capacity.

In addition to tools for work, consumables of different types will be required, namely:

- Staples;

- drill;

- sawing;

- dowels and screws;

- nails of various sizes;

- polyurethane foam or silicone;

- L-shaped metal profiles;

- Masking tape or protective film.

If you plan to make slopes of plaster, MDF or plasterboard, in addition to all of the above, you will also need mortar, adhesive for plasterboard, mesh for grout, perforated corners, and in addition, paint and wallpaper for finishing.

If wood is taken as a material for the slopes, then it will be important to process it with special stains and protective compounds that give the coating strength and resistance to fire, moisture and pathogens.The technique of slopes varies depending on what material is used for their arrangement.

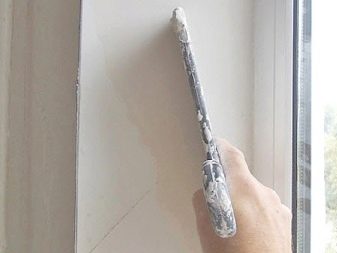

Plaster and painting is the most budget and simple option. For this, a ready-made mortar is taken on the basis of cement or gypsum, mixed with water (the proportions are indicated by the manufacturer on the packaging) - the material is ready for use! We pay special attention to the fact that the surface must be clean and degreased.

Even before starting work, it is necessary to remove dust, dirt, foam and concrete residues. Then it is necessary to expand the corner seams and the slope seams, this is important to ensure maximum adhesion of the plaster to the brick wall. First you should plaster the wall, and then proceed directly to the slopes.

During installation, it is imperative to ensure that the joints of the wall and the window are tight. If gaps and gaps are found, then it is necessary to seal them with tow or felt dipped in a solution of gypsum, and further process with mounting foam.

To the sides of the window opening there should be 2-4 cm - this space will be filled with plaster.

The first layer of plaster is laid in the groove of the future slope, then it is carefully leveled and left to dry, after hardening it is transferred to the second layer, etc. In one go you can apply 5-8 mm of mortar, the layers are leveled upwards.

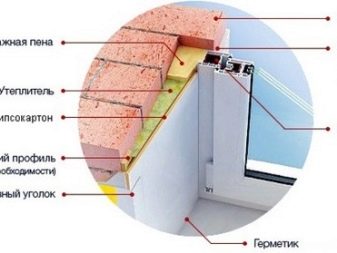

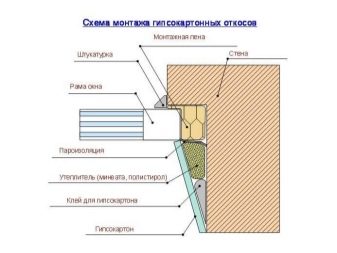

At the device of slopes it is necessary to give preference to moisture resistant gypsum plasterboard - GKLV. There are two basic ways to install this coating: frame and frameless.

First you need to decide how you will fix the gypsum plasterboard - on glue or on the profile. If the distance from the window frame to the wall is too long, then it makes sense to install profiles, and with a small gap, you can safely use the adhesive mixture. Fixing profiles, as a rule, is made on dowels. It is very important that an air gap is not created in the space between the wall and the drywall, since this can very badly affect the thermal insulation of the living space.

That is why it is mandatory to fill it with insulation, most often for this use mineral wool, but you can use the usual foam. If the gaps are too narrow, then it makes sense to use foam, however, it should be handled very carefully,since during curing it tends to increase in volume, which often causes breakage of the plasterboard coating.

Along the perimeter of the window frame is attached L-shaped profile. It is applied with a horizontal bar. Alternatively, you can take the profile in the form of the letter “F”, it should fit in a vertical plane. After that, it will be necessary only to cut pieces of gypsum boards of the required size and fix them in the profile.

In the frameless method, HL is fixed on the glue, and the solution must be diluted in such a concentration so as to ensure the fastest setting. Keeping gaps under control is very important. In this case, the plasterboard section along the edges of the joints, which will later be the angles between the upper and side slopes, should be made at an angle of 45 degrees. This will make the fixation quality and tight.

In order for the glue bays to be distributed over the gypsum board surface evenly and fixation was the same over the entire area of the material, the GCR sheet should be strongly pressed with a wooden bar, and for additional reinforcement, use spacers attached to the sill.

Full fixation of the adhesive composition, as a rule, occurs in 1-2 hours.

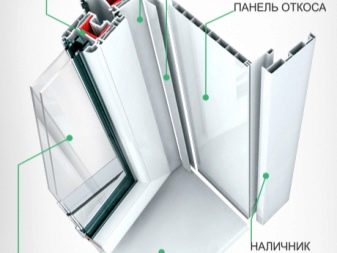

The use of plastic for the design of slopes has its own nuances and technical features. To work will require:

- PVC panels directly - choosing them should take into account the parameters of the future slope (length, width and depth);

- F-shaped profile - used for edging the outer surface;

- U-shaped profile will need to trim the adjacent areas;

- polyurethane foam - at least 2 cylinders;

- quick fix glue;

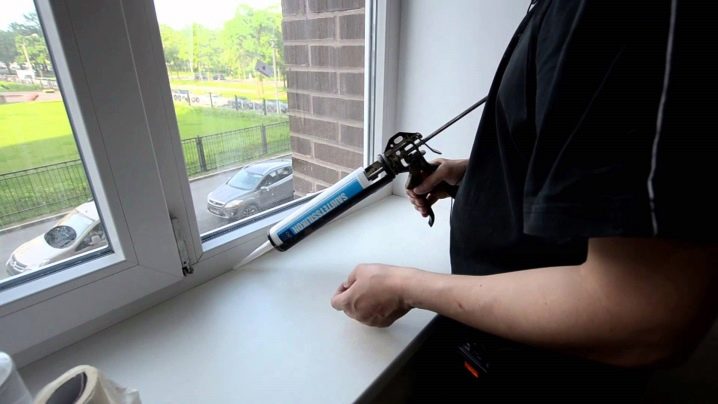

- acrylic silicone.

In addition, you will need tools with which you can sew slopes:

- roulette and triangle - for the most accurate measurements and drawing corners;

- gun for foam cylinders;

- gun for squeezing sealants and silicone.

Production of plastic slopes takes place in several stages, step by step:

- In case the gap between the wall and the frame is more than 2 centimeters, all irregularities of the filled in foam must be cut off and a small groove made in it, the thickness of which should correspond to the size of the plastic panel. Thus process all the box around the perimeter.

- If the width of the gap is less than 2 cm, then only those areas of foam that can interfere with high-quality installation are removed.

- Next begins the preparation of panels for installation.First of all, it is necessary to determine the method of joining the panels - as a rule, they are fixed at a right angle or at an angle of 45 degrees, and the second option is more aesthetic from the point of view of design. At the same stage, all the required measurements are carried out. Here you will need a ruler and a pencil, and then with the available tool, the blanks are cut according to the measurements.

- Then, the panels are directly mounted. Usually they are mounted on glue, which is poured into the groove or inserted into the U-shaped profile fixed on the box.

- All the gaps that form between the slopes and the wall are filled with sealant that will firmly and firmly hold the entire structure. The foam is applied with a thin strip, given that it has the ability to expand, so if you overdo it, it simply deforms the plastic.

- In the next step, an F-profile is glued around the perimeter of the opening.

- At the final stage, the joints are rubbed with silicone, for this it should be carefully applied to the seams and smoothed with a moistened cloth.

The installation of effective slopes from sandwich panels is made according to a similar scheme,the only difference is the lack of need for additional thermal insulation, since there is already a heater in the composition. However, additional hydro and thermal protection of the window does not hurt in any case.

Fastening the slopes of wood, mirror panels and stone requires special construction skills, therefore professionals must engage in such work. Otherwise, you risk wasting your time and money.

Tips and tricks

Installation of plastic windows is a rather expensive occupation, therefore, after their installation, many owners of a house or apartment refuse it, arguing for the high cost of such work. Someone thinks that they will be able to install the slopes on their own, and someone believes that the window will live for a while without the decoration. This position is quite erroneous, since, as practice shows, very few people shortly after installing the glass packs attach themselves to the slopes - then there is not enough time, then materials, then money. Such an approach is fraught with the most unpleasant consequences, and they can come already after a couple of years.

Any professional builder can give several reasons why it is not necessary to postpone the finishing of slopes “for tomorrow”:

- The foam quickly rots under the influence of moisture, which leads to the appearance of mold and fungi that are dangerous to human life and health.

- Foam does not differ in resistance to sunlight and collapses under its influence.

- Due to the influence of adverse weather conditions, gaps and cracks appear between the foam and the window frame over time.

- Uncovered by any material, the foam quickly loses its insulating properties.

This list is far from complete, however, these few facts are enough to understand that the delay in arranging effective slopes leads to a violation of hermeticity, hydro and thermal insulation of new windows, which means that they will not be able to effectively protect the room and its owners. from wind, cold and extraneous noise.

Well, in conclusion - a few recommendations for the care of the slopes, which will help to significantly extend their service life.

- Plastic options are easier to use. Caring for them is not a problem.. To clean such surfaces from household pollution, you should use simple soap and water, it is unacceptable to use cleaning abrasives, as well as acid-base solutions - only in this case plastic will serve you faithfully for many long years. Plasterboard slopes are most often covered with latex-based paint, which gives them particular resistance to abrasion. They can be regularly washed and cleaned without any damage to the decorative appearance and physico-technical condition.

- Besides, it is quite simple to replace or repair such a coating, and a nice bonus will be the ability to change color at any time or when there will be a complete change of interior. Cork slopes need almost no maintenance. The only procedure that needs to be done regularly is to wipe the coating with a soft, damp cloth, preferably with a flannel.

- Much more trouble caused plastered slopes. This is due to the fact that between the frame and the slope itself quite often there are cracks. This is due to the lack of plasticity of the material, so the temperature drops act on the coating in a disastrous way.Care of slopes of this type is reduced in the periodic restoration of the integrity of the coating. To do this, use sealants and special grouting and tinting. Such slopes should not be washed frequently, as this often leads to the appearance of unwanted mold.

- When arranging slopes, joints are most often treated with silicone.which, as time goes by, gets unstuck, dirt and dust eats into it and, as a result, it loses its aesthetic appearance. Do not be upset - all minor repairs can be carried out at home on their own. To do this, you need to purchase white or transparent silicone and, in accordance with the manufacturer's instructions, apply it to the cleaned damaged surface with a special gun.

The rules of care are quite simple, but only their exact and strict observance will significantly extend the life of your slopes, which will delight you with their attractive appearance for many years and will not disappoint with their quality.

On how to choose the slopes for plastic windows, see the following video.