Rules for the decoration of internal slopes on the windows

The function of the slopes when installing window systems can not be overestimated. After installing the window, the view of the opening remains in an unattractive form and it needs to be decorated with something. The slopes are installed around the perimeter of the window in order to hide the damaged section of the wall or its finish, remove the mounting foam from view, fix the insulation material. All these elements are closed slopes, which themselves serve as additional thermal and sound insulation, as well as give the design a complete and aesthetic look.

Special features

The slope is the space between the window frame and the supporting wall in the room. It is called that because it is usually done at an obtuse angle relative to the window frame. Such a turn maximizes the penetration of daylight into the room.The rules of finishing depend on the chosen material from which the slope will be made, and do not differ from any other finishing works using this material. However, there are specific subtleties that need to be paid attention to, as well as installation methods that can reduce the operating time. The technique is chosen individually depending on the preferences of the host and its capabilities.

In the past, a wooden box served as a slope, which was covered with a casing. In modern times, for the manufacture of a window, double-glazed windows are used, which improve light penetration and increase the width of the slope, since instead of a box they use only one window frame. The frame can be made of metal, wood or plastic. The homogeneity of the material used in the manufacture of the frame and the slope, gives the design a holistic look, so most often the metal goes to the metal, wood - to the tree, and plastic - to plastic.

On the other hand, a room with a window opening can be concrete, brick, wooden or iron. This factor is also taken into account when choosing the material from which the slope will be made, since it can be an extension of the wall, and not the window frame.

Modern window systems are designed to minimize the leakage of heat from the room. For the successful implementation of this function, they are isolated from the wall with a layer of polyurethane foam, which is afraid of exposure to ultraviolet radiation, moisture and mechanical damage. Internal slopes are necessary to preserve the integrity of this layer. The scope of work for mounting slopes depends (not always, but mostly) on the window measurer. When dismantling old boxes often manifest hidden defects of the window opening, which could not be detected before.

Walls can have air cavities or a terrible condition that leads to partial destruction. Stucco old slopes can be very strong, especially hard to work with concrete walls. In wooden houses - the presence and condition of the deck. The measurer, starting work and ordering a window, should have a good experience and think for the future and about the slopes. The main feature of the finishing of internal slopes is the ability to make them as simple as possible, which reduces the time of their installation.

Observing the necessary technological process of the material chosen for work, it is almost impossible to make a slope in less than 2.5–3 hours. Installation time is reduced only if several slopes are mounted at the same time, for example, the whole house or apartment. Basically, the slopes have the form of a flat monophonic plane. They are not subject to mechanical loads.

It should be noted that in most cases the slopes are hidden from the eyes by curtains or curtains, and they are remembered about them only when washing the window. Therefore, preference is given to easy-washable monophonic material.

Kinds

Classification of species implies the material used and the technique of performance depending on it, and the final decorative appearance of the structure often does not coincide with the materials of execution. crumbs. And also slopes can be covered with wallpaper, varnish, various paints. But under any decorative layer, the slopes will consist of a choice of one of several materials most commonly used in modern construction.

In this regard, the slopes are divided into several types.

Plastered

Plaster - is a traditional material for finishing window openings. In its original version, the method was used to save money and in the conditions of shortage of finishing materials.

The process consisted in leveling a part of the wall using a primer, applying plaster and subsequent painting of slopes. Thus, the slopes became a continuation of the wall, but did not have an airtight adhesion to the window frame. As a result, cracks formed over time, the insulation was low. The windows had to be additionally insulated from the outside not always in aesthetic ways: clay, cotton wool, moss. To date, the technology of applying plaster has undergone significant changes, and now this type of slopes is considered one of the most stylish options.

Plasterboard slopes

This is a modern and economical way of facing a window opening. Drywall retains heat well, is an inexpensive material, and its texture serves as an excellent basis for applying any kind of decoration. Pieces of drywall often remain after the renovation of modern premises, and in order to save them, they can be used as material for slopes.The disadvantages of this type include the instability of drywall to dampness, as well as the tendency to deform at the joints of the window and the wall.

Plastic slopes

Are today, perhaps, the most popular type of cladding window openings. The plastic used for slopes can have different modifications and texture, can serve as an ornament in itself, and can be styled for any material. Plastic panels are durable and practical, easy to install. It is easy to hide with thin sheets all the unsightly “insides” of the window opening - insulation, mounting foam, wall imperfections.

Plastic is perfectly washed with conventional household products, is not afraid of moisture and prevents drafts. The disadvantages of plastic can be attributed to its high cost, as well as fragility at low temperatures in unheated rooms. In the building materials market, plastic panels are represented in a wide variety of colors. It is not difficult to choose any shade of white, beige, milky color to the window frame, as well as any other color or pattern to the wall, wallpaper or a separate accent of the interior.

Wood

The tree is considered an elite type of slopes, has a high cost and requires special care. As a rule, wooden panels are left in their original natural color, coated with varnish. Wooden slopes it makes sense to put as a continuation of frames of wood material, which are themselves an indicator of respectability, or as a continuation of a pronounced log wall. For example, if the interior is made in the style of country, chalet or rustic.

The main advantage of wood is its environmental friendliness, excellent “warm” appearance and durability of the material. The disadvantages include the high price, as well as the observance of special rules for the care of wood.

Cork

Cork as a facing material has its advantages in the form of a high level of noise and heat insulation, it is presented in different natural shades and is pleasant to the touch. However, the high cost of cork panels in relation to low strength, rustic appearance and complexity in the maintenance is a significant disadvantage. Due to these circumstances, cork slopes are not popular and are quite rare.However, they can be borne in mind when developing a particular style direction in the room.

Materials

In addition to the external data of the material of the frame or wall, the choice of cladding will depend on the thickness and practical condition of the window opening. Sometimes after the dismantling of old windows, you have to change a pre-selected solution using one or another material. When planning, it is desirable to consult a specialist who will be able to analyze the state of the surface, as well as reasonably advise the choice of the type, and accordingly the material of future slopes.

For installation, you need to calculate the amount of material and prepare all the necessary tools. It is worth considering in more detail the most popular options for finishing materials for slopes.

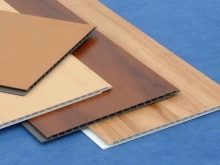

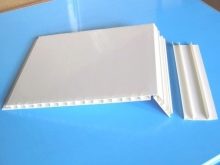

PVC panels

Plastic sheets for cladding are called clapboard. On sale they are represented by the standard shape of an elongated rectangle of different widths. As a rule, these are long panels that are easy to cut and fasten to horizontal and vertical surfaces. Due to the fineness of the material, plastic does not take up space and serves as both a decorative and functional coating that protects the inner layers of window openings.

The best option for installing plastic slopes are sandwich panels, called for the similarity with a closed sandwich. Between the two sheets of lining is a thick layer of foamed polystyrene, which serves as a warming material and allows you to simplify the installation of slopes.

The number of panels is calculated from the height and width of the slopes, and also the wall thickness is taken into account. To the received footage worth adding 15-20% of the reserve material. If you plan to install slopes on your own, without the involvement of specialists, you should carefully read the theory and select the appropriate professional tool. Included with the panels you need to purchase the following materials:

- U-shaped or F-shaped profile, profile for the inner corner;

- thermo-insulating material, if lining is used, and not a sandwich panel;

- wooden slats and screws of the required length;

- white or colorless silicone for sealing seams;

- polyurethane foam.

Drywall

The material is comfortable and durable, it is commonly used in paneling for pipes, multi-level ceilings, and is also excellent for creating slopes.Among all types of drywall for slopes, you should choose the GKLV type, which is easily recognizable by the greenish shade. Such drywall has increased strength and resistance to moisture, which is of fundamental importance for window openings.

Installation of drywall constructions can be carried out in two ways - adhesive and frame. Accordingly, in addition to the base material, it is necessary to purchase either drywall adhesive or special profiles from which the framework will be built. The profiles are fastened together with screws and dowels, after which the cut facing sheets are fixed on them.

Before starting work, you need to clean the old lining, remove the crumbling layer of plaster or damaged insulation. Since the adhesive method requires a flat surface, the base is leveled by applying ordinary putty. It is advisable to treat the prepared area with an antifungal solution, especially if the room has high humidity.

It often happens that there is no way to ensure a completely flat surface, and therefore the calculations of the material can be with errors.In this regard, it is better to stock up materials with a margin and to cut off extra parts during the installation process. The slopes of wood or cork material are made on the principle of plasterboard.

Decorative plaster

Decorative plaster owes its popularity to a special aesthetic appearance, practicality and durability. The material serves as a finish and can be applied to any surface. It is perfect for leveling drywall surfaces, and can also be applied to concrete, brick or wood. The composition of the decorative plaster includes components that allow you to get a different texture on the coated surfaces. The plaster is capable of hiding minor irregularities and defects in the base material, enhancing its sound and heat insulation qualities.

Decorative plaster is divided into several types, depending on the filler in the mixture.

- Textured. It is in its composition that heterogeneous granules are added, on which the subsequent texture will depend. It can be imitation of marble chips, natural stone, marble veins, the effect of silk or velvet, crumpled fabric or paper, lint or astrakhan.

- Relief. Received its name for the method of application. The mixture is applied to the surface and using rollers or stencils is converted into abstract patterns or embedded patterns.

- Venetian plaster is the most respectable and expensive way to finish, so it does not make sense to make slopes with its use. But if the plans are facing the wall with Venetian plaster, then part of the mixture can be left on the slopes.

Installation

From the correct installation of slopes will depend on the reliability and tightness of the entire window unit. Slopes provide not only appearance, but also tightness, additional protection against drafts and moisture. With certain skills in the construction business, you can make slopes with your own hands, the main thing is to comply with the technology and basic installation rules. For PVC panels, the installation process will be as follows:

- First, the surface should be cleaned, remove excess construction foam with a construction knife. The cleaned area is leveled with putty, the cracks and crevices are plastered;

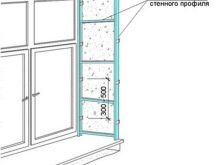

- when the surface is ready, exposed wooden slats, which will serve as a frame for mounting panels.The profile is fixed on the frame, and the slope space itself is insulated using foam plastic, mineral wool or foam;

- Lining or sandwich panels are inserted into the profile, which are fixed in several places. Joints are treated with silicone.

When mounting the plasterboard slopes using the frame method, you need to correctly set the supporting base so that the dimensions on each side of the window are the same. The process is performed in the following way:

- the distance from the window to the wall is measured, the lines indicate the installation boundary. The guide profile is fixed with the outside on the line;

- after the frame is ready, it is necessary to warm the slope inside as well as when installing PVC panels;

- By the size of the frame, drywall is cut, parts of the drywall are fastened with screws to the designated places. Joints can be covered with a mixture of non-woven fabric.

The adhesive method makes it possible to finish the window block in a simpler way: the cut gypsum panels are fixed on the surface with construction glue or foam.

Stages of installation of slopes with plaster have their own specifics. Before starting work, the window sill and window should be sealed with a protective film, if it has already been torn off during the installation of the window construction.Further, the process takes place in full compliance with the rules of applying decorative plaster on any surface. For slopes, it is best to choose a mixture with small granules of the same size. The more granules, the harder it will be to apply the mixture in a uniform layer. This job requires some skill. The composition of the mixture with small particles, as a rule, has a more liquid consistency and a lime base, therefore, it is quite simple to apply it.

The first step is to apply a layer of acrylic primer on the prepared surface. Then the plaster mix is prepared, on the small area the specificity of the texture and shade is checked. Plastering is done in different ways depending on the desired result, namely:

- using a steel float or trowel;

- using a roller or sponge;

- spraying with a brush, broom or brush.

Tips and tricks

To obtain a quality result, you should pay attention to the advice of practitioners and designers. It is worth paying attention to several nuances that can help in the proper design of the window opening:

- For maximum daylight penetration into the room It is desirable to build an unfolded angle. With the same purpose for small windows, the best option would be the slopes and frames of light colors. In addition to the standard white color, you can choose light beige, coffee and milk, delicate tones of pastel shades.

- For rooms with high humidity - kitchen, bathroom - choose materials resistant to water and detergents. PVC panels are best suited for these purposes, but there are also decorative acrylic plasters that do not let in or absorb moisture. Their main advantage is a breathable effect that prevents the appearance of fungus and mold.

- The plaster serves as an excellent finishing material for window openings in the form of an arch, trapezoid, or any non-standard shape, which is difficult to decorate in other ways. For skylights, where there is a risk of color burnout in the sun, silicone-based plaster is suitable. It is insensitive to ultraviolet and the coating will not lose its color, even while on a hot roof.

If there are curtains and curtains on the windows that will hide the slopes, then it does not make sense to spend money on expensive finishing options.But on the windows with shutters decorated slopes will serve as a frame and decoration around the window opening.

Beautiful examples

If the interior of the room to luxury and respectability, then, of course, the usual plastic slopes will be evident with its simplicity. In this case, you can choose a refined decor, depending on the stylistic direction. It has long been customary to decorate window openings with stucco, carving or painting, because windows are the “eyes” of a room and an important architectural part.

- The sophistication of a classic interior will emphasize stucco moldings or moldings - decorative overhead slats.

- For the style of rustic fit the accentuation of the window opening with natural or artificial stone.

- In the interior of the country will look great coarse wood, and in the style of the chalet - noble wood species, for example, wenge or mahogany.

- Stylized antique carved wooden slopes with cracks and patina decorate interiors in the style of Provence and vintage.

- Carved lacquered wood will suit the style of the Russian hut.

- For the urban style loft, it is better to choose the style of brickwork.

- For the slopes in the bathroom, you can choose a large ceramic tile or mosaic option.

- An unusual effect will create a mirror slopes, and at the same time and visually increase the window and the penetration of light into the room.

Rules for trimming internal slopes and their types, see the following video.