Choosing exterior metal window slopes

Even without being a professional builder or a master-finisher, it is easy to understand what function the window slopes perform. These elements of the window construction are especially important when performing exterior finishes. Indeed, in this version, the important task of protecting the installation seam and the entire opening from external natural factors and temperature changes also falls on the slopes. In this article metal window slopes will be considered: their features, types, advantages, disadvantages and installation rules.

Species

- Metallic slopes. Most often made of metal profiles or galvanized sheets: copper, steel, aluminum.Metal sheets are treated with a durable polymer coating.

- Plaster finish. Perhaps the most affordable and economical option. At the same time, such a finish very poorly protects the opening and the window structure. The layer of plaster, being in the open air, begins to crack with time. Therefore, such a lining will require a systematic update.

- Plastic cladding is also a very popular type of finish. This material is lightweight, easy to size adjustment, which makes installation easy and affordable for self-fulfillment.

- Exterior finish metal siding. To install such slopes will require additional lathing. This lining reliably closes all gaps and provides very good protection to the installation seam.

- For facing the window openings of a wooden frame or in case the window frames are made of wood, finishing may be appropriate. wooden slopes. This option looks very original, and the tree is a good insulating material.

- Gypsum plasterboards can also be used as an external facing of openings.This material is not characterized by high rates of waterproofing, weakly retains heat. Finishing drywall suitable for summer houses or verandas. It is also a good option for the inner lining of the opening.

Purpose

Slopes are part of the window opening. By location, they can be external or internal. Both types of window slopes perform a decorative function, giving the opening an aesthetic appearance. Beautiful window openings are always pleasing to the eye. Manufacturers offer a lot of options for color design and texture data finishes. This allows you to design window openings in different styles, and most importantly, it allows you to maintain the stylistic unity of the room or the exterior design of the facade of the whole building.

However, the external slopes perform another important function. These elements protect the layer of foam, which fits into the opening when installing the window unit. The integrity of this layer in turn ensures the stability and reliability of fastening the frames of the window block. In addition, external slopes also provide sealing of the opening, and as a result, additional thermal insulation of the room.And this is important in the cold months of the year.

The conclusion is that the exterior finish of the opening is not limited to the task of aesthetic appearance. For this reason, it is much more expedient and safer to use metal slopes outside the room.

Benefits

The finishing of external slopes with metal has quite a lot of advantages due to the properties and characteristics of this material:

- metal slopes have almost unlimited service life, so it can be said without exaggeration that they can last for ages;

- metal is a very durable material, besides products are covered with galvanizing, which will reliably protect the structure from rust and corrosion;

- Most manufacturers cover products with a stable polymer layer, so that the slopes can retain their original appearance (they do not need to be repainted and restored);

- the rollout of slopes makes the appearance of the entire window structure aesthetic and complete; the color selection will allow you to veneer windows in the same style with the exterior of the entire building;

- installation of products is quick and easy, and installation can be done independently;

- metal is resistant to natural factors, well protects the layer of foam from wind and moisture, due to this additional insulation of window openings occurs;

- the product does not require special and thorough care, you just need to wipe the surface with a dry or damp cloth as it gets dirty or dusty.

disadvantages

Metal slopes have very few drawbacks, but they should still be mentioned.

- As a drawback, it is worth noting the relatively high price of such products. Facing metal slopes is not a cheap pleasure. Although the high cost, without a doubt, is compensated by durability and a number of other characteristics of metal products.

- Metal cladding cannot be installed on arched window openings. This is the only limitation on the shape of the design of metal slopes.

- Another disadvantage is that when installing metal slopes, it is necessary to additionally use noise-absorbing tape or softening materials. If you install metal cladding without it, during rain or hail, the slopes will emit a strong knock due to the impact of drops on their surface.

Recommendations

- It is not necessary to postpone the outer lining of installed window units. Exterior finish of the opening should be carried out as early as possible or simultaneously with the installation of the window. This will protect the mounting foam from damage, dampness, fungal and mold damage.

- The most convenient option would be to order metal slopes in the same company in which the windows were ordered. First, the products will be delivered, and if desired, the customer and installed simultaneously with the installation of window designs. Secondly, professionals will make measurement for the manufacture of metal slopes.

- When choosing a manufacturer, pay attention to how long it has been on the market and what feedback it has on its products. Feel free to ask for product quality certificates. Poor-quality cladding will not be able to please with its durability, and the appearance of the slopes can quickly deteriorate if a low-quality coating is used.

Self install

As already mentioned above, metal slopes can be installed with your own hands. To do this, you only need to carefully read the procedure for the installation work.

Required tools and materials:

- galvanized metal sheets;

- scissors for metal;

- screwdriver (also suitable drill with a nozzle);

- measuring tape;

- polyurethane foam;

- sealant;

- antiseptic.

Consider step by step instructions for self-installation of metal slopes.

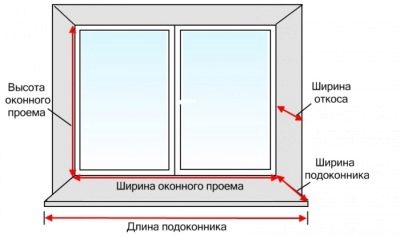

- It is worth paying special attention to the accuracy of measurements. It will be very difficult to install a structure that does not initially fit in size. It is important to measure all sides of the opening, as it may not be symmetrical at all. Using a measuring tape, you need to measure the height of each side, the width of the opening, as well as the width of each of the four slopes.

- In the next step, it is necessary to prepare the opening for the installation of metal sheets. Excess foam should be cut with a knife. Gaps and cracks on the surface (if available) should be cleaned and plastered. Seams must be treated with antiseptic and sealant.

- If the slopes will be made independently, then the resulting dimensions should be transferred to metal sheets. Next, scissors for metal cut design of the desired dimensions.

- Installation of the lining begins with the installation of the lower element-low tide.To prevent the metal sheet from emitting a strong sound when it rains, you can put softening materials under the tide or place it on a layer of foam. Experts recommend using noise-absorbing tape for installing the lower slope.

- After installation of the tide, installation of the side slopes is performed. The lower edges of the side cladding elements are trimmed at an angle to fit the ebb. The side slopes are attached to the frame of the window structure using screws with a press washer. For better thermal insulation, you can put a small layer of foam under the side slopes.

- The last element of the cladding is installed last. It is also attached to the frame with screws.

- All gaps should be filled with foam and sealant.

- If the slopes were made independently and the metal sheets do not have a protective coating, after installation all the elements of the outer lining should be coated with anti-corrosion paint.

You will learn more about the installation of metal window slopes by watching the following video.

Professional Tips

On thematic forums and Internet sites, it is often recommended to fill in the gaps between the metal sheet and the mineral wool opening, rather than foam, for better thermal insulation. This is not a good idea.Mineral wool is hygroscopic, besides quickly compressed. In the best case, such a "heater" will last a year and a half.

A good alternative to the foam in terms of thermal insulation is penoizol, you can also put basalt wool in the cavities.

Not bad protects the opening and provide additional insulation outer splat and outer corner.