Choose an adjoining window profile

The adjoining window profile is a universal bar that is capable of performing plastering, protective and sealing functions simultaneously. It is distinguished by reliability, durability and ease of installation, the main thing is to choose and install it correctly.

Special features

The adjoining profile is used for trimming slopes. It is becoming an increasingly popular building material and is gradually replacing roll-tape sealants. Because high-quality plastic provides a first-class stable sealing and reliable sealing of all installation seams that are on the windows. Additionally, the profile is equipped with a special reinforcing mesh. Due to this, it is possible to firmly fix the plaster on the slopes and prevent the formation of irregularities, cracks, shedding and other defects.

The material of the slats is made in strict accordance with the state standard. He is not afraid of mechanical damage, temperature changes, direct solar radiation, it is vapor and moisture resistant.

Installation of the profile is simple and does not take much time.

Device and technical characteristics

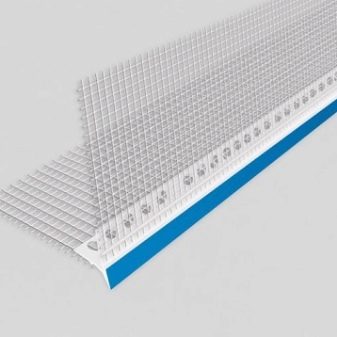

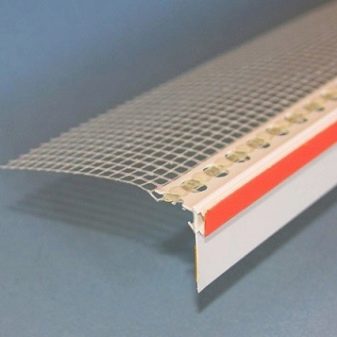

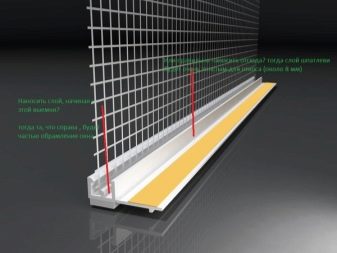

The junction profile consists of several elements.

- Polyvinyl chloride base. The main material for the manufacture of slats is solid PVC, to which is attached a self-adhesive thin plate for sealing, made of polyurethane. Due to this, the profile is attached to the window frame. It provides a dense fixation of structural elements, and also performs the function of a kind of damping gasket - completing the expansion of materials under the influence of temperature and wind. Plate (lamella) ensures the preservation of plaster and slopes.

- Cuff for protection. It is made of soft PVC, similar to plastic.The cuff is necessary for giving an esthetic look of a design. It closes joints, cracks and other defects that exist or may appear on the window block.

- Tear-off bar. On it there is an adhesive strip with a protective film, removing which you can easily fix the polyethylene (membrane) to prevent plaster from falling on the window. If necessary, the film is also easily removed.

- Reinforcing mesh made of alkali resistant material.

Species

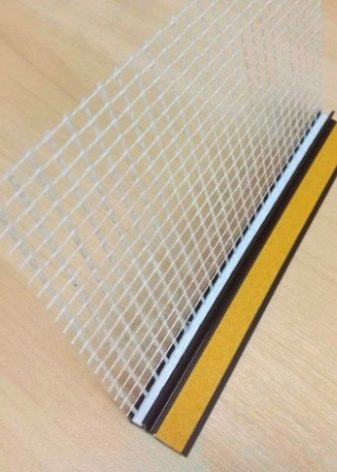

Window profiles come with a grid and without it.

With mesh

It is a thin and even strip shelf with a strong protective mesh and a self-adhesive seal that is designed to frame the window frame. The strip has a neat, aesthetic appearance. And also the profile is equipped with a side strip, which is necessary for fit protective film, protecting the window (door) unit from pollution, moisture, mechanical damage, formation of mold fungus. This is the most common version of the adjacent window profile.

No mesh

Since this type of profile does not have a mesh, it is usually used exclusively for interior decoration. But if you do not plan additional reinforcement, you can apply it to the exterior. This profile makes the process of applying plaster noticeably lighter, guarantees a high-quality and uniform coating.

In some cases, the profile can be supplemented with PVC corners with a grid or profile with an open drip. In the first case, it will be possible to achieve a higher degree of protection of windows and strengthening of corners. In the second, to eliminate the chance of ingress and accumulation of moisture in the corners of the structure, to provide additional reinforcement of the plaster layer, to reduce the number of cracks and other defects.

Scope of application

The plastic profile is used in the process of building window slopes both outside the building and inside the building. It guarantees a clear and reliable fit of the plaster mixture over the entire surface of the slopes.

The adjoining profile is also applied when finishing door slopes in the place of junction with blocks or other facade materials. Another profile serves as an effective "beacon" at 6 and 9 millimeters, based on the size of the mixture layer.

Advantages and disadvantages

Window profiles are popular for their numerous advantages:

- affordable cost;

- simplicity and ease of installation;

- effectiveness in combating cracks between the layer of plaster and window (door) blocks;

- effective protection from the adverse effects of the environment;

- reliable insulation of insulating seams;

- reducing heat loss and heating costs;

- resistance to mechanical damage and dirt (will not become a boot);

- ensuring reliable adhesion of the plaster mixture to the surface;

- esthetic and harmonious appearance;

- no need to use additional sealants.

Among the shortcomings, it is possible to single out only that, if carelessly handling, the profile may be damaged.

Selection rules

When buying material, be sure to pay attention to several important parameters.

- The presence of a protective cuff. If there is no such element, then seams will be visible at the junction of the slope and the frame. In addition, the end of the bar is made of polyurethane foam, which perfectly absorbs dirt and moisture. So, after each window wash the frame will become increasingly dirty, its appearance will become much worse.

- Profile color. In the case when the profile is made of high-quality primary polyvinyl chloride, it has a uniform white shade.This profile is harmoniously and beautifully combined with the window unit. If the material has a gray or dirty gray tone, then the profile is made of recycled PVC. It is not only less aesthetic, but also more fragile.

- Product height For standard work with plaster and putty it is necessary to choose a profile with the smallest height. Moreover, if you plan to finish with insulation, this value increases. On the modern market there are adjoining profiles of different heights: 6 mm, 8 mm, 9 mm and others. They are labeled as follows: 6x2400, with the first digit indicating the height, the second - the length.

All designations are in millimeters.

Mounting scheme

- To begin, mark the line where the window profile will be attached to the frame. To do this, you can use a laser or a normal bubble level.

- Then cut the profile of the required size using special scissors for metal.

- Now thoroughly clean the frame of dust and dirt, in order to achieve the highest quality fit of the plank to the frame. So the connection will definitely be strong and reliable.

- Next, remove the protective film from the strip and fix the lamella in the pre-marked place of the frame.To do this, immediately set the bar on the intended line and press firmly to the frame.

- Then completely remove the protective film and stick the profile.

- Spread reinforcing mesh, plaster the surface.

Remove the bar and film only after the plaster has completely dried.

Make sure that the air temperature in the room does not exceed 40 degrees Celsius. Ideally, it should be about 5 degrees.

You can learn how to plaster window slopes with your own hands by watching the video below.