How to choose a plastic corner for slopes?

At the completion of repair work, the question often arises how to choose the right plastic corner for the slopes. After all, you always want the interior of the house to please the eye with elegant and relaxed design.

Special features

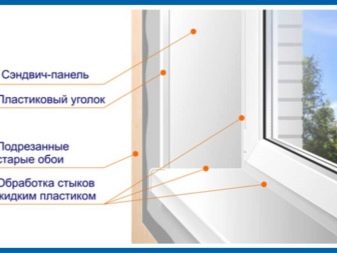

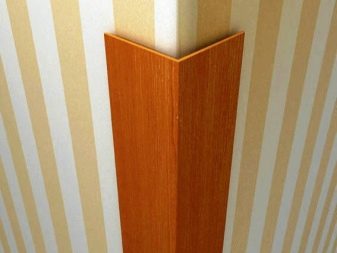

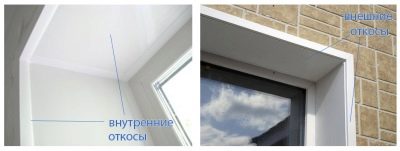

To give the inner corners of window and door openings of the desired and neat shape, install special plastic corners for slopes. This finishing material is part of the decoration and is needed to hide the angular gaps that occur when using materials of different textures. Corners are assembled at the final stage of repair and completely modify the decoration of windows and doors. They not only bring an elegant touch to the overall atmosphere of the house, but also create a protective function.

Corner parts for slopes are made by hot bending PVC sheets using a special technology, due to which they become strong and durable.

They are used in various works on decorating the house and are necessary for:

- facing window and door slopes, arched openings inside the apartment;

- protection of the corner panels of the wall during plastering or wallpapering;

- when laying tile.

PVC corners have many advantages:

- they can close the gaps of any material at an angle of 90 degrees;

- can be used for a long time (service life - up to 25 years) and at the same time do not lose their basic properties;

- Easy installation with glue, which can be done on its own, while respecting the correctness of the calculation of cutting;

- plastic material, comfortable when cutting;

- relatively low cost;

- insignificant weight, which does not load slopes;

- do not require additional painting and processing;

- protect corners from wallpaper wear;

- not influenced by ultraviolet radiation, so do not fade and can be used for a long time;

- due to the huge number of colors and shapes, they perfectly match any interior and add integrity to the whole room design.

The disadvantages include some fragility of the material, so you need to cut carefully and special tools.Also, the corners do not tolerate high temperatures and, when ignited, emit a toxic gas that adversely affects human health.

Kinds

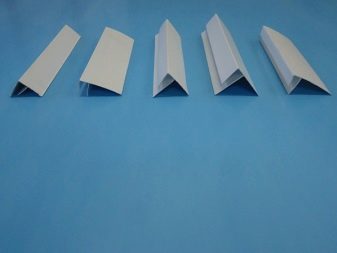

Manufacturers offer various types of plastic PVC corners in accordance with the size and scope of application.

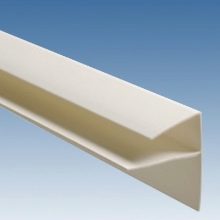

- Standard, or P-profile. It is used to strengthen the window and door slopes, and it is recommended to install it at the initial stage of the installation of slopes. The purpose of this profile is to decorate and protect external corners from deformation. It also helps to hide the gaps between the coatings, which do not connect very tightly.

- Versatile, or L-profile. It is used when installed on curly or arched openings. Such a profile is a flexible corner, the shelves of which converge into a corner of 90 degrees. Very convenient for mounting, because when bent, it keeps well the desired position for installation.

- F-shaped. Without special efforts, it can be fastened to the end sides of the panels, even without glue, since it has a special jumper. Unlike other types of such a profile can be easily removed during the painting of walls or wallpapering.The main purpose of this detail is to hide the gaps between the wall panels, as well as the decor of the openings. In addition, it plays the role of a casing, which fringes a door or a window around the perimeter.

- T-profile It is used if you want to achieve the perfect border of the junction between the slope and the panels. It perfectly connects various finishing materials, which have a heterogeneous texture, and is easily fixed on any surface. When laying tile hides unevenness of the tiles on the joints with a flat base of the floor.

- Removable. This type of corner detail has a latch and has a high ductility. It can easily bend to 3-6 mm. It is not necessary to remove them during the repair - you just need to fill the wallpaper with a spatula under the corners. This allows for assembly much faster.

There is also a self-adhesive version of PVC corners, which is characterized by versatility, since it does not need to buy glue separately. In addition, it has good flexibility, which provides an extremely simple installation. For the convenience of the user, they are often sold in rolls up to 50 meters long, and it is possible to purchase a part of any desired length in order to avoid joints.

In the repair work using plastic and perforated corners. Their purpose is to strengthen and protect internal and external corners from damage and cracks. Often this type of material is used to impart greater strength to protruding joints and leveling the surface.

According to the type of finishing processes, internal and external PVC corners are distinguished. In turn, the outer angle can be 90 or 105 degrees. The angle of 90 degrees is fixed so that only one side of the border is visible, and the angle with a reversal of 105 degrees is mounted with both shelves up.

According to their structure, the products are divided into a rigid structure and a soft, or flexible, folding profile. Rigid design is a classic rectangular profile, both shelves of which are formed into one. Such products are used in the design of the corners where you need to make a bend of 90 degrees.

For the embodiment of the final image of the interior using white or color decorating parts that fit the overall design of the room.

All parts are manufactured according to the standards of the Building Regulations and Rules (SNiP).

Dimensions

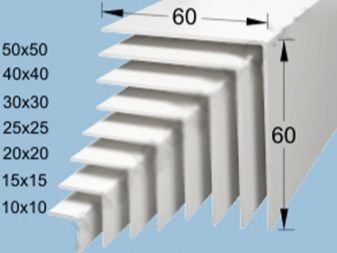

Angular parts are available for sale in narrow strips of length 2600, 2700, 2800 and 3000 mm with the parameters of shelves from 10 to 100 mm.

Depending on the application, angles with different sizes are used:

- for arched openings take 5 * 17 mm, 10 * 20 mm, 15 * 25 mm;

- To create a perfect joint, you will need a T-profile with dimensions of 12 * 10 mm, 18 * 10 mm, 20 * 10 mm, 22 * 10 mm;

- to strengthen the slopes will need a corner in size from 20 * 20 mm to 50 * 50 mm;

- for the slopes on the windows take the corners of small sizes 10 * 10 mm or 15 * 15 mm.

How to install?

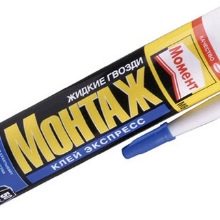

When all the finishing work is completed, you can begin the process of mounting plastic corners. It begins with the selection of glue. There are special adhesives that are used to work with PVC parts. The most suitable option is a compound called “liquid nails”. You will also need a stationery knife with replaceable blades, a handsaw or scissors for cutting metal, a measuring tool, glue and masking tape.

The profile is mounted in several stages.

Regardless of where you need to glue the decorating part (on the window, door or arched opening), you must first take measurements and properly cut the finishing material.

After that you should prepare the surface where the sticking will be done.

- It is necessary to cut off the extra elements that interfere with the fixing of the corner part: pieces of old decorative material or foam, protruding plaster and others;

- degrease well, otherwise the area will not hold well.

Then you need to apply the adhesive directly on the finishing material is not very thick. Press the billet firmly, and remove excess glue. Detail further fix paper tape. It must be pasted in several places and left for a day. After 24 hours it can be removed.

A very convenient option in the design of PVC products - a corner with adhesive tape on the inside. With it, it is enough to remove the film, after which you can immediately glue, pressing down along the entire length. It is very important to immediately put the profile correctly, because the second time it can no longer be used.

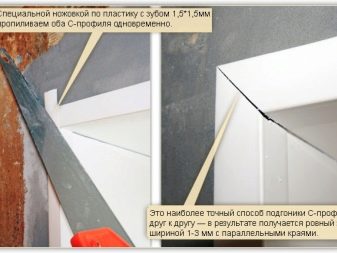

There are several options for joining internal corners:

- the areas are superimposed on each other, while the gaps are covered with a hermetic means or putty to match the material;

- one of the strips is cut to the base, for example, if the upper part is left with allowances of 20 mm on each side, then the side slats are cut to the same level as it;

- perform trimming slats at an angle of 45 degrees.

Tips

There are several recommendations that must be considered when choosing and installing plastic corners for slopes.

- It is necessary to buy finishing material only after all measurements are made, when all the parameters of the slopes are clear. For 90 degrees, a rigid profile is suitable, and for corners with large deviations, use a flexible folding product. In addition, the choice of the correct length of the profile will effectively save when it is purchased.

- The decorative material should be selected after mounting the window or door, when it is known in what condition the openings. So it is easier to choose the type of profile.

- It is necessary to consider for what type of room decor is needed. If you need a plastic product with high wear resistance, it is more practical to mount a wide angle piece, which is particularly durable. And small corners are in perfect harmony with the interior of the room.

- If the flexible corner does not keep its shape, it is better to refuse the purchase.

- Plastic corners are a rather delicate material, so in order to avoid cracks during cuts, it is advisable to use scissors or a hacksaw.

- When the coal slopes are assembled in an apartment with already completed repairs, for the effect of greater fixation, it is necessary to strip a narrow strip along the entire perimeter of the decorated opening from any surface.

- For sticking the corner piece on a plastic surface, it is better to take a tool of the "second" glue-gel type. On the surface covered with plaster or plasterboard, it is preferable to use "liquid nails".

- Works on mounting decorative corners are made only after the completion of all finishing processes.

- When installing it is important to observe the correctness of the material docking in order to avoid unnecessary work with gaps.

- When purchasing a material, it is worth making sure that the profiles are absolutely flat, with symmetrical sides and without deformation.

If you do not follow all the rules for ensuring stability when installing plastic corners, their practical and aesthetic function is lost.

How to install a plastic corner for slopes, see the following video.