Plastic slope installation rules

Slopes are important final details of the window construction. Such details make the window more aesthetic and neat, but their installation sometimes turns into a real problem. Today we will take a closer look at how it is possible to install plastic slopes.

Special features

Slopes play a significant role in the overall window construction. These parts are made from a variety of materials: from natural wood to cheap drywall. However, plastic slopes are considered to be one of the most popular and frequently encountered.They can be found in many homes.

Practical slopes of plastic are chosen by many consumers, since they are versatile and easily fit into many styles of interior. Such details look harmonious in most ensembles, as they have a low-key and neutral look.

However, it is worth paying attention to such a feature of PVC slopes - in conditions of temperature drops and when the house shrinks, they can acquire cracks. Many homeowners face such problems.

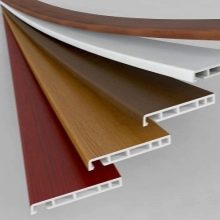

But also plastic slopes are distinguished by the fact that they are represented not only by classic white, but also by multi-colored copies. Due to the wide range, it is possible to choose the best option for a window design of absolutely any color and shade. With a well-chosen set, the whole interior as a whole will look very attractive.

You should not think that plastic slopes can be installed only with plastic window structures. In fact, such elements can also complete windows made from other materials, such as natural wood. The main thing is to choose slopes that fit the frames in color and style.

Installation of plastic slopes may do it yourself.

Of course, for some masters, this work may seem too laborious and difficult, but if you follow simple rules, the result will definitely not disappoint the home master.

Advantages and disadvantages

Currently, plastic slopes are in great demand. They can be found in many city apartments, private houses and even office premises, which once again confirms the universality of such details.

The slopes of plastic are chosen by many consumers, as they have many positive qualities.

- The main advantage of plastic slopes is that they are not subject to rotting, as, for example, options made of natural wood.

- High-quality slopes made of PVC materials are durable. The term of their service is the envy of most other structures present in the market.

- According to experts, the installation of such options slopes only seems to many homeowners difficult. In fact, to carry out such work you do not need to have special knowledge and rich experience - you can easily cope with everything yourself if you follow the instructions.

- Plastic slopes are undemanding in matters of care.They do not need to be treated with protective compounds or cleaned of frequent pollution with expensive means. Such details can be put in order with the help of a usual soap solution or a universal cleaning compound, which is sold in most modern stores.

- With such elements it is permissible to use flexible trim.

- Plastic is not afraid of aggressive household chemicals. For this reason, it can be cleaned using strong detergents that can harm other materials.

- High-quality slopes of PVC materials are not afraid of damp and moisture. Under its influence, these materials do not begin to rot or lose an attractive appearance.

- With the help of plastic slopes, you can easily hide any defects of the joints.

- To install such materials do not need to pre-level and trim the surface of the bases.

- Many consumers say they opted for plastic products because it is cheap, but it looks attractive.

- The range of plastic slopes today gives customers the opportunity to purchase the perfect option for any shade.

- Plastic slopes are not subject to freezing.

- Slopes made of plastic do not have a sharp and unpleasant smell.

- Such plastic structures will not cause the appearance of allergic reactions in households.

- As part of most high-quality plastic slopes there are no hazardous and toxic substances. However, when buying such parts, it is still worth asking for quality certificates to verify this personally.

- Plastic items have good thermal insulation qualities, which are noted by many consumers who have installed such parts.

- Plastic slopes do not need to regularly tint, refreshing the look.

Of course, these elements also have disadvantages, which you definitely need to be familiar with if you want to complement the window design with such details.

- If you plan to install plastic slopes, then you should have free time and patience - this work takes more than one hour. In addition, the design of such elements can take quite a lot of finishing materials (for example, plaster mix).

- After installing plastic slopes, as a rule, a lot of garbage remains, which will take a lot of time to clean.

- Plastic can not be called a very durable material.It can be damaged even if accidentally hit. And also you should not push too hard on the plastic slopes either during installation or after it. This can cause serious damage to such parts.

- In the process of shrinking home plastic slopes can get ugly cracks, get rid of which is unlikely.

- If you purchased colored plastic panels for the design of window designs, then you should be prepared for the fact that over time they may lose their original brightness of color.

- In many PVC-slopes there are toxic components that can harm the health of the household. As mentioned above, for this reason, it is recommended to examine quality certificates in which all information about a product is recorded before purchase.

- In the event of damage or deformation, it is unlikely that the original appearance will be returned to the plastic slopes.

- Such slopes often exfoliate from the windows, because not all the constituent elements can efficiently and reliably adhere to the plastic.

- According to many people, plastic slopes look too simple and patterned in a tandem with windows and doors.With their help, it is unlikely that it will be possible to give the interior a rich and elegant image.

- In rare cases, mold and fungus appear on plastic slopes.

Especially often such problems arise in homes where there is no quality insulation.

As you can see, plastic slopes have quite a lot of pros and cons. Of course, many problems with such parts can be avoided if they are properly installed and provide the living space with good thermal insulation. It is equally important to acquire such components in proven retail outlets in order not to stumble upon low-quality goods.

Kinds

There are several types of plastic slopes. Let's get to know them better.

PVC panels

Such types of slopes are most common. They are very popular because they have a democratic cost and are established in a short time. However, we must not forget that cheapness in this case may indicate a low quality of materials, therefore, one should not expect too much from PVC panels.

Slopes of PVC panels have one serious drawback - they are characterized by low strength.

To damage such materials is not difficult, and for this you do not need to make great efforts.

Sandwich panels

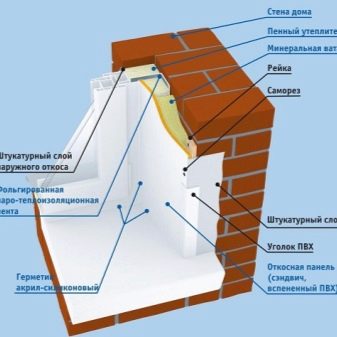

They are more modern and progressive materials. Such slopes have 2 protective layers, which in turn, revet insulated layer. Such details are good because they do not require additional insulation.

Today in stores you can find sandwich panels of various modifications. Such materials may have different performance characteristics and cost, so consumers with any requirements and budget can choose the right product.

Outdoor

External slopes in the window construction are no less important than internal ones. These parts have a beneficial effect on the service life of windows, as they provide good protection from the outside.

Plastic exterior slopes have several important advantages:

- they to a certain extent warm both windows and walls;

- provide the room with additional noise insulation;

- make the window unit more durable and resistant to wear;

- with external plastic slopes the window block looks more aesthetically pleasing and neat.

For the exterior design of windows can be used as a sandwich panel, and PVC parts.

Universal

No less practical are universal slopes made of plastic. The similar detail goes together with a platband and a decorative slip. In this case, the front side of the universal slope is covered with a special protective film, due to which this element is less susceptible to damage during transportation and installation.

Universal slopes have many advantages. Here are the main ones:

- easy installation;

- attractive appearance;

- UV resistance;

- affordable cost.

In addition, plastic slopes may have different textures - rough or glossy. Of course, consumers more often choose the second option, since such details are less intricate in the care.

Device

Popular PVC panels have different sizes. Such parts are extrusion panel with a length of 10 mm. The width of this part is 250 mm. Also in it there is a platband with a cable channel cover attached to it. If necessary, when installing such parts, you can use the expander.

As for the sandwich panels, they are available in the following dimensional framework:

- 1500 x 3000 x 10 mm;

- 2000 x 3000 x 10 mm;

- 1500 x 3000 x 24 mm;

- 1500 x 3000 x 32 mm.

The thickness of the front plastic in this case is 0.7 mm, and the working surface is 0.5 mm.

The thickness of the slope will directly depend on the rigidity of the entire structure as a whole, even if the height of the window is modest.

Traditional plastic panels differ from PVC parts in that they have a fixed bend angle of 90 degrees, and this is not always convenient. PVC platband with cable channel can be installed at any angle.

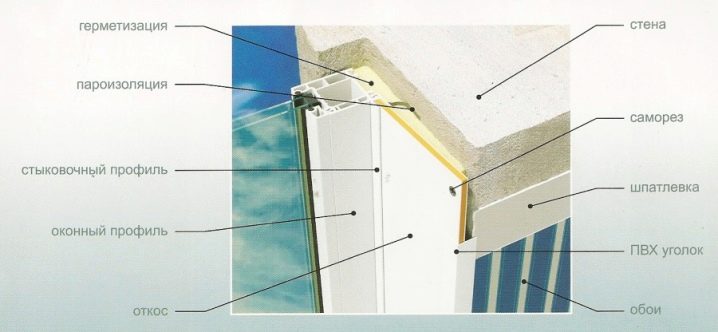

The component unit of the plastic slopes are starting profiles. They are as follows:

- I-profile;

- F-profile;

- L-profile.

I-profile provides for installation directly on the wallto which it is planned to fix slopes in the future. For this you can use simple screws. This type of profile has a shape resembling the letter “I”, so its installation, as a rule, is not difficult.

Such profiles are used not only when installing plastic, but also plasterboard slopes. In addition, they can be used for mounting various decorative elements.

F-profile has the shape of the corresponding lettertherefore, it is installed quite quickly and easily.

It is also permissible to mount this part with plastic slopes and parts from sandwich panels.

L-profile is most often used when installing plastic slopes. It is set perpendicular to the window. These parts have a normal turn.

In addition to the starting profile, plastic slopes also have the following components:

- slope panel;

- casing;

- corners.

Required tools

If you decide to make the installation of plastic slopes with your own hands, then you should stock up on the following materials and tools:

- starting profile;

- wooden bar;

- external and internal corners of plastic;

- platbands;

- glue;

- high-quality insulation;

- waterproofing tape;

- sealant;

- polyurethane foam;

- putty knife;

- dry putty;

- clean and dry container;

- jigsaw;

- building level;

- screwdriver;

- construction gun for "liquid nails";

- self-tapping screws.

Acquire only high-quality and branded products, so that in the process of work you do not have unnecessary problems.

DIY assembly

If you stocked up with all the necessary fixtures, you can proceed directly to the installation of plastic slopes. Consider step by step how to do it yourself, without involving experienced craftsmen.

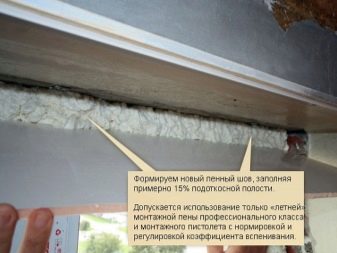

There are 2 ways to install plastic slopes near the window structures. So, if the assembly seam at the base is too large, then the work must be done in a certain way.

- First you need to remove all excess foam. The stationery knife will easily cope with this task. However, do not remove too much foam mass, since the cut must be flush with the frame.

- And also need to remove the plaster, which is in poor condition and ready to crumble.

You do not need to remove absolutely the entire layer of finishing - it is enough to remove only the damaged elements.

- The surface of the base must be cleaned of any dirt and dust.

- Treat all substrate surfaces with a primer. It is advisable to give preference to formulations with deep penetration with antiseptic ingredients in the content.

- Next, you should install a wooden rail. It must be fixed on the outer perimeter of the window opening.For fixing this part it is better to use dowels and screws.

- It is recommended to make the design in such a way that it is installed on both the vertical and horizontal sections so that the racks do not come into contact with the upper part.

- This is followed by one of the most important procedures - cutting the foam to form a groove in which the plastic panel will be installed in the future. Note that each element should dip approximately 0.8-10 mm.

- Trimming should be done near the frame so that the fit is as tight as possible.

- After completing all of the above steps, you need to cut the parts.

- Plastic can be cut with a hacksaw or electric jigsaw. At the same time on the edges of the slopes may remain notches, which can be removed with sandpaper.

- Now you can make a preliminary installation.

This way you can determine if there are any defects or problems in the resulting structure.

- If you are using double-sided plastic, then you should mark the wrong side and slightly oshkurit it. So you can achieve better adhesion of materials.

- Details should be installed in turn in the right places. Previously they need to be inserted into the prepared groove. Then all elements are carefully aligned using the level.

- The outer edge of the panels needs to be pushed back and dotted with foam. But at the same time be very careful, as its surplus may warp the material.

- Fix the parts among themselves with masking tape.

It should be glued to the joints and along the perimeter of the walls.

In order for the resulting structure to dry completely, it will take about a day. After that, you can proceed directly to the finishing measures - the slopes are processed with sealant and adjusted to the corners, which are planted on the glue.

There is another way to install slopes, which is very different from the above. With this technology, fasteners of all parts are much faster and easier using a starting profile.

First, the bases are prepared for the future installation of slopes - it is necessary to clean all surfaces and remove all defects from them. Next, you will need to apply a primer mixture to all parts of the base.

- Then you need to install wooden slats.They need to be mounted near the frame. Fasteners should be made in such a way that the bar slightly went on it.

- Note that with this method of installation, the rail must be pre-processed at an angle. To do this, you can use a plane. The slope should be equal to the angle of the slope. Of course, you can use the saw, but with such a tool, ideally accurate performance is simply not possible.

- Each component part should be customized strictly individually and fixed on dowels. It is not recommended to use simple screws, as they will not be able to provide maximum reliable fastening of materials.

- Next comes the turn of the start profile installation. It must be attached to the screws to a pre-installed and secured bar. To carry out such work, it is recommended to use rigid material to make the slopes stronger and more reliable.

Do not use soft and cheap profiles, as they can easily and quickly bend.

- Make all the necessary measurements. It should be borne in mind that the plane should be measured starting from the frame, and not from the edge of the profile. Transfer the resulting parameters to a separate sheet, and then draw up detailing. Transfer all measurements to the panels themselves, and then trim them.

- Then you can proceed to the direct installation of plastic slopes. They should be fixed with foam. It needs to be poured in small volumes.

- Note that next to the window frame voids will be larger than the edge. That is why the foam should be distributed so that nowhere took place swelling.

- Next, fix the panel with adhesive tape glued to the walls. After that, the finishing of the windows with plastic slopes is completed. It remains only to apply the lining.

When installing the side parts of the window slopes should be optimally distribute the insulating material. If the walls in the dwelling are already insulated, then this stage can be skipped.

In this case, it is permissible to proceed to the installation of decorative corners only after the entire structure has completely dried. Connect external modules and trim angles to 45 degrees. Treat all joints with sealant.

Plastic slopes look good in a tandem with doors. To install the door slopes of plastic, you will need to carry out the following work.

- First you need to mount the frame. To do this, you will need to measure the doorway and cut the slats down from the measurements made.

- Drill holes for dowels on the markup and secure the slats.

- For uneven bases, wedges or thin bars can be used.

- Then you need to make the cutting panels. At the same time, carefully measure the angles of inclination.

- Cut 3 blanks - 2 side parts and one for the lintel. Attach these parts to the walls to notice the flaws.

- Starting slope to attach to the wall in the doorway.

- Trim all the corner seams, and then mark the bend line on the back of the blank.

- Make a vertical cut with a knife in the panel cavity, without touching the face of the part.

- Reapply the slope to the base, correct it, and attach to the small screws to the frame.

- Now you need to fix the outstanding edge. To do this, you need to define the border of the panel, move away from it 2 cm in the direction of the opening and outline the vertical bar.

- Based on the markup, you need to drill 6-7 holes, and then hammer wooden wedges into them.

- Press the edge of the slope to the wall and screw it.

- Now you can install the second slope, and then make plastic liner plastic.

- The top edge of the workpiece should cover the ends of the side protruding parts.

- Now you need to cut the material at an angle and glue the joints.

- Internal seams need to be sealed.

Door slopes made of plastic can be installed and frameless way. To do this:

- to process bases with soil;

- cut plastic panels, based on the measurements made;

- apply glue to the workpiece and press the part to the surface of the base;

- edges and corners can be adjusted until the glue is completely frozen;

- then glue the side slopes and close the lintel;

- in the completion of the work you need to fill the seams with sealant.

How to finish?

In the case of window slopes, it is necessary to degrease those places in which the panels are most closely in contact with each other and the sill. After this, the seams and gaps should be covered with a sealant (preferably acrylic). Remove traces of glue and sealant with a cloth moistened with acetone. The space under the window sill is better to finish with plaster.

Themselves slopes if desired, you can paint, plaster, or "close" with a decorative stone. It all depends on the preferences of the owners.

Of course, before applying decorative materials, all surfaces should be cleaned from building dust, if any.

Tips and tricks

- Before attaching wooden blocks when installing plastic window slopes, it is advisable to treat them with anti-fungal protective agents in order to protect them from imminent decay. The same applies to door designs.

- When trimming with plastic slopes a window opening, it is necessary to use glue and sealant very carefully. No need to pour them in large quantities.

- It is recommended to install plastic slopes in a well-heated room, since such parts become softer when heated. So, working with this material will be much easier.

- Detailing can be done in different ways - transfer measurements to the material or make a stencil, but whichever option you choose, you need to take into account that you will need an extra 10 mm to insert into the groove. In addition, it is necessary to carefully measure the thickness of the necessary parts, as they will form a common perimeter.

- If you are going to sheathe a heater along with the slopes, then it should be selected so that it fits the width of the gap and does not conflict with the materials around it.

- Note that the insulation of window slopes will be useless if you have not laid out the insulation around the perimeter, but installed it in separate fragments.

- Plastic door slopes should be selected in accordance with the color and texture of the door. For example, panels that imitate this natural material are ideal for wood / wood webs.

If you plan to install an F-profile, then you should take into account that it can only be attached to completely cleaned surfaces.

Beautiful examples

- Laconic PVC slopes in tandem with plastic windows of the same color will look bright and expressive if you surround the window opening with orange, coral or red textured wallpaper. Dilute such a bold contrast with live plants in pots on the windowsill.

- The plastic slopes made under the color of wood with a natural pattern look very nice and expensive. Such elements will be in harmony not only with wooden windows, but also with structures made of plastic under the tree. Surrounding surfaces can be trimmed with materials in pastel colors to create a cozy atmosphere.

- Simple white door slopes are recommended to be installed only with doors of the same design. Similar details will look interesting in an ensemble with contrasting wall trim.

You can find out how to do the installation of the plased slopes by looking at the video below.