How to choose a window bar?

Currently, the popularity of natural building materials is returning. Production companies, using the most advanced domestic and foreign technologies, offer consumers lumber of excellent quality from a wide variety of tree species, which are used to design windows and doors. This article will be devoted to the choice of window bar.

Features and benefits

The window bar is a profile-molded product, which is manufactured in two ways: the product can be glued or solid. The strength of glued laminated timber is not only not inferior to the whole, but even surpasses it. This is due to the fact that the wood fibers are arranged when gluing in a special way, which gives the material high strength.Solid timber is recommended to be used in climatic zones with a temperate climate without sharp fluctuations in temperature throughout the year.

Most modern construction organizations give preference to the glued version. Firstly, it gives significantly less shrinkage, and secondly, it is durable and reliable.

The versatility of this building material makes it possible to use it in completely different temperature conditions.

For the manufacture of window beams used wood of different wood species.

- The cheapest option is a spruce or pine. The latter is easily processed and is a building material with high mechanical strength and high thermal resistance.

- Larch is the best option in terms of price-quality ratio. It has good water resistance, is not subject to rotting and durable.

- Well, the most expensive, elite and reliable in this series is oak bar. However, as in the case of larch, when you buy this material you need to carefully monitor the humidity values during storage and the conditions of their drying.Oak has excellent frost resistance and increased insulation performance. Mechanically very durable and water-resistant.

Qualitative windows from a wooden bar have many advantages:

- safety and environmental friendliness caused by natural raw materials, namely wood;

- high thermal insulation and sound insulation, in a house with such windows you will not be distracted by extraneous street noise;

- durability and external aesthetics;

- The window bar tolerates increased loads for bending and compression, it is resistant to mechanical damage.

Production technology

In the production of laminated veneer lumber, it is necessary that gluing be carried out on high-tech equipment.

The manufacturing process is very complicated and the quality of the output produced at the output depends on its quality.

- First of all, wood is sorted according to criteria such as type, degree of humidity and, of course, quality. Then there is a cut of wood on the machines and drying in special chambers. The percentage of moisture in the wood should not exceed 12%.

- Next comes the process of rejection of unacceptable quality slats.The remaining suitable lamellae are treated with special mixtures and impregnations and glued together in the final format of the finished product.

- In the production of laminated veneer lumber, usually 3 to 5 lamels are used. The lamel is a board which receive when cutting wood.

Types and classification

Let's talk about the classification and types of window bars used in homes.

It can be classified by the following features:

- manufacturing technology;

- type of wood;

- variety;

- number of joints;

- types of cut;

- types of profile timber.

It should be said that for timber from larch and pine requirements according to GOST and TU are not as high as for oak material, eg. If you choose between wood according to GOST and TU, then you should, of course, make a choice in favor of Gostovskoy products, as it is of higher quality.

Oak window frames are three- or four-layered. The latter are used in areas with extremely low temperatures (below -25 degrees Celsius).

Oak timber is divided into several types.

- Grade "A". This type is made without defects and is the most durable.

- "AB". Internal lamellae may be spliced, minor defects are allowed.Lamellae can vary in their color tone. That is why you should pay attention to the monotony and uniformity of color. In this case, uniform color is a quality indicator.

- "AT". Any defects of wood both outside and inside, as well as spliced strips of lamellae are allowed. Voids, damage and knots reduce the strength and durability of the material.

The window timber is divided into three categories according to the number of joints of glued surfaces: KKK, DKK and DKD, respectively, the third, second and first categories.

By types of cut, it is divided into radial and tangential.

- At a radial saw cut, the timber has a uniform color and texture. Such a timber is durable and is not deformed in building structures.

- When tangential cutting it has a pronounced texture and wave-like pattern. Such products are more aesthetic.

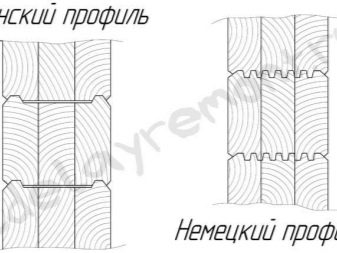

According to the profile types, the timber is divided into Scandinavian (Finnish) and German (“comb”).

- Profile "comb" has a more rigid connection and increased thermal insulation. And after drying, products from such a profile become non-separable.

- Finnish profile can be easily understood if necessary.

Stamps and prices

Among the popular domestic producers of timber can be noted woodworking plant "Energy South" (Rostov-on-Don), Moscow "Vyshnevolotsky lespromhoz", "Siblux" (Biysk) and many others. The average price of oak bar per meter is: grade "A" - from 550 to 1,200 rubles, grade "AB" - from 500 to 850 rubles, and finally, grade "B" - from 450 to 770 rubles.

Among Russian producers of windows from a bar, LLC Bisectrix (St. Petersburg) is distinguished. A double-glazed window made of glued laminated timber of the 1st or 3rd category pine with a profile width of 78 millimeters will cost from 9,300 rubles. The same glass unit, but from larch it will cost about 12,300 rubles and more. When using glued oak beams, the price will increase to 17,500 thousand rubles and more. Also noteworthy is the Irbis plant in Novosibirsk. It produces window beams of larch at prices from 435 rubles per square meter.

Modern technologies for the manufacture of wood window beams allow wooden windows not only to compete with plastic analogues, but also to exceed them in aesthetic and other parameters.

How the glued timber for wooden windows is made, look in the following video.