Membrane waterproofing: types of materials and the benefits of using

Constant exposure to groundwater and soil moisture is extremely negative for the performance of the foundation. Water is a known catalyst for chemical reactions, which gradually leads to partial or complete destruction of the bearing elements of buildings. That is why to increase its service life using waterproofing materials. The most modern of these are membranes.

Special features

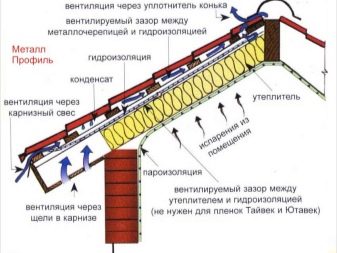

Waterproofing membrane materials are widely used in the arrangement of the roof, as well as basements and basements. Depending on the main components in the structure of the coating, several different types of membranes are distinguished, each of which has its own advantages, disadvantages, and peculiarities of use.Therefore, it is very important to choose the membrane correctly - only in this case the coating will provide effective and long protection against water and precipitation. The membrane is used to perform work of several types:

- moisture-proof - a set of measures aimed at protecting the building from the ingress of surface moisture and capillary suction;

- waterproofing - These are works that are designed to protect the structure from surface moisture, which directly enters the building as a result of the accumulation of water near the foundation (groundwater or formed as a result of prolonged precipitation and melting snow).

Benefits

Membrane insulation is one of the most popular ways to protect floors from the adverse effects of moisture. This is due to its exceptional technical and physical characteristics:

- Membrane materials stretch very well due to increased elasticity and tensile strength.

- Differ in quite high resistance to critical temperature conditions. The working range of coverage ranges from -60 to +120 degrees Celsius.

- Low weight of the material, which greatly facilitates its transportation and simplifies the technology of the device.

- When laying, there is no need to use fire - and this is the main difference between membranes and roll materials on a bitumen base.

- Long service life. With proper installation of membranes, they will serve at least 50 years.

- One of the main components of the composition of the membrane are flame retardants, which cause a high degree of flammability of the coating.

- The material can fit on all types of foundations, however, the coating has the greatest efficiency in straight sections of the roof, in which there are no roof structures (pipes, light boxes, lift shafts, etc.).

- The membrane is characterized by pronounced diffusion properties, so moisture does not accumulate under it.

- Membrane materials can be laid even at sub-zero temperatures.

- You can even install this coating on thermal insulation material. This can significantly reduce the cost of forming a leveling screed.

Species

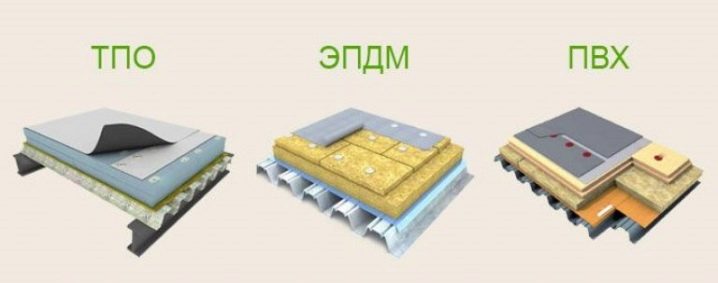

There are several types of membrane waterproofing:

- PVC;

- TPO;

- EPDM

Also there is a liquid membrane and roll. Let us dwell on each of these varieties of waterproofing coating.

PVC

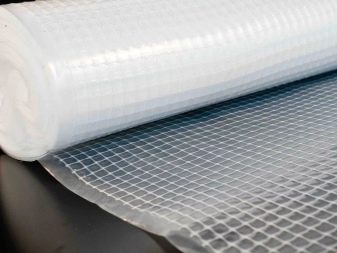

Polyvinyl chloride film membrane today is considered the most popular finishing option, as well as a fairly economical solution for arranging the required waterproofing. This material is a two-layer vapor-permeable non-reinforced PVC-canvas: its upper part consists of chalk, as well as flame retardants and special plasticizers, and the lower one is made of PVC in pure form with a small content of dyes.

Due to the influence of the main components in the structure, the PVC membrane is a wind- and hydro-protective film, which provides increased hygroscopicity and resistance to the effects of acid-base solutions and their salts, in a large number represented in soils of any type.

The material has good elasticity, so that it can be fixed at the lowest temperatures.

Dyeing pigments in the composition of the membrane play an important role - they allow in the shortest possible time to detect the places of breakdowns and promptly repair damage to the integrity of the waterproofing layer.Polyvinyl chloride membranes are available in various versions: they can have different thicknesses, which makes it possible to make the most efficient use of the coating. At the same time, the choice of one or another size, in the first place, is influenced by the depth of the foundation - the larger it is, the thicker the films should be.

Waterproofing, as a rule, keeps within on unprepared surfaces. However, it should be borne in mind that direct interaction with phenol-containing foams, as well as bitumen-based materials or polystyrene foam often leads to a violation of the integrity of the coating. To avoid this, many manufacturers form another lining layer made of geotextiles. It effectively protects the material from the unpleasant effects of any contact with the above substances.

One of the most important advantages of PVC membranes is the ease, simplicity and speed of joining the canvases to each other. This procedure is carried out using a building hair dryer, which is exposed to hot air. This technology causes high strength and maximum tightness of the seams, which overlap and form a smooth seamless coating.

Among the drawbacks of using PVC membranes is its weak resistance to mechanical damage, as well as its low environmental friendliness due to its volatile plasticizers.

Tpo

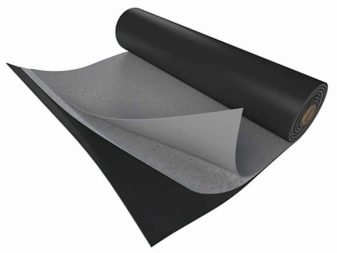

This type of membrane waterproofing materials is created from a polymer blend, the main components of which are ethylene-propylene rubber, as well as polypropylene. This is the so-called rubber membrane. The composition causes the compound properties of rubber and plastic, and the introduction of special equipment and plasticizers makes the membrane flammable and most hygroscopic. Due to the reinforcing layer of synthetic fibers, the membrane acquires high strength and durability.

The main advantage of the material is its increased elasticity and tensile strength. And besides, TPO-coating made from natural materials is environmentally safe and can be used in rooms where adults and children live. This type of membrane has found wide application in waterproofing pools, it is protected by tanks for the transport of drinking water, and also lined with artificial reservoirs.

In the arrangement of foundation insulation, such coatings are used quite rarely - the reason lies in their rather high price, which is often unavailable to most of our compatriots.

EPDM

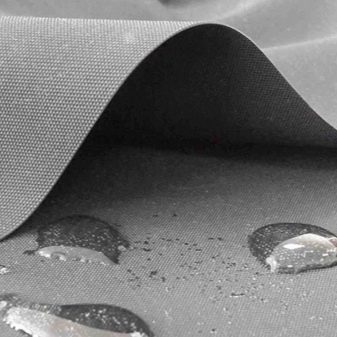

The EPDM membrane has extremely high technical and physical characteristics. This is a very elastic coating that easily withstands the movements of the most diverse type, it exhibits particular flexibility at critical low temperatures in winter and does not change its operational properties in the summer heat.

The advantage of EPDM membranes over other coatings is their compatibility with all kinds of bitumen materials and absolute environmental friendliness.

But among the shortcomings can be identified the adhesive component in the connection between the canvases of such a film. The seam obtained in this case does not differ due reliability and adhesion strength is significantly inferior to its welded counterparts. Such indicators of strength and durability of the coating are due to the introduction of synthetic rubber into its composition, as well as the reinforcement mesh of polyester.

Installation

Flat membranes are materials produced from high or low density polyethylene, and polyolefin or PVC can also be used as raw materials.Such membranes have in their structure two layers of films, each of which has a thickness of less than 2 mm, on the surface of certain types there is corrugation, due to which a large adhesion with coatings is provided.

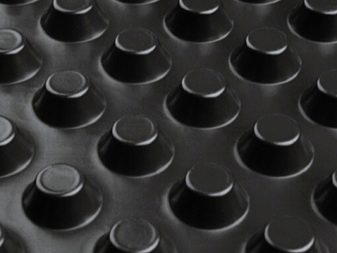

Profiled membranes are made from HDPE. Visually, this material resembles sheets with a square or round section, as well as several protrusions in the form of spikes. That is why many people call the membrane pimply.

This is a separate type of membrane design. Its feature is profiled coatings. This design makes the material truly versatile and allows you to perform a variety of tasks:

- When the profile is fixed to the basement wall, a small gap is formed, which forms an air cushion, provides the necessary ventilation and maintains the necessary temperature. A certain ordered system of protrusions on the elements of the membrane creates all the conditions for the uniform distribution of the degree of soil pressure on the walls of the supports and minimizes the risk of the occurrence of point loads.

- When fastening a profile directly to the ground in combination with geotextile, such a membrane plays the role of a vertical drainage system of the near-wall type,provides effective removal of excess moisture and significantly reduces the amount of groundwater.

Membrane waterproofing materials can be stacked in several ways:

- Flat film creeps on a flat base, always dry. Sheets should be connected with each other overlap by 5-10 cm, welding is used to fix them to each other, but the use of construction adhesive tape or adhesives is allowed.

- Self-adhesive membranes have a protective layer covered with thin paper. Before use, it is removed and the film is glued by pressing and rolling it tightly with a roller. Such membranes are stacked with a large overlap.

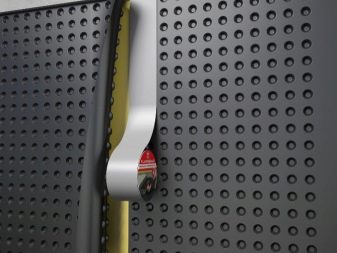

- Profiled membranes stacked using mechanical fasteners, as well as special laminated strips and pressure plates.

Manufacturers Overview

The most popular membranes are "TechnoNIKOL" and Tyvek Soft.

"TekhnoNIKOL" produces modern waterproofing materials that are of high quality and durability. The assortment list includes several types of membranes:

- Super premium class - coating, which is widely used in the northern regions with harsh climatic conditions.Such a membrane consists of three layers of PVC with the addition of a large number of flame retardants and plasticizers, which increase the resistance of the coating to fire and adverse weather factors.

- The premium membrane has the same performance characteristics, but is used on flat surfaces.

- Membranes for waterproofing structural elements of bridges and tunnels.

- Polymeric membranes are popular for arranging swimming pools and other rooms with high humidity.

Tyvek Soft waterproofing membrane is another market leader in waterproofing products, which features a durable polypropylene-based coating.

Among the advantages of this brand include:

- resistance to UV radiation;

- increased moisture resistance;

- allows you to create a favorable microclimate in a residential area for several decades.

How the installation of the membrane on a flat roof occurs, you will learn from the following video.