Modular ladders: types and installation

The transition from one floor to another in private homes takes place with the help of stairs. Their design has not changed much over many years, however, due to improvements and the emergence of new methods for the production of materials, these devices have become stronger, lighter and more practical. The development of trends in design and construction changed the overall appearance of the product. The most visible example of stairs, including old customs and new building materials, will be modular.

It is not difficult to make such an option on your own, it is important to understand the sequence of work, to have basic knowledge of handling the tool and draw a diagram with the necessary calculations.

Special features

It may seem that the modular stairs and their fences are intended only for decoration, but this is a wrong opinion.The materials used and the method of attachment give modular structures a large level of strength. One more indispensable advantage of a modular staircase is a small consumption of necessary materials and a compact design, which makes it possible to install the product in a small area.

In addition, time-appropriate design and reasonable cost make modular designs quite attractive for their use in the interior.

To understand the principle of modular construction, you must first look at the usual stairs from the monolith. Absolutely monolithic structures, of course, does not happen, as additional details and accessories will always take place. However, structures made of concrete or metal are often made in one piece in the main bearing part. In this case, with a modular product, the carrier part is constructed from separate parts.

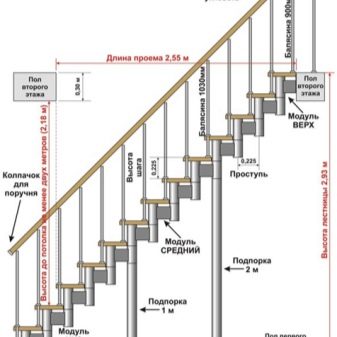

The joining parts of the modular ladder design the frame and produce its attachment to the ceiling. The standard set of elements, their number and size vary depending on the configuration of the premises, the distance between the floors, and the angles of inclination.In fact, the installation of the product occurs as an assembly designer. And this design has both advantages and disadvantages.

The usual equipment of this type consists of the following parts:

- elements of the product frame;

- steps;

- support legs (they are also called support parts);

- handrails;

- railing rails (balusters).

Depending on the expected load, conditions of use and requests for design compliance, components for modular designs can be made of the following materials:

- Stainless steel. It is allocated with high protection against corrosion and influences of the aggressive atmospheric phenomena.

- Structural steel. In this case, emphasis is placed on the mixed aesthetic properties and protection, which are created using the intended paint and polymer compositions.

- Wood. A rarely used option that is used at low loads and in the case of the priority of decorative qualities.

For the steps mainly used polyvinyl chloride material or wood. The texture of natural material adds naturalness and closeness to the nature of the product,especially in the variant with the use of solid wood. Used to achieve this effect and the material of veneer sheets, glued or pressed.

Today, angular designs on metal frame are quite popular. They are suitable for giving, and for a private house. Such a ladder is easy to assemble and has more positive than negative reviews.

Advantages and disadvantages

Just like all designs, modular ladders have their pros and cons. The result of the product depends only on individual preferences. The main advantages of these products can be noted:

- A large number of different types and stylistic directions, makes it possible to choose any option in the range of material from which the stairs are made, and color palettes. The modular design is great for any interior.

- Easy installation and repair. Such qualities give the structure fastenings and design features.

- The property of adjusting the mechanism, capable of turning the structure up to three hundred and sixty degrees.

- The ability to combine several suitable materials in the application of mounting steps.

- Low cost of the product.

- In the swivel or screw versions takes a small area of the room.

- Low complexity of installation. In some cases, for the repair of this design it is possible to change the part in need.

It should be noted and the disadvantages. Ability to settle and relax in the joints of the structure. To avoid these problems, it is necessary to install auxiliary elements, because of which the general appearance of the interior deteriorates.

In the variant with a large width of the steps, under load, the material from which they are made may bend. As a result, loosening and distortion of the structure occurs. To prevent this, steps must be reinforced with corners, which makes it possible to attach the ladder to the base. It is advisable to install them through each step.

Types of designs

Before you decide to build a modular structure in your home, you need to think carefully about its location and a certain type. A variety can be any.

- Marching, a simple straight staircase with large steps. It is perfectly adapted for its purpose, however, because of its design, it requires a large space in the room.

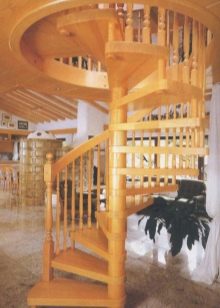

- Screw the staircase occupies a small area of the room, but when you climb or descend along it, you have to expend effort.

- Swivel with auxiliary platforms. This type of ladder does not take up much space, and this design makes it easy to move along it. It is made of several marches with reversal platforms.

Such products have one bright distinguishing feature - the chain kosour. It becomes an accenting fragment of the whole structure. The bend itself is constructed from a set of parts that can be made both straight and at any angle, which makes it possible to mount a ladder of almost any configuration. Kosour is attached to the lower and upper support parts of the stages, which ensures the necessary reliability for the entire product.

The supporting part, which adds strength, becomes a supporting pipe, which is installed every one and a half meters. But if there is a strong wall nearby made of durable material, you can do without this element, with the support of the wall.

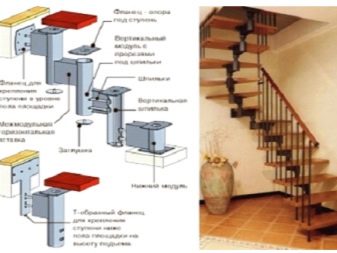

In addition to the above-described distinguishing features of the modular ladder, there are three more options for assembling modules.Each of them has its advantages and disadvantages that must be considered when choosing a staircase.

One of them is the manufacture of a coupled kosour by mounting its parts “element into element” and fastening them with a pair of fragments with fixing bolts. Such designs are the stairs of the old generation and have a large number of drawbacks. First, this alternation of steps is firmly fixed, which makes it impossible to regulate them. The second, after installation, a small curvature is obtained, which is not corrected even with the help of locking bolts. Third, the material has a sagging, over time, the whole structure settles. However, there are advantages, for example, ease and speed of installation of modules.

The second method of assembling and designing the elements of a ladder is made using threaded studs. This product does not have, as the previous version, the curvature of the kosour. However, the complexity of the installation covers this advantage. And the inability to adjust the steps in height enhances the negative impression. Through some load when using it, screw connections are weakened, which require constant tightening, which is very difficult.

The last version of the stairs from the modules is a combination of a multitude of developments and improvements, the instances described above and made using the clamp method. The biggest advantage of such products is obtained by the ability to adjust the size of the steps.

In addition to adjusting the rotation of the element, it is possible to rotate the very fastening of the steps.

Taking into account the mounting of the screw connection for these structures, the fastening force is differently distributed, and the structure is not loosened for a longer time. In all cases, you can use fasteners that hold the ladder. With their help it is possible to fix one part of the march to the wall, and the other to the handrail, which will be the main element. However, they are often used in second-generation modular products. Such simple fasteners are placed between the steps, increasing the strength of the whole structure.

Today designs with rotation by 180 degrees and platforms are rather popular. For them, it is best to choose prefabricated components manufactured in Russia.

Installation Recommendations

With a ready-made design scheme, it is possible to use several methods.One of them is to order the stairs from the manufacturer according to the plan. Another is to select all the necessary details of a modular ladder in specialized stores. The third is to make the modules yourself. What to choose from this, everyone decides for himself.

The best and easiest option is to place an order with the manufacturer. Since in the end you get a finished design with delivery, made according to all standards and qualities, you only need to design it in the right place, and this does not require special skills.

Initially, it is necessary to fix on the floor the main module of the product, which will become its base. To do this, first you need to measure the desired distance and mark it.

All measurements and counts must exist in the product documents or in a pre-prepared scheme.

Next, setting the element in the required place, markings are made for drilling. Then you will need a drill or a hammer drill to drill holes for fasteners. Install the stair part in the marked place and fix it with the fastening element. Then install the modules of the construction in sequence.

After the penultimate part is installed, it is necessary to check the reliability of fastening of the entire product. What is needed to match the configuration of the kosour and that it does not require dismantling the last module. After checking, in case of correctness, you should install the finishing element, pressing it to the overlap between floors or to the wall surface. Next, you need to mark the points for mounting holes, remove the last element and drill the place to install fasteners. Then we install the module back and fix it in the intended place. Further, using fixation bolts, all elements of the kosour are fastened.

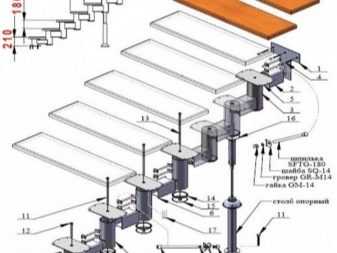

The final work includes the installation of fasteners for every detail. This is done by a simple method. Elements have eight holes, four of them are needed for fixing to the details kosoura. You can only put the plate to the part and screw it up with four bolts.

Next steps are set. Initially necessary, if they are made of wood, attach them to the intended place. Adjust in place and bottom mark the holes for fasteners.Then drill one millimeter hole through which the steps are fixed.

When the design does not provide for reinforcement, steps need to be strengthened against the wall auxiliary. Here you can use simple corners.

Assembling of staircases in a private house can be done independently. Before you collect it you need to make a drawing and calculate the amount of materials required.

Interesting examples

Very attractive - a screw version, thanks to this design does not require a large space, while it looks fully presentable, and fits well with any interior decoration, emphasizing the center of the entire room.

Wall option also does not take up much space, but despite its simplicity is the most common solution of design ideas. Such interfloor ladders are adapted to any situation.

A beautiful product with a bend, looks very charming, but requires a large area of the room. However, due to the design features, such a staircase can visually expand the space.

See below for how to install a modular ladder.