Features of modern metal stairs for the home: manufacturing and finishing

For the manufacture of stairs in Russia, the metal is used most often. It is cheaper than natural stone, and statistics show that metal ladders are second in the number of wooden ones in terms of installation frequency.

Features of metal structures: the pros and cons

In private construction, metal ladders are used less frequently than in industrial ones, where, for example, metal ladders for sewer manholes are widespread. But the main advantage and advantage of steel stairs is that they can be combined. The combination of stone and glass trim is just great.

There are several other advantages.

- High level of strength and durability. Metal is among the strongest and most reliable materials. Structures made from it are resistant to stress, damage, temperature changes, exposure to aggressive substances.

- Long service life. Such ladders serve more than 50 years.

- Fireproof. Iron stairs do not burn and do not support burning.

- Easy operation. The ladders made of metal practically do not demand service.

- Aesthetic appearance. Metal ladders often look less cumbersome than wood or concrete.

- Cost benefit. Ladders from metal are cheaper than wooden analogs on average by 15 - 20%.

- The ladder can be installed in a few days.

- A large number of forms and types.

There are some disadvantages to metal stairs.

- If the steps are made of wood and attached to a metal base, a creak will be heard when walking.

- The ladder needs to be painted, otherwise corrosion cannot be avoided.

- During operation, the staircase makes noise, which is not always convenient.

- Surface treatment with protective compounds is a laborious process. First, the metal will have to oshkurit, then all covered with anti-corrosion composition.

- If the ladder is made unprofessionally, the welds will look inaccurate and difficult to fix.

As for the cost of construction, the range here is very wide. It depends on the size and type of construction, the availability of additional elements and other things.

For the original project and unusual design decisions will have to pay extra. Terms of installation of the product also depend on a large number of factors. If the staircase is bulky, installation should be carried out at the very beginning of work so that the decorative lining is not damaged.

With the installation of a number of structures can only handle specialists, and this further increases the cost.

All disadvantages, if desired, can be eliminated if the estimate allows you to include additional funds. For example, it is possible to install not wooden steps, but stone ones, instead of ordinary steel, you can use chrome.

Main elements

Before you choose the shape of the structure, you need to figure out what components the ladder consists of.

Although there are many types of stairs, there are three common elements:

- bearing parts;

- fencing;

- steps

The bearing part interconnects the main structural elements. She is responsible for ensuring that the load is distributed evenly. At the expense of the basis between themselves platforms and floors are connected.

What are steps, no need to explain. They are the first to take the entire load and transfer it to the base.

Let us consider in more detail the structural elements in relation to metal staircases.

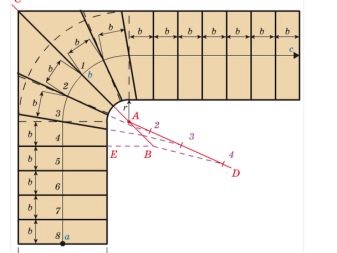

- Middle line. This lane is imaginary, roughly passing through the middle of the span, if the staircase is straight.

- Kosoura. Beams on which steps are installed.

- Bowstring. A beam with a slope, steps are attached to it.

- Balustrade. The fence is small in size. Consists of figured columns that are interconnected and are located around the perimeter of the opening.

- Handrail. One of the details of the railing. Can be placed on the walls or on individual racks.

- Ladder span. The march, which consists of beams and steps, is an inclined element.

- Railing. Rather, security fencing, most often not carrying element.

- Pillar Rack for fixing the railing.

- Boltsy. In some cases, the bottom of the ladder is a railing.The steps in this case are suspended from the railing by bolts, which are called boltsy. Such a device is rarely used, most often for high-tech interiors.

- Console. This is a carrier stage, one side of which is embedded in the wall. The load when using this option is not redistributed evenly, such devices are designed for low weight.

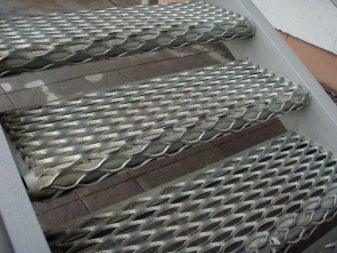

As for the steps, they are not as simple as they may seem. If we talk about service ladders, it is usually a steel corrugated plate, but the steps of the stairs to the second floor of the house consist of two main elements.

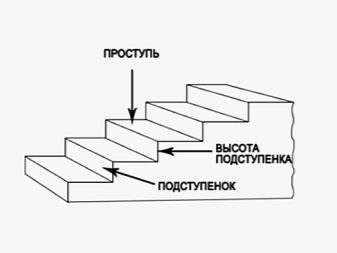

- Proceed. These are the horizontal planes you are stepping on. The depth of tread - step, height - rise.

- Podstroyenok. Vertical plane steps. This element makes the steps more durable.

If the marches are not originally designed for heavy weights, they can be performed without risers.

As for materials, internal metal stairs can be made of:

- corrugated steel;

- proftruby;

- sheet steel;

- welded lattice;

- fittings;

- notching;

- channel;

- I-beam and so on.

You can make a staircase with your own hands from a metal corner. From it is convenient to perform the framework of the whole structure, as well as the frame under the fence.

Regulatory requirements

For the installation of staircases developed specific requirements set forth in several state standards. In short, the design process must also take into account the SNiP. The difference is that the requirements of GOST are obligatory for implementation, and the SNiP is a recommendation.

It should be noted that, in addition to convenience, stairs of any type should be as safe as possible for people.

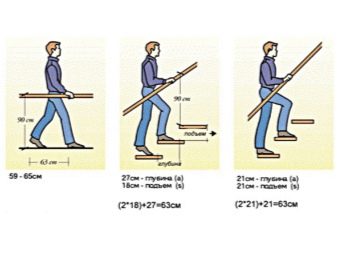

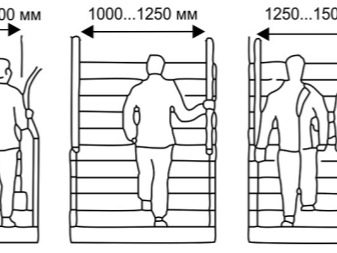

- Fences, taking into account the average height of a person must be at least 90 cm tall. The parameters of the steps: span - about 25 cm, lifting 12 - 20 cm.

- The width of the march is not less than 80 cm and not more than 1 m.

- Strength level: 180-220 kg / sq. cm for platforms and marches, 100 kg - for railings.

- In the march should be from 3 to 18 steps, it is better if there are an odd number of them. A design is considered ideal if all marches are of the same size with an equal number of stages.

- The staircase should be fully illuminated. Each span should be well viewed, you can use additional lighting steps.

- Requires anti-slip protection. For this purpose, special pads on the steps. If the stairs are lined with ceramic / stone, you can equip all with aluminum profiles with rubber inserts.

An important point concerns the staircase fence.The distance between the bars of the grille in fences should not exceed 15 cm. Such a requirement is easily explained, especially if you have small children. There are many cases when a child simply sticks his head between the bars, which then leads to injuries.

If you plan to use glass as a protective structure, use hardened or reinforced material.

All components must be connected to each other by welding or bolts.

The supports should be made of high strength carbon steel / cast iron. The entire structure must be treated with an anti-corrosion agent.

Regardless of which scheme or drawing is being developed, sufficient attention should be paid to ladders. If the design is fragile, it is fraught with injuries for people.

Types and design options

The most popular types of stairs made of metal will consider below. We note immediately that the frame can be open and closed. Closed processing after assembly is not necessary, and open requires grinding and cleaning. And now about the varieties.

Straight ladder with metal kosoura

In this case, steps and components of the fence are installed on the kosour.

How many kosour will be depends on the width of the flight of stairs, as well as the level of load on it.Kosour can be one, as in the example below, or several.

This type of construction has several important advantages:

- ease;

- visually does not clutter the space;

- increased strength (can be used in industrial facilities);

- if necessary, you can use any decor for decoration.

Ladders Inclined on Bowstrings

This design, in which the steps are based on the beams placed on the sides of the march.

Advantages of the design:

- many options to perform;

- strength;

- metal base can be used to make spiral and straight stairs.

Ladder with the soaring steps - console

First of all, it simplifies the space. The steps, which are frozen in the air, perfectly fit the houses, decorated in the style of minimalism.

Despite the fact that the design seems fragile, it is absolutely reliable and durable.

Combined version

Combining the console + oblique frame. The steps are “airy”, but at the same time they have a reliable base in the form of a metal kosoura, which is installed along the wall.

Spiral metal stairs

In this case, the steps are arranged in a spiral, around the central pillar. Such ladders are highly reliable, and they can be made of shaped pipes. Even if their production was carried out according to a standard design, the appearance will be completely different due to the color and other décor.

Ladders of this type are used more often in small rooms, the cost is relatively low.

Modular construction

Fit into any interior from a modern to classical. Elements of the ladder are universal, styles are diverse. Such a ladder can be assembled by yourself, it only takes a few hours.

Flight stairs

Flight stairs are the simplest similar products in design. It is easy to place in a room of any size. It is considered the safest design.

Metal stairs with glass steps

Working with this design is complicated due to the presence of a large number of glass elements. Glass is used only the most durable, fully complying with all safety requirements.

Dvuhmarshevye stairs with a platform

This type is allocated separately, as it has a significant advantage over other structures: an intermediate platform between the spans.

In addition, there are the following positive qualities:

- it is easy to design;

- no need for large labor costs in the manufacturing process;

- substantial savings on building materials;

- high degree of comfort;

- safety in operation;

- presentable appearance.

In the process of building two-stage ladders, it is better to combine several materials in order to optimize the cost and develop a successful style solution. For example: the frame will be metal, and the elements of the decor will be wooden or be veneered with stone.

Virtually all types of stairs, which we discussed above, can be prefabricated. Their advantage lies in the fact that they can be assembled, even if the house has already been finished and walls are finished.

If you are far from professionalism in the manufacture of stairs, you can choose already ready. They are modern, light and fit perfectly into the interior of any private house.

The design of the stairs depends on the area of the room in which it will be located.It should complement the overall picture, and not fall out of it.

It is necessary to focus on the style in which the housing itself is decorated.

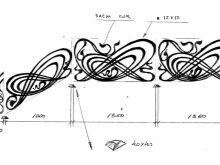

In classic interiors, it is better to place expensive staircases with natural wood trim or luxurious forging on metal.

But in the case of minimalism unnecessary details to anything, you can perform a ladder design of Plexiglas.

Attention should be paid not only to the staircase itself, but also to the space under it. If there is an opportunity, there you can arrange a place for reading and recreation.

Three methods of manufacture and installation

It is more difficult to make an interfloor metal staircase than a wooden one, even if we talk about simple variants. In order to weld metal structures, you must have at least minimal experience and skills in working with metals. And if we discuss casting and forging, the process is even more complicated. And now a kind of step by step instructions.

Before you start work, it is useful to study the literature and other special sources, as well as purchase the necessary tools. First of all, it is a welding machine, and the inverter-type device will be suitable for beginners as the easiest to use.

Still need:

- Bulgarian;

- mechanical saw;

- emery wheel.

If the steps are made of wood, you will have to purchase:

- circular saw;

- self-tapping screws;

- set of drills;

- electric drill.

But you should also consider:

- room size for installation;

- what the staircase is for;

- what elements of safety the construction will be filled with;

- how the stairs fit into the overall interior of the house.

Of course, you need to decide on the design. For example, a spiral staircase would be an excellent option if your house has a high ground floor.

There are several ways to make metal stairs:

- forging;

- casting;

- manufacturing by welding;

- bolt fastener.

Let's talk a little more about the first method.

Wrought iron stairs are very popular and are widely used in interiors. Immediately, we note that in the construction of metal structures, the use of forging extends to support posts, railings and decorative parts.

The structure is mounted as follows:

- all pigs are given a pre-planned shape;

- using a welding machine frame is made;

- the frame is filled by collecting the pattern according to the drawing;

- turn over the section, boil the other side;

- section is mounted on cooked pillars.

The most important step is the welding of all forged parts of the stairs.

The second option: the manufacture and installation of stairs using casting. This method is used to make complex, with a rich pattern design. The duration of the work depends primarily on the level of complexity of the project.

The most common type is "casting in the ground." Procedure:

- a sketch of the future ladder is made;

- a model is being developed;

- the frame prepared in advance is filled with molding sand and the model is placed there;

- after tamping the mixture, the model is removed and the metal is poured into the mold.

Ladders made in this way do not rust, they can be painted with any paint.

Consider the third method of making a homemade ladder - using a welding machine.

First, for the frame we need a channel and a corner. At the initial stage, you need to make a frame and weld a corner. When this work is done, the seams are filed. During processing, the burrs that have formed on the metal are removed.

In the next step, the structure is primed using a special solution with additives against corrosion and rust formation. At the final stage, the product is painted, then the railings are made and the resulting product is planted on the frame.

Types of modern finishes

The most spectacular design solution can be called a combination of metal and wood. Making a natural tree gives the entire interior a respectable appearance, a kind of nobility.

Apart from aesthetics, metal structures with wooden elements also have other advantages:

- reliability;

- wear resistance;

- safe and comfortable movement;

- convenient descent and ascent.

Depending on the design project and your budget, you can make a tree cladding only steps, as well as steps simultaneously with the risers.

The wooden massif will bring to the house an atmosphere of comfort, natural freshness and harmony.

For veneering the most popular are:

- cherry;

- oak;

- nut;

- the Red tree;

- ash and the like.

Important: for facing works, the moisture content of the wood should not exceed 12%.

Despite all the advantages, wood trim is not an expensive pleasure.If you plan to do everything with your own hands, you can use the budget option - laminate. It is not only cheaper, but it is easier to process it than an array of wood. The quality will be somewhat lower, but this is a reasonable compromise.

There are even advantages to laminate wood:

- good sound insulation;

- the lack of squeak even a few years.

We can conclude that if you want to perform a beautiful finish and save - laminate is a great way out.

The next option is tiling. Tile is not afraid of water, dirt and stiletto heels. But the edge must be grooved to avoid injury. This method of lining is equally successfully used for street stairs and structures located inside a country house. The coating can be made in marble, granite or natural stone.

Finishing plasterboard sheets - another way of plating. Care must be taken not to damage the sheets, and the smallest pieces must be attached to the bottom of the flight of stairs.

Metal stairs are widely used in interiors made in the style of a loft. In this case, lining is practically not required, it is better to leave it in its natural form.

Interesting options for home

If your plans include the construction of a two-story house or a summer house, you simply cannot do without a staircase to the second floor. We propose to consider several options for every taste, style and wallet.

In the first example, you can see a staircase with wood trim and wooden handrails. The design is light, air, despite the metal frame.

Spiral staircases look great in the interiors of country houses, especially with elements of forging. An important feature is that it is better to entrust the implementation of such a design to professionals.

An interesting option would be a metal staircase with floral ornaments. The whole structure seems to be floating in the air without touching the ground. The staircase leads to the attic floor, is equipped with fairly wide steps, which virtually eliminates injury.

Next example: a metal staircase to the second floor, the ornament on the railing of which is made using laser cutting. Elegant, unusual, does not clutter up a free space.

Reliable and durable designs are made of metal profiles. If you strive for reliability and practicality - this option is for you.

Let's summarize a little. Ladders from metal perfectly proved both from the functional party, and from esthetic. Thanks to a variety of designs, you can choose the option for any room.

To learn how to make a staircase with your own hands, see the next video.