How and with what to fasten the stair balusters?

Ladders consist of many parts and the necessary elements that make the overall structure safe, reliable and convenient. Despite the apparent complexity, such objects can be made by hand. The installation of each part must be approached with full responsibility so that the result does not cause disappointment. Today we will talk about how to properly fasten stair balusters.

What it is?

Before getting a closer look at the methods of installing the stair balusters, you need to figure out what they are.

Balusters are very important components of the stairs.that are installed along their entire perimeter between the base and the railing. The main task of these parts is to prevent the fall of a person.

Fencing

Most often, the stairs are installed in private homes.These structures not only allow residents to move freely to the upper / lower floors of the building, but also decorate the whole environment.

Similar constructions consist of several important elements., without which it may be unsafe to use them. So, staircase fences are necessary. These parts make the design more convenient to use.

The main functions of stair railings are:

- Security. This parameter should be put in the first place, as the barriers make it possible to move safely along the stair structure. Safety is especially important when it comes to an intricate spiral or very steep staircase.

- Support. Thanks to the fences, it is much easier to descend and climb stairs - balance is maintained, the load is distributed correctly.

- The decor. These details give the stairs a more organic and complete look. In some designs, fences are accent details and attract major attention.

By way of installation, the following types of stair railings are distinguished:

- Handrails.These elements are mounted on the wall as a straight pipe or profile with the help of secure fasteners.

- Railings consisting of balusters and pillars. These types of fencing are classic. They consist of vertical slats, horizontal framing and the railings themselves.

Requirements

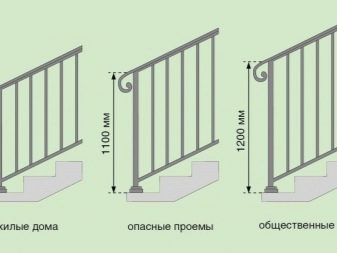

Stair railings must meet a number of specific requirements. First of all, any structures that rise from 60 cm should be fenced. This applies to terraces, balconies, galleries, and external stairs with feet and ramps. In addition, the boundaries should be complemented by the boundaries of the internal staircase opening.

Constructions that rise to a level greater than 1.8 m must be fenced off with a railing of 1.07 m.

If the width of the stairs is less than 110 cm, then it is permissible to install the railing on one side only. If this figure is more, then the railing should be put on both sides.

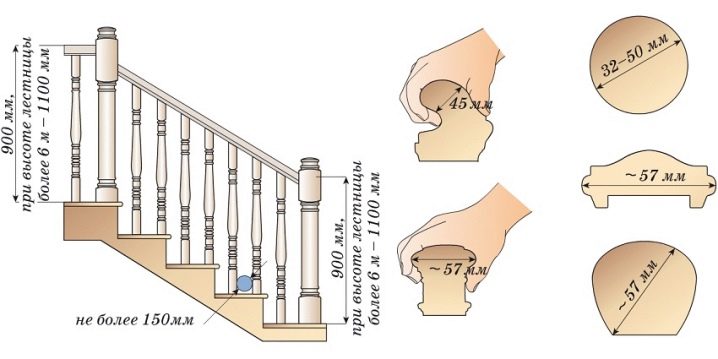

The height of the inner stairs should not be less than 90 cm. Spiral and curved stairs should also be equipped with railings on both sides. Handrails are not placed on internal structures that have only two steps, as well as on external stairs with three steps. One of the stair railings must be uninterrupted.

The handrail should not extend beyond the fence more than 30 cm. It must be attached so that it is at a distance of 4 cm (minimum) from the wall. There should be no sharp corners or protrusions on the railing of the stairs.

The structure must be treated with refractory means. If small children live at home, the stairs are supplemented with a second handrail. This element is set much lower. A balustrade should be installed along the entire staircase.

In the railing should not be present transverse bolts for the safety of children. Also, to ensure child safety, it is necessary to install vertical barriers to a height of up to 1.2 m. If people with mental disabilities live in the house, this parameter should be increased to a mark of 1.8 m.

Fences should not constrain the free space on the stairs. The largest value by which the width of the structure can be cut is 10 cm. Fixing points for handrails should not be more than 1.2 m apart. Fencing fixtures should go deeper into the staircase by 3 cm. Glass should not be used to fill stair enclosures.

Types

Ladder designs are different. This or that type of fencing installed directly depends on their structure.

Consider them in more detail:

- For spinal stairs. Such fences are distinguished by the original form. In such details, as a rule, there is a large number of exquisite bends. In the case of metal structures, additional decorative elements are often installed on the fencing by welding.

- For flight of stairs. Similar designs are distinguished by a discreet appearance - they have straight and long marches. Fences can be installed on the steps of such stairs, and on the walls that are nearby. The main advantage of such designs is that they can be given any appearance, turning to any stylistic direction.

- For spiral staircases. Such ladders are rightfully recognized as the most spectacular and rich. In these designs, the railing should be a continuous spiral. Such parts are made quite difficult - for this you need not only to have relevant knowledge, but also special tools.

Device

Stair railings consist of the following components:

- baluster and supports;

- handrails;

- filling in.

Balusters are racks in a vertical position, which are attached to the bottom of the steps, bowstring or kosouru. The upper edge of these parts serves as the basis for the subsequent installation of the rail itself. The strength, durability and reliability of the staircase are directly dependent on the quality characteristics of the balusters, therefore, their choice and installation must be approached thoroughly.

The shape and size of handrails is developed taking into account their basic functions. The person most often comes into contact with these elements, moving up the stairs. For this reason, handrails should have a perfectly smooth and pleasant to the touch surface without any kind of points.

The role of filling the railing usually play elements of solid or lattice type. They are fixed between balusters so that fences are safer. In addition, the filling often serves as a decorative addition to the structure.

Species

Ladder rail-posts are made of different materials. The performance characteristics of these parts depend on this parameter.Let us consider in more detail what types of balusters exist, and what features they have.

Wood

Balusters made of wood are very common. They can be made from different wood species. Such details look especially interesting and harmonious, if they are supplemented with carved ornaments - with such decorations classical interiors look more presentable and more expensive. Most often in the production of balusters such wood species as beech, birch, oak, pine and many others are used.

The most affordable are pine and birch elements. Despite the low cost, they look attractive and do not give out their cheapness. However, pine itself does not like dampness and moisture, so it can be installed only in dry rooms.

Much more expensive are oak or beech balusters. These elements look expensive and aristocratic. Despite the seemingly insignificant, oak or beech balusters can beautify the situation, making it a luxurious touch.

Wooden balusters have the following disadvantages:

- options made of soft wood are susceptible to damage;

- such parts must be treated with special protective compounds so that they last as long as possible and do not lose their original attractiveness;

- wooden balusters do not tolerate temperature fluctuations and high humidity;

- These elements do not look organically in all combinations (for example, they will not look with metal steps).

Such elements may have the following forms:

- Cylindrical. These are simple wooden pillars. They can be supplemented with thread. The diameter of the cylindrical elements may be different.

- Flat. Flat stair balusters have a discreet appearance. In cross section, these elements have the shape of a narrow rectangle or ellipse.

- Sculpture-carved. Such types of balusters can be called the most attractive and original. Usually they are made by hand from expensive tree species, and therefore they themselves are quite expensive.

Stone

The balusters made of stone look good and expensive. Most often in the manufacture of these parts used marble. It boasts excellent strength characteristics, long service life, solid appearance and massiveness.Stone structures are more wear-resistant than wood, as they are not afraid of any temperature drops, or high humidity, or mechanical damage.

However, stone balusters are not chosen as often as they are expensive. In addition, some users of this material seems overly bulky.

Stone balusters are not suitable for all interior styles, so their selection should be approached very carefully.

Glass

Glass balusters are cast, so you will not see seams on them. Beautiful models of crystal glass are able to decorate not only the staircase itself, but also the entire interior as a whole. Often, such details complement the backlight - as a result, fabulous designs are obtained, attracting rapt views.

Of course, according to safety regulations, it is better not to apply to such elements if there are young children in the house. Even the most durable tempered glass can be accidentally damaged / broken and hurt by fragments.

It is recommended to prefer balusters made of laminated silicate glass (triplex).Such materials are covered with a special film, which does not allow the glass to crumble into small pieces.

As for the color solution, it can be absolutely anything.

Concrete

Similar details in the style of the Stalinist Empire style are made as follows: concrete mixed with gypsum or pure gypsum is added to special molds on a wire frame. It is possible to make a form for balusters with your own hands, using a little ingenuity.

Concrete balusters will look harmoniously far from each interior. For example, in houses made in a modern style, such details will not look. It is better to install them on outdoor structures, gazebos or terraces in suburban / suburban areas. However, you need to take into account the substantial minus balusters of concrete - they do not differ in durability. Concrete and gypsum structures may collapse due to temperature fluctuations, precipitation and external influences.

Metallic

Fences for stairs are most often made of metal.

The popularity of such products is due to their positive qualities:

- they are not subject to mechanical damage and deformation;

- differ in long service life;

- do not lose their visual appeal over the years;

- can be made in different directions and be both simple and very effective, decorated with patterned lines and weaves.

Aluminum and stainless steel

These products have a lot in common. It concerns not only their design, but also operational characteristics. Aluminum and steel balusters are not subject to the formation of corrosion, and also have a perfectly smooth texture.

Models of aluminum and stainless steel can be nickel-plated, chrome-plated or gold-plated. The choice of a suitable product depends only on the preferences of the owners.

Forged

Forged balusters are considered to be the most beautiful. They have a very original and sophisticated appearance, demonstrating the financial situation of the owners and their great taste. To create such elements used malleable material that is seamlessly processed and molded.

Forged balusters can be made in two ways: cold and hot forging.

Cold forging is made from blanks and is more often used for the manufacture of simple fences.In this way, you can bend metal rods into unusual curls.

For hot forging, you need more time and effort - with this method of making balusters standard standard solutions are not used, as this is a scrupulous handicraft that can only be carried out in a special workshop. Thanks to hot forging, truly unique products are obtained in the form of leaves, flowers, curls and other openwork elements.

Forged balusters look good in combination with other materials. For example, it may be a wooden railing. In a single tandem, such products look stylish and fit both the classical and the gothic ensemble.

Polyurethane

Polyurethane balusters are lightweight. Such parts are available in various forms and are quite inexpensive. These types of staircase parts are made of high density polymers - such materials do not fear mechanical damage and heavy loads.

Polyurethane balusters consist of a special shell and a support - a metal rod. It is the last element that gives the entire weight of the product, making it more reliable and sustainable.

Many consumers choose these types of balusters, because they can mimic almost any natural material.

How to choose an item?

The choice of balusters depends on what material is present in the basis of the very structure of the staircase. So, for wooden products it is recommended to purchase balusters from a similar material of the same breed. In this case, it is necessary to ensure that their shades match. If you want to build a more original design, then you can create a spectacular combination with wood of completely different tones.

As for metal balusters, they can be used in the design of a spiral staircase. With wooden basics, they will look disharmonious.

Note that models made by hand or forged copies can cost a pretty penny, but with their help the staircase will find a really expensive and spectacular look.

Concrete details should not be acquired for interiors in more modern or gentle stylistic directions. With such balusters, you should always be careful, because they can disrupt the harmony of the environment, getting out of it.In addition, concrete options will not last long, especially if they are outside the house.

Universal are considered glass designs. They should be chosen if the situation in your home is made in a modern and high-tech style. For the Gothic ensemble, retro or classic such items are not always suitable.

Pay attention to the quality of performance balusters before purchasing them. There should be no scratches, chips or sharp edges / particles on such parts. From the purchase of damaged items should be abandoned.

Optimal distance

Mounting racks railing, it is necessary to correctly make the markup, as well as to identify the correct distance between the individual elements.

To do this, follow these simple rules:

- the step between balusters should not be less than 15 cm;

- if there are children in the dwelling, it is just as important to take into account when fixing the balusters - in this case, the space between them is better to do even less;

- the ideal height of the racks for fixing the railing should be 80-100 cm;

- balusters must be made of the same raw material suitable for the material of the staircase;

- posts need to be fixed at 2 points - in the upper and lower parts.

The optimal pitch between supports is 15 cm. If this indicator is larger, this may increase the risk of injury. If you can not meet this requirement, it is permissible to put 2 racks at once on one step.

Fixing methods

It is permissible to put supports on the edges of the steps or on the string. So, if the width of the steps allows, it is permissible to install two elements on them at once. The quality of the structure as a whole will depend on how reliably and firmly the balusters are installed. Today there are several basic ways to fix these details. Let's get acquainted with them.

Studs

The mounting of columns with the use of a threaded rod on a string is used in situations where the parts are arranged clearly perpendicularly. To attach the balusters to the rail, these components are not used.

To make a threaded stud, you need screws that have a head with six edges (such parts are called "wood-grouse"). These fastener elements are fixed in pre-drilled holes at the bottom of the posts. Pin and hole must be sealed with glue. These types of fasteners are not bad for fixing wooden balusters.

Self tapping screws

Applying screws and screws, it is possible to attach the balusters to the floor. These fasteners can be used when installing both wooden and iron objects.

The most popular are such approaches:

- stalker;

- the use of a plate for support;

- use direct fixation.

These methods have much in common. A sturdier connection with steps can be achieved using plates attached with 4 screws. Screws can be attached to the railings on the side rails.

If the step is equipped with the risers, then the removal of the fastener to the lower part is convenient. If the risers are removable, then the areas with connections will need to be properly hidden.

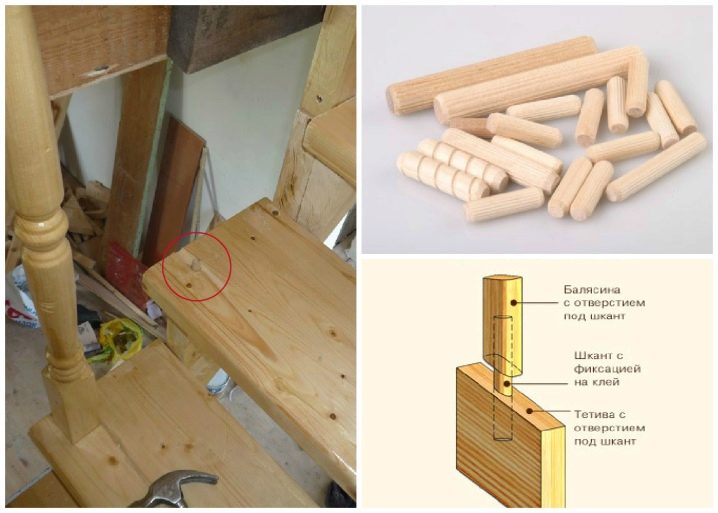

Dowels

Dowels and rods are mainly used in the construction of woody bases. It is important to remember that their diameter should not be larger than ¼ of the rack diameter, and the length should be 2 diameters of the baluster itself. In this case, markup should be applied to each element - and the railing, and steps, and pillars. The depth of the hole should be half the diameter of the dowel. Installing fasteners, missed glue, you must start with the steps,and then move on to the railing.

Such fasteners can be used when mounting balusters on the plane on which the laminate.

Installation Features

In order to properly fix the balusters with their own hands, it is important to take into account some features of such work.

Consider how to properly fix balusters made of wood on the example of fasteners-dowels:

- First, make a marking on the base and make holes that have a depth of half a dowel.

- Smear the attachment areas with glue.

- Install the dowels from the tree in the hole. Next they need to put balusters.

If you decide to take a stud for fasteners, then the work plan will be different:

- The steel stud must first be sharpened from the side of the cut half at an angle so that it is easier to insert into the hole.

- It is necessary to make a hole in the stair with a diameter of 2 mm less than the pin itself. Then you need to carefully wrap it all the way using a gas wrench.

- Next, the post is drilled in the center of the section and wind it on the outstanding part of the thread studs.

- If the upper oblique shear of the column does not coincide with the given, then it is still tightened with a gas wrench.

To strengthen the balusters on the basis of screws, mainly use fasteners with a diameter of 0.5 cm and a length of 4.5.7 cm. Plastic dowels are used under the head of “grouse” and self-tapping screws.

So, in the step below, screw the screw (through). The support stand is screwed onto the outstanding thread in the center of the butt-end, by manually turning it to the stop.

In this case, take into account some of the nuances:

- Stick to the optimal pitch between the balusters (15 cm). It is important to comply with this requirement if there are small children in the home.

- Adhere to a suitable height of supports - 80-100 cm.

- Mount each support in a pair of dots - at the top and bottom.

- The thickness and cross-sectional area of the baluster does not affect the safety and strength of the construction, since these components are not carrying.

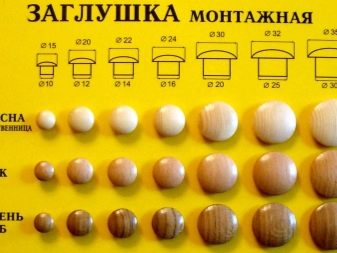

Decorative caps

Places where screwed fasteners are visible have a negative effect on the aesthetics of balusters. To solve this problem, you can use special decorative caps. Corks made of wood are expensive, so it’s best to turn to cheap plastic options if the design and design of the stairs allow it.

Since the plastic is not painted, the owners may be faced with the problem of choosing the appropriate shade of plugs from the presented palette.

See the video below for tips on installing balusters.