Drywall Adhesive: Selection Criteria

Among the variety of modern materials for construction, which are used for finishing walls, drywall is deservedly popular. Such a choice of the majority of buyers and builders is based on the fact that it has a lot of advantages, among which environmental friendliness and a perfectly flat surface after finishing are particularly notable. This material perfectly manifests itself in contact with finishing materials, if the glue is chosen correctly.

Special features

To reduce the cost of installing drywall sheets using profiles, there is an alternative way to do this work, which involves the purchase of special glue.

In addition to the main purpose, drywall adhesive can be used for:

- fixing mineral insulation;

- gypsum panels;

- gas concrete slabs;

- polystyrene foam materials.

Glue for GKL - products that are used only for interior work. As with any building material, the composition has advantages, among which are ease of use and quick installation. The surface for pasting sheets of drywall does not need to be pre-leveled, it is enough to clean it from dirt. This composition is economical. By opting for a similar method of mounting products, you can save money and the amount of glue in comparison with work involving the use of profiles. Work with a similar multifunctional composition will allow to obtain high quality and durability of interior decoration in the room.

Types and characteristics of glue

The characteristics of the adhesive solution are directly dependent on its composition.

Construction adhesive

Construction adhesive requires strict adherence to instructions for its preparation. Manufacturers indicate this information directly on the packaging. Work with him is done with a spatula. The composition is applied to the surface in a circular motion. The intervals between strokes should be from 15 to 30 cm.

When gluing plasterboards under special control, there should be an evenness of their installation. To do this, use the building level. If necessary, you can correct the location of the plasterboard sheets, but no later than 10-15 minutes after gluing the material to the surface. Construction adhesive for gypsum plastics was originally used as a tile composition. However, due to its moisture resistance, environmental friendliness and resistance to low temperatures, the composition is considered universal.

Polyurethane foam

Works with assembly foam are carried out according to the following technology:

- 8-9 holes are made in the sheet, drilling is performed around each;

- pieces of foam rubber are glued to the panel, leaving a gap of 10 cm from the holes;

- sheet attached to the wall with screws and washers;

- pour the composition into the holes;

- washers are removed;

- screws tighten all the way.

Mastic on a plaster basis

Gypsum variety consists of glue and lime. To make such a mastic, you need to pour glue with water for 15 hours, after its swelling, lime, already diluted in water, is added to the composition. Usually, a steam bath or a gas stove is used to obtain a thick consistency.In conclusion, gypsum is introduced into the solution. The advantages of this type of glue include the absence of shrinkage after complete drying and antibacterial properties. Therefore, such a composition is recommended to purchase for rooms with a high probability of occurrence of mold and mildew.

With sawdust

There is a mastic with the addition of sawdust. Such an adhesive solution in thickness resembles sour cream. For the preparation of gypsum sawing mastic, you need to mix gypsum and sawdust in a ratio of 4: 1 and add glue to the composition (25 grams of dry composition are needed per liter of water).

Sulfate-alcohol mixture involves mixing water and bards in a ratio of 4: 1. The consumption of gypsum is determined based on the consistency of the composition obtained. Ready gypsum mixes are notable for their good ductility and provide additional sound insulation. A positive feature of this composition is its ability to take the form of a surface, which is especially important in situations where it is necessary to level the wall.

Special formulations

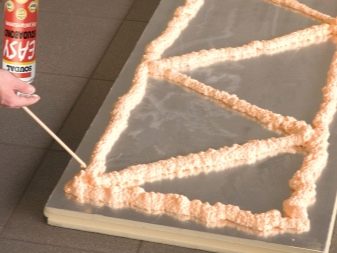

Special adhesive for drywall produced in cylinders. Usually it is enough for 15 squares of area. The technology of application involves the processing of the composition of the surface around the perimeter with the further coating of the plane independently.At the same time strips of glue are made on the base every 30 cm.

Elastic polyurethane composition produced in cylinders. It is designed for laying plasterboard and gluing seams. In addition, he showed himself well as an adhesive for gypsum or ceramic tiles. Works with him are carried out with the help of a special construction pistol. Sometimes polystyrene glue contains polystyrene foam fibers that have a beneficial effect on thickness.

How to choose?

To make the right choice when buying adhesive for plasterboard sheets, you should take into account the type of surface you need to work with. More often, specialists have to work with concrete, brick walls. Sometimes in the work you have to deal with penoplex, which warms the surface. Drywall to the penoplex stick with a plaster composition. Brick walls, aerated concrete, gas-block and coquina involve the installation of gypsum plasterboard on gypsum mortar. This option is the most economical and efficient, since on average, 1 m2 will need 5 kg of the mixture.

For concrete bases with a minimum curvature, it is recommended to choose one of the following options:

- polyurethane foam;

- plaster glue;

- cement composition for tiles;

- acrylic or plaster base putty;

- polyurethane adhesive composition.

To glue the sheets of drywall to polystyrene foam, fit acrylic putty and glue-foam. Stick plasterboard on the plasterboard surface can be almost any kind of glue. However, for a small seam between the materials and maximum preservation of the floor space, it is worth using a silicone compound or liquid nails. For gluing on drywall tiles in the kitchen or bathroom, you can use silicone sealant or adhesive compositions for tiles. If you have to work with the window slopes of gypsum board, most experts advise to glue the surface together with acrylic putty.

Decorative ceiling elements will be better kept on the base, if you glue them with liquid nails or synthetic glue (they will allow you to carefully attach the surface of the plinth or baguette). Choosing glue for work in large rooms, it is important to be rational about the expense item, so you should opt for mixtures in bags.HL many people call “dry plaster”, because after installation of the material, you can immediately begin the finishing work.

Manufacturers

Thanks to modern technical capabilities, on the shelves of building supermarkets are presented products of a huge number of manufacturers for repairs. These products are represented by well-known global brands and domestic firms.

Knauf

The company Knauf remains in the list of leaders in the production of construction goods. Many experts prefer this particular product. The adhesive compositions presented by the company are of excellent quality with a minimum level of consumption during the installation of drywall.

The main advantages of German products are:

- warranty on all types of goods;

- small rock fit mixes;

- excellent compatibility with GKL manufactured by other manufacturers.

Volma

Also in demand plaster mix brand "Volma". It has the best plasticity indicators of the material. This series is more affordable than the German Knauf PerlFix products. But the flow of the adhesive composition they are about the same.

"Titanium"

A series of universal adhesives "Titan" on the Russian construction market is very popular. Means possesses good adhesion. It is compatible with many materials, including drywall.

Henkel

Henkel manufactures a line of construction adhesives Ceresit. Mixes are popular in Europe and the Russian market, thanks to high quality products. For drywall, Ceresit CM 11 glue is used, recommended for installation in rooms with a high level of humidity.

Tips

To plasterboard sheets better glued, the surface under the installation should be prepared. This process consists of priming and cleaning. Glue preparation for work (in the case of using gypsum powder formulations) involves dilution and stirring with a drill with a nozzle.

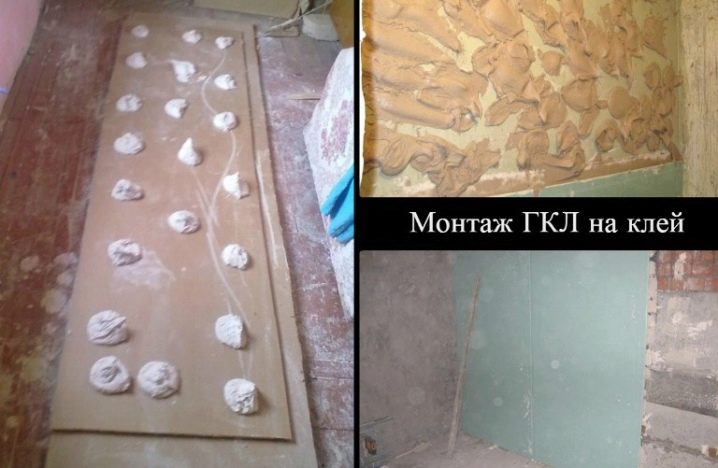

The technology of applying the mixture consists in laying the composition in the form of small cakes. on the surface of the sheet at a distance of 20 cm. You can distribute the composition directly to the working surface. Then the gypsum plasterboard is applied to the wall and is well pressed for high-quality gluing. The alignment of the material is carried out with a rubber hammer.

To glue the plasterboard ceiling, it is more convenient to use for fixing dowels. They will help keep the material until it is completely dry, so that the sheet can be glued to the maximum quality possible. Drywall - quality material for the creation of various designs, wall and ceiling. However, improper sealing of the seams between the sheets can lead to the formation of cracks. It is important to carry out these works using plaster. The type of composition should be selected depending on how the finishing will be carried out. After the composition has dried, the surface is completely ready for finishing: the walls are glued with wallpaper, painted or decorated in any chosen way.

On the intricacies of sticking drywall, see the following video.