Types and criteria for selecting fittings for heating

The fittings used for arranging heating radiators are a separate segment of products on the market of equipment for heating systems. Also, these elements are used to control structures. Armature differs in type and functionality, depending on which it is selected for a specific task.

Introduction

The heating system, compiled and implemented by high-class craftsmen, is a complex configuration necessary to provide the necessary temperature conditions in a private house or apartment. Every detail is important in it. In addition to boilers, pipes, radiators and other essential equipment, control components are indispensable.

All fittings used for heating systems are divided into types.Regulatory and control valves for heating are available. Consider each of the types in more detail.

Requirements for material production and task elements

To understand what the above elements are, you need to understand their functionality. The general task of the valve is to adjust the coolant flow, which is distributed throughout the system. With their help, the user can at any time increase or decrease the volume. Each of the types of valves (No. 1 - stop valves, No. 2 - regulating) in a certain way affects the operation of the structure and has its specific functional purpose.

Option number 1

Shut-off valves are used to completely stop the coolant in a particular section of the plumbing system or radiator to force a decrease in flow. As a rule, for such tasks choose valves or taps that differ in design.

When buying parts you need to pay special attention not only to the model, but also to the material from which it is made. Large manufacturers use top quality stainless steel. Products of the highest grade must withstand temperature loads and high pressure.These indicators must be specified in the technical passport or on the body of the element.

Option number 2

This reinforcement class is used for the safe and coordinated operation of the entire structure. One of the main purposes of adjusting elements for heating systems is to stabilize the pressure level inside the pipe. When used on the basis of water supply systems, parts regulate the heating of water by mixing hot and cold liquids. For greater practicality, some models of devices equipped with electronic control panels.

For the manufacture of various materials are used. The most common is malleable iron, brass and bronchus. Armature of steel for radiators is used extremely rarely, due to the special properties of the metal. It is practically not adapted for use in systems with hot water.

Note: manufacturing companies that work in this segment of the market continue to work on the development of new configurations, to increase efficiency and ease of operation. On the shelves of large specialized stores for sale you can find the combined nodes.The main advantage of such models of heating fittings is simple and easy installation, compared with the installation of single components of the system.

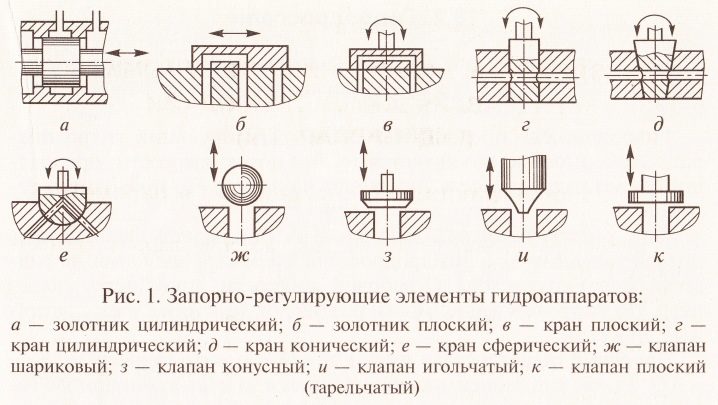

Varieties of elements of the locking type

- Cranes heating. Without these parts it is impossible to imagine the work of the heating system. To organize the operation of the system, one of the types of cranes is used, depending on the principle of controlling the ceiling of heat carriers.

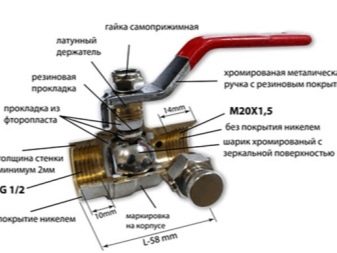

- Ball Valves. The main feature of such elements is a special structure. In the inner part of the crane is a special ball with a through section. When turning the knob, the diameter of the hole changes up or down. To control the element is used a lever that rotates 90 degrees. This parameter is quite enough to shut off the valve in the valve. For smooth adjustment the ball valves are not used.

- Stock For greater practicality and tightness, taps are fitted with ceramic or rubber gaskets. To fully open or close a channel, you must turn the knob several times. Unlike the type of elements, which is indicated above, the rod valves are characterized by smooth and precise adjustment.The installation process is carried out in full accordance with the technical characteristics of the heating system.

Advice from a specialist: lately, the popularity of paronite gaskets has been growing.

This material retains its shape during operation is much better than similar options.

- Heating valves. According to external signs and design of the valve is very much put on the rod valves. Their main difference is the increased size. Also used is a different form of internal channel valves. In the process of their manufacture, manufacturers adhered to the wavy principle, thanks to which elements are able to withstand sudden pressure drops. Gate valves are actively installed on the central heating pipelines.

- Regulatory elements. The valves of this type are used to provide control over the functionality of the heating system. With their help, you can adjust the work of both individual sections, and the whole structure.

Mayevsky's crane

To prevent air plugs in the pipes, this device is used. The design includes a needle valve, which is completely sealed in the closed state.The element is installed on the top of the battery. Also, the crane Mayevsky will help get rid of air traffic jams when they are in the system.

In order to fix the problem, you should loosen the tap a little using a screwdriver. Reduce the level of compression should be until the characteristic hissing sound disappears.

Check valve

To prevent the reverse movement of the coolant in the pipe set the check valve. This element is used for the correct operation of heating systems in apartment buildings or private buildings. The principle of operation is quite simple. The heat carrier presses on the valve seat, due to which it retreats and allows the fluid to circulate through the pipes.

The element is designed in such a way that if the liquid begins to move in the opposite direction, it comes to its original position automatically. For arranging branched heating systems, check valves are indispensable parts.

This device is often mounted in batteries in the form of valves. Its presence greatly increases the efficiency of the system and the level of its safety. For effective and convenient process control, experts advise installing a check valve equipped with a pressure level regulator.

Mixing units

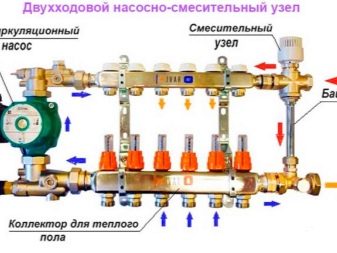

The name of this element speaks for itself. They are needed to mix hot and cold water in water heating pipes. Also, the parts are used for the full functioning of the "warm floor" systems. Their design is very similar to the configuration of needle valves.

Nodes are divided into two types:

- Two-way. Mixing water with different temperatures occurs due to the fact that in the tap with this modification, the stem opens to a predetermined height.

- Three-way. Products have special valves. In the process of movement, moving from side to side, they open or block access of fluid.

Depending on the model, the mixer can be controlled either automatically or manually. The first option is equipped with an electric drive that is synchronized with the temperature sensor of the heating system. Depending on the programmed temperature indicator mixer works.

Safety valve

The element is used to prevent the pipe from breaking through as a result of a sharp increase in pressure. The main task of the device is to vent air or an excessive volume of fluid from the heating system.A quality valve dismantles the increased resistance to high pressure, compared with the Mayevsky crane.

The principle of the element is built on the effect of water pressure on the saddle, as a result of which the stem rises. As long as the level inside does not fall to the optimum value, the safety valve will remain open. Experts recommend installing the device on the back of the pipeline.

Additional elements

This class includes thermometers and pressure gauges. The device is necessary for maintaining control under temperature and pressure. It is worth noting that measuring devices should be placed in the heating boiler, but additional devices in the rest of the system are necessary for the system to operate properly.

The use of fittings for heating must take into account all the necessary operational standards. In the relevant documentation, which comes bundled with the devices, manufacturers specify the minimum and maximum indicator of pressure and temperature.

Locking and Regulatory Elements

Separately dwell on this group.This class combines the characteristics and purposes of the elements belonging to different groups. The armature combines the functions of control and overlapping flows.

The segment includes the following elements:

- Balancing valves.

- Regulators differential pressure operating in automatic mode.

- Thermostatic radiator valves.

The elements specified in this group are used to implement a quantitative control of the coolant. The devices provide the flow of fluid that enters the heater, due to the partial overlap of the flow area of the pipeline.

The functionality of each device

Balancing valves are mounted in the area of the battery outlet. They can be installed at the beginning of the riser or at the very beginning of the branch. Most often, experts mount the elements on the back of the line.

The installation process of valves and fittings may vary depending on the number of batteries. As a rule, the installation of such elements is carried out using automatic pressure differential regulators. They are installed together with valves and connected using a capillary tube.

Each device performs a specific function. The device, listed first in the list above, provides the flow of heat carrier to the riser or branch line, and the second element monitors this indicator in accordance with the operation of radiator thermostats.

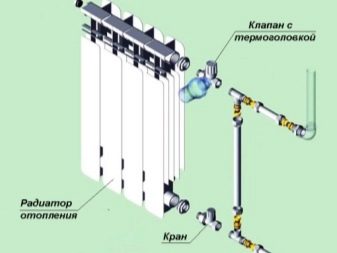

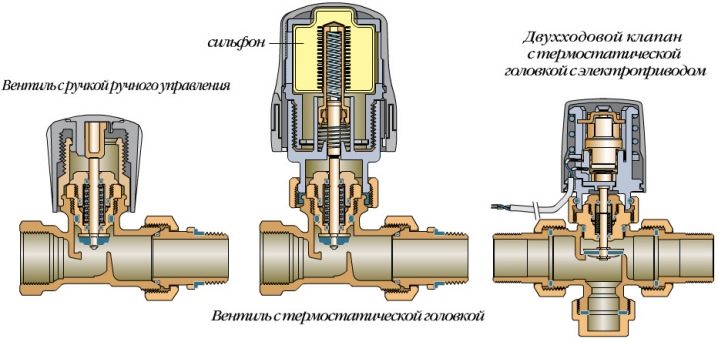

The last element is a reinforcement for radiators. A thermostatic valve regulates the amount of hot water flowing through the battery. The duct depends on the temperature in the room. Due to the automation to use the device is easy.

On a note

Depending on the type of heating system, the element can be additionally equipped with a thermal head, as well as a remote type thermal regulator. Additional devices are needed for more precise control over coolant flow. Such devices are mandatory elements of most modern systems, for which the main criterion is the economical use of energy carriers.

Making the right choice

When choosing fittings for heating, be sure to pay attention to the following characteristics:

- Dimensions. The first thing to note is the indicator of the diameter of the nozzles at the exit and entrance.This feature plays an important role in connecting to the trunk. The golden rule - the valve should not interfere with the circulation of thermal media.

- Adjustment. The ability to control matters to the accuracy of the fluid head. Choose wedge taps for a smooth and smooth adjustment process, and choose ball models for the fastest overlap.

- Addition. Be sure to appreciate the possibility of connecting additional devices.

For information on the types and criteria for selecting fittings for heating, see the following video.