Features of scraping wooden floor

During the overhaul of the house you need to take care of everything. An important task is also the care of the flooring. On the market there are many varieties of materials, each of which deserves attention.

The greatest demand over the years is parquet and natural wood. This can be logically explained, because wood looks presentable and fits any interior design. Of course, it has its own characteristics, including the need for thorough care. And if you have such a floor at home, you will surely notice that over time it has faded, rubbing appeared on it, and this means that it is necessary to carry out certain activities. This is a scraping wooden floor, which will solve the problem of lost presentability.

The question arises whether it is possible to do this work independently, or it is necessary to apply for the service to qualified specialists. Of course, this work requires certain skills, but if you carefully study all the details and follow the instructions, you can do it yourself and achieve the desired result.

What is scraping?

There are several varieties of finishing materials for flooring. Among the huge selection of natural wood is in great demand and does not lose its relevance over the years. Parquet is an indicator of excellent quality, durability and prestige. Natural material is identified with comfort and warmth, but it is necessary to properly care for it, otherwise it will no longer look beautiful.

Scraping saves the floor from scuffing. This process is difficult, but very effective, thanks to it, you can extend the life of the wooden coating. With the help of scraping, remove the upper thin layer of parquet or wood floor. For this purpose, special equipment is used, which consists of sharpened metal knives.This process will allow to achieve a density and an ideal flatness of the coating.

If the parquet looks uneven and old, it is recommended to use a drum machine. It works neatly and will not remove excess layer. Sanding pads can become dirty very quickly if bitumen leaves between the gaps, which means that it is necessary to make a replacement. Of course, we must not forget about the species of wood, as it is important to take into account during the scraping.

If the floor is of exotic material, it is better to consult with an experienced specialist.

Moisture is considered the enemy of any wooden covering. And if there are problems with this, it is impossible to carry out a scraping, as the floor will be deformed. First you need to make sure the parquet is dry, and only after that get down to work. It is important to note that the room must be warm and dry and well ventilated.

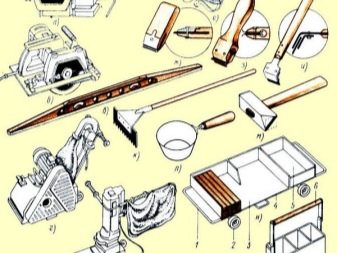

Instruments

To perform the task at the highest level and extend the life of the flooring, you need to stock up on the appropriate tools and equipment for grinding. To begin, you will need a scribing machine - this is the main device for solving this issue.In everyday life, the best option would be a grinding drum machine, where a removable abrasive belt is installed.

As for the cost, it is not available to everyone, since the device is offered at a high price, but you can rent the equipment if you decide to upgrade the wooden floor yourself. But for those who plan to start working in this area and provide grinding services, it is important to get a high-quality, reliable device, thanks to which you can achieve the perfect result.

Any room consists of walls and corners, it’s impossible to manage with a drum machine, as it cannot cope with some sections. In order to tricol expensive flooring of valuable species or parquet, it is necessary to take an angle trimming. Be prepared that a lot of debris will appear during work, because the abrasive turns the top layer into dust, which means you need a vacuum cleaner to collect everything.

There is a mechanical device with which you can also grind, and this is a manual cycle. The cost of such a device is available to everyone, although the expenditure of power is much more than during the operation of the machine cycle.It will take a lot of time, so be prepared for this. The great advantage of this unit is that it is capable of handling hard-to-reach areas.

For sanding you will need sandpaper of different gritAfter all, you will start with large options and move towards smaller ones. Even a seemingly perfect floor can have cracks, because with time defects appear on the surface. So stock up with white spirit, sponge, glue with putty, and then you can fix the problem areas. Thus, it is important to prepare the complete equipment so that at any moment the necessary tools are at hand.

Where to begin?

First of all, from the room where the work will be carried out, it is necessary to take out all the furniture and household appliances. If you have stationary objects in the room, use a strong film and cover everything around, leaving access to the floor in all areas. The joints must be fixed with scotch tape, since the dust is able to make its way into the smallest gaps, and then it will be much more difficult to restore order. If the walls are glued wallpaper, or painted with waterproof paint or plaster, they do not need protection.

Otherwise, use a film and secure it with a meter from the floor to protect the finish from damage.

It is extremely important to check the condition of the entire floor, examine defects and eliminate problem areas. If you find rot, deflection or cracks, you will need to take appropriate measures to eliminate them. To do this, study the information, consult and use useful recommendations to prepare coverage for further work. Even small gaps cannot be ignored, use plaster to seal them, and only then can you continue.

If during the work you have applied a special glue, wait until it dries, level the coating with a planer, and then process it with emery paper. As for the plinths, they need to be dismantled. In the old floors, nail heads often protrude, and it is necessary to immediately deal with it, namely, to drown them with a hammer. Walk around the perimeter with a vacuum cleaner to remove debris and dust particles.

If you see the mastic on the surface, use white spirit and a washcloth to remove this protective layer.

Is it possible to loop without special knowledge?

This question can be answered in different ways. First you need to decide what area you are going to process, and how much is expected. In addition, it is important to study the nature of the surface, as the scraping of parquet, solid wood affects the choice of equipment and other details. If you turn to professionals for a service, you cannot call a single price, since each company provides its own value.

If you use special equipment from a leading manufacturer, you can do the work yourself, just before it is important to study all the details and follow strict instructions, then the result will meet the expectations.

When you decide on your own to grind the floor at home or in the country, carry out the preparatory work, stock up on tools and follow the rules.

Machine Scraping

Make sure that the room where the work will be carried out is closed, because the other room will be protected from dust. In this case, one should not forget about airing, so open the windows. Scraping pine boards and other types of wood coating is necessary in glasses to protect the eyes.Another important equipment is a respirator, you can do with a gauze mask. The grinder works very loudly, so you will need earplugs or headphones, as long as the noise does not come, and you feel comfortable working.

Since it is necessary to start with the drum equipment, it is necessary to insert a large-grain sandpaper into it. Start the treatment of the coating from the corner and move along the wall. As soon as you stop the machine and turn it, you need to tilt it back a little so as not to scratch the floor.

The next lane must be made in parallel, and so - every time. In the unit there is a special place where dust is collected, so do not forget to check it and change it. During work, sandpaper is quickly erased, watch for it, in time to install a new one, but observe the indicator of grain. As soon as you have walked the first time over the entire surface area, install a medium-grained pelt, and repeat everything again.

Do not forget to follow the rule regarding the direction of the perpendicular.

During the last scraping sandpaper with fine grain is used, and then it is necessary to move parallel to the floorboards.As you can see, grinding is not such a difficult task, if you use the right materials, have high-quality equipment with you and follow the step-by-step instructions. If you do everything qualitatively and measuredly, the result will be amazing. Walk on the wooden floor with a vacuum cleaner, as after grinding there will be a lot of residue.

When to carry out finishing work?

Experts recommend not to do this immediately after the scraping. Wait a day for the dust to completely settle, then clean up again. After that, you must use a soft sponge with white spirit, and walk on the surface. The final stage is varnishing. Regarding the choice of finishing material, here you should consult with a qualified specialist, as there is a wide range of such products on the market.

How to ottsiklevat a floor manually?

This method also has the right to exist, although it is not as much in demand as the previous one. It is suitable for small rooms, and in those cases where it is not possible to use the overall equipment.It is impossible to compare the processing manually and with the help of the machine, since each of the options will be effective when used correctly. If there is a limitation in finances, or you need to chime a small room, then you can use this method.

There are several types of manual processing of painted wooden floor. The first is the operation cycle. This device is used in small areas, for example, a floor in a niche or corners in a room. Thus, the working surface must be compact.

The next option is sanding with sandpaper. This method is considered the most affordable, as auxiliary material is cheap. You will not need a lot of time for processing, because here you need to rub the parquet. Costs depend on the amount of sandpaper you need.

Scraping frequency

It all depends on the measure of wear of the floor, as well as the breed from which it is made. The quality of wood plays an important role, as soft breeds need to be processed much more often. Of course, here it is necessary to take into account the intensity of use of the room.

If we are talking about a public institution where there is frequent movement, then it most often does not fit parquet, but another wooden covering. The same applies to dance halls, cinemas and other similar places. Experts say that high-quality parquet should be polished every twenty or even thirty years.

If the coating is solid, then scrapping should be done every ten years.

The timing of wear is affected by the technology and quality of varnishing. If the floor is covered with less than five layers, and the degree of contamination of the room is high, then it is necessary to do sanding more quickly. And thanks to high-quality work, the floor will look like new, which means that the lifetime of the coating will last.

How to protect the floor from wear?

After the sanding procedure, it is necessary to do varnishing. And here it is important to use quality materials. High demand in this area are varnishes based on solvent or water. The latter option is popular due to the rapid drying and the absence of an unpleasant odor. To ensure that the coating is durable and resistant, at least three layers of varnish should be applied.

.

Safety

Every specialist will agree that scraping the floor is a responsible process. During operation, appropriate equipment is used that requires proper handling. If you do not follow safety precautions, you can not only damage the floor, but also jeopardize your health. Therefore, it is important to listen to the basic recommendations to avoid any trouble.

First of all, remember that the tool must not be pressed while workingso that the boards do not create a recess. The room where the scraping is conducted must be tightly closed, the rest of the rooms are insulated with doors, and the slots are closed with polyethylene.

Remove hair, hanging clothes and any parts that may get into the mechanism of the grinding machine, because it can lead not only to unit breakage, but also to injury. It is better to use workwear in which it will be convenient to work.

Many experts hang the wire on the shoulder so that it does not get into the device, but if this happens, you must urgently disconnect it from the network and contact a professional master who will repair it.

If you have long been thinking about updating the wooden floor in your apartment, in the country or in a country house, but do not want to spend money on the services of a specialist, there is a way out. After reviewing the information provided, you can hold an event on scraping with your own hands and achieve the desired result. Be careful and success!

To learn how to make scraping wood floor, see the following video.