How to insulate a wooden floor with your own hands?

Any floor covering can lose decorative or technical properties over time. Often, an attractive wooden floor becomes cold and walking on it without warm shoes causes noticeable discomfort.

In such a situation, there is no need to change the floor, but it is enough to carry out the appropriate repair, and the floor will last more than a dozen years.

A wide choice of materials for thermal insulation allows you to choose the appropriate option for the price and characteristics, as well as make repairs yourself in a short time.

Why do you need to warm?

Wood is a natural material that is safe for humans. It does not emit harmful impurities during operation and rarely causes allergic reactions.However, one has to pay for naturalness, since the board is prone to the formation of rot and mold.

In order to avoid such troubles, It is important to observe the temperature and humidity levels in a wooden house. That is why so much attention is paid to the insulation of wooden floors in residential premises, since these measures allow not only to create a comfortable floor covering, but also significantly extend its service life.

It is also worthwhile to warm the floor in order to reduce the overall consumption of materials for walls and foundations, for example, in the construction of frame private houses. By performing thermal insulation of the floor covering, the following problems can be avoided:

- low, uncomfortable temperature in the apartment;

- high level of humidity;

- high costs for space heating;

- destruction of the floorboard due to the detrimental effects of fungi or mold;

- condensation on the windows and walls of the house;

- deterioration of health due to constant high humidity and interaction with pathogenic microorganisms (mold, fungi).

Mold, especially black, can cause not only severe allergic diseases.It can penetrate the lungs and bronchi and provoke the development of aspergillosis - the most complicated pathological condition, which in some cases ends in disability or death.

Timely warming of a wooden floor is a guarantee of a safe microclimate in a dwelling. But it is possible to carry out work on thermal insulation at any time, including with the natural wear of materials, when the flooring begins to lose its positive properties. The following types of flooring need special protection:

- overlapping cold basement;

- attic floor;

- interfloor floors (in multi-storey private houses).

The floor is the coldest part of the room, since according to the laws of physics, cool air always descends. This is especially true of private wooden houses, as the soil is in the immediate vicinity under their foundation. Therefore, it is important to warm the wooden floor in such homes.

In addition, the tree cracks over time, and rather large cracks form between the floorboards, into which (in the absence of adequate thermal insulation) cold air freely penetrates.

Choosing materials

When selecting the optimal insulation for a wooden floor, one should take into account not only its cost, but also such characteristics as environmental safety, fire hazard, lightness of construction, durability, ease of installation, low thermal conductivity.

All modern and time-tested materials have the listed properties. In order not to be mistaken with the choice, you should consider some points:

- The cost of insulation should match the financial possibilities. For the right choice should not succumb to advertising, since most of the materials, both expensive and budget segments have equal technical characteristics.

- In the presence of small rodents do not choose porous materials, such as foam, as they can be easily damaged by mice or rats. In case of forced neighborhood with pests, it is necessary either to get rid of them beforehand, or to give preference to mineral wool or fiberglass materials.

If the budget is completely limited, then you can safely apply the well-known and inexpensive expanded clay. Rumors that it can have a negative toxic effect on the human body have not been confirmed by scientists.

The material is safe, is cheap, so you can use it without concerns for health and budget.

The materials used for the insulation of wooden floors are represented by: mineral wool, expanded clay, sawdust, polystyrene foam, penofol, isover. Let us examine each in order.

Minvat - the most demanded material for floor insulation. It can be made of slag, fiberglass and stone rocks. Minwat fireproof, has excellent sound insulation properties. However, this material loses all its properties when wet, so it is important to pay due attention to the evaporation from the bottom and top of the insulation. The disadvantages can be attributed to the fact that the mineral wool should be handled with extreme caution, using protective equipment, since the fine dust from it, which is formed during the installation process, can negatively affect the human body, especially the respiratory tract.

Expanded clay - is widely used for the installation of bulk floors. It is safe for health, perfectly retains heat due to its porous structure. The only drawback may be the complexity of the work, compared with the installation of more modern heaters.

Sawdust - one of the most budget options. It copes well with the direct task - to warm the floor, but this material is susceptible to moisture, and therefore requires proper waterproofing. In addition, it does not create an effective noise protection.

Styrofoam (foam) - a popular material. It is used in both private homes and well-equipped apartments. Perfectly warms the floor, soundproof the room, but is afraid of moisture, from which it loses its properties and quickly becomes unusable.

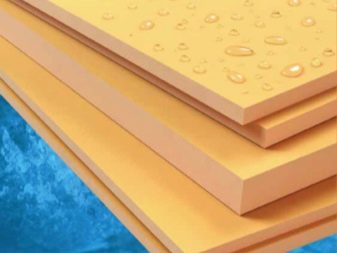

More modern, extruded polyfoam is devoid of these disadvantages, as it tolerates higher humidity much better.

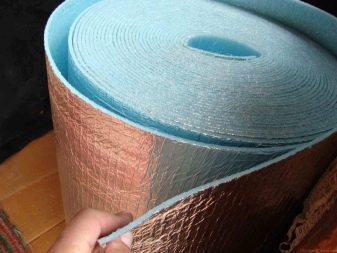

Penofol is a material, one of the sides of which is represented by aluminum foil, and the other is a heater, for example, polyethylene foam. In addition to the main function, thanks to the foil combines noise and waterproofing. Resistant to damage, durable and safe for humans.

Izover is a material that can warm the floor with or without lag. Available in several forms - roll, mats and plates. This is a modern material that allows installation without prior preparation, for example, treatment of the subfloor with clay.

It is environmentally friendly, affordable, perfectly reduces the noise level in the room.

Whichever material is chosen, it is important to take into account its features when constructing a floor heater, as well as to follow the technology and order of work.

Milestones and technology

The process of installation of floor insulation depends, first of all, on design features. There are the following types of styling technology:

- on the ground;

- on a concrete screed;

- indoors using lag.

In order to insulate the floor on the ground, you must perform the following steps:

- Ramming the ground from the underground and pour a layer of Pschs, which is then compacted with clay or bitumen. This treatment provides effective waterproofing.

- Backups are installed on the first layer under the logs, usually brick or concrete blocks are used for this purpose. With the help of roofing material, the supporting structures are waterproofed around the perimeter.

- Lags from a wooden bar with dimensions of 150x150 mm are arranged.

- Under the construction, bars are installed on which the sub floor will be laid.

- Windshield is placed over the boards.

- The selected insulation material is being installed.

- Waterproofing is placed on top of the insulation,which prevents the destruction of the material due to moisture.

- Then you can install a finished floor, either on the heater directly, or on plywood.

Warming the floor on a concrete screed is carried out in the following sequence:

- the surface is thoroughly cleaned with dirt, debris and dust;

- fit a layer of waterproofing material;

- the heater is mounted;

- on top fit vapor barrier;

- installation of the finished floor.

This option allows you to warm the floor without dismantling the old concrete floor, provided that it is in good condition. If there are small cracks or pits, then they can be repaired with a concrete mix (finished or independent production) and, after drying, proceed to work.

The lags are usually insulated wooden floors in private homes and cottages. In this case, the existing floor can be left without opening. This method is implemented by the following sequence:

- between the lags of the subfloor fit the boards of the subfloor;

- there is a vapor barrier on top with overlapping walls of 10-12 cm;

- further insulation is installed;

- it is possible to lay a finishing decorative covering (by linome, laminate, parquet, tile).

Particular attention should be paid to the warming of village houses, in which, in addition to internal workings, it is often necessary to warm the facade or foundation of a building. To do this, outside the bottom is also installed insulation.

In the next video, you can view a visual instruction on floor insulation for lags.

Tips and tricks

In order to conduct the insulation of the wooden floor correctly, with minimal financial costs and construction errors, Some subtleties should be considered:

- Even if the insulation is planned to be carried out on the old floor, it is necessary to open the base and see the condition of the structures holding the floor from below.

If the lags are rotten or damaged, they should be replaced. So, you can avoid problems with the floors in the future and to insure against double work.

- The main condition for choosing a heat-shielding material is its low weight, resistance to compression and mechanical stress. All the classic insulation materials used for many years in construction for the purpose of thermal insulation of floors have all these qualities.

- Very often, in order to prevent the destruction and formation of mold, the lags and the subfloor are treated with specialized antiseptic compositions.In addition, when setting up the floor, preference should be given to timber and softwood boards, larch, it is allowed to use plywood, which has protection from moisture.

Very often, without opening the floor is warmed with carpet or linoleum. To this end, insulation is mounted below the new pavement. In the toilet and bathrooms often use the system "warm floor".

Refer only to well-known and popular brands that produce quality products for floor insulation. Otherwise, you risk “throwing money down the drain” and not get the desired effect.

Warming a wooden floor is a necessary procedure, which, subject to all rules and regulations will save up to 20% of the heat in the room, hold a favorable microclimate and protect the home from the formation of mold and mildew. Modern materials will allow to carry out work quickly and independently, even to those who have very little experience in construction work and self-repair.