Metal siding under the log: material features

Metal siding under the beam is very popular among consumers, they leave a lot of positive reviews about such materials. Today, many choose such coatings, because externally they are very similar to natural wood, while siding panels have their important advantages. This article describes the features, the nuances of the use of such material, useful recommendations of experts:

Special features

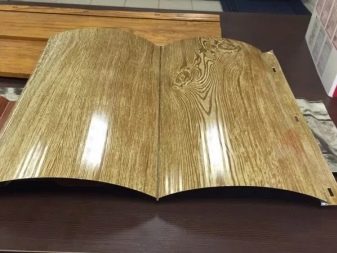

Siding panels are made of metal sheets. Products of the required format are produced by hot rolling. Then a primer is applied to each panel, which protects the surface from corrosion and makes it more durable.

Similar products are made from galvanized steel.The material is quite thin (usually its thickness is not more than 0.7 millimeters). Products differ from each other in size: there are options from 0.5 to 6 m in length. Special polymer coatings are applied to metal siding panels, which provide reliable protection of surfaces.

Scope of use

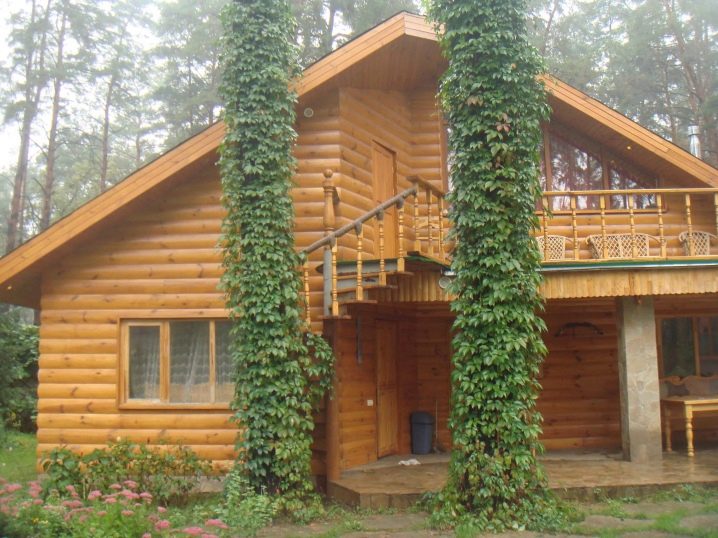

Siding materials made of metal are particularly often used in the construction of public and industrial buildings. For private houses, metal coatings have always been rarely chosen by consumers, because they do not provide a favorable climate indoors and are not associated with coziness and warmth (unlike, for example, natural wood). But production technologies are now actively being improved, and modern companies offer materials from metal, which are quite suitable for finishing private residential buildings.

Advantages and disadvantages

Metal siding under the log - a material that has a rather high strength. It is resistant to chemicals, sunlight, and wear. There are other qualities of such coatings that are important for consumers:

- Resistance to fire.That is why such siding panels are often purchased for buildings, where there is a rather high risk of fire. It should be borne in mind that when exposed to the flame, the paint or polymer coating may peel off and deform.

- Resistance to significant temperature changes. Such materials are suitable for a variety of weather conditions, for different climatic zones.

- Resistance to corrosion. This positive quality provides a special polymer coating, as well as a primer material. It should not be forgotten that in carrying out installation work, some products are cut, shortened. In this case, the protective coating is damaged, and corrosion occurs there. It is also not necessary to combine alloys of aluminum and metal products.

- When heated, the metal does not expand as much as vinyl siding. For this reason, it is not necessary to provide for a gap in the implementation of finishing works and to worry about the fact that the products can deform to a large extent with time.

- Metal has a long service life. You need to be careful with aluminum panels: such products are less resistant to mechanical stress than other metallic coatings. They should not be hit.

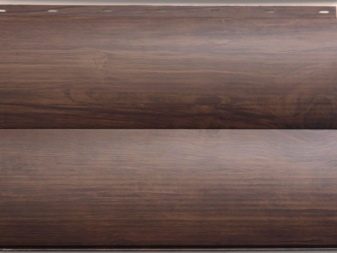

- Decorative.The color of such coatings is characterized by saturation, they imitate well-rounded logs very well.

The metal siding under the log has some disadvantages:

- The inability to recover deformed panels. The exact geometric shape of the products will not be returned.

- Inability to provide insulation. To minimize losses, you will need to take care of additional insulation.

- Pretty heavy weight. Metal siding heavily loads the foundation, foundation. It is possible that they will have to strengthen.

In the heat of the metal can become quite hot. Because of this, the temperature in the rooms can increase significantly. This problem is most relevant in cases where there is no ventilation gap, and the coating itself is dark.

Transportation and storage

In order for all properties and characteristics of metal siding panels to remain the same, it is necessary to create optimal conditions for the storage of such materials. It is worth noting that this recommendation is not as important as in the case of wooden products: in this regard, with metal siding is much more convenient.

Make sure that in the room where the coating will be stored, the air temperature was relatively low. Pay attention to humidity: it should not be increased. If conditions in the storage area are unfavorable, the service life of the products may be reduced.

Delivery terms for metal siding panels are more important:

- Do not put anything else on the panel. Although they are characterized by increased strength, but under the influence of significant weight may well be damaged.

- If you are going to transport the siding in the back of the machine, carefully fasten the material.

- To avoid mechanical damage, you should pack the coating quality.

Remember that with a strong impact, the panels may be deformed. Take care when transporting them. If the additional protective layer on the material is damaged, it is very likely that in the future you will have to face such a problem as corrosion.

Since the block house - as the siding panels under the log are also called - is semicircular, the risk of damage significantly increases. Defects occur more frequently on such surfaces.In order to keep such materials holistic and durable during transportation, it is better to put them in several layers (they should not move freely in the package during the trip).

Assembly work

Installation of metal siding panels is a job that is not very difficult, but its implementation must take into account various important nuances. Finishing is carried out in several stages.

Remember that you will need to take care of all the measurements. It is necessary to carry out cutting with maximum accuracy. Otherwise, you will spend a lot of time correcting errors, and it will be very difficult to deal with them.

How to prepare the surface?

If you want the finish to be of the highest quality, you will first need to carefully prepare the surface. So you can avoid serious problems in the future. Some recommendations should be taken into account:

- Examine the foundation, walls and assess their condition. In the case when you are not sure that the base will cope with a significant load (or there are serious defects), you will have to strengthen it. To do this, fill in additional supports for the foundation and reinforce the base with mesh.

- If necessary, peel off the old paintwork, its peeling pieces.Remove all unnecessary from the surface.

- Cracks and cracks will need to cover up.

- Apply an antiseptic coating on the base. If combustible materials were used to create the wall, use flame retardants as well.

- Think about how it will be possible to bypass areas of communication that interfere with the finishing work. If possible, delete them.

Warming and crate

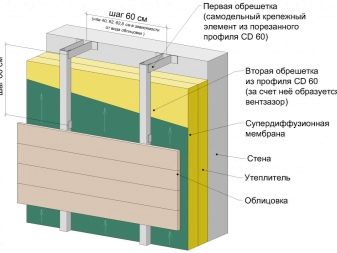

Since metal siding panels need to be installed on as flat a base as possible, you will have to take care of creating the batten. It is necessary to build it, using the recommendations of experts.

- Apply flame retardants and antiseptics to the wood beam, attach it to the base. To make the design even, lay the substrate. Using a level, set the racks in increments of 0.5-0.6 m. Fix them with dowels and screws. If the facade is ventilated, it will be necessary to pre-lay the counter grilles. Fix a heater on it and stretch the main racks from above.

- You can make a crate on the suspensions. U-shaped galvanized profiles are used for this. On the basis, you will need to outline the lines: you will fix the brackets using them, using screws and dowels.Cut the racks of the desired size and secure them on the hangers using a level. Jumpers are used for extra rigidity.

Regardless of how you make the crate, you will also need to additionally revet the door and window openings. From the outside around the perimeter, frame them with the help of racks. These elements should be connected to the common frame. If used wood beams, you need to put insulation in the cells.

If the crate was created from a metal profile, it should be noted that the insulating material should not interfere with the implementation of steam exchange. Plates that provide heat insulation should be fixed on hangers (brackets) for frame racks. With the help of special plastic dowels, an additional fixation should be provided.

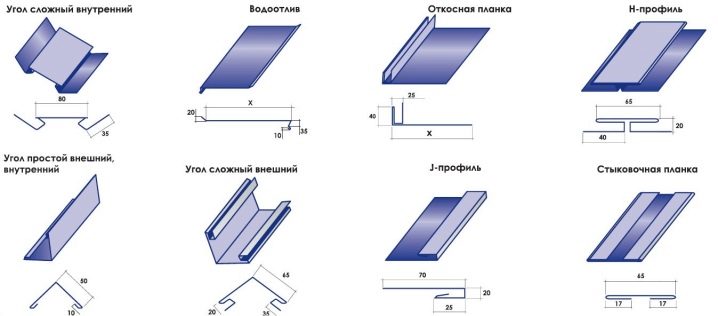

Accessories

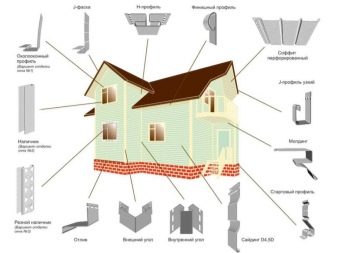

Components are installed in a specific order.

- Set the start bar. Attach a profile to the corners, then you will need to mark its boundaries. For panels it is necessary to define a reference point (below). From the ground it is placed at a distance of 0.4-0.5 cm.

- Focusing on the starting strip, install the corner elements. Angles should be set 1 cm below.These elements should be fixed with screws. To control the process, use a level.

- Carry out the laying of the H-profile, connecting strips. If you plan to finish the wide wall or combine shades, install connecting strips between the corners. To align these elements, use a level. It is necessary to fix them with the help of screws.

In the case when siding panels are made to order, and you have little experience in the implementation of such finishing works, you should install all the necessary elements before making accurate measurements. So you can avoid inconsistencies.

Panels

Starting to install siding will need from the corners of the building. To fasten the panel, use screws. Special lock joints are also provided: with their help, all the upper elements cling to the lower ones.

Standard panels sometimes have to be cut, because their dimensions do not always allow covering the entire surface. To do this, you can use a hacksaw for metal products. The hot disc of the grinder can spoil the protective coating.

Install all the elements until you reach the top.Then install the finishing slats. From above they will need to be attached using self-tapping screws, because they only have locking connections from below.

Make sure that there are no deviations. With each new element it will only increase. Do not forget about the use of the building level: it should be used after the installation of each pair of elements.

Care

Such coatings need to be carefully looked after: in this case, they will preserve the aesthetic appearance for a long time. Walls lined with metal siding panels will need to be cleaned from time to time. To do this, you can use a window cleaner and a brush with not very stiff bristles. Periodically inspect the facade: it should not be chipped and scratched. Having noticed defects, eliminate them by means of a primer: the protective polymeric covering has to be complete.

For other features of metal siding under the log, see the following video.