What are the sizes of siding?

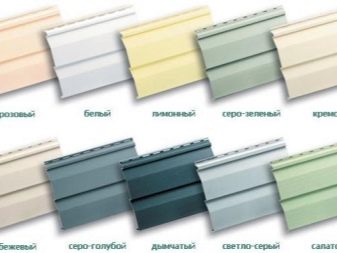

Siding has become widespread when facing the facade of buildings. This is due to the resistance of the material to the environment (humidity, frost and sudden temperature changes, squally wind), strength and aesthetic appeal. Panels are painted in pastel or bright colors, can be glossy or matte, and also imitate stone and brick masonry, wood and ceramic surfaces.

Siding release form - panels, the dimensions of which depend on the type of profile, the characteristics of its application and the manufacturer.

Special features

The main advantages of siding - its resistance to moisture. Plastic models do not transmit moisture, metal counterparts have a special polymer coating that provides water-repellent properties of the material.

It is important that the siding has high strength, which makes it a reliable material for covering the house. In this regard, the metal panels are stronger, they are not afraid of mechanical shocks.

Due to the small coefficient of expansion, the profiles do not crack in the cold and withstand 60 freezing cycles. The presence of an anti-hill lock allows you to use the material without fear even in regions that are characterized by squally wind.

The service life of the material is also impressive, which, on average, is 30-60 years depending on the type of panels.

Most siding panels have a small (3-6 kg per m2) weighttherefore, additional strengthening of the foundation is not required. Profiles can be mounted together with the insulating material (mineral wool in rolls or polystyrene). Fixation is carried out directly on the wall or crate (made of wood or metal). If the method of mounting on the batten is chosen, then you should not worry about the evenness of the walls. Thanks to this technique, it is easy to hide surface irregularities and cracks.

Due to the presence of the locking mechanism, the panels are easily assembled on the principle of a children's designer. In other words, installation can be carried out without the involvement of professionals, it is possible to install the material even at low temperatures.However, in this case, the panel should be preserved for 24 hours at room temperature.

Using siding with imitation of various surfaces, it is possible to achieve interesting stylistic decisions. It is important that the material imitates stone, wood, brick as accurately as possible; you can only suspect this stylization in the vicinity.

Finally, siding differs in price affordability, its price will definitely be lower than the cost of facing with stone or brick.

Sizes of different types

Dimensions siding profiles are not governed by state standards. Each manufacturer independently decides what sizes the panels will be.

The dimensions depend not only on the brand under which profiles for outdoor work are produced, but also on their type. It is important for what type of finishing the profile is intended. So, front options are smaller thickness than the basement. The latter are designed to protect and decorate the basement of the building, which is more susceptible to moisture, road reagents, and mechanical damage. This is the reason for the thickness of the socle panels, 1.5-2 times the height of the standard profile for the facade.

Information about the width, length and height of the siding is necessary to accurately calculate the required number of siding packages, taking into account the waste during installation.

Wooden

It has strength and moisture resistance, but only under the condition of regular processing with special compounds. The material is characterized by good performance of heat and sound insulation, unique color range and unique texture, high cost.

Manufacturers are recommended to adhere to the following indicators in the manufacture of the material: length - from 2 to 6 m, width - no more than 22 cm, thickness - no more than 2.2 mm.

Cement

The material in the base has cement mixtures and modifiers, and to ensure its strength, special cellulose fibers are added, which have a reinforcing property. The result is a solid monolithic material that is resistant to frost and high humidity. However, cement panels are not suitable for every type of foundation, because they give additional load on the foundation of the building.

The length of such panels can be from 3 to 3.6 mm, width - 20 cm, thickness - 0.8-1.2 mm.

Vinyl

It is made on the basis of polyvinyl chloride, some amount of acrylic is allowed in the composition (it turns out acrylic siding, which is a kind of vinyl).Plastic panels are characterized by elasticity, as well as the richness of the color palette. The latter fact is due to the addition of a coloring pigment directly to the composition of the product at the production stage.

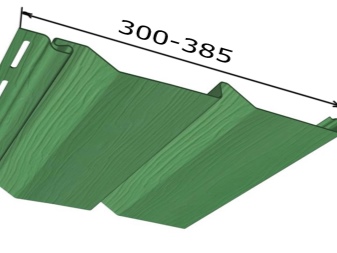

Classical for PVC panels is a height of 2.5 to 4 m. Longer panels are optimal for cladding high buildings, because it is possible to avoid seams on the surface. However, their use requires skill - the profile bends and can crack.

The total width of the panel is 20-30 cm (useful width is 2-3 cm less), and the thickness does not exceed 0.7 - 1.2 mm. The weight of one profile is in the range of 1.5-1.9 kg.

American-made siding has a slightly different standard width - from 20.5 to 25 cm.

Dimensions may vary depending on how many rails attached to 1 panel. Single (marked with S), double (marked - D) and triple (you can recognize it by the marker T) models are distinguished.

Ceramic

The ceramic profile made on the basis of clay and other natural components is environmentally friendly, and therefore it can be used not only for external, but also internal lining.

Standard dimensions are: length - 3-4 m, width - 19-22 cm, profile height - no more than 1 mm.

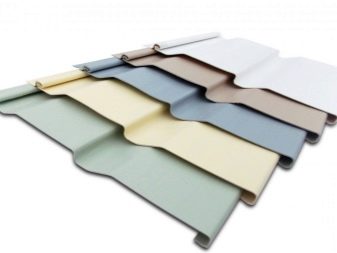

Metal

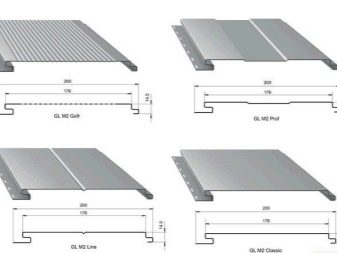

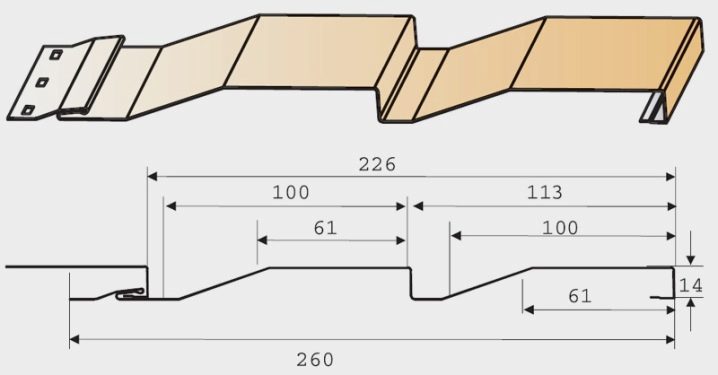

Metal siding is made of coated steel with a protective polymer coating. Profile dimensions depend on its type. There are several options for the material - flat panels, ship board, herringbone and double herringbone.

For metal siding, the shipboard standard height is 0.5-6 m with a width of 25 cm and a material thickness of 0.5 mm. The herringbone modification has a width of 25 cm with a profile length of 0.5-6 m and a profile height of 0.5-0.6 mm. The weight of metal siding is on average 4 kg per m2.

The thickness of the material consists not only of the thickness of the metal frame itself, but also the thickness of the polymer coating. On average, the last layer has a thickness of at least 40 microns.

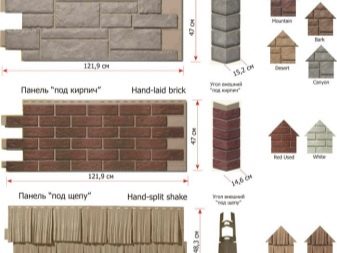

Basement panels

Panels for mounting on the base can be presented in any type of siding. In other words, they are made of metal, vinyl, fiber cement, ceramics, wood. The most popular and most suitable for this area of the house are vinyl (as well as acrylic) and metal profiles.

A feature of siding is the compactness of its size. As a rule, the form of release - small rectangles, the length of which corresponds to the standard height of the basement in the houses. Panels of this size are easy to install, fasten almost without waste.

Traditionally, the length of the material is 1-1.5 m, width - from 40 to 90 cm, thickness - not less than 2 mm (2-4 mm). Siding with increased thermal insulation properties may have a smaller thickness. It can be mounted without insulation.

How to calculate the quantity?

When buying a material, it should be purchased so that it is enough for the entire facade, taking into account the stock. This is due to the fact that the shades of the panels of the same manufacturer of different batches may have slight differences in color.

Get the right amount of material will help accurate calculation. The easiest way is to invite a professional measurer, usually the manufacturer or the store provides their services free of charge when placing an order with them. The advantage of this method is that the specialist will accurately calculate the required amount of siding and take responsibility for the actions taken. However, there is a risk that the measurer, who is interested in increasing the purchase check, will aggressively offer components that can be dispensed with.

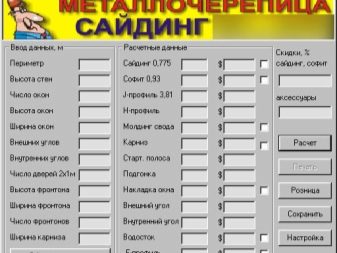

You can also use a special program for calculating the consumption of material.

Often, such calculators offer to use construction stores and companies,involved in the manufacture of siding.

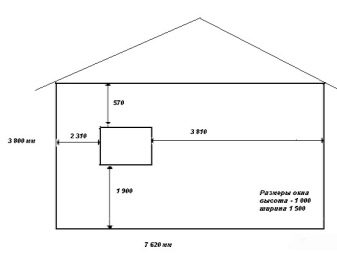

To determine how many panels to buy, will help a simple calculation "in the old manner." To do this, find out the dimensions of the profiles to be used, as well as the dimensions of their components. In addition, you need to measure the height and length of the walls, basement, openings (door and window). And also measure the height of the corners of the structure (internal and external).

Having made the necessary measurements, proceed to the calculation of the number of rows of profiles on the wall. The height of the latter is divided by the width of the profile (useful, not total). The resulting number is the number of rows. If you multiply the number of panels in a row by this factor, you get the total required number of profiles. It remains to divide this figure by the number of panels in the package, and the result is rounded up. The result is the number of siding boxes needed for cladding.

However, on those parts of the wall where there are openings, fewer profiles are required. To do this, calculate the length of the profiles in this part of the structure and their number.

The counting of accessories is done piece. Determine the number of corner strips by dividing the height of the wall by the height of one slat.The number of platbands is determined on the basis of the perimeter of the openings. Measuring the perimeter in the upper and lower parts of the walls, determine the number of starting (fastener, for fixing the bottom row of siding) and final (the final element of the mounted surface) strips.

The calculation of starting and finishing slats is carried out without taking into account the material stock. In order to save money, a siding panel can be used as a lower secondary rail, in which the lock joints are pre-cut. The number of elements of the J-profile can be determined by dividing the total footage of the vertical cuts near the window and the diagonal planes on the gables (the profile is used for these sections) by the length of one panel.

When calculating it is important to follow some recommendations.

- When measuring the height and perimeter of the walls, consider the size of the projections and niches. For their design used J-profile and special corners.

- Calculating the length of the walls, remember that it will increase slightly on both sides due to the installation of the batten for siding.

- Before you buy a particular material, analyze the features of the dimensions of several of the most popular models.It is more convenient to draw a table for this, including such columns as the name of the material, its length, width, the required number of panels and components, the approximate cost of the cladding. Such a hint will help not to get lost in the parameters of different types of siding and will allow you to find the most optimal option for the price.

- The most accurate calculation of the required area, perimeter and height of the surfaces is possible using a schematic plan of the house, which shows the exact parameters.

- Having calculated the required number of panels, add to this number another 15% for allowances, overlaps and trimming.

- If it is necessary to purchase the material, it is important that the new batch has the same series and number as the one purchased earlier. Otherwise, the shades of materials from different batches may vary.

It is impossible to sheathe a building without resorting to cutting siding. For these purposes, you will need a circular saw with a hard diamond disc for cutting fiber cement, electric jigsaw or a saw, a metal knife to give the metal or vinyl profile the required length. Cuts are processed with emery.

An overview of the front materials - vinyl siding and basement panels, see the following video.