How to cut polypropylene pipes?

Polypropylene pipes are widely used in the organization of water supply systems. To work with this material requires special tools. High-quality cutting tools greatly facilitate the installation process. The fact that it is better to cut polypropylene pipes will be discussed in this article.

Special features

In the construction market, most often you can find polypropylene pipes 12 meters long. When installing a water supply system or underfloor heating, it is often a challenge to cut the product into shorter sections. For these purposes, a special tool is needed. Speed and ease of installation depend on convenient and high-quality cutting.

There are many types of tools for cutting PPR. Specialized tools are equipped with a sharp blade, as polypropylene is a durable material. Using a tool of poor quality, you can severely damage the pipe. In addition, the uneven cut line will have a negative impact on the quality of installation.

When connecting the elements of the water supply system end-to-end, it is important to ensure that the sealing of the seams is at a high level. Otherwise it may lead to leakage. For this reason, it is recommended to use special scissors for cutting pipes.

Instead of special tools, polypropylene pipes can be cut with a hacksaw for metal. However, this method of cutting is more laborious and less quality, since roughness remains at the edges of the cut, and the line itself in most cases turns out to be uneven.

Kinds

There are many modifications of tools for cutting polypropylene pipes. Each type has its own design features and specifications.

The following types of devices can be distinguished:

- precision scissors;

- manual roller pipe cutter;

- the device with the ratchet mechanism;

- battery cutter;

- pipe cutter guillotine.

Precision tools have a fairly simple design. It is possible to work with such a device with one hand. Such scissors are suitable for cutting pipes with a diameter of from 3 to 41.5 millimeters. The device is equipped with a blade made of alloy steel. This option is suitable for performance of work of small volume.

The roller-type pipe cutter is an arc-shaped body with a handleequipped with rollers and a flat round blade. The rollers perform the function of rotation of the pipe, and the blade is equipped with a sliding mechanism. The cost of such a model is low. However, the roller type tool is convenient in operation and allows for smooth cuts at an angle of 90 degrees.

Ratchet tools are a more convenient modification of roller scissors. Such devices are easy to use: the support and the cutting rail with a blade make it easy to open and close them effortlessly. Thanks to the wide support, the tube is securely fixed in the device. The sharp blade easily cuts through the material, not allowing it to change position. It is possible to work with such tool with one hand, without making special physical efforts.

Cordless scissors are distinguished by their high cutting speed. Basically, such a tool is used by masters in laying water supply systems. The device is equipped with a small electric motor. This allows you to quickly and easily cut the pipe into a large number of segments.

Pipe cutter-guillotine is used for cutting large diameter pipes (from 63 to 350 millimeters). The cutting tool is equipped with a sharp blade with a Teflon coating. When cutting with such a device, the edges of the pipe sections obtained are ideally even and smooth.

It is worth noting that the various modifications of scissors differ depending on the diameter of the pipes that they can cut. Models for small products (up to 42 mm) cost less than devices for cutting pipes with a diameter of 75 millimeters.

Browse popular models

In the modern market a rather wide range of scissors for polypropylene pipes is presented. Before buying, you can get acquainted with the ratings of popular models, which will allow you to choose the most high-quality tool. However, it should be remembered that in stores often there are fake devices of expensive well-known brands.

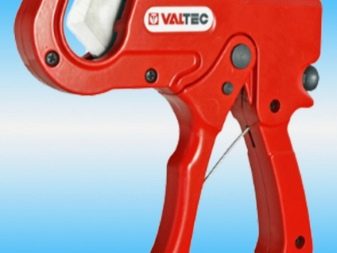

Valtec

Guillotine pipe cutter brand Valtec is designed for cutting pipes with a diameter of not more than 3.2 centimeters. The device is equipped with a ratchet mechanism, which ensures high quality cutting of plastic products. When working with a pipe cutter, it is not necessary to independently open the support and the cutting rail after cutting, as the tool is equipped with a spring, which returns the structural elements to the original open position.

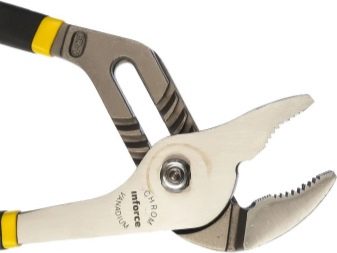

Inforce

Inforce ratchet cutter features a good price / performance ratio. The device is designed for cutting pipes with a diameter of up to 4.2 centimeters. The tool is equipped with a sharp steel blade that allows you to make a high-quality cut without irregularities and roughness.

The disadvantage of this device can be considered metal handlesOn which there are no rubber pads. With a large amount of work to use such a tool will not be very convenient.

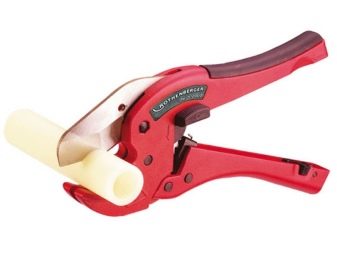

Rothenberger

Rothenberger pipe cutters are distinguished by their high quality and convenient construction. Cutter for polypropylene pipes can cut products with a diameter of 0.6 to 4.2 centimeters. The cutting element of the device is very sharp and durable, which allows you to cut pipes with thick walls, without leaving any defects at the cut-off point.

Handles of the tool are equipped with a clamp that provides possibility of safe storage of the tooland also allows you to carry it with you. On the arms there are rubber pads, which makes working with the tool more convenient. Also on the case there is a special button, when pressed, the bearing and the cutting rail return to their original open position. The disadvantages of these devices include a rather high cost compared to counterparts from other manufacturers.

How to choose?

When choosing a suitable tool for cutting polypropylene pipes, it is necessary to evaluate the technical characteristics and functionality of each option. Devices may vary in some design features, price and quality.

Inspecting the tool in the store, you should pay attention to its basic parameters.

- Blade quality. It is desirable that this element was made of stainless steel. It is also important the value of the angle of sharpening the part, which should be 30 degrees.

- Handle device. It should fit comfortably in your hand. Otherwise, it will be quite difficult to perform high-quality pipe cutting.The most convenient way to work with the tool, the arms of which are rubberized.

- Reliability support for pipes. This element should be stable and quite wide. Otherwise, the pipe will be poorly fixed between the support and the blade with the blade, which will lead to an uneven section.

- It is desirable that the device be equipped with an automatic removal of the support and the slats with a blade, so that these elements return to the open position after cutting.

Also consider the degree of need for adaptation. If you plan to use the tool for personal needs only once, then there is no point in acquiring an expensive model. In this case, you need to choose a device with the best value for money. Electronic tools are necessary for craftsmen who often face the challenge of cutting polypropylene pipes in large quantities.

Another important factor influencing the choice of scissors is the diameter of the pipes. In size and some characteristics of polypropylene pipes, which require special scissors, can be divided into several types.

- PN 10 - such products are designed for cold water supply systems, as well as for heated floors.Such pipes can withstand the effects of coolant temperatures within 45 degrees and a pressure of not more than 1 MPa.

- PN 16 - this modification is used for laying centralized heating. The pressure inside the pipe should not be too high.

- PN 20 - this type of pipe has a universal purpose. The product is allowed to be used for laying the system not only cold water supply, but also hot. Products can withstand the internal effects of temperatures not exceeding 80 degrees.

- The pipes PN 25 represent products from a covering from aluminum foil. This material provides the ability for pipes to withstand high temperatures (95 degrees) and a pressure of about 2.5 MPa.

How to use?

The process of cutting polypropylene pipes will largely depend on the tool used.

There are several highlights of this process.

- First of all, it is important to make accurate measurements of the necessary segments and make labels on the pipe.

- Then you need to open the tool and position the pipe labeled to the blade. To make the blade easier to get into the material,on the marked area, you can pre-make a small incision with a knife.

- Smooth movements, but with the application of a certain effort, it is necessary to push the tool handles. Acting too quickly is not worth it, otherwise the pipe may change its position, and the cut will be uneven. It is also important to follow the angle of the cut, which should be exactly 90 degrees.

As noted earlier, the subtleties of working with a device depend on its type. After buying scissors should be carefully read the instructions. Before the main work, you can also practice cutting the pipes on unnecessary scrap (if, of course, there are any).

How and what to cut polypropylene pipes, see the following video.