Polypropylene pipes: features and table diameters

Today, when repairing or installing plumbing or heating systems, they often acquire all sorts of polymer pipes. The most common of these steel pipes made of polypropylene, due to their strength and durability, they almost everywhere replaced the metal elements. Both professionals and beginners in the repair business have appreciated their consumer properties.

Special features

The inner surface of polymer products is smoother, which reduces the resistance to movement of water in the system.

Polypropylene pipes, unlike all the others, have several more advantages.

- Cheapness Polypropylene is an inexpensive material, and manufacturing technology is no longer new and fully debugged at many manufacturing plants. This does not allow to monopolize the market, as well as to produce component elements according to the same standards.

- Strength. Among other polymer pipes, polypropylene is practically the thickest. Because of this, they have a larger size and, consequently, greater strength, they are also almost impossible to bend.

- Aesthetics. Due to the bending strength, the heating system or the water supply from polypropylene boasts an almost geometric definition of the lines. And the polymers of which the pipes are made can be given any color both at the factory and by painting them independently.

- Durability and corrosion resistance. The inner surface of the material is treated with special means that protect the pipes from the buildup of solid particles on its walls. According to the manufacturers, polypropylene in the system for supplying and discharging cold water can retain its operational properties for up to 80-100 years.

- Low weight and easy installation.The material is about 9 times lighter than metal, which makes installation of pipes possible even for a beginner alone.

- Noise isolation. The flow of water through such pipes does not create a buzz and rustle.

For all its merits, polypropylene systems have some drawbacks:

- the need to install additional compensators that protect the pipes from linear expansion;

- the need to buy and install insulation due to the fact that polymers have low resistance to elevated temperatures;

- the material deteriorates faster under the rays of the sun, if you do not cover it with any enamel or paint.

Due to the almost complete versatility of pipes made of polypropylene, there are many areas of their application. With their help, they install a hot and cold water supply system in private and multi-storey buildings, equip sewers and storm drains. Polypropylene makes ventilation and pneumatic systems, irrigation and drainage structures. Polypropylene pipes of small diameter can be equipped with a “warm floor” in the house, and chemically active substances are transported through large pipelines.

Their physico-mechanical properties according to GOST are as follows:

- density 0.9 g / cu. cm;

- melting point +149 ° C;

- coefficient of expansion 0.15 mm / mm;

- thermal conductivity (at + 20 ° C) is 0.24 W / ms;

- heat capacity (at + 20 ° C) is 2 kJ / kgS;

- tensile strength of about 35 N / kV. mm

What are the?

On any types of polypropylene pipes must necessarily be marked, from which you can get information about raw materials and operational features of the product. In various stores you can find pipes of several categories, depending on the composition of raw materials.

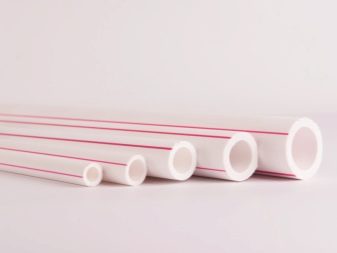

Marked with PPR (PPR)

These are products made from a statistical or random copolymer of polypropylene, which has a crystal structure of molecules. Pipes with such markings can be used for installation of both cold water supply and the heating system due to resistance to temperatures ranging from -170 to + 1400С. And they are also the most resistant to shock loads, therefore they are used in the installation of sewer systems and drainage systems. Their external diameter ranges from 16 to 110 mm.

Labeled PPH

Such products made of polypropylene contain in their composition special modifying additives: nucleator, antistatic and flame retardant.They help the polymer to gain increased strength, due to which such pipes are used in the installation of external cold water supply systems, drainage and ventilation. Modifiers in the composition have a too low melting point, due to which such material is not suitable for arranging heating systems. Pipes with PPH marking are, as a rule, the maximum size and are used in industrial construction.

Labeled PPB

Such polymers consist of homopolymer blocks (micromolecules). Such blocks alternate with each other, differing in the composition and structure of the molecule, thereby increasing the impact resistance of the entire product. PPB-pipes are used for the installation of "warm floor" and water supply systems.

Tagged with PPs

A polymer called polyphenyl sulfide is a higher grade material than all others. Apply it to almost any system, including heating, ventilation and transport, due to increased wear resistance, impact resistance and the ability to withstand high and low temperatures. The cost of polyphenylsulfide pipes is significantly higher than the rest of polypropylene, and the diameter of finished products ranges from 20 to 1,200 mm.

Depending on the resistance of polypropylene pipes to the pressure of the fluid passing through them, there are also several types.

- N10 (PN10) - pipes with an outer diameter of from 20 to 110 mm and an inner diameter of from 16 to 90 mm, used for installation of heating or “warm floor” with heating not more than + 45С. Such products withstand pressure on the wall of 1.0 MPa with a material thickness of 1.9 to 10 mm.

- PN16 - pipes for the supply of water with a temperature of not more than + 60C and a working pressure of up to 1.6 MPa. This type of product is quite rare due to its specificity.

- N20 (PN20) - pipes with an outer diameter of 16 to 110 mm and an inner diameter of 10.6 to 73.2 mm. When the material thickness is from 1.6 to 10 mm, the heating and water supply systems mounted from it are able to withstand pressures up to 2 MPa and temperatures up to +80 C.

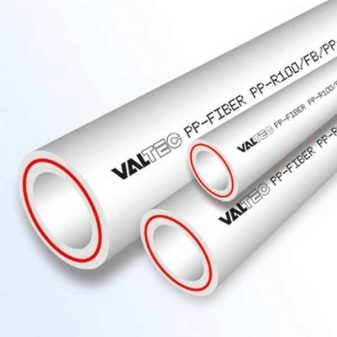

- N25 (PN25) - polypropylene that can withstand pressure on the pipe wall up to 2.5 MPa. Such products have additional reinforcement with aluminum foil, which allows their use when installing hot water and heating systems with temperatures up to + 95 ° C. The inner diameter of 13.2 - 50 mm and the outer diameter of 21.5 - 78 mm is not a hindrance to high impact resistance due to the multi-layer pipe.

As well as polypropylene products of even one type can vary in size. Their diameters depend on the pressure of the fluid on the pipe wall, its quantity and temperature. They are selected depending on the purpose of the highway. For each classification of products there is a specific size table, according to which it is easy to choose the right one. The diameters in it can be presented both in parts of an inch (1/2 inch, 3/4 inch, 1 inch), and in millimeters (20 mm, 63 mm, 160 mm), which is much more convenient.

Below is a table of sizes, from which you can find out the conformity of steel pipes with polypropylene.

Equivalent pass | Outside diameter | ||

Steel pipes for gas pipeline | Steel pipes for plumbing | Polymeric pipes from polypropylene. | |

10mm | 17mm | 16mm | 16mm |

15mm | 21.3mm | 20mm | 20mm |

20mm | 26.8mm | 26mm | 25mm |

25mm | 33.5mm | 32mm | 32mm |

32mm | 43.2mm | 42mm | 40mm |

40mm | 48mm | 45mm | 50mm |

50mm | 60mm | 57mm | 63mm |

65mm | 75.5mm | 76mm | 75mm |

80mm | 88.5mm | 89mm | 90mm |

90mm | 101.3mm | - | - |

100mm | 114mm | 106mm | 110mm |

125mm | 140mm | 133mm | 125mm |

150mm | 165mm | 159mm | 160mm |

160mm | - | 160mm | 180mm |

200mm | - | 219mm | 225mm |

225mm | - | 245mm | 250mm |

250mm | - | 273mm | 280mm |

300mm | - | 325mm | 315mm |

400mm | - | 426mm | 400mm |

500mm | - | 530mm | 500mm |

600mm | - | 630mm | 630mm |

800mm | - | 820mm | 800mm |

1000mm | - | 1020mm | 1000mm |

1200mm | - | 1220mm | 1200mm |

In addition to the supply of water and sewage to a private or multi-family house, polypropylene also houses major highways for the installation of water supply and sewage to large residential districts and industrial facilities.Most often, polymer pipes of large diameter are not used for heat transfer, since polypropylene pipes may be deformed due to high temperatures.

Standard sizes of polypropylene pipes PN (10, 20 and 30) are shown in the table below.

Outer diameter of the pipe | PN10 | PN 20 | PN30 | |||

Internal diameter of the pipe | Pipe wall thickness | Internal diameter of the pipe | Pipe wall thickness | Internal diameter of the pipe | Pipe wall thickness | |

16mm | - | - | 10.6mm | 2.7mm | - | - |

20mm | 16.2mm | 1,9mm | 13.2mm | 3.4mm | 13.2mm | 3.4mm |

25mm | 20.4mm | 2.3mm | 16.6mm | 4,2mm | 16.6mm | 4,2mm |

32mm | 26mm | 3mm | 21.2mm | 5.4mm | 21.2mm | 3mm |

40mm | 32.6mm | 3.7mm | 26.6mm | 6.7mm | 26.6mm | 3.7mm |

50mm | 40,8mm | 4.6mm | 33.2mm | 8.4mm | 33.2mm | 4.6mm |

63mm | 51.4mm | 5.8mm | 42mm | 10.5mm | 42mm | 5.6mm |

75mm | 61.2mm | 6.9mm | 50mm | 12.5mm | 50mm | 6.9mm |

90mm | 73.6mm | 8.2mm | 60mm | 15mm | - | - |

110mm | 90mm | 10mm | 73.2mm | 16.4mm | - | - |

How to choose?

In order to choose a quality product with a long service life, it is necessary to pay attention to certain information that can be easily obtained from the seller in the hardware store, as well as examining the product packaging and assortment.

Manufacturer

It is best to study in advance customer reviews and ratings of various manufacturers. The highest quality products are produced by German, Czech and domestic companies. European pipes are more expensive than Russian due to the cost of transportation and import.The cheapness of Turkish and Chinese-made products may surprise you, but you need to find out in advance the very best Asian manufacturers, and be prepared for unpleasant surprises. The leaders among producers of polymer pipes are two Czech companies Wavin Ekoplastik and FV-Plast, as well as the domestic company Pro Aqua, whose products on the building materials market are even cheaper than some Asian analogues.

Equipment

When installing a water supply or sewage system in large quantities, various fixers, wiring for the coupling and other components will be required. It is advisable to purchase them from the same manufacturer as the pipes themselves, and from the same material.

Marking

It is necessary to find out in advance and pick up pipes of that capacity and resistance to temperatures that will be needed to repair the old or build a new water supply or heating system. It is better to take the product a little higher performance than necessary to leave a margin of safety in an emergency.

In order to choose the right pipe for the inner diameter, it is necessary to know the speed of water movement along the supply line (V) and the average flow rate (Q).

For a private house or apartment, the internal diameter can be calculated by the formula:

Diameter = square root of (4 - Q - 1000 / n * V),

where n is the number pi, equal to 3.14.

However, most often in private construction used pipes with a diameter of 20 mm, installing connectors for them by default.

For multi-storey buildings, pipes are selected depending on the height and type of room:

- for houses of 5 and less floors, polypropylene pipes with a diameter of 25 mm are used as a riser;

- for houses of 6 and more floors - pipes with a diameter of 32 mm;

- wiring for apartments and in them is performed with products with a diameter of 20 mm.

Tips

Replacing or repairing piping without buying professional services is not too easy, but possible. The main thing is to carefully follow certain rules and prepare all the necessary tools.

First, all the preparatory work is carried out.

First of all, it is necessary to draw up a project in which the whole layout of water distribution in an apartment or house will be reflected:

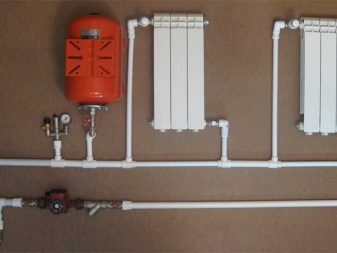

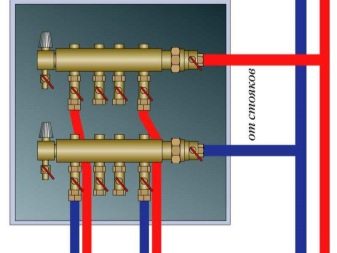

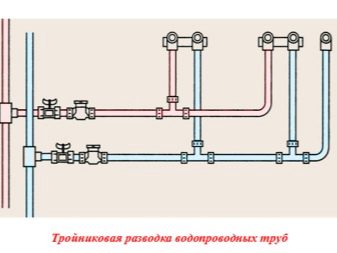

- collector circuit;

- traditional (triple) scheme.

Choose the method of connection to the heating circuit of radiators in one of four ways:

- flow-through;

- with bypass;

- with three way valve;

- with valves.

After that, purchase the necessary materials, as well as special tools for cutting and soldering. You can purchase a ready-made set, or each product yourself, or rent them.

The required minimum is:

- pipe cutting scissors;

- electric welding machine with a special stand;

- shaver to remove the outer layer;

- fasco-picker and calibrator;

- various nozzles in order to glue parts of pipes by heating (soldering).

In addition to such specific equipment, you will need a conventional wrench, tape measure, marker and soldering kit.

In addition to the pipes themselves, it is mandatory to purchase all the necessary fittings, which include various couplings, ball valves, clamps, plugs, adapters, elbows and other additional polypropylene products. The quality and thickness of the material of all fittings must match the material of the pipes themselves. It is best to buy all the components from the same manufacturer from whom the lines themselves were taken.

Depending on the thread, all connections can be divided into detachable and non-detachable. The latter implies a connection by soldering directly two products.

After all the preparatory work, you can proceed directly to the installation of the system.

Pruning

With the help of special scissors-pipe cutters at an even angle (in order to prevent influx during soldering) the pipes are cut to the required length. If there is no experience of such work, it is better not to cut off all the products at once, but to stretch this work as needed, each time re-checking measurements.

Chamfering and shaping

After the edge of the pipe is cut, it is necessary to make a small chamfer so that it is inserted into the socket. For this job, both a special calibrator and a screwdriver attachment are suitable. If the pipe has additional reinforcement with aluminum, then it is removed by the shaver for one specific size, after which everything is washed and dried.

Heating and bonding

Polypropylene products melt at a temperature from 260С to 280С by a special soldering iron. Before turning it on, the drone and the sleeve are mounted on the iron, and the device itself is mounted on a cross-shaped base so that the hot elements do not come into contact with the melting parts. After heating the soldering equipment, one of the parts is mounted on the drone, and the second is placed in the sleeve.To maintain the desired depth of the connection, you can apply a preliminary marking with the marker on the ends of both pipes. All work is desirable to carry out in thermal gloves. The parts placed in the soldering iron are heated and matched to the intended trait by the force of both hands for 4-10 seconds, after which it is necessary to allow the polymer to cool and make sure that the resulting seam is correct.

Pipeline fixing

It is not enough just to connect the acquired pipes, they need to be fixed to the walls and the floor in order to prevent sagging and deformation. Polymer products can be fixed with the help of three types of clips: single, type-setting or with a clip. Or clamps heels, paired or special wall. The first difference from the second is that the clip allows the tube to move freely along its axis, and the clamp reliably fixes it in a single position. It is not recommended to stack polymer products (and, moreover, radiators) directly on the floor; for “hanging” them in space, special metal or plastic brackets are sold. The clamps located on them additionally tighten several pipes close to each other,which allows the system to occupy less space and not to bump pipes against each other with a large water pressure.

Improper installation of the system can lead to thermal stretching - change in size by polypropylene when heated. If it is too rigid to fix the product to the surface, then a gap may form in the place of adhesion.

To minimize the stress of the material, it is desirable to use compensators in the installation process. They are circular, L-shaped, U-shaped and Z-shaped. Their type is selected depending on the characteristics of the installed plumbing or heating system. But it is also not worthwhile to mount the polypropylene line close to the corner, a small indent is needed for the product to move at the time of its expansion from the temperature of the liquid.

Summing up, it can be noted that correctly planning the pipeline system, having made all the calculations and purchasing materials, it is quite possible to do the installation by hand. Buying fittings in a slightly larger amount than required by the calculations, and making timely amendments to the pipe trajectory during the installation process will avoid many errors.A full check after installation will allow you to forget about the repair of plumbing and heating for the next 30-40 years.

About what types of polypropylene pipes are, see the following video.