Characteristics of polypropylene pipes for cold water

To date, polypropylene pipes for cold water are much more popular than metal counterparts. Such products have earned their popularity due to their durability and reliability. After all, even if the pipeline freezes in the winter, the polypropylene remains without damage and is not deformed.

Pipes made of polypropylene can withstand temperatures up to 95-110 degrees, and not lose their original characteristics.

Specifications

Pipes made of polypropylene for cold water have low hydraulic resistance, and also provide a reduction in heat loss in heating systems. Unlike metal, polypropylene does not corrode, does not enter into a chemical reaction with substances from water, it is inexpensive. In addition, such pipes are quite resistant to ruptures at temperature differences.A smooth inner surface of the PP pipe eliminates the formation of scale and lime scale, even if the water has an increased level of hardness.

But also important is the factor that the quality of water in polypropylene pipes does not change, because the material is chemically inert. And even when heated, it does not emit toxic substances, unlike polyethylene. So, such pipes can even be used to supply drinking water. Another feature of the PP pipes is the minimum noise level, they do not buzz when they are filled with water. In this case, the pressure and flow rate is not affected.

With all these advantages, polypropylene pipes have some disadvantages. For example, they are not highly resistant to mechanical loads. And also can collapse when exposed to temperatures above 110 degrees.

Species

There are 2 types of polypropylene pipes for cold water supply on the modern building materials market.

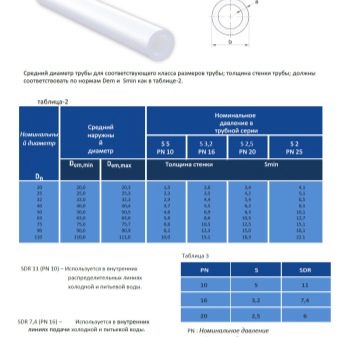

- PN10. Intended for installation of cold water supply systems up to + 20 ° С. And also with their help, you can make a system of "warm floor" with a temperature of up to + 45 ° C. Maximum working pressure - 1 MPa.

- PN16. Designed for installation of water "warm floor" with a maximum temperature of + 60 ° C. Able to transfer up to 1.6 MPa.

The more pressure and temperature can withstand the PP pipe, the thicker their walls will be.

Due to the fact that the material tends to expand as the temperature rises, it is also necessary to install special compensators and sliding supports when installing pipes. And also presented models of reinforced pipes made of polypropylene, but they are already used for heating systems.

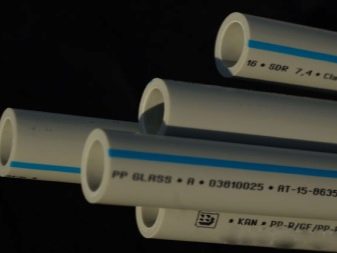

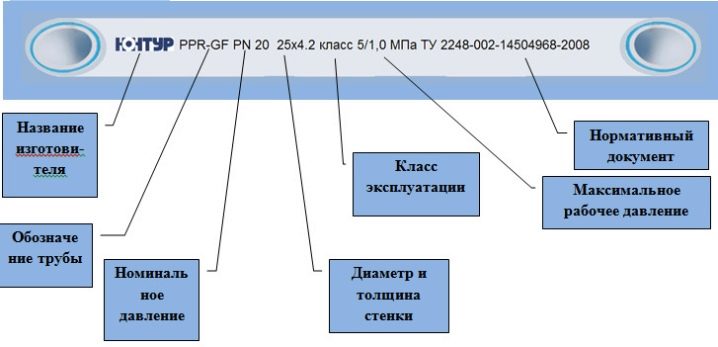

Marking

In the factory marking of pipes laid a large amount of important information for the buyer. Such data will help you choose the right product in accordance with the parameters of a specific engineering system.

We give the most popular types of pipe markings from PP:

- Valtec - the name of the manufacturer (can be anything);

- PPR-GF is a type of product, where PP is polypropylene, R is randomized, GF is with a fiberglass reinforcing layer;

- PN20 is the product class by the rated pressure of the working medium, here it is up to 2 MPa;

- 32x4.2 - thickness and diameter of the walls;

- class 5 - class of operation according to GOST P 52134-2003, here - class 5, it is useful for installation in radiator heating systems with temperatures up to 90 ° C;

- 2.0 MPa - the maximum working pressure that this type of pipe can withstand;

- TU 2248-002-1454968-2009 - an official document, which corresponds to the quality of the product.

Volumes

The greatest demand is for pipes whose volume is 20.25, 32, 50 mm. For the installation of drainage systems, pipes with a diameter of 110 mm are used, and 40, 63, 75 and 90 mm are also selected for the main line. To choose the optimal size of a polypropylene pipe, it is necessary to correlate it with the dimensions of the tips on the soldering iron.

Installation Features

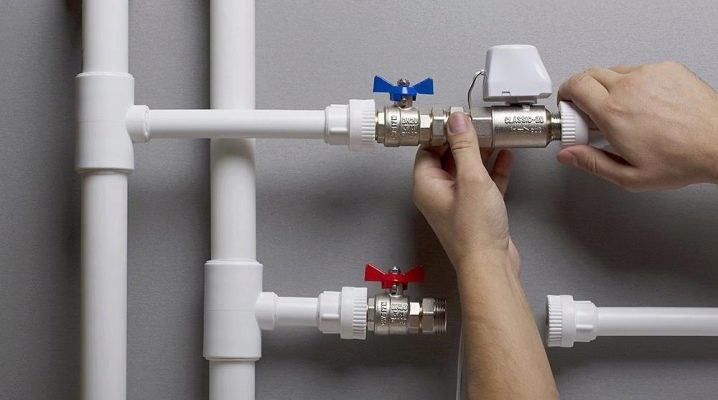

Before proceeding with the installation of pipes, you should complete all the preparatory work: calculate in detail all the necessary parameters, prepare the necessary equipment and tools.

Further work is divided into the following successive stages:

- dismantling the former water supply line;

- preparation of all necessary blanks in accordance with the scheme;

- equipping the end parts of the steel range with special couplings for connection, if it is required to connect polypropylene and steel water supply networks;

- soldering pipes and fittings using polyfusion technology;

- installation of locking mechanisms;

- preparation of ducts for the pipeline in the walls;

- making holes for fasteners;

- installation of polypropylene water pipes.

If there are metal elements in the water supply system, then polypropylene pipes are fastened with the help of fittings, which are also equipped with a metal insert. During installation, a fum tape is applied to the thread, the edge of which should be in the direction of the thread clamp.

The following is important:

- you should not make too thick a layer of fum tapes, 2 turns are enough;

- Do not overtighten the threaded connection to prevent damage to the fitting.

To make a turn on the highway cold water, you can use 2 ways.

- Fitting.

- Heating material with a hair dryer. Do not heat the material over an open fire, as polypropylene may melt immediately. But it is also important not to forget that PP pipes have properties to expand under the influence of temperature. Therefore, in the process of their installation, it is necessary to leave some free space around the drainage system or tee, as well as near the walls. Connection of parts is carried out by means of soldering couplings.

Be sure to perform a seasonal drain of water so that parts of the system are not damaged by temperature changes.

Spike technology

To properly connect the cold water supply system of polypropylene elements, you must do the following:

- place nozzles of suitable diameter on the welding machine;

- set the temperature on the device to 260 degrees, wait a few minutes for the equipment to fully warm up;

- make the pipe blank by cutting off the required size at a right angle, prepare the fitting and “land” on the heated nozzles;

- after a full warm-up, remove the pipe and fitting, do the docking and wait a few minutes, not allowing turns in the docking process;

- if the pipe is still incorrectly docked, then the whole procedure will need to be done anew.

Use this instruction, and you will be able to correctly and quickly prepare a cold water supply system using polypropylene materials.

In more detail about types of polypropylene pipes and their accessories you can learn from the video.