Rules for the selection and use of fittings for polypropylene pipes

Polypropylene pipes today have practically supplanted metal counterparts, both when creating heating systems and water supply mechanisms. This is not surprising, because if we compare the properties of polypropylene pipes and metal pipes, the first will have more advantages. They have a more affordable cost, are easy to install and durable - the service time is up to fifty years. And in order to connect such pipes, usually used fittings, which will be discussed below.

Special features

It should be said that all polypropylene products are created in accordance with GOST No. 52135 "Pressure pipes from thermal seams and shaped connectors for heating systems and systemswater supply ".

According to this document, such elements can be applied to:

- hot water supply mechanisms;

- floor heating with low temperatures;

- in pipelines through which cold water is transported;

- in radiator-type heating where high temperatures are present.

It should also be noted that pipes and fittings of this type can be made of various categories of polypropylene:

- PPV (block copolymer);

- SPR (copolymer);

- BCP (homopolymer).

If we talk about the difference between these types of materials, it is the resistance to the effects of certain temperatures. For example, options from BCP cannot be used in heating mechanisms. There you can only use PPV and PPR.

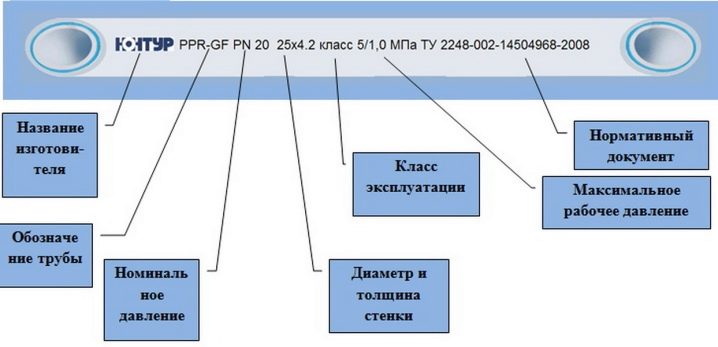

Often in the labeling of such products found the abbreviation MRS. It may indicate a working pipeline pressure when the fittings can last the stated time. Usually this parameter looks like PPR-63, which means that the working pressure is 6.3 MPa. There are also numeric values: 80, 100, and so on. Also on the market recently appeared solutions, the working pressure for which can be 25 MPa.

The advantage of fittings is that they make it very easy to assemble almost any kind of pipeline that will work perfectly with any medium. This was made possible due to the chemical neutrality of the material itself. Everything can be connected in just a couple of hours. And at this time enters not only welding, but also mastering the technique of working with the welding machine.

It should be noted that polypropylene perfectly tolerates temperature extremes. If it freezes, it expands slightly, and if it heats up, it takes on its size. The material also copes with short-term mechanical loads, but it is better to protect it from long-term mechanical effects, as well as the effects of ultraviolet rays. In addition, the advantage of such pipes will be their low cost.

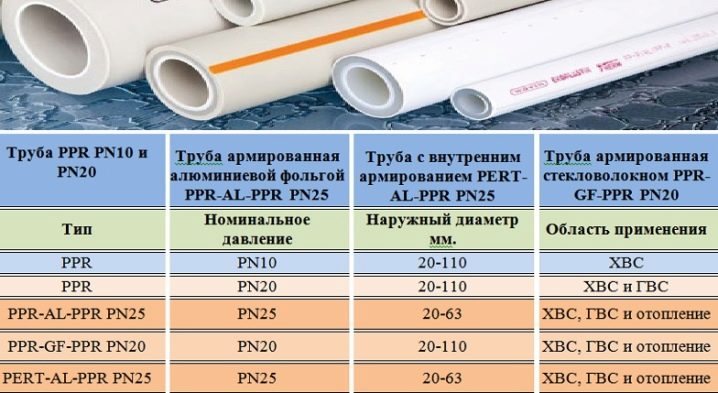

At the same time, such solutions have some drawbacks. The first is almost complete oxygen tightness. If the pipes are plumbing, this is not a problem, but if it is a heating system, then it is better to stop at the version of pipes with full reinforcement from aluminum, which have a smaller percentage by 3/4 of the thermal expansion type.

Another disadvantage is serious thermal expansion, which makes it necessary to use compensators.

Kinds

Today you can find products made of polypropylene in various colors. Color does not affect pipe performance. Only black pipes will have higher resistance to sunlight.

If we talk about the areas of use, then there are four groups of pipes:

- PN10;

- PN16;

- PN20;

- PN25.

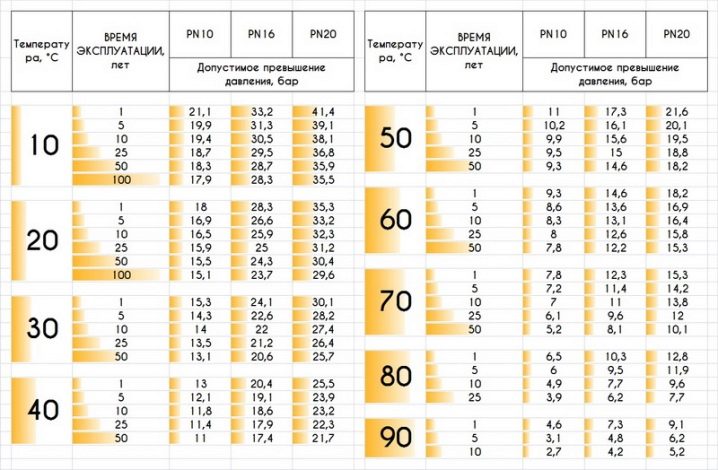

The first type is a pipe with a small wall thickness. They are usually used where the pressure is up to 1 MPa and the temperature does not rise above 45 degrees. For example, to create warm floors. The second type is pipes with slightly thicker walls. Here the temperature can not be higher than 65 degrees, and the pressure - 1.6 MPa. These are used in the mechanisms of cold water supply with increased pressure. The third category withstands pressures up to 2 MPa and temperatures up to 80 degrees. Can be used to create a central heating mechanism.

The latter category withstands pressures up to 2.5 MPa and temperatures up to 95 degrees.

The last two groups of pipes are usually used for building heating systems, connecting such systems with boilers, as well as distributing hot water. In addition, these two categories have special reinforcement parts.Pipes also have different diameters and sizes in the range from 16 to 110 mm. For the selection of the size there is a special table. When we chose pipes, we begin fitting fittings for them.

For the installation of various mechanisms of polypropylene pipes today use the following types of solutions considered:

- Couplings connecting and transitional. The first is used to make a transition from a pipe of various diameters to others and for such a transition, but right from the fitting. The second type is used to connect pipes of the same diameter.

- Squares. They can also be called elements of connective nature. Usually they are used in cases where it is necessary to make an angled pipeline. As a rule, we are talking about an angle of 90 degrees.

- Tees normal and transitional. The first type is used simply for branching heating or water supply systems, and the second type will be used where there is a need to dissolve pipes of different diameters.

- Cross. It is used to make at one point the largest possible number of branches of the whole mechanism.

- Support. This part is used to attach a pipe to the wall.

- Attachments-plugs of various types. If we talk about the model for soldering, then it is used to jam the end of the pipe either temporarily or permanently. But the threaded version is used specifically for temporary threaded plugging from the inside without reeling. In this case, the sealing is carried out thanks to a special sealing ring, which is usually supplied in the kit.

- Compensation loop. It is commonly used to compensate for the increase in linear type on straight pipe portions.

- Combined couplings are used to switch from PP to iron.

- A combined bracket with a special mount is needed to switch to metal from polypropylene pipes at an angle of ninety degrees. And the usual combined angle is used where there is a need for rigid mounting during installation. As an example - the same faucet for watering or mixer. If the weight of a two-plane pipe is large, and it is in limbo.

- The plasterboard square is used for high-quality fastening of pipes to plasterboard.

- Ball valves are used where you need to open or shut off the flow of fluid.

- Valves have the same purpose as the tap. The difference is that with it you can adjust the water supply. In addition, it can be useful for repair, as opposed to a crane.

- Plaster valve. It is usually used to make a hidden installation for water supply.

- Radiator valve - used to connect the radiator to the heating riser. Plus it is that there is no need to use an additional coupling of the combined type.

- Square and coupling with cap nuts. Such devices are detachable and therefore are used where a connector is required. Usually they are used when installing the same water heaters.

- Coupling American plastic detachable. This type of fittings is used in cold water supply systems where a connector is needed.

- A detachable coupling is used where a special detachable connection is needed. To install such a part, you need to find a fitting for a soldered pipe with a socket.

- A split-type American socket is used wherever a connector is needed. Usually used to install heated towel rails and risers.During installation, you should look at the gasket in the American. If it is rubber, then it is better to refuse its installation in the specified cases. After some time, such a gasket will fail.

- The wall kit is used during the complete installation of the bathroom faucets.

- The double angle wall kit has the same meaning as the previous one.

- The welded saddle is used to make an additional outlet in the pipe without disturbing the integrity of the whole mechanism. To mount it, you will need a special nozzle.

- Filter - used to cleanse the fluid from the mechanical particles.

- Bortiki and flanges - are used to connect the flange type.

It should be said that this is an incomplete list of all fittings and auxiliary parts. There are still various shaped parts that are used for sewer pipes.

Manufacturers

To date, the market can find a large range of polypropylene pipes and fittings from manufacturers from both Russia and from abroad. Of course, the products of the latter will be substantially more. The fittings of the Czech company FV Plast are quite popular.As a rule, for their manufacture, gray polypropylene of the Hostalen group is used. This enables the company to produce products that can perfectly compete with Western European counterparts.

You should also separately highlight the products of the German company Banninger Kunststoff-Produkte GmbH. Due to its plasticity and high quality, such fittings tolerate freezing better than their counterparts. In addition, they have excellent technical characteristics. For example, to create heat supplying systems there is a line of the “Stabi” series. All models that are presented here are reinforced with a layer of perforated aluminum. And the models of the “Faser” line have glass fiber reinforcement.

Another company from the Czech Republic, producing high-quality products in this area - Wavin Ecoplastic. The company uses only ecological plastic in the manufacture of its products. Spare parts and pipes of the company can withstand pressure up to 20 atmospheres, which will be a really interesting solution for many.

Do not fall behind in this matter and the Italians. The Italian company Valtec manufactures products of three categories - pipes, reinforced with foil, fiberglass and simple with thin walls.The products of this company are easy to recognize, as the sockets here are usually cone-shaped and during welding there is no roll made of material that is melted. Another important point is that the combined fittings of this company received an octahedral shape from the outside, which makes it possible to use the most common keys when working with them.

Separately, it is necessary to say about the products of companies from Turkey. Customers speak well of Kalde products. Particularly interesting are the pipes of this company with aluminum reinforcement, but the foil there will not be solid, but perforated. It goes without saying that for each category of pipes the company also produces the necessary sets of fittings. Another company from Turkey - Tebo. All products are made from resistant polymer Polypropylene Random Copolymer. It meets all requirements and standards. Pipes with different diameters and sizes are produced. For the reinforcement in the pipes of the company used solid foil.

In the market there is another company from Turkey - SPK. Its products are considered to be of very high quality, and for some products made of polypropylene the price will be two times lower than for similar solutions from European manufacturers.It is known that the company receives raw materials from the Netherlands, the equipment at its plants was brought from Germany, and production is in Turkey. The company's products can be called high-quality, because the fittings and pipes perfectly tolerate work in the climatic conditions of the Siberian region.

How to choose?

When choosing fittings, several factors should be taken into account. If, after installation, it will be in concrete, then currents of a wandering character will cause the destruction of the metal compound somewhere in 18-20 years. It is for this reason that for connections that will have contact with concrete, it is better to choose fittings for soldering. If you decide to install the plumbing yourself, it will also be a great solution to use such fittings. Soldering iron and fittings have a low price, so it would not be superfluous to purchase a little more elements than you need to first just practice welding them.

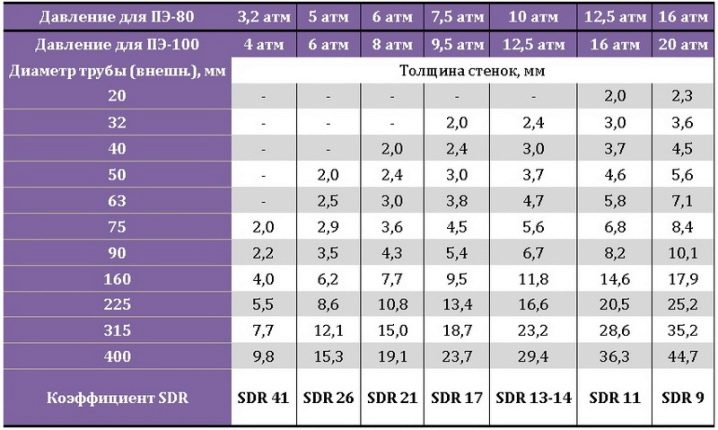

If you are looking for fittings of various categories - for example, compression and crimp, then you should pay close attention to the size of the walls and their thickness. Some models write the abbreviation SDR,which means the ratio of wall thickness and tube diameter. If this indicator is different for these elements, then you will not be able to do something. Either the fitting tube will be larger than the diameter of the pipe from the inside, and it will simply not be possible to install it so as not to damage the rubber seals, or it simply will not be possible to make it tightly pressed against the pipe and various seals.

Before choosing different models, you should ask at the point of sale a document of conformity. Everything that is produced or legally shipped to Russia must have documentation and fully comply with GOST. In addition, it will be a sign that in front of you - not a fake. But materials that do not have documents are most likely imported illegally or created illegally, which means it is not possible to check their characteristics.

Tips

When creating pipes and fittings made of polypropylene, fusible materials are usually used, and therefore the choice of such products must be approached very carefully. If you need a fitting, it is better not to take a compression model, but to buy a threaded one.Such a structure is easy to disassemble and it will not deform the product at the point of compression. In addition, before purchasing components for propylene pipes, it would not be superfluous to check whether they comply with the prescribed specifications. For example, you can not use soldering in the case when the material of the joined products differs in composition.

Experts also recommend covering the junction of elements of the pipeline metal with layers of nickel, zinc or chromium. This will make it possible to make the connection of metal with polypropylene reliable. In addition, before paying for fittings at the checkout they should be carefully looked at. If you see even the slightest signs of deformation in the form of chips, blisters, cracks or something like that, then such fittings should be replaced. Otherwise, carrying out the installation, they can simply become unusable or break down already at the stage of the start of operation of the pipeline.

In addition, if you wish, you can choose the color of the fitting, if it is important. In general, only black color has a higher resistance to ultraviolet, and so it does not have any influence on the characteristics of the fittings.Thanks to repeated experiments, it was proved that the fittings welded with a pipe into the socket, have greater reliability than any other. Such compounds are much less likely to give leaks and do not burst even if the system maintains a constantly high pressure.

If a fitting needs to be labeled, then it should be done in such a way that it is perfectly and clearly visible on it. The most high-quality solutions have a trademark, the name of the manufacturer, date of creation, as well as consignment. All the above information must be on the fitting. In addition, it should be applied in such a way that it can be read even after fitting the fitting.

In general, it should be noted that the selection of fittings for polypropylene pipes is quite difficult and responsible. To make the right choice, you need to have a clear idea of how the heating and water supply systems are generally arranged, to understand the characteristics of various polypropylene pipes, and also to know exactly how you will create this or that system indoors.Also, if necessary, you can consult with a specialist if, for example, you need fittings for sewer pipes, and you do not know which solutions will be better.

To carry out the selection of fittings on their own is a real task. To do this, you just need to know their technical specifications, understand what you need and know how the water supply or heating system will be arranged in your particular case.

For information on how to choose polypropylene pipes and tinting, see the following video.