Features and purpose of compensators for polypropylene pipes

The compensator for polypropylene pipes is considered an important element of the pipeline. It eliminates the negative effects of linear expansion inevitably arising in the DHW pipes and the heating system, and ensures uninterrupted communications.

Device and scope

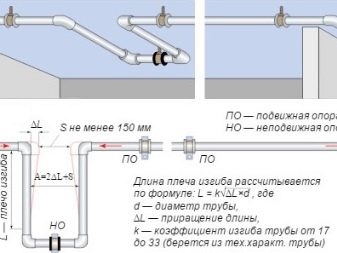

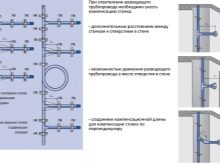

Polypropylene highways are distinguished by a number of significant advantages: they are sufficiently resistant to chemical components, they are lightweight and have high strength. With the help of plastic pipes it is possible to create a system of any configuration, giving the pipeline a vertical or horizontal direction at any angle.The only drawback of the system is the tendency to linear expansion of pipes with increasing coolant temperature. As a result of prolonged exposure to the hot coolant, the pipes are lengthened and sag. To prevent this from happening, a special connecting device, called a polypropylene compensator, was used on long sections of the pipeline.

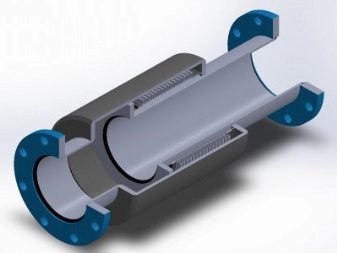

The compensator is represented by a loop-shaped design that takes on physical exertion.arising from the increase in pressure and temperature in the pipes. Make compensators using the method of injection molding, and as the material used polypropylene. Despite the simplicity of the design and budget cost, the U-shaped compensator is considered a significant part of the pipeline: it significantly extends the service life of the pipeline and increases the reliability of the system as a whole.

The element is able to withstand a pressure of 10–18 atmospheres and can be installed on any part of a polypropylene pipe whose length exceeds 10 meters. The only limit to using the compensator is the water temperature in excess of 90, and in some models, 100 degrees.

In addition to reducing the effects of linear expansions, compensators ensure complete tightness of the system. with hydraulic shock, stabilize the working pressure, quench eddy currents and significantly increase the service life of pipes. The scope of application of compensators is wide enough. The connector can be installed in communications that provide water for all types of buildings, as well as in heating utilities and sewer systems of premises for any purpose. The installation of the element can be performed on vertical and horizontal pipes, including both flat sections of the highway, and corner joints and branches.

Advantages and disadvantages

The expediency of using polypropylene compensators due to a number of indisputable advantages of these elements.

- Purchasing affordability and low cost allow for a small amount of money to form a technically flawless pipeline system that will fully comply with all building codes and regulations.

- The equalization of pressure and the separation of the vortex flows inside the system contribute to the uniform distribution of the load on the inner surface of the pipes and ensure the integrity of the structure.

- Due to the simple device and high quality materials, compensators are distinguished by their overall reliability and long service life. With proper installation and compliance with operating conditions, compensators can last 50 years or more.

- Full compatibility of compensators with all types of polypropylene pipes ensures absolute tightness and proper functioning of the system.

The disadvantage of compensators is their compatibility only with polypropylene pipes. This type of connections is not suitable for installation on metal pipelines.

Kinds

On the modern market of sanitary equipment there are several varieties of polypropylene expansion joints, differing in form, place of installation and degree of permissible load.

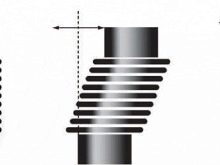

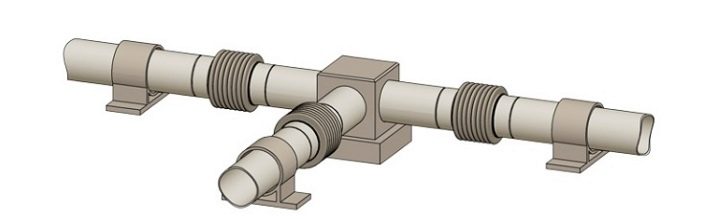

- Axial bellows model of surge arrester and CSR. The bellows compensator is distinguished by its ease of installation and the presence of fastening guide assemblies that serve as a fixed support. The cost of the product on average is 200 rubles.

- KSS brand represented by shear models that are designed to compensate for the linear expansion of two sections located in different planes relative to the central axial line.The compensator is equipped with one or, more often, two bellows corrugations made of alloy steel and connected to each other with the help of connecting fittings. The price of products varies from 120 to 180 rubles.

- Rotary models of the brand PCB used to equalize the pressure and prevent linear expansion at the bends of the pipeline at an angle of 90 degrees.

- Universal models of the KSU brand differ in three options of the working course: angular, cross and axial. Used to build small systems with a large number of branches, as well as in the presence of restrictions in the use of bellows species. The cost of models depends on the complexity of the device and can reach 500 rubles.

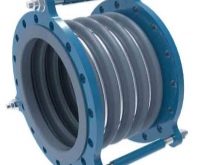

- Rubber flange model brand KR is a type of bellows expansion joint. The part is used for damping shock waves resulting from a sharp increase in operating pressure, and also as a compensator for the displacement of the central axis. The cost of products varies from 60 to 120 rubles.

Criterias of choice

Before proceeding to the choice of a polypropylene compensator, measure the diameter of the pipes or corner elements involved in the installation.The most common size of plastic pipes used in residential and public buildings is a cross section of 20-40 mm. And if practically any type of compensators is suitable for water pipes, then when installing the heating system, it is recommended to give preference to the flange model.

This is due to the need to form a reliable hermetic connection. and method of fastening flange species. The fact is that for fixing such models not the main pipe is used, but a counter flange. Thanks to the use of this technology, a very tight and durable connection is formed, which is especially important for ensuring the smooth operation of the heating system.

In case of emergency situations, the element is easily dismantled and, if necessary, replaced with a new one. When choosing, one should pay attention to the amount of maximum permissible loads that the compensator is able to bear. Thus, bellows models with a length of 25 cm and a cross-sectional diameter of 21.5 mm easily cope with pressures up to 16 atmospheres, while the power of shear models 17 cm long and 18 mm cross section is only 12 atmospheres.Flange expansion joints are considered the most powerful type and, with a length of 29.5 cm and a diameter of 20 mm, they are able to withstand a pressure of 18 atmospheres.

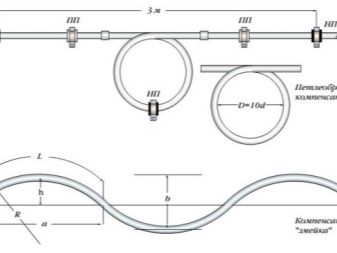

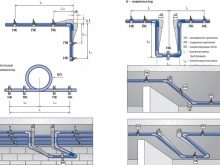

When determining the number of compensators, it should be borne in mind that the distance between two adjacent elements on straight sections of the pipeline should not exceed 3 meters. In addition, when choosing compensators, it is necessary to take into account the total number of turns of the pipeline, the number of supports, the presence of hard and soft sections and the distance between them, as well as the change in pipe sections along the entire length of the pipeline.

The most universal model used both for arranging hot water supply and for mounting the heating system is Kozlov's thermal compensator. This domestic development is considered very popular among Russian consumers. Product features include a wide range of cross-sectional sizes, the values of which vary from 2 to 6.3 cm, as well as the possibility of connecting the connector using a transition sleeve.

Models are easy to install, they are characterized by small dimensions., fits well into the pipeline system and does not clutter up the interior.The compressive compensation capacity for models with a cross section of 2 cm corresponds to DN 25, and for products 25 mm thick, to DN 32. The maximum allowable temperature is 100 degrees, and the working pressure corresponds to 16 atmospheres.

Assembly technology

Compensators can be installed using flange and welded joints. When welding is used, the elements are fixed in such a way that it is not possible to break the connection without cutting. The advantage of this method is a completely sealed seam, and the disadvantages include the impossibility of quickly removing parts in case of accidents or repairs. To perform the welding process, use a special soldering iron designed for polypropylene pipes.

Before installation, the part of the compensator that will enter the polypropylene pipe must be thoroughly cleaned from burrs. The thermostat of the soldering iron should be set at 260 degrees, and after the heat indicator goes out, you can start welding. The connection process is as follows: the end of the pipe and the end of the compensator are heated by a soldering iron until the polypropylene melts,after which the parts are tightly connected and for some time held in that position.

During the setting and hardening of polypropylene it is forbidden to correct and rotate the joined elements. Crucial fixation and ensuring the immobility of the joint until the moment of complete solidification of the material is of decisive importance.

Flange method is more common. It forms detachable joints and is distinguished by the method of attaching the compensator to the pipeline. When using this technology, not the surface of the pipes is used as an attachment, but the end of the counter flange. This provides a stronger and more rigid connection and minimizes the chance of leakage. The advantage of this type of fastening is the ability to quickly open the pipeline system in the event of an emergency. The disadvantages include the complexity of installation and the need to consult specialists.

Before installing compensators, you need to make sure that the connector and the pipe are compatible, and also check the parts for the absence of mechanical damage and scrap. Before performing work should cover the nodes with a cloth of asbestos.This will prevent contact with the exterior of the pipeline and the compensator of hot splashes and preserve their original appearance. When carrying out installation work, it should be remembered that only one connector should be placed between two adjacent fixed supports.

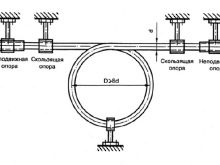

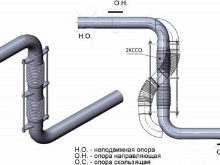

Particular attention should be the installation of corner models. At their installation the pipeline needs to be fixed well. To fasten the construction, the use of sliding and fixed type supports is recommended. Moreover, the support, located directly next to the compensator, should be securely fixed with a clamp and rubber gaskets. The installation of angle compensators requires the calculation of the possible expansion of both the main pipe and its perpendicular branches.

After the calculations, the results of calculations are applied to the drawing. In drawing up the scheme, it is necessary to take into account the difference in cross sections not only of the pipes being joined, but also of all the elements of the pipeline. Based on the results of calculations, you should decide on the power of the models and choose the method of their installation.

Polypropylene compensators are important elements of heating and hot water systems.They help to form a stable and not prone to deformation of the pipeline and significantly increase the life of the main networks.

In the next video you will find a review of the Kozlov compensator for polypropylene pipes.