Methods for connecting polypropylene pipes

Polypropylene pipes have long gained great popularity among consumers. Unlike metal versions, polypropylene pipes are significantly lighter in mass, and methods for connecting this type of communication do not require skills to work with a welding machine and metal-cutting tool, as is the case with iron pipes.

Special features

As with any other kind of plumbing communications, installation of polypropylene pipes has a number of features.

- When butt welding, the walls should not be thicker than 4 mm. The joining surfaces must be otvettsovany, and the strict parallelism of the connected elements must be observed.When joining it is recommended to use special guides.

- Since it is impossible to make threading on a polypropylene pipe, threaded fittings are used for threaded joints, and a sealant and Teflon tape are used to seal the joints.

- When welding polypropylene pipes, it is necessary to ventilate the room. With a negative temperature in the room, this type of work should not be carried out, since docking with insufficient heating of the elements does not guarantee the tightness of the connection.

- When welding with polypropylene pipes, it is necessary to heat the soldering iron to the desired temperature and install it on the stand. During the work it is necessary to observe safety precautions, as we are talking about high temperature, which is 260 C.

For a good connection of elements, it is necessary to withstand the melting time required for a certain diameter of the pipe.

Below are the values of diameters and time intervals.

- 16 mm - 5 seconds;

- 20 mm - 6 seconds;

- 25 mm - 7 seconds;

- 32 mm - 8 seconds;

- 40 mm - 12 seconds;

- 50 mm - 24 seconds;

- 63 mm - 40 sec.

What is necessary?

For the installation of polypropylene pipes will need special tools for cutting and connecting elements.

The list of tools includes such devices as:

- pipe cutter;

- welding machine;

- sweep;

- glue gun;

- marker for marking;

- connecting part and tape measure.

Pipe cutter for polypropylene pipes it is better to use a professional one - such a tool guarantees reliability and an ideally even cut, it will not allow the formation of burrs on the cut surface. When choosing a pipe cutter, one should consider such an important parameter as the minimum and maximum pipe diameter. The tool should be chosen with a blade only of alloy steel.

Welding machine manual type should have a thermostat and a stove for heating, having openings for installing nozzles. For welding machine need a pair of nozzles with Teflon coating. It should be chosen from well-known brands that have proven themselves in the market, as the tool of dubious manufacturers in the process of operation can fail, which will stop all work.

Stripping are manual and in the form of nozzles on the drill.

- For stripping the outer layer, couplings with internal knives (shavers) are used. Under the diameter of the pipe, which is cleaned, pick up the desired clutch. Also use double-sided couplings that allow you to work with different diameters.To clean the inner layer of the pipe, take a sweeper-facer, in which the knives are inside. The tube is inserted into the tool and turned several times.

- Stripping in the form of nozzles on the drill differ from the manual versions only by the presence of a rod that is inserted into the tool holder.

Glue gun can be used as an alternative to other types of compounds. This tool has two advantages: glued seams are almost as good as welded and other joints, and glue quickly sets. Such connectors perfectly fasten fittings and other elements.

Ways

There are several ways to connect polypropylene communications. Choose which method to use depends on the type of PP-pipes and their purpose.

Cold welding based on the bonding of elements with a special adhesive composition. It is applied on the parts that need to be connected. First, the glued surfaces must be degreased. After applying the adhesive, wait for some time and connect the pipe with the desired element. After a short period of time (about 20 minutes) the connection will stabilize and be reliable.

Connection using steel or cast iron fittings. This method is suitable for pipelines with a small diameter. Typically, fittings are installed at the bends and ramifications of communications. The fitting includes elements such as the cap, sleeve and clamping ring, which is located in the nest of the product. The pipe is fixed by means of a folded ring which is included in the design of the fitting.

During the connection fittings need to follow a step-by-step plan of action:

- the pipes should be cut at a right angle;

- all burrs need to be removed on the surface to be joined;

- then you need to install the nut from the fitting on the pipe and put a clamping ring on it;

- after that, it is required to insert the pipe into the fitting and fasten the connection with a clamping ring and a nut.

The connection with the use of flanges is considered very reliable, can withstand high temperatures and high pressure. This method is used in the case when you need to connect polypropylene pipes, without resorting to welding. For the connection bolts are used, which are screwed into the flange thread.

When connecting with flanges, the following installation rules must be observed:

- at the junction of the pipe it is necessary to cut, avoiding the appearance of burrs;

- the gasket, which is installed on the cut, should have a protrusion of 15 cm;

- put a gasket on the flange and connect it with another flange mounted on another pipe to be joined;

- it is necessary to install the gaskets in such a way that their section does not touch the bolts;

- more than one gasket on the flange can not be installed, as this will reduce tightness.

Coupling using couplings. To connect the couplings on the pipes, you need to make a thread for their subsequent installation and for a tight connection wrap a little tow on it. The joining edges should be cut exactly and mark the place of installation of the coupling with a marker. Then you need to apply lubricant to the coupling and install it on the pipe, in the previously marked place.

Welding refers to the hot joining method. This type of connection is one of the most reliable, and its essence lies in the melting of polypropylene with a special apparatus under the action of a temperature of 260 C. The elements heated to the desired temperature tightly pressed together, and after they cool down, a reliable connection is formed.The time after coupling to the final polymerization of polypropylene will take 20 minutes.

Before you start the connection by welding, you need to remove all the irregularities and burrs, and if the pipe has a layer of foil, then it must be processed by cleaning with a facing machine.

When joining by welding, the following sequence of actions should be observed:

- turn on the welding machine and heat it to a temperature of 260 C;

- The nozzles of the apparatus should be put on the connected propylene pipes — this should be done very quickly;

- when the welded elements begin to melt, they are removed from the apparatus;

- connect the melted elements with each other by firmly pressing for 15 seconds;

- the connected elements need to be polymerized for full setting - this usually takes about 20 seconds.

Common mistakes when joining by welding:

- displacement of elements during welding at the time of their heating;

- when joining the elements, they cannot be rotated - otherwise the seam will be unreliable;

- when welding cranes, the location of the valves was not taken into account, and they could not move freely.

PND or PVC pipe can be connected by soldering. This is especially true for polyethylene construction.

How to connect?

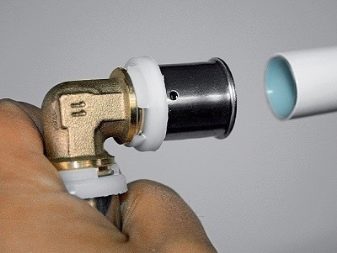

In the case when you need to connect a polypropylene pipe with a metal one, you can use a threaded connection method. To do this, you will need special fittings, one end of which is smooth, and the second is threaded under a metal pipe. With this type of connection the diameter of the pipe should not be more than 40 mm.

The thread on the fitting can be both external and internal. A smooth surface on the back side is needed for welding a plastic pipe. For tightness mainly used flax soaked with linseed oil.

The tow should be applied a maximum of two turns and in the direction of the thread.

The sequence of actions for threaded mounting method:

- at right angles make a cut of the pipe, its end is greased with grease, and then put the thread with a thread-cutting tool;

- remove all chips from the thread and seal the butt joint;

- a thread is screwed onto the pipe;

- The opposite smooth end of the coupling is welded to the polypropylene pipe.

Polypropylene pipes can be connected both by welding and in a cold way. More preference is given to the first option, since it is considered the most reliable and durable.

Welded joint

Prior to welding, polypropylene pipes and fittings for them must be treated with a degreasing solution, and then allowed to dry - only after this procedure can you proceed directly to welding. Such preparatory work is necessary for any type of PP-pipes, except for those that are reinforced with foil. In a reinforced pipe, the shearing is done by a special cleaning tool (shaver) into which the desired end of the pipe is inserted and turned several times. After stripping, the upper part of the pipe must be degreased.

On the pipe it is necessary to put a mark with a marker, marking the necessary distance to press it into the fitting. Then the end of the pipe must be mounted on the mandrel and insert the fitting into the sleeve of the welding machine. All actions should be done very quickly and clearly. After this, the connected elements are heated strictly for the allotted time.

After the elements to be welded have melted, they need to be removed from the nozzles and quickly press the pipe into the fitting.Some forces are required for joining, since the elements to be welded need to be pressed in tightly and kept in this position for some time. It is not necessary to clamp joining elements for more than 20 seconds, since this time is enough for their firm grip. After connecting, be sure to allow to cool for a few minutes.

Connection of polypropylene pipes with metal-plastic variants

In this case, the coupling method is considered to be a reliable method of connection. For installation, you will additionally need two keys of the adjustable type, sealant and tow.

The sequence of actions when connecting polypropylene and metal-plastic pipes:

- the split element is disassembled into two parts;

- on the part with external thread, you need to wind the tow and fluff it with silicone sealant;

- the second fitting also wraps the tow, and everything is lubricated with silicone;

- parts of the connection must be twisted together manually first, and then hold down with an adjustable wrench.

Soldering or welding pipes at home is not difficult, given the recommendations.

Tips

- To weld the seam at the junction of the polypropylene pipe was strong,The elements to be joined must be of the same chemical composition of which the polymer is composed. Therefore it is worth buying pipes of one manufacturer.

- Welding is most convenient to carry out in a convenient and spacious place, which will allow you to collect several elements of communications. Then they will only fix in the right place.

- When using a welding machine it is strongly recommended to use special gloves - they will save hands from burns.

- Tools for installation should choose a quality - from proven brands.

If the installation is a one-time, it is inappropriate to buy it - it will be much cheaper to rent the necessary equipment.

You can find out how to make a welding machine for polypropylene pipes with your own hands by looking at the video below.