How to choose and install polypropylene pipes for heating?

When they talk about heating, they often focus on boilers, radiators, regulators. However, the pipes used to connect these parts to each other are no less important for creating a high-quality heating system. In recent years, solutions made of polypropylene have become increasingly popular, so they should be given special attention.

Special features

Polypropylene pipes for heating are recommended by experts in cases where a long period of service and thermal efficiency come first. It is worth considering that only reinforced structures meet the necessary requirements to the full. Traditional metal pipes only seem to be "eternal" and "indestructible"; in fact, after 12 months, their quality begins to deteriorate. Inevitably internal corrosion appears.A similar problem is unusual, we note, copper pipelines, but they belong to a completely different price group, so the comparison is inappropriate.

Welded joints of polypropylene pipes are mechanically strong, which further increases the service life. Low thermal conductivity is also a great help for normal operation. The difference from pipes for water supply is obvious: it is the need for reinforcement, which allows you to stabilize the structure at a significant temperature. Some increase in payment in comparison with plumbing structures is also justified by the improved appearance. The number of compensatory loops is reduced, which simplifies the system and further increases its reliability.

Kinds

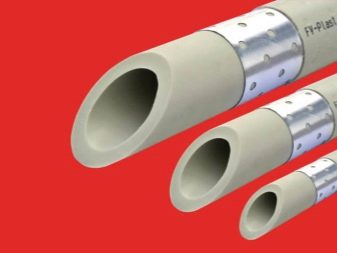

Plastic reinforcement is achieved by various methods.

Among the mass products now there are five main options for strengthening pipes:

glass fiber;

perforated sheet;

special composites;

solid sheets;

aluminum profile.

The difference between them is quite significant, and it's not just the cost of the final product. Of great importance and heterogeneous technical characteristics of pipe products.So, hardening using a solid sheet requires mandatory stripping of pipes before installation. Because the work is more difficult, longer and more expensive. Reinforced sheets make it a little easier to work, but the problem is in their increased permeability to oxygen, which has a negative effect on the service life of the boiler and other metal parts.

Part of the manufacturers went the other way and began to produce pipes, reinforced with fiberglass. They do not require sophisticated stripping, but are more expensive than the usual option. Consumers should also think about structures hardened with a special kind of composites. Such substances impart significant mechanical strength and reduce the intensity of thermal expansion. Therefore, the service life increases noticeably, and in this regard, such pipes are no worse than those reinforced with aluminum.

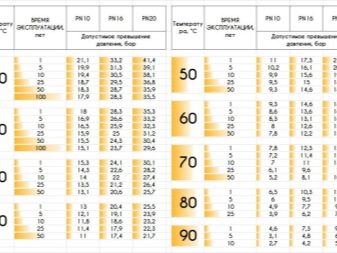

Another important point is the temperature that particular pipelines withstand. By itself, polypropylene becomes soft at 140 degrees, and already at 175 it turns into a liquid. But it is important to bear in mind that a very high temperature, even not reaching the specified critical values, can deform the pipe inside at high pressure.Therefore, regulatory documents proceed from the fact that water should not be heated to more than 95 degrees. Reinforcement does not so much increase the resistance to heat, but reduces the risk of destruction of the heated pipe under the action of brute force.

What is better - polypropylene or metal-plastic?

This question cannot be considered idle: these are the two most important alternatives for creating a home heating circuit. Metal-plastic, which follows already from its name, combines plastic and metal parts. Polyethylene is placed outside and inside, and aluminum foil is separated between its layers. Metal-plastic is subject to the damaging effects of ultraviolet rays, that is, it is not suitable for areas directly illuminated by the sun. It is undesirable to put such pipes and where sparks can fall on them.

Polypropylene is connected more reliably by welding using a soldering iron. Connect metal-plastic so simply will not work, for this we need special fittings and a special mechanism. But even the joint meeting all requirements cannot be made as reliable as when using polypropylene.If the pipe has to be bent, the plastic will transfer such processing calmly, but the polypropylene construction will require the use of angles and other elements. Polypropylene is ahead of metal and plastic in another respect - it is more resistant to possible defrosting.

Even the most vigilant and responsible owners may experience a situation when the pipe suddenly freezes. Then it will expand, but at the moment of thawing it will return to the original geometry. The combination of metal and plastic is incapable of this, it will simply be torn by ice, and subsequent repairs will be extremely expensive.

It is also important that metal-plastic costs about twice as much by itself. Summarizing all this, we can confidently say that it is suitable only in special cases, when polypropylene obviously fails.

Dimensions

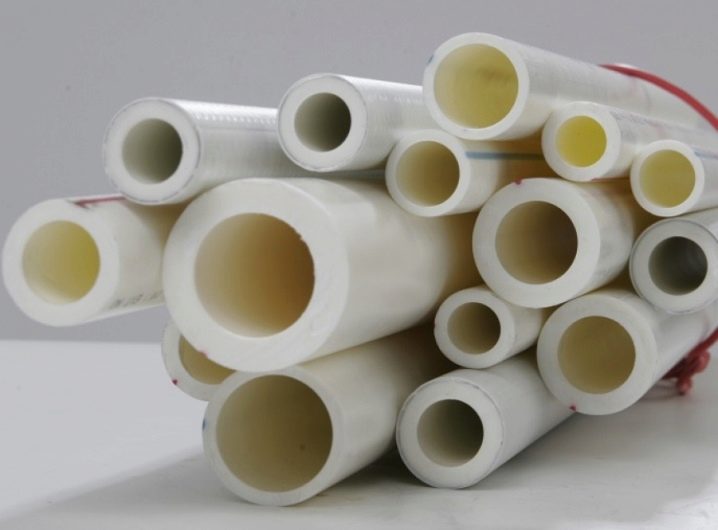

It is not enough just to choose the material and even deal with the type of its gain. Heating pipes are classified according to such an important parameter as the diameter, which determines their throughput. The table of standard sizes helps to obtain the necessary information. The cross-section of pipes made of polypropylene varies from 0.5 to 40 cm.The higher the building or the larger its total area, the larger must be the section.

The length in most cases is 4 m. But much depends on the technical policy of a particular manufacturer. The walls can have a thickness of 0.19 to 1.51 cm. The reinforcing layer in reinforced products often ranges from 0.1 to 0.5 mm, and if it differs from these values, it is only insignificant. With an outer diameter of 20, the wall thickness is 1.9 mm, and for pipes of category 32 this figure already reaches 0.3 cm.

Manufacturers

It is important to look not only at formal indicators, but also at the credibility of the manufacturer. In the market you can meet PPB, PPR. Other types of polypropylene are not suitable for organizing heat supply in a house or apartment.

As in many other industries, the rating of pipe products is headed by German concerns:

Rehau;

Banninger;

Wefatherm;

"Akvaterm".

Banninger, for example, uses a heat-stabilized material labeled as PPR-CT. The advantage of this solution is the ability to apply pipes of smaller cross-section than those of competitors, and at the same time fully cope with the tasks.

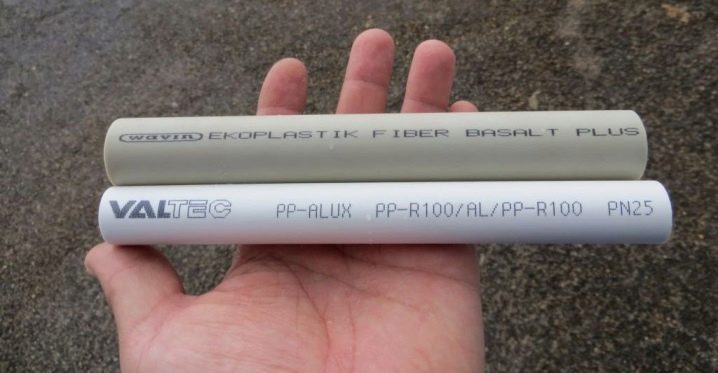

The quality of Czech brands is almost as good as German counterparts,Especially highly valued by professionals are polypropylene pipes "Ecoplastic". The main diameter supplied under this brand is from 16 to 25 cm. During the production of pipes, the material stabilized during heat treatment is also used.

Turkish products are a time-tested manufacturer like Valtek. The company has mastered the production of products reinforced with both aluminum and fiberglass. The declared service life is 50 years. Delivery of pipes is carried out in the form of segments of 400 and 200 cm each. Chinese and Russian polypropylene structures, unfortunately, are inferior to products from the three countries listed.

The only exceptions among domestic suppliers are Pro Aqua (the product is designed for 95 degrees) and RVK (this company reinforces pipes with aluminum). As for deliveries from China, it is permissible to use only Blue Ocean and Dyzain, other manufacturers show themselves much worse. Of the remaining firms can pay attention to Tebo, “Vesbo”, Pilsa, Novaplast.

Experimenting with unknown brands is not recommended. The results of such experiments are almost always deplorable. Regardless of the manufacturer's reputation, you should always clarify that the pipes really belong to the line for heating.

Despite the differences of enterprises in individual countries, the basic moments of the technological process are the same everywhere. Preparation of raw materials for work is done using an extruder. Secondary raw materials are used only in a mixture with the main type of semi-finished products. The granules heated to 240 degrees (however, instead of them there can be chips), melt and form plastic. Since the inside of the device is covered with Teflon, polypropylene will not stick.

Criterias of choice

But the size, type of reinforcement was determined, and even the desired manufacturer was selected (or several manufacturers). The user opens the directory and finds that several options are suitable at once. And formal technical descriptions with sections, lengths do not help to make the right decision. Non-reinforced pipes are suitable for hot water supply, but they are useless for connecting central heating and for use in a private house for heating. When it is known that the temperature in the circuit will reach 70 degrees or more, it is recommended to choose pipes with glass fiber reinforcement.

It is possible to supply cold water through any channel, however, it does not make sense to use expensive heating elements for this purpose. Any polypropylene constructions will have to be welded, and on the places of a reversal, discrepancies - to use fittings. Technologically, welding always takes place according to the same scenario, but pipes with aluminum foil will have to be processed, removing all metal filling to the depth of soldering. It is necessary to take into account the nuances of hardening with aluminum. The outer type implies placing the foil in 0.1-0.2 cm from the outer edge, and the inner one means placing it in the center of the polypropylene structure.

In the second case, it is required to dismantle all the plastic to the required depth before welding. This work requires great care and attention. But worst of all, the slightest mistake makes the joint too unreliable by modern standards. When the water seeps through the foil, it will sooner or later wash the plastic part and penetrate it. Therefore, whenever possible, you should give preference to single-layer or reinforced through glass fiber options.

Aluminum lovers argue that due to the foil air penetration is reduced. But this argument is not always true, because in many cases the foil has a perforation or a longitudinal gap, and does not cover the pipe diameter at 100%.As for manufacturers, everything is clear: absolute preference should be given to German goods. Supplies from the Czech Republic are just as good, but the payment for them will be less. The average price level is typical for pipes produced in Turkish factories.

Any company that has been on the market for a long time (even Russian and Chinese enterprises) supplies high-quality pipe products. As for the occasional scandals, it is almost always after careful consideration the case turns out to be a banal fake. The stronger the demand for a particular trademark, the more people try to purchase certain pipes for their home, the higher the probability of being faced with counterfeit. Before buying, you should familiarize yourself with the official website of the manufacturer.

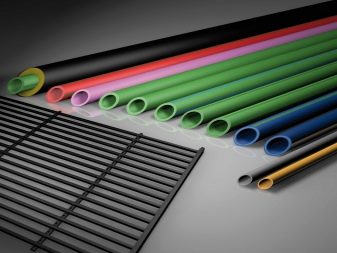

Any little things matter:

writing letters in the logo;

the number of large letters;

color marking.

Falsifiers, even the most desperate, try to let a little, but change the logo - it helps them to reduce the legal consequences of their act. Attention should be paid to the range. When the store offers pipes of a different color, size, cross-section than indicated on the website, this is 100% not original.It is recommended to look at the walls, because in the pursuit of cost reduction, developers of fakes are trying to reduce them or make them different in thickness. Normal fittings should be perfectly even. It is advisable to carry out these visual checks even in company stores and official dealers.

Important: if you select polypropylene pipes for central heating or for a large house, you should focus on the options that transfer the maximum pressure. The term of the normative service of the product must be at least the same as that of other elements of the pipeline.

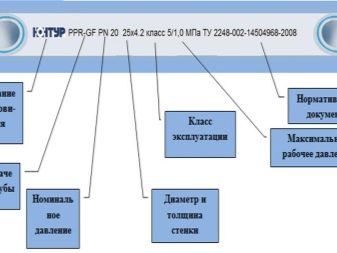

Marking PP-B indicates the possibility of using pipes on individual highways warm floor. For hot water they are applicable only in places where the water does not warm up above 20 degrees. Polypropylene pipes of the PPR category, specially manufactured specifically for heating, may have different working pressures and a maximum tolerable internal load.

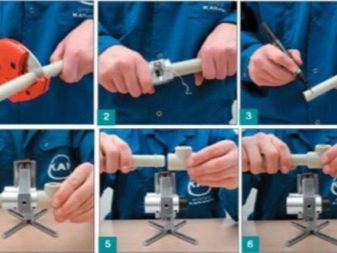

Installation

High-quality polypropylene pipes can be connected to the system with their own hands, without recourse to professionals. For work, you will need threaded fittings and couplings connecting the lengths of unequal length. When hot water meters are installed, threaded couplings are used.The advantage of such connections is the possibility of dismantling the faulty device at any time. But flexible hoses and straight sections of the pipeline can be easily installed using cheaper one-piece joints.

Couplings should be used as transition elements for a bundle into a single whole of straight parts of heterogeneous length. Before assembling the heat pipe, each part should be checked, whether there are any violations in it or dirt. It is recommended that the pipes in the room are kept at a normal temperature about 24 hours before the heating is changed or until it is installed from scratch.

It is unacceptable to expose polymer products to significant mechanical stress or fire. It is strictly forbidden according to technological standards to make threads on a pipe made of polypropylene. We'll have to limit the use of the thread that is applied to the production.

To do the job, you need to prepare:

welding device;

scissors for cutting polymers;

accessories for the welding machine;

electric fretsaw;

hand saw.

Before starting any actions, it is worth preparing diagrams and drawings. All sections of the pipeline, all points of connection of the pipes between themselves and to the auxiliary equipment are indicated in detail and meticulously.It is very important at this stage to decide which radiators to put in the apartment and where exactly they will be placed. Having distributed the pipes and couplings, measure them and cut them according to the drawing. Be sure to arrange a trial inspection (fitting) to identify possible weaknesses and shortcomings.

When welding with a polyfusion socket, the welding machine should create heating up to 2700 degrees. Only under this condition can a solid uniform seam be made. A special soldering iron is equipped with three connectors, each of which can handle pipes of a certain section. Processing time is set by the manufacturer (indicated in the special documentation). Bound items must be held in the connectors until the final cooling.

Excessive rush has not helped anyone in the connection of polypropylene pipes. Those 10-20 minutes that will be spent on familiarity with safety standards when working are very important. Cutting the pipe, you should remove from them the slightest burrs. Measured and marked with a marker the depth of insertion of pipes in the coupling. This is the only way to avoid skewing that inevitably appears when installing "by eye".

Welding start with the part that is thicker.Push the parts to be joined as tightly as possible. Heated parts are removed and joined according to the marks. A certain effort must be applied, but it is categorically unacceptable to rotate something.

We must not forget about the difference in the cooling time of the seams, determined by the diameters of the parts. It is advisable that by the beginning of the installation there was a certain supply of pipes, since even leading manufacturers have a defect.

Tips

Reviews of professionals and consumers about specific brands and modifications of polypropylene pipes are very important. But in any case, it is worth remembering that this material, being heated to 80 degrees, is lengthened by at least 2 mm per meter. This applies only to reinforced versions, polypropylene expands much more without hardening (up to 1.2 cm per 1 m length). Marking after the letters PN is very important. The corresponding figures show how large the nominal pressure is, which does not reduce the service life.

The value “20” indicates that the pipe is suitable for hot water supply and heating. But products labeled as PN25 can be safely applied even in the central heating circuit, they will withstand the pressure created there. Cutting plastic and foil on a hardened pipe is best done by a so-called shaver.

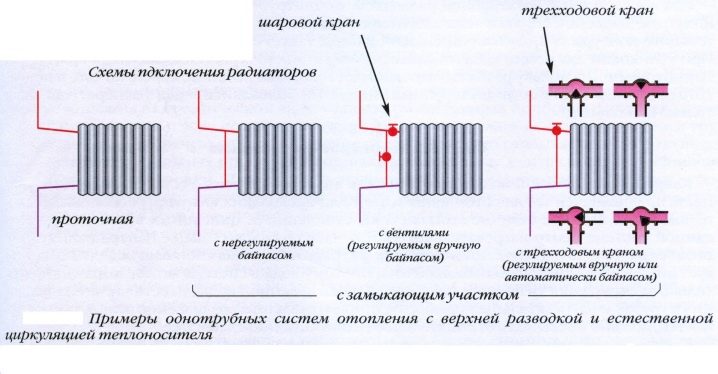

It is possible to connect radiators to heating systems:

through bypass without adjustment;

by flow method;

using valves;

based on three way valve.

It is worth considering that the fittings are very expensive, and if possible it is necessary to minimize its use. On the other hand, adjustable valves make it possible to control the power output by radiators separately in each room without disturbing the hydraulic dynamics in the system.

Regardless of the manufacturer’s decisions, the installation kit should include:

pipe cutting shears;

shavers (removing the outer layer and aluminum);

welding machine with a special stand;

calibration equipment;

chamfering device;

nozzles to help reheat soldered parts.

It is also impossible to mount polypropylene pipes without markers, adjustable wrenches, tape measures, and other tools. The cheapest are adapters, tees and angles from the same polypropylene. Important: it is better to buy a few pieces of fasteners more than required, as unexpected corners may suddenly appear. The quality characteristics of the material of the fittings and their thickness should correspond to the similar properties of the pipes being joined.It is useful to know about the differences in the connection of pipes with a cross section of up to 6.3 cm and those that are larger than this value.

Usually pipes from 63 mm in diameter (inclusive) are soldered end-to-end, and if they are smaller, it is necessary to use a bell-shaped technique. Its essence is that the melting of the cut end allows it to penetrate into a wider socket on the fitting. When two pipes are connected to each other using a coupling, it should not be allowed to flow at the junction. If it appears, the movement of water will be disturbed and the pressure in the system will become uneven or fall to an unacceptable value. A detachable connection is formed by soldering to the ends of the pipes to be connected a pair of threaded inside and outside fittings.

Cutting with a pipe cutter should not give a bevel cut. Elongated edges contribute to sagging and narrowing of the lumens of fittings. Even the extended stand, helping to maintain the right angles when cutting, do not allow to give up manual control.

When purchasing or renting a pipe cutter, you need to make sure first that it is really suitable in diameter for the pipes used.When trimming is done, a chamfer is inserted into the socket.

In the absence of a special calibrator, a screwdriver attachment can replace it. It is allowed to prepare the chamfer in the hands, it does not need to use a vice. The cut is made very simple: the pipe is placed on the tool, after which it is scrolled several times, applying force (pressure). Important: do not replace the shaver with a simple knife. Such savings result in the destruction of soldered surfaces and a decrease in the strength of the connection between them.

When the chamfer is ready, every detail should be as clean as possible. Soldering pipes made of polypropylene can be at temperatures from 260 to 280 degrees. But in the absence of special training or a lot of experience it is better to stay at the lowest value. The working part of the soldering iron is covered with nozzles of a bilateral type (mandrel and sleeve), after which the apparatus is placed on the platform in the form of a cross. At home, very good results are achieved using 800 W welding, more powerful devices can be safely left for professionals.

On reaching the operating temperature, the device reports the lighting of the light bulb.It is advisable to use gloves when working with pipes. If the room is cool, it is worth increasing the warm-up time compared to the recommended for 2 seconds. The movement of pipes and fittings in relation to each other is permissible for a maximum of 10-12 seconds. Violating this rule, home craftsmen immediately receive a poor-quality compound; adjustment of parallelism of axes is possible at most 20-30 seconds.

A very important circumstance: even well-welded pipes can be broken if their subsequent installation violates the requirements of technology. In the process of repair, there are often situations when you cannot do without pulling the pipe out of the clips. Therefore, the clip itself (any) must be qualitatively held by dowels in the wall.

To press the pipeline and give it rigidity, you can use:

clips;

single performance clips;

their “composing” counterparts;

heels on "heels", dual and wall type.

It is worth considering that the fastener market for polypropylene pipes is very mobile. Some options are off the stage, others are beginning to be actively used. Therefore, the final choice should be made directly in the store to eliminate all misunderstandings.Of course, responsible installers buy fasteners for pipes, and not pipes for fasteners. Clips are used to allow the pipeline to move freely along the axis, and thanks to the clamps you can rigidly set its position.

A common and very bad effect on the result is the neglect of thermal expansion. Hard fastening, especially when using a contour without a reinforcing layer, may result in deformation of the joints. But since it is still necessary to use clamps, compensators in the shape of the letters “Z”, “P” or angular in the form of the letter “G” are attracted to help. For technological reasons, it is forbidden to put polypropylene pipes in the corners. Be sure to leave a gap so that they can move when expanding.

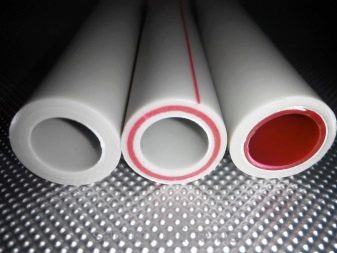

When all compensators are soldered and the pipes are attached to hard and soft joints, the system should be tested. To do this, the pressure is applied a little more than the limit level provided for the period of operation. The PN20 pipe is designed for pressure up to 2 MPa at a temperature of 80 degrees, and PN25 - by 2.5 MPa and 90 degrees, respectively. Occasionally, a modification of PN16 allows water to pass no hotter than 60 degrees with an internal pressure of 1600 kPa.It is useful to pay attention to the colors of the pipes: for example, green and black designs are protected from ultraviolet radiation.

When it is required to dock plastic pipes with each other, straight couplings and squares are used for this (at the corners of 90 and 45 degrees, respectively). Couplings that are threaded inside or outside, not bad help to connect polypropylene with metal. The thread and the lath on the square indicate that it is designed to connect pipes with taps or with various types of mixers. Tubular contours help to bypass perpendicularly directed pipes.

It is recommended to install a coarse filter at the entrance to any heating pipe.

A typical control element will be a ball valve and a through valve. During installation, it is necessary to carefully monitor the cleanliness of the surfaces of the heated nozzles, and as soon as the need arises, remove the adhered polypropylene from them with wooden rods. It is worth remembering that such cleaning is allowed only when the surfaces of the nozzles are heated. All welding work is performed strictly on a flat plane, away from highly inflammable objects.The soldering iron comes to the working temperature in 10-15 minutes.

If you have to solder directly "on the wall", the nozzle has to be fixed on the edge of the heating part. It is undesirable to weld polypropylene at negative air temperatures. Dirty pipes and fittings before welding must be degreased with alcohol or soapy water, and then dried. In cases where something went wrong and the connection turned out to be of poor quality, you can only cut the fitting and weld on a new one instead of a damaged part. Putting ball valves, you need to carefully orient them, avoiding the support into the walls or something else.

On the surface of the sockets and couplings there should not be any cracks and deformations. The slightest defect can negate any efforts of installers. High-quality installation implies that along the edge of the coupling there is clearly visible an unbreakable strip running along the diameter of the roller. This strip is formed from molten polypropylene. If you have to boil pipes that are thicker than 4 mm or wider than 5 cm, butt welding is used. It requires the involvement of sophisticated equipment and qualified specialists, so it will not be considered in detail here.

Sometimes there is a need to form auxiliary branches from pipelines. Welding of saddles helps solve this problem; it is also used if the goal is to connect heat pipes of different diameters without adapters. Such work is carried out using a milling drill. The seats should be perfectly dry, and the heating tubes should be mounted on a semicircular shape.

Theoretically, you can do the work with conventional attachments, but it will be almost impossible to guarantee the quality of the connections.

On how to choose polypropylene pipes for heating, see the following video.