Polypropylene pipes: how to choose and install?

Thinking about the overhaul of an apartment or a private house, first of all it is necessary to change outdated communications. Recently, propylene water systems are given a significant preference, since they are protected from the effects of corrosion and durable.

Special features

If you are planning to carry out major repairs in a country house or cottage with the replacement or laying of necessary communications, then polypropylene pipes will be an excellent solution. PPR have gained wide popularity among customers due to high quality, affordable price and simple installation. Polypropylene is the most common and safe material for both external and internal systems.

It is ideal for creating plumbing and heating networks.

Polypropylene products have a number of advantages that make them indispensable:

- Pipes of this substance are resistant to corrosion damage. For many years, the pipeline maintains integrity and quality characteristics.

- The period of operation exceeds the service life of metal products several times. It is more than half a century in the case of hot water and heating, 100 years - with cold water.

- It is not subject to various biochemical influences.

- Even extreme weather conditions do not affect the reliability of structures. Tees with tubes are not destroyed during the winter frosts.

- There is no vibration and noise. Existing slight noise in the pipes will not cause inconvenience to others.

- There is no strong hydraulic resistance, so there is no effect of the inner shell of the product on the water pressure. Not observed and the formation of layers, which disable the metal model.

- Products made of polypropylene can save 20% more heat of hot water, which is different from steel pipes.

- Easy to install.Using a pipe soldering iron, you can easily and quickly solder reliable hermetic connections. The product under consideration melts at a temperature of + 260 ° C.

- A large number of couplings. It is possible to construct a water supply network of various shapes.

- The material does not affect the health and health of consumers of water.

Due to its low cost, this product is chosen by the majority of potential buyers.

As disadvantages of these pipes, a noticeable tendency to thermal expansion is distinguished.that requires the use of special mounting technology. Also, the polypropylene pipe cannot be bent, therefore it is necessary to use special tees. However, using fiberglass reinforcement technology, thermal expansion is reduced to an acceptable level.

Which is better - polypropylene or metal-plastic?

Polypropylene and metal-plastic pipes are used in the process of designing a water supply network (also drinking water), in constructing a divorce of a heating system or hot water supply. Moreover, both samples are not subject to corrosion, do not change the color and taste of the liquid and are easy to process.

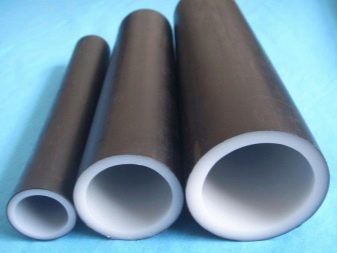

Structural features are divided into single-layer and three-layer polypropylene pipes.

In the first case, it is a monolithic pipe, which is made of polypropylene base. The second type is a more complex reinforcement of the “pipe in pipe” type. The walls are made of two polypropylene levels with a reinforcing layer between the layers. As a material to increase the bearing capacity of the structure, ordinary fiberglass or foil is used.

These groups have almost similar physical features:

- working pressure level reaches 2.5 MPa;

- the size of the temperature limit of the pumped area is 70-95 degrees Celsius (this indicator is affected by the grade of polypropylene and the presence of reinforcement);

- the product is able to withstand temperatures up to 120 ° C;

- thermal conductivity of the walls of the frame is 0.15 W m / ° C;

- The degree of roughness - 0,015.

Single-layer variation from multilayer differs only in resistance to expansion at high temperature. For example, in a single-layer tube, the expansion is 0.15, and in a three-layer tube it will be 0.3-0.07.A smaller figure is characteristic of reinforcement, which is reinforced with fiberglass base.

According to the class of structural bases used in the production process, polypropylene pipes are divided into 4 types:

- PPH - suitable for CWS, the material of manufacture is polypropylene homopolymer;

- PPB - fittings for wiring hot and cold water, the basis - polypropylene block copolymer;

- PPR - used for supplying hot water and heating, made from polypropylene random copolymer;

- PPS - a sample that is resistant to temperature extremes, made of fire-resistant polypropylene.

Based on the geometrical values, the product line is divided into 34 subgroups having a throughput diameter of 10-1600 mm. For domestic purposes, apply PP products with a diameter of 10-40 mm.

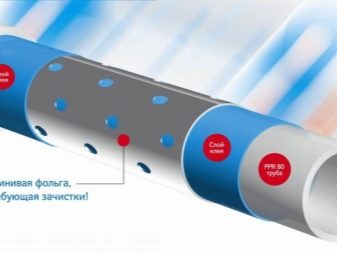

Metal-plastic samples are produced in a three-layer structure: external polymer, intermediate metal and internal plastic layers. In addition, a foil of aluminum acts as the reinforcing material of medium layering, while the external and internal foils are polymers of various designs.

Based on the features of the structural basis, metal-plastic is divided into 3 categories:

- polyethylene - (PE-AL-PE);

- polypropylene (PP-AL-PP);

- polybutene (PB-AL-PB).

These properties sometimes make it difficult to determine the product: polypropylene is either metal-plastic.

This is due to the fact that the three-layer PP-reinforcement, having metal reinforcement, can be attributed to metal-plastic products.

In view of this, the main features of metal-plastic pipes are similar to the PP variant:

- working pressure level is up to 2.5 MPa;

- the maximum temperature of the pumped atmosphere rises to 95-110 ° C;

- thermal mode for normal operation is 120 degrees;

- thermal conductivity of the walls of the frame - 0.43 W / m * K;

- roughness degree - 0.07.

Geometrical components divide the entire line into 11 varieties with an internal diameter in the range of 10-90 mm. The value of the minimum outer diameter of such a product is 14 millimeters, and the limit - 110 mm. At home, use products with external / internal diameters of 16/11, 20/14, 25/20, 32/25 mm.

The advantages of metal-plastic products are almost identical with polypropylene: low roughness, which guarantees high sterility of the inner surface,low thermal conductivity, small size.

But considering these features, the metal-plastic sample is inferior to its polypropylene counterpart. This is most noticeable in terms of heat conduction, since metal-plastic is covered with foam. It also weighs more than a polypropylene product. The pipe from metalplastic serves from 25 to 50 years.

However, this product is highly resistant to temperature changes, which reaches 110 degrees Celsius. In this regard, the valve is used not only for laying the water supply network, but also for the installation of heating circuits, including the "warm floor" technology.

Another advantage is flexibility, which does not require a corner fitting. But it is worth remembering that pipe products with polyethylene polymer layer have similar quality.

From the minuses of metal-plastic products, there is a slight resistance to heat distortion, despite the fact that this indicator is 8 times less compared to PP-pipes. In addition, with a pressure jump, this part does not burst at one point, but the process of separation will occur: the separation of the metal layer from the polymer surface and the insert. Consequently, the result of water hammer will be serious consequences.Most plumbers and fitters choose metal-plastic constructions or their polypropylene similarity for household plumbing systems and heat pipes.

Moreover, many circumstances affect the choice of a particular product option.

Pay attention to the following points if you plan to install the pipes yourself:

- For plumbing or wiring, use metal-plastic specimens. For the installation of tees fit spanner key.

- When buying plumbing or wiring on a turnkey system, buy polypropylene from the master, as it will be several times cheaper than metal-plastic.

- In the case of installation in a closed place (inside the walls, in grooves), it is desirable to arm with a reinforced polypropylene pipe, which has one-piece joints. After all, over time, the threaded sleeves for metal-plastic will unwind and tightness will be lost.

- For a long service life, polypropylene models are ideal, which can last 2 times longer than metal-plastic specimens.

- For DHW, choose a metal-plastic that can withstand 110 ° C.Remember that the maximum resistance to hot water in polypropylene is 90-95 ° C.

- The integrity of the plumbing and heat pipelines with a pressure of more than 10 atmospheres can be ensured by installing reinforced PP-pipes with a minimum number of detachable connections.

Specifications

The emergence of thermoplastic “Random copolymer” (PP-R) allowed us to make a big step forward in the field of application of plastic profiles. The ability to withstand temperature changes, long service life and brilliant technical features made it possible to use it in various areas of industrial production.

It should be noted that polypropylene products differ depending on the properties and performance indicators. When making a choice in favor of shaped pipes, do not forget to check the proportionality of their technical features to operational conditions. Moreover, the scope of application of pipes divides them into reinforced with aluminum foil or fiberglass.

They are used:

- when building hot and cold water schemes;

- in the agro-industrial sector;

- at installation of the "heat-insulated floor" system;

- in the heating structure;

- for the transport of chemicals;

- in the pipeline of compressor devices.

Recorded 6 classes of use of PP-pipes according to the nominal temperature conditions:

- cold water supply (class labeling - XB);

- hot water supply network (maximum rate - 60 ° C);

- hot water supply (up to 70 ° С);

- when creating the system "warm floor" (low-temperature level - up to 60 ° C);

- functioning in the schemes of high-temperature floor and low-heat radiator heatings (up to 70 ° С);

- for high-temperature radiator heating (up to 90 ° С).

Below are the necessary parameters of polypropylene products:

- The density of the material is the lowest among all plastic substances - 0.91 kg / cm².

However, the outer layer has high hardness and wear resistance.

- The mechanical reliability of products is affected by the period of application of force. In addition, this value is associated with a phased heating or cooling. In this case, we are talking about a sufficient level of strength, regardless of operational features. The maximum value is 35 N / mm.

- A large percentage of resistance to chemically aggressive environment -destruction of the surface layer takes place, coupled with the high-temperature effect of a strong acid compound.

- The level of cold resistance is not less than -15 ° C. In most cases, the pipes are mounted for coolant at positive temperatures.

- The melting point of polypropylene products - 160-170 ° C, taking into account the constituent components.

- The softening point is 140 ° C.

- The maximum temperature level of coolants does not exceed 120 ° C.

- The level of working pressure is from 10 to 25 atmospheres.

- The size of the outer diameter - 16-125 mm.

The diameter, presence and appearance of the reinforcing layer affect the bend radius of the pipe.

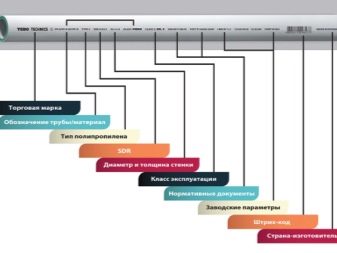

Labeling information on polypropylene products includes data on raw materials, design pressure, thermal mode.

The letter mark of the product is PN. Products are divided into 4 subgroups based on the estimated working pressure:

- PN10 indicates the level of fluid pressure to 10 atmospheres. Their main purpose is to transport low-heat-transfer fluids (maximum 45 degrees Celsius) in a cold water supply system or under floor heating.

- PN16 are used with a pressure in the device not exceeding 16 atmospheres and a working temperature not exceeding 60 ° C. Recommended for use in low-temperature heating circuit.

- PN20 is considered the most common brand. It is used to transport liquids up to 95 ° C with a pressure level up to 20 atmospheres. This feature allows you to apply it in the heating system and in the DHW.

- PN25 has the lowest rate of linear deformation, can withstand sustained water pressure up to 25 atmospheres with a temperature not exceeding 95 degrees Celsius.

Today, the most demanded pipe pressure products PND used in the installation of almost any communication scheme. Their release passes according to GOST 18599-2001.

The scope of their application is quite wide:

- construction and repair measures of the external water mains intended for the transport of various liquids;

- construction of underground engineering structures;

- the formation of reclamation and irrigation schemes for agriculture;

- construction of new and reconstruction of existing wells, deformed by corrosion;

- pipeline construction for industrial purposes;

- operation for the needs of pipeline transport;

- preparation of pressure and gravity discharge system of discharges and wastes;

- transfer of gas exhibiting inertia upon contact with polyethylene.

Pipes are made of polyethylene of different classes, which affects the level of pressure and cross section. Products are classified from PE 63 to PE 100+. Pipe products are produced in black with blue marking stripes.

Pressure products are sold in pieces of 12 meters or packed in coils with a length of 50-1000 meters. Operation of this product should be carried out at an optimal temperature regime not exceeding 40 ° C, which will ensure its operation for a period of 50 years. They can withstand temperature loads up to 60 degrees, but it is worth considering that their lifespan will be significantly reduced.

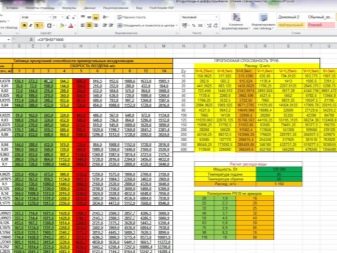

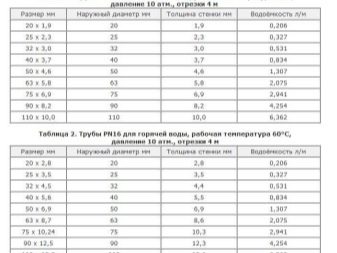

In order to correctly calculate the pipeline device for liquids of various purposes, it is necessary to take into account the value of throughput, which depends on the diameter parameters. This parameter is calculated by the volume of the moving fluid over a set time period. The table shows the bandwidth data:

So, in the case of plastic products, the bandwidth level throughout the long-term operation is almost unchanged,as under the action of liquids, the plastic base retains its original state without being subjected to destructive influences.

Metal samples are subject to corrosive growths, which reduces the level of patency.

And in the case of hot water supply, layering occurs faster and more actively.

Dimensions

Taking into account the fact that polypropylene pipes are used in most installation works, they are implemented in a large dimensional range.

Typical dimensions of products are defined in the following indicators:

- Diameter (5-400 mm). Products of small diameter are suitable for the installation of a pneumatic system, medium - in private and high-rise construction, large - for the construction of high-capacity engineering systems.

- Length. A typical indicator is 4 meters, but it is not a reference characteristic. This ratio is considered by each manufacturer in different ways.

- The wall thickness is 1.9 - 15.1 mm.

It is worth noting that the polypropylene pipe is produced as a single-layer and multilayer structure. The second type involves reinforcement: products from five layers, with aluminum lining between the layers.The reinforcing layer has a thickness in the range of 0.1-0.5 mm.

When selecting fittings for laying water supply systems, a diametric value of 20 mm is used. If it is necessary to lay communications in apartment buildings, then a special diameter calculation is applied for polypropylene products. Each stage of construction work requires an adjustment value. This is due to differences in the laying of the network for a separate apartment, entrance, house, quarter, neighborhood. Experts are guided by the basic rule, which is to increase the diameter of the line with increasing fluid demand.

In most cases, polypropylene products of the following sizes are chosen for the construction of high-rise water communications:

- for the construction of risers in a five-story building - 25 mm;

- wiring in residential areas - 20 mm;

- system of risers in the construction, providing for 9 or more levels - 32 mm.

Large-diameter polypropylene products are mainly used for building liquid supply systems, heating facilities, sewers, which should provide a solution to the problems of water supply and drainage in homes, residential areas, industrial buildings, hotel complexes and other buildings.

For example, products with a diameter of 500 mm are installed at those points where cold drinking water is needed, which is supplied from a storage pool to the area of a large city. However, a polypropylene construction of a large size cannot solve the problem of transportation of heat carriers due to significant thermal loads, which add elasticity to polymer lines.

If it is necessary to build a ventilation system and drainage of industrial buildings, the main material is polypropylene pipes with a minimum diameter of 400 mm.

Scope of application

Characteristic features of polypropylene products can be used for the following purposes:

- in systems of cold, hot water supply, heating structures, sewer pipelines, with floor heating;

- output of soil and runoff water (due to the presence of a high degree of strength with respect to chemical reactions);

- for irrigation, ameliorative, drainage systems;

- when transporting aggressive chemicals and compressed air;

- in the creation of ventilation schemes.

They are chosen to conduct water in a private house, for the construction of water supply systems in the country, in a country house.

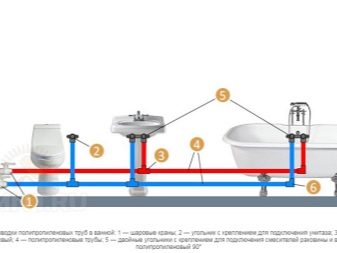

Many owners to reduce the cost of repairs in the bathroom of the apartment themselves spend part of the work. Installation of pipes can become one of such works. In this case, polypropylene pipes that meet all the necessary characteristics of such structures are indispensable helpers.

Manufacturers

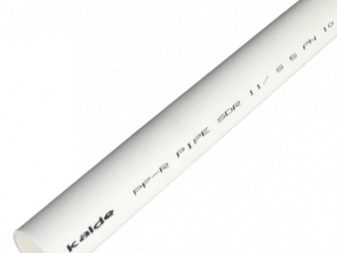

According to the authoritative opinion of the analysts of the pipe market, rating of polypropylene products appears as follows:

- the palm belongs to German products of such brands as Pexay, Akwatherm, Banninger, Wefatherm;

- silver medal - for Czech Ecoplastik polypropylene pipes;

- the third place is occupied by the products of Turkish manufacturers Pilsa, Firat, Tebo, Valtek and Vesbo, Jakko;

- Fourth in the ranking appear Chinese pipes Blue Ocean and Dyzain;

- in fifth place are Russian products.

Polypropylene products from the Czech company Wawin Ecoplastik is a famous brand that has won the trust among consumers.

These products are used for:

- layout of ventilation structures, water supply;

- construction of heat supply schemes - basic and underground;

- designing high pressure cold water supply and low pressure channels;

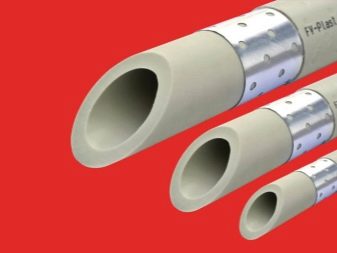

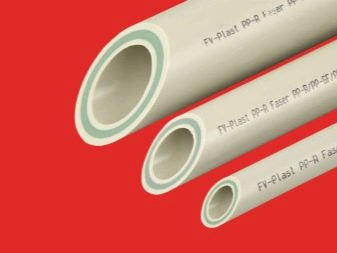

Excellent characteristics allocate production of the FV-Plast company with special aluminum inserts. This makes it possible to withstand changes in temperature. It is involved in the construction of the water supply line, "warm floors", the supply of heat.

The result of the professional activity of German manufacturers was leadership in the market of pipe structures due to the large number of positive reviews among users. Installation of water transfer and heating schemes will take place without difficulty with Wefatherm products. The main advantage is a perfectly smooth inner surface, which allows for a long time to maintain the original pressure level of the pipeline.

Thanks to a wide range of fittings, you can connect different types of pipe products.

The first place in the production of polymers for underfloor heating, fire extinguishing systems, ventilation scheme is occupied by Akwatherm.

When purchasing a reliable product for building a DHW heating system with a pressure of up to 20 bar, experts recommend focusing on the German product Faser. They are made in green color with a diameter of 16-250 mm, white color with a cross section of 20-40 mm.

Engineering communications in residential buildings, industrial enterprises will serve for a long time and flawlessly with pipes from the company Rehau. However, to perform installation work with this product, it is desirable to attract a professional.

Subtleties of choice

Choosing from a large number of submitted samples on the market, pay attention to the following important points:

- Information on working pressure. Marking indicates a maximum limit for a temperature of 20 degrees. Heating water circuits require the installation of products that are marked with symbols corresponding to 20 and 25 atmospheres. Do not forget that polypropylene specimens are able to withstand extreme stresses, but increasing the temperature reduces the resistance of the substance.

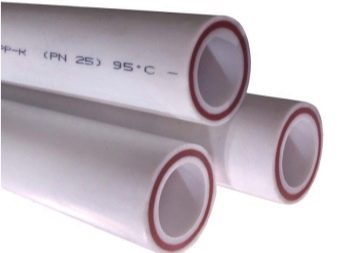

- The temperature level of the working medium - the propylene product must contain information about the maximum temperature parameter of the hot liquid.In most cases, the digital indicators “750 ° С” or “900 ° С” can be detected on the surface. Moreover, polypropylene products have a color indicator strips. The red line indicates that the pipe is suitable for hot water supply, the blue shade is ideal for supplying cold liquid.

- Reinforcement information - an abbreviation consists of letters of the Latin alphabet, which indicate the structure of the reinforcing layer. The choice in favor of models, reinforced with aluminum or fiberglass, remains for the buyer. You can not decide, then better buy composite pipes.

- The fourth point is the size of the diameter of the product. Pay attention to heat information and hydrodynamic calculations. So, separate sections of communications need fittings of different diameters. The calculations take into account the values of working pressure, temperature indicators of heat transfer media, the power level of the installation, the number of connected points. A home heating circuit connected to a centralized system is mounted with consumables having a diameter of 25 mm.

The size of the internal section of the liner shall not exceed the diameter of the riser pipe. To connect radiators to the heating main, samples with a diameter of 20 and 26 mm are used.

Uninterrupted operation of heating in the apartment or house will provide reinforcing products of the required diameter.

So, for high rises, the basic rule is the size of the inner tube section. This is due to the fact that the walls of the polypropylene pipe are thicker than that of steel. Nonspecialists find it difficult to determine the technical intricacies, so the choice remains on the external components.

In the "Khrushchev" and later built apartment buildings install systems with a diameter of 26 mm, in Stalinist buildings - 32 millimeters. For a private house, the wiring process is performed in one or two pipes of 32-40 mm cross section, the batteries are connected using fittings of 20-26 mm in size.

Installation

Installation of polypropylene models is carried out by thermal docking or sealing with a special soldering iron. To obtain an even seam, it is recommended to try soldering on inexpensive product models and tees or residues from the previous installation. Spike occurs very quickly, and if you do not have time to hold a reliable fixation of the parts in the desired position,the damage to the seam is no longer avoidable

Today, 3 types of welding measures are used for uniform adhesion:

- polyfusion or coupling - suitable for diameters up to 63 mm;

- butt or flange - diameter exceeds 63 mm;

- using electro-fitting.

Any welding work leads to a permanent joint, if they were carried out by heating the connecting points before the melting stage of polypropylene structures. For the first option, an installation that makes socket welding is useful, for the second, an installation that has a clamping hydraulic mechanism.

Blow torches are equipped with hills with different diameters having a teflon coating. They are used to melt the inner surface of the socket part or the couplings of the outer end part of the pipes.

Before welding the product, where the aluminum foil is on the outer surface, smooth it out to the size of the entrance to the tee or other fitting. Other materials do not need this. The soldered part must be cleaned from dust particles, degreased.

Then you can begin the installation process:

- The armature, which is installed at an angle of 90 degrees, is cut with the help of special scissors or a hacksaw for metal.

- A nozzle of the required size is attached to the soldering equipment and it is connected to the network to heat up to 250-270 ° С.

The approximate warm-up time comes to 15-20 minutes.

- The outlet fitting pipe on one side of the installation is put on the mandrel, and on the other side the end of the product is inserted into the sleeve opening to the level of the welding depth.

- After both elements have been heated, they are removed from the nozzle and are connected to each other with fast movements while observing the double alignment. The diameter of the parts affects the heating period.

- Within a few seconds, the weld will cool. At this time, you can not make turns or bends. Otherwise, the connection cannot be corrected, it is cut out.

In the case of underheating, the joints will be unreliable, and overheating - the product will lose its shape and the welded joint deforms.

Connection with metal or metal-plastic products will become possible with the use of fittings with threaded inserts at one end, and additional seals.

Polypropylene products tend to change the parameters during heating, therefore, for the DHW installation procedures are carried out using sliding supports and various compensators - round, L-and U-shaped.

Proper installation of the structure does not require quick replacement due to the high level of strength and quality.

More about polypropylene pipes and a soldering master class are waiting for you in the next video.