The subtleties of wall decoration clapboard

Modern technologies in construction and repair are constantly being improved, a lot of new materials appear. GCR, OSB, plastic are in demand and are widely used, but wood still does not give up its own positions. In particular, lining is very popular and popular, it is practiced when covering ceilings, walls, window and door slopes. The material can be used for internal and external works.

Features and Purpose

Lining is a natural and environmentally friendly material. Its positive features include the following characteristics.

- Nice appearance. Never repeating the original wood pattern makes it possible to create an extremely interesting finishing material.The variety of colors, shades and contrasts gives the opportunity to actively apply it to designers in their own projects. Through this material, you can not only change the appearance of the interior of residential premises, but also make the facade of any home more attractive.

- Durability. Boards lining thoroughly soaked with all sorts of protective agents, the treated surface will serve more than a dozen years. Boards tightly join each other when laying, resulting in an extremely strong surface that perfectly protects the internal or external walls from the influence of negative factors.

- Easy installation. Even those who know absolutely nothing in construction can carry out the installation. The ease of installation strongly attracts consumers, since spending a minimum of time on mastering the most important rules of finishing, it is possible to save considerable funds on the remuneration of specialists.

- Good sound insulation. When installing the wall panel between it and the house wall, an insignificant air layer is formed, which counteracts the penetration of third-party sounds and ensures silence in the house.

- Affordable price. The cost of the material varies in a relatively wide range, which makes it possible to choose the most economically viable option. It should also be noted that the laying does not require careful preparation of the base, which helps to reduce the estimate of finishing works.

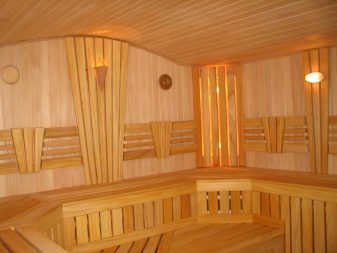

Lining is almost universal productused for covering various types of surfaces, ranging from walls in a room to ceilings. It can be used for finishing a bathroom in an apartment, a bath, a sauna, office premises, facing a log house of log, timber, frame, brick houses or buildings of aerated concrete. It is possible to hem clapboard roof, since the used tongue-and-groove joint allows you to give the facing a monolithic coating.

Types and characteristics

Lining can be made of wood, MDF (wood waste), as well as PVC (plastic lining).

Of wood

Wooden lining is the ancestor of the entire lining, which has not lost its popularity in our time. Lining of wood is widely used in both external and internal lining of buildings.It is especially respectable looks in the hallways or saunas. Of course, in order for the service life of a batten to be long, even in places with high humidity, appropriate tree species, such as linden or alder, must be the basis for making it. Other wood species (pine, spruce) are suitable for use in more acceptable temperature conditions.

This material may also be different in shape. There are several types of profiles.

- Standard profile - front side with equal bevels on both the groove side and the spike side. In this case, the outer corners and edges of the profile are straight and look somewhat rough.

- Profile with the name "soft line" gives the lined surface a smoother look, aided by rounded bevels. The calm lining also looks smooth. But unlike the “soft-line”, it has a shallower groove and a shorter spike, which significantly reduces the performance of the material, since the profile locks can disperse when temperature and humidity fluctuate.

- If in the standard profile you additionally make grooves on its back side, then you will get the so-called lining. Such grooves are made to prevent the accumulation of condensate behind the mounted profile, since air masses circulate between the base and the profile.

- Lining "American." Due to the virtuoso copying of solid wood is the most successful replacement for solid wood. Its demand contributes to an acceptable cost, which is significantly lower than the cost of the array. Its popularity is also due to the peculiar design, which managed to captivate the hearts of designers, and resistance to the effects of high humidity and precipitation, which makes it possible to use it for exterior decoration.

From MDF

This material can be attributed to wood, but relatively. The raw material for its production is finely chopped wood waste or wood dust. Due to the specialized heat treatment of raw materials, a sufficiently strong and relatively light material comes out, the ecological characteristics of which make it possible to use it even in children's and bedrooms.

The undoubted advantages of the profile of MDF is almost unlimited color range. Due to the ability to externally reproduce not only the patterns of the tree, but also the pattern of stone, marble and other materials, the profile has gained particular popularity among people with modest material wealth.

Walls lined with MDF look cozy and stylish.

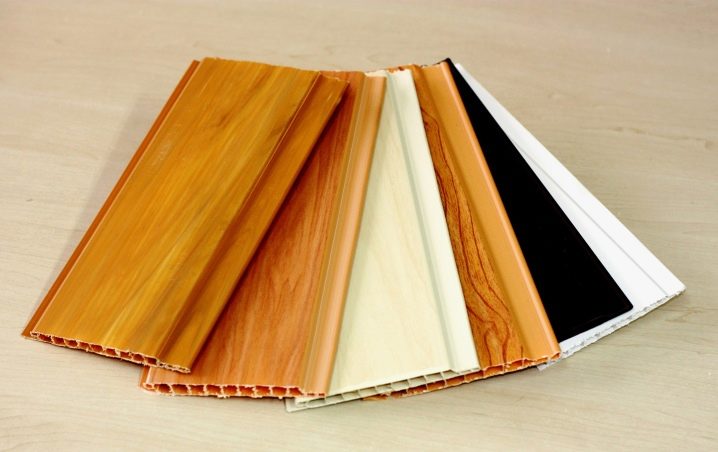

Plastic

The profile from plastic, or PVC of a panel is a strong competitor of the first two types of lining. Often, the plastic version is chosen because of its relatively low cost, low weight and still the same ease of mounting and reliability in operation.

It is safely used in both exterior and interior decoration of the house. Although this material is environmentally friendly and can be used in almost any room, it is necessary to realize that such material will not add a certain comfort to the room interior. The walls look good (or some of them), lined with plastic lining on the balcony or in the bathroom. However, in the living room or bedroom, such a design can look a little awkward. Where PVC panels look especially attractive is on the ceiling, and then only in common areas, such as kitchen, bathroom, corridor.

When deciding whether to install PVC panels on the ceiling and walls, make sure that there is no open flame, or just something hot, as such material is freely deformed from high temperatures, loses color and then cannot be restored or repair.

Dimensions

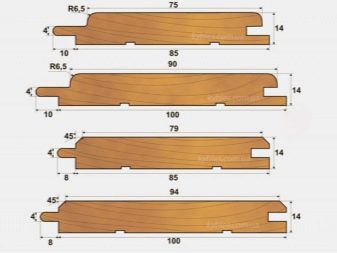

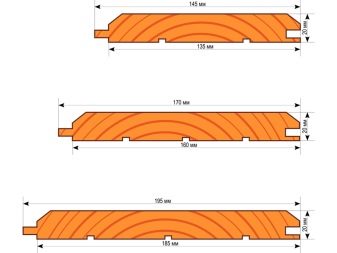

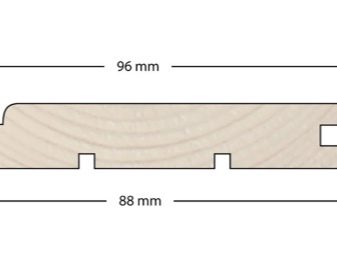

Immediately it should be noted that the size of conventional and eurolining different. The length, thickness and width of a regular profile are established by the manufacturer.

Lining from wood which typical the typical sizes is in the greatest demand.

- The shortest board length is 0.2 meters, the greatest length is 6 meters. Such dimensions make it attractive for those who intend to carry out the covering of the bath, balcony or living room.

- The width of the profile can be from 76 to 200 millimeters. This size makes it possible to perform high-quality veneer both inside and outside the house.

- The thickness of the board in this case is from 12 to 40 mm, the size of the spike is from 4 to 5 mm.

If wooden profiles are analyzed in length, then they are divided into two classes: long ones are used for cladding, short ones - for cladding roof moldings.Short boards are cheaper due to the fact that the blanks are made from the remnants of the production of long boards.

The dimensions of the lining can be from 1.5 meters to 6 meters in length. Thickness can be 13.16 and 19 millimeters. The width of the lining is 80, 100, 110 and 120 millimeters. This width is perfect for covering large spaces. Thorn size - from 8 millimeters to 9.

For Euromask the following differences in size are allowed:

- length +/– 5 mm;

- thickness 0.7 mm;

- in width - one millimeter;

- spike size can be +/– 0.5 mm.

Subtleties of installation

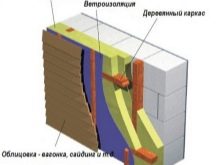

Usually for cladding clapboard on the grounds, wood frames are created with a distance between carrier profiles from 40 to 60 cm. Similarly, the subsystem can be made of galvanized metal profiles, only to attach the clamps instead of studs (for rooms with high humidity anodized or copper) it is necessary to use metal screws or rivets with a small cap of type LN 9 mm.

Slats can be directed both vertically and horizontally. In the horizontal direction, the compensation channels on the back side perfectly remove moisture (very good for steam rooms),and in the case of the horizontal direction of the sheathing, the penetration of moisture into the lock is excluded (excellent for facades).

I must say that the wall paneling made of wood, mounted horizontally, can be practiced for covering wooden and metal partitions. Sometimes it is directly on the racks sheathe the walls of frame buildings. A good decorative effect can be extracted if the boards are installed diagonally, although there are difficulties with cropping and planning the economical use of the material.

It is better to install forcing boards to the enclosing structures with a compensating gap (up to 10 mm). After mounting, the external and internal corners of the junction are closed with timber dobrings. Similarly, for these purposes, you can use a rope of jute, hemp or flax, which is excellently combined with wood and reliably seals the technological gaps, since it repeats all sorts of curvilinear surfaces with the utmost precision.

Facade

In order to finish the facade in a horizontal direction, it is recommended to carry out works from the bottom up. The first strap is mounted with a spike down and mounted on the crate.The second panel is installed so that its spike went into the groove of the first, after which it should also be mounted on the crate. All subsequent panels are mounted in the same way.

Fixation of the wall paneling on the batten can be done by means of screws, nails, brackets construction stapler, as well as specialized fasteners. It would not hurt that the fasteners pass through the groove strip when mounting the board, then it will be invisible. When installing each panel, it is necessary to strictly control the accuracy of its location - it must stand parallel to the other boards. Distortions and offsets are not allowed. It is also important that the boards are located strictly in the same plane, that is, they should not be higher or lower relative to each other.

For door and window openings, joints of walls, specialized skirting boards, profile angle and slats are used. The second option is the installation of batten strips perpendicular to the base of the facade. Boards are installed and fixed in a vertical position. For wall joints, two strips are used, which are placed at the right angle. The openings of doors and windows are made in the same way (an ode bar covers the escarpment, the second one establishes a platband).

In some cases, it is required to use a double frame for eurolining.For him, the bars are nailed in two layers, the top is made perpendicular to the bottom. The reinforcement of the frame is required on large facades, where the own mass of the cladding is large, and the load on the supporting structure is increased.

Varnishing and painting of the wall paneling should be carried out after the installation is completed, and treatment with protective means, both inside and outside, should be carried out before installation.

When cladding the facade, the wall paneling can be used together with other materials. This will give the appearance of the house a more expressive look. You can also use the lining of various colors.

Interior finish

Slab, of course, can be nailed directly to the ceiling or wall, but only under the condition that they are smooth and made of wood, which happens very rarely. As a rule, a framework is first constructed on the surface (the slats are fixed), and then the facing material is nailed on. There is a small, but very significant nuance. If the lining is to be mounted in a vertical position, then the rails should be horizontally packed on the wall in steps of approximately 0.5-1 meters. If a horizontal position is chosen for the casing, then the slats are arranged vertically.

This is done for more reliable adhesion of the frame with clapboard. Naturally, the wall should be smooth, because all the slats in the frame should be at the same level. To do this, you need to use a plumb and level when working. Upon completion of the preparatory work, you can proceed to the trim. Experts recommend starting from the corner and move on rake for rake.

In rooms that do not require flawless beauty (in particular, outbuildings and utility rooms) can be used for fixing and nails. Of course, not ordinary nails, but special ones with small caps.

You can just beat the planks in the center, but to form a decent appearance, it is better to hammer in the studs in the grooves, then they will hardly be noticeable. But if you want the surface to have a nice aesthetic look, it is better to use special brackets for fixing.

Recommendations

Mounting lining required to follow the rules. At this stage there should be no omissions or defects, otherwise the lining may be fragile and will not last long.

Between the slats and the base (wall, facade, ceiling and the like) There must be a ventilation meter in 1-2 centimeters. Often, when mounted, it is overlooked, closing the space for ventilation with thermal insulation. For normal ventilation between the installed clapboard and the ventilation layer must be left empty space. If this is not done, the material will begin to get wet, crack, bend.

If there is no space for ventilation during the work, the casing must be removed. In the presence of insulation there are 2 ways to create a ventilation gap: you can remove part of the insulation or “increase” the frame, thereby increasing the distance between the base and the skin.

In the process of mounting their own hands when leveling the Euro-rail slats, you must act very carefully. In order not to spoil the material while knocking their ends, it is necessary to correctly calculate the impact force. Actually, due to the fear of splitting off a groove, often when mounted, small misalignments of the slats are left. This should not be allowed - the material must fit perfectly smoothly, exactly parallel to the initial bar. Otherwise, the skew will only increase, because of which the whole lining will be a curve.

If the boards are already mounted skewed, you need to find the one with which the discrepancy went. All trim installed after it must be dismantled. Then the uneven bar is aligned and the lining is mounted first.

When heated, the tree expands and shrinks as it cools. To compensate for the transformation of its dimensions when laying the skin along its contour, they save a space of a few millimeters. If the installation is done without a gap and the boards abut against the walls, the skin will be deformed over time. To correct this error, you need to dismantle the baseboard and slightly trim the strips from the edges. So, when facing the walls, the extreme slats should not reach angles of 5-6 mm. The same - with joints with the ceiling and floors.

Often, the lining is fixed to the frame by klyimery (brackets of special configuration). Meanwhile, conventional brackets can be used only when it is necessary to sheathe interior and dry premises. It is better to use nails or screws for external cladding, as well as for covering rooms with high humidity. Standard brackets in such episodes provide a not very secure fit and the skin deforms as the wood becomes damp and also under the influence of sharp temperature fluctuations.

If the room covering with high humidity or facade is implemented using not very strong brackets, it is necessary to strengthen the fasteners. The easiest option is through fixing with nails or screws. It should be noted that in this situation their caps will be visible on the surface of the skin. If this is unacceptable, then the panel should be removed and re-installed using more reliable fasteners.

In accordance with the regulations, eurolining should be covered with protective equipment after mounting. In fact, this is not always done, as a rule, the material performs its functions without special coating. The result is the appearance of fungal growths on the surface. If the tree does not have time to deteriorate, it is necessary as soon as possible to apply a protective substance to it. If the fungus has already been formed, the surface of the boards must be treated with a special tool from the fungus, and then applied protection. In some cases, before applying the protection, the surface is sandpapered to remove the spoiled wood.

Lining examples

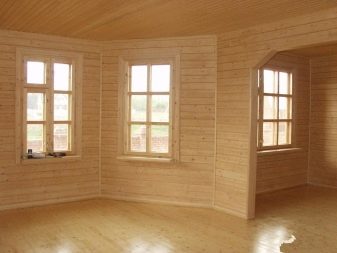

- There is an opinion that the wall paneling is more suitable for a bath or a summer house than for an apartment and a cottage.Such a mistake is successfully refuted by designers who harmoniously fit wood veneer in a wide variety of styles and directions.

- Lining of wood in the interior harmoniously combined with wallpaper, tiles, plaster. With a professional combination of textures, you can create a stylish and elegant interior.

- Lining can be an integral part of the interior in the Scandinavian style. In this design, it is in harmony with artificial or natural stone and large beams on the ceiling.

- Anyone who is in love with Provence, will certainly fit the execution of the walls of the material from the wood of natural colors. In this embodiment, the connection of wood with plaster and floors of rough boards looks pretty and at ease.

- Another style that requires the use of natural wood veneer is Russian. Walls lined with a block house look like log walls.

- It is possible to apply lining and in hi-tech style. In this embodiment, the materials are painted with paint in neutral white or gray, and are used as a background for saturated accessories.

- Fans of minimalism are likely to like the combination of lining with a strict lining ofceramics and stone.

How to cladding a wall with clapboard, see the next video.