Cover for the well: the choice of design and manufacturing methods

When building a private house or cottage away from the city water supply system, one of the most important courtyards is a well. To keep the water in it always clean, cool in summer and not freezing in winter, any well must be closed. Previously, for this purpose, special wooden sheds were built, which can still be found on some sites, but now as a decoration.

In addition to the usual wells, from which drinking water is collected at the site, there are also storm water inlets, inspection, drainage and sewer wells, various industrial wells, over which it is not advisable to build separate wooden houses. Therefore, almost all modern wells are closed with a special lid.On the features and varieties of this device and will be discussed further.

Special features

The cover for the well, whatever it may be, is always entrusted with only one function - the protective one. According to plumbing rules and regulations, some types of wells (especially with drinking water) are prohibited to use without protective overlap. It not only protects the hydraulic structure itself, but also prevents the ingress of various materials.

At the well should not fall precipitation, various debris and foreign objects. Access to water in direct sunlight is undesirable, otherwise the water may “bloom”. The cover protects animals and people from accidentally falling into the well and at risk of injury or choking. In addition, the cover on the dacha well can act as a decorative element, the final ensemble of courtyards.

Depending on the type of the well itself, the covers that are used to cover them are also classified. Marking is applied to them according to GOST and is as follows:

- K - cover for sewage;

- D - storm water inlets;

- PG - fire hydrants, located under the surface of the earth;

- B - water wells;

- C, TS - viewing elements of water supply and heating systems;

- M - for the pipeline;

- T, GTS, MTS - telephone manholes;

- in the form of relevant drawings (telephone, raindrops or gas lights), which are applied at the request of the customer.

Materials

There are certain requirements for the material from which the well cap is made. They must be durable and wear-resistant, have increased resistance to various damage and deformation under the influence of moisture, as well as to the appearance of mold or rust. A strong cover can be blown away by a strong wind, so they must be heavy and fit tightly.

Plastic (polymer)

The most practical and inexpensive product for use in a suburban area are plastic covers that can be used both on plumbing and technical and sewer manholes. According to its properties, plastic is not inferior to metal counterparts, having a lower weight, which makes it easy to carry and install one person on its own. Such covers can be of any shape and color, various patterns and patterns, be made in the form of grids with cells of various sizes. It is easy to fix them with ordinary bolts, and such covers serve up to 50 years.

Among other things, the plastic plug is universal in use both at the summer cottage and in well drilling, since polymers can be operated even in extreme conditions, this will not reduce their strength. They can withstand high temperature differences, high loads and interaction with petrochemical products, they can be put on thermometric wells. The strongest plugs are made by treating hot polymer sand with pressure and further cooling the mixture.

The lack of well plugs made of PVC can be attributed to the lack of a single marking and universal size. Pick up the product will have, focusing solely on the measurements.

Of wood

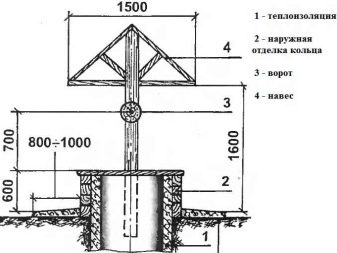

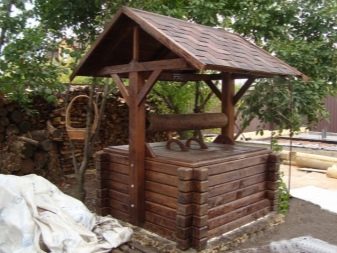

Most often wooden buildings are erected in country houses and near country cottages. The wooden well cover is to a large extent a decorative element, which, however, retains all its protective functions. In addition to the wooden floors above the well, small houses with a real roof are built, which adorn the courtyard and provide additional shade.

The advantages of the material are safety and high environmental friendliness, which is a significant advantage when installing a well with drinking water.The wood is durable and durable, it is not covered with mold when it is adequately treated with protective compounds, and it is definitely not covered with rust. The cost of wood is not so high, and to make a product out of it with your own hands in the presence of a little experience will not be difficult.

The only drawback of wooden plugs is the need to install insulation, so that in the winter, the surface of the water under it is not covered with a layer of ice.

Metallic

This material is rarely used for the manufacture of well plugs. Heavy alloys with constant contact with water quickly become rusty, and light stainless steel will break under any wind and will not be able to provide the necessary fit. Most often, the metal is combined with another material and only individual elements are made of it. For example, textolite overlaps with metal corners are often found. The most common material of metal plugs is cast iron.

Cast iron

Products made of cast iron are most often placed on sewage and storm facilities. They are made of cast iron alloy (SCh20) with the addition of graphite, which increases strength and increases the service life of up to 100 years.Pig-iron hatches are suitable for any sewer wells and they do not need to be warmed, they are extremely resistant to damage and extreme loads. At the same time, cast iron is a heavy material, its structures are overall, expensive and difficult to transport. For these reasons, installing them on wooden or concrete log cabins is impractical.

Concrete

As a rule, caps of concrete goods (reinforced concrete products) are not used in private possessions. They are made in cases where the sewer wells are made in non-standard forms.

However, if the sewer network of a private house is made of reinforced concrete rings, the mounting rim for it is made of appropriate materials.

Dimensions

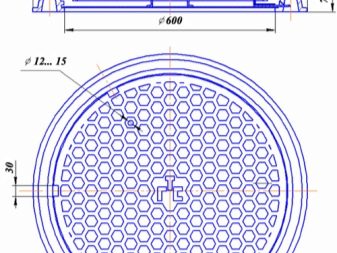

Virtually all types of well covers are either round or rectangular in shape. A round lid does not fall inside the hatch, the appropriate shape, and more reliably adjacent to it. In cases where a round structure cannot be mounted, for example, a well is equipped with a square log frame of wood rather than concrete rings, the shape of the square is used.

According to the requirements of the state standard, the diameter of round hatches should vary within 450–550 mm, and the maximum load on them should not exceed 600 kN.Square covers should have a size in the range of 300-800 mm and be as tight as possible and pass the waste water. The latter is relevant for trellised covers covering rain inlets.

Sewers have lettering symbols that depend on their class of load.

- LM is a small-sized lightweight hatch weighing no more than 45 kg, which is installed in the pedestrian zone and the zone of greenery.

- L - light hatch up to 60 kg, used in cities and towns in residential areas (for example, A15 hatches).

- C - an average hatch weighing up to 90–100 kg, installed in car parks of the carriageway of parks.

- T - heavy hatches weighing up to 120 kg, installed on urban roads, along which transport is intensively moving.

- TM - heavy hatches made specifically for highways, weighing up to 140 kg.

- ST - superheavy hatches weighing up to 155 kg for airfields, docks and other areas with high load.

In addition, large reinforced concrete hatches with various symbols (P-15, P-10, P-25) are classified according to weight:

- lungs (less than 2 tons);

- medium (less than 5 tons);

- heavy (up to 25 tons).

How to do it yourself?

Most often, the well cover owners of country and country houses are made independently.It is desirable that it was not only strong and durable, but also combined with the style of the well itself.

In the presence of children of preschool age, it is best to make such a lid, which is closed with a tight valve or lock. At the plug itself should be installed comfortable handles for which it can be raised, or a system of runners, along which it will move.

Wood option

One of the simplest types of well overlap is a simple wooden shield in the shape of a circle or square. To make it, you will need boards with a width of about 13–15 cm and three beams with a cross section of 4 x 4 cm. Additionally, you need to purchase a special sealant, nails and bolts, metal or wooden handles and paint and varnish coatings.

Placed close to the bars, cut along the length of the shield, stuffed boards in the required quantity (depending on the size of the intended cover). For better fixation between the two bars, you can fill the third. The resulting structure is cut grinder to the desired shape and grind. All the slits between the boards are sealed with a sealant or special splashes, and then coated with linseed oil and stain.

To protect the wood from moisture, the resulting lid is lacquered on top, and at the final stage the finished handle is assembled with nails or screws. This design does not attach to the well, and fits on the tip and removed if necessary.

More reliable is a double cover in the form of a shield, in the middle of which is cut a hatch with two wings. The shield itself is tightly fixed on the tip, and the shutters are planted on metal hinges and locked on a tight shutter. Such a more complex structure is mounted from eight bars, half of which has a cross section of 2 x 2 cm and half - 4 x 4 cm. In addition to them, you will need 2 cm thick boards, 2 swivel hinges, ready-made metal handles, a hook, fasteners, compactor and paintwork. materials.

On two thick beams you need to fill the trimmed boards so that you get a rectangular hole in the middle. The two remaining timber 4 x 4 nail on the side walls to strengthen the structure and all of it is polished. The leaves are made of the same boards, stuffed on two boards with a cross section of 2 x 2 cm each. Ready polished sashes are put on the hinges and fasten them to the walls of the hole in the middle of the shield. All cracks are sealed, handles and latch are fastened.The resulting cover is covered with enamel, wood stain and varnish, and then mounted on the well.

Cap with metal frame

The monolithic part of such a cap is attached to the wellhead, and the movable element is enclosed in a metal frame. It requires: metal pipes with a square section, metal corners and tape (45 mm wide), a sheet of PCB. In addition, you will need hinges, seals and paints.

The corners are cut into pieces of the desired size and are welded in the form of a square or rectangle, the welding points are smoothed with a grinder. Sections of the required length are cut from the profiles and welded along the perimeter of the fixed frame. The seams are cleaned and primed again. Two plates are cut from the PCB (by the size of the metal frame) and fixed to each other with self-tapping screws.

Between the two layers of PCB can lay a layer of insulation, if necessary. Formwork made of planks is placed on the edge of the well and a metal frame is fixed on it. A metal tape is placed around the wellhead, and concrete is poured into the space between it and the frame.Textolite sash is connected to the frame with swivel hinges and screwed the handle.

The whole structure is covered with two layers of enamel to protect from moisture.

Concrete

Concrete covers for hatches are usually purchased in finished form to the diameter of the concrete goods of the rings from which the well is composed. They are both monolithic and with a hatch. However, this design can be made independently. For this you will need: wooden boards for formwork, reinforcement, concrete and film.

A 10-cm deep hole is dug in the ground, coinciding in shape and diameter with the diameter of the well. The bottom and walls of the resulting recess are lined with foil, and in its center a square or rectangular formwork is made. After that, concrete form is poured into the formwork 50 mm in thickness, and until it is dry, a reinforcing mesh is installed. 50 mm of mortar remaining up to the edge of the solution are added to the grid and they wait about 24 hours for it to solidify completely.

The dried concrete slab is removed from the ground and it covers the end of the well, smearing all the cracks with fresh mortar. In a small hole in the middle of the resulting structure, insert a cap from any material.

From plastic polymers

It makes no sense to make such a lid at home, because you will have to buy equipment that exceeds the cost of several dozen purchased items. In any hardware store or on the market a variety of polymeric overlappings of various colors and sizes are sold. The purchased product is mounted on the well with ordinary bolts or put on the tip, like a nylon cover on a regular can.

Tips

To give a simple wooden cover a more aesthetic look, it can be painted the color of expensive wood (oak, alder).

As a heater, you can use foam, polyurethane foam or polystyrene foam.

Plastic covers can be ordered from the manufacturer, and he will apply any relief or pattern on its surface. It will cost several times more expensive than buying a standard version, but will allow you to become the owner of a unique product to suit your own taste.

The best solution would be to buy or manufacture such a plug that matches the material from which the well was mounted.

She not only looks better, but she does not have to change it as much as the well itself.

If you need to make a cover in an urgent order and the absence of ready-made handles for it, you can just nail two bars arranged in parallel. They will be able to rest and slide the cover off, making much less effort than lifting it from the bottom.

Beautiful examples

The antique well is equipped with a modern dark-plastic plastic lid. The convex relief, made in the form of a large wooden lattice, is combined with a less relief surface, denoting the boundaries of the well hole. The hinged hinged door with metal handles fits snugly to the hole and protects it from even the finest sand and dust.

The summer well with a collar, into which, if necessary, a small vibration pump can be lowered, is made entirely of wood. The roof erected above the tip protects from the scorching sun, and the decorative elements made of wood remind of old fairy tales.

Conventional well manholes of reinforced concrete is quite difficult to do so in order to decorate their site. Most often, these elements are trying to decorate with flower pots or decorative stones.

Different materials can be shaped and texture completely different. Metal camouflage under a tree, a tree under a stone, and plastic - in general under anything.

Summing up, it can be noted that a high-quality cover is the key to a long and safe operation of the well structure. You can buy plugs of any size and shape, the main thing is to choose a reliable manufacturer. If skills allow, you can make it with your own hands, following a simple algorithm of work, then confidence in the quality of the finished product will be one hundred percent. As in the case of the finished product, and with a homemade it is also important to comply with all rules of operation.

The process of making covers for the well, see the following video.