Cleaning wells: fixtures and work recommendations

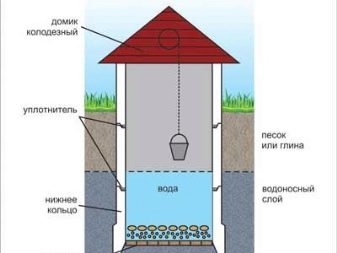

Well - an invaluable help in obtaining clean water for drinking and technical needs. But the problem is that the active circulation of the fluid gradually leads to clogging. It is possible to cope with similar troubles, only it is necessary to strictly follow a certain technology of work.

Signs of pollution

Start by recognizing signs of contamination. Indeed, each type of blockage differs by a special approach and cannot be eliminated according to a universal template.

- The appearance of turbid water even in a very small volume almost always indicates that particles of soil enter the cavity of the well.Penetration of them there becomes possible due to the weak tightness of wall joints, which can shift or leak. Much worse if the water gets one or another color.

- Green ebb indicates that the well has become a place of active reproduction of microscopic algae. And if the liquid turns black, it often leads to the conclusion that organic matter not only got inside, but also decomposed.

- Water with excess iron concentration becomes yellow; Immediately it should be borne in mind that ordinary cleaning in such a situation is powerless. Purification through special filters helps to cope with excessive saturation of well water with iron. To recognize the "strong" metal helps and specific taste, which appears even earlier obvious visual signs.

- At the cottage and in the farmland, the water raised from the well may be sweetish due to the presence of nitrogen. He gets there with fertilizers (nitrates) and cannot cope with this problem until the source of these substances has been blocked.

- Yellowish color often attaches to water that has entered the home source from the swamp; The difference from simple overflow with iron is that the color is relatively weak.Green tone, other than algae, is sometimes associated with the penetration of hydrogen sulfide from secondary sources. Recognize this is easy by the appearance of a characteristic putrid odor.

- Clay falling into a well is sometimes provoked by the action of quicksand. It mechanically destroys the most durable and stable structures, and the rock saturated with moisture easily finds insignificant cracks and immediately penetrates them. The presence of lime in a significant amount is determined visually as is pollution from dirt and silt. If there is comparatively little lime, the water “simply” becomes hard. On household appliances and utensils, plumbing and pipes appear scum.

Dirt may appear as a result of continuous operation of the well, and almost immediately after digging.

The problem of poor-quality construction, non-compliance with sanitary and technological standards aggravates the problem. In any case, you should not expect that the pollution will disappear itself after some time. But it is not too sensible to overly rush, using random or recommended by someone means. Much more correctly, having found the root cause of the blockage, deal with the tools and ways that really help with the cleaning.

Remedies

Enthusiasts and engineers have developed many tools with which you can clean almost any well from mechanical dirt. The simplest option is to use a scraper. He removes blockages that appear on the walls of the mine. But before you scrape these walls, you should try to clean the well with pumps. This is much more productive than trying to solve a problem manually.

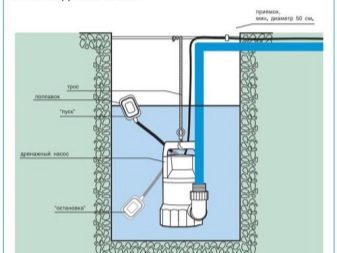

The drainage pump, lifting water upward, at the same time will pull out also dirty particles which have collected in it. The role of the pressure pump, mounted next to the tip, will also play its role. This is such a high-tech "scraper" that creates a strong, intense flow of fluid. Importantly, pumps as a device for narrow and wide wells are suitable to the same extent. Avoid the failure of the drainage unit in the sludge will help placing it on a special stand.

It is recommended to choose those pumps that are designed for dirty water; even if the top clogging seems insignificant, it is impossible to predict how the situation will change at the very bottom and when there is a shortage of liquid.

The pressure hose is placed in a reservoir of approximately 300 liters.When it is impossible to use pumps, a bucket (or scoop) often comes to the rescue. This tool is easy to make even with your own hands, as long as sheet steel and a few simple tools for working with it are available.

Those who tried to actually clean the well with a ladle did not give up on it. True, such work is very tedious and time consuming, but at least financially it is easy. The scoop should be thrown into the well shaft with the tip down, ensuring that it pierced the accumulated sludge. When working, they try to capture the dirt as much as possible (at one time they remove it from 2 to 3 kg).

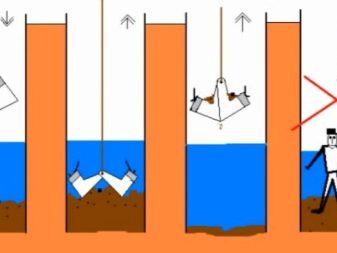

A more complex option is a grab; this tool is suitable for a narrower scope of work.

In appearance, a grab is such “jaws”, at the closure of which deposits are captured at the bottom. After lifting, they open, releasing the collected dirt. Like a scoop, a grab is best done with your own hands. But the point is not so much simplicity, but the fact that almost no one offers such a tool in the free market.

When cleaning sewer wells, along with the tools listed above, you can use the sludge pump. This is the so-called sewage disposal vehicle, equipped with a vacuum pump and a special tank. Contrary to the name, such equipment is suitable for removing not only one sludge. It perfectly copes with sand and grease, with various particles of solid rocks. Only abrasives are dangerous for a relatively soft hose that takes dirt into the tank. The disadvantage of this method lies in the fact that you have to pay, specifically to call assistants.

Cleaning technology

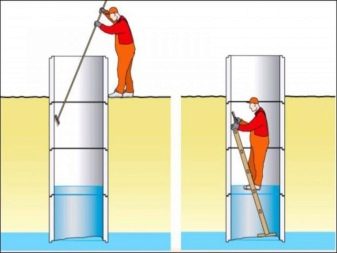

It is not necessary to turn to specialists at all - the well can be cleaned with your own hands, even without descending into it, but remaining on solid ground. Manual cleaning begins with a thorough pumping of water, moreover, consistent. Pumping the mirror by 400-500 mm using elongated tools clean the walls mechanically. In this work, it is categorically unacceptable to use even the most gentle household chemicals. Most of the work is still carried out inside and you need to carefully monitor that the structure of the rings remains intact.

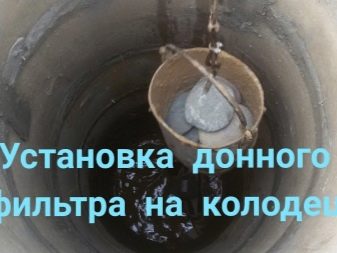

Reaching the bottom, the liquid is pumped out completely and begin the crucial stage of cleaning.It is necessary to wash the bottom filter, and it is desirable to lift the stones upward, where it will be possible to do this more efficiently. The seams, even without visually noticeable deformations, need to be sealed with cement with the addition of liquid glass. This will make it difficult to mix surface waters with those going through the mine. Be sure to be disinfected.

You can do without descending with automated cleaning, it has already been discussed - this is the use of drainage and deep-well pumps. This technique helps if you need to cope with only a minor clogging. At 50 cm from the bottom of the pit place the pumping unit. A hose from the feed pump is placed even closer to the bottom. Comply with this placement is very important; breaking it will not allow achieving a good result.

It is necessary to continue work strictly until the suction pump delivers perfectly clean water.

For maximum quality assurance, it is recommended to analyze the water samples after cleaning in the chemical and biological laboratory.

If necessary, it is recommended to use a winch to lower various mechanisms and apparatus into the well.This adaptation is relatively simple, but it helps a lot to save power. And, of course, work at the bottom of the pit requires an appropriate mental attitude.

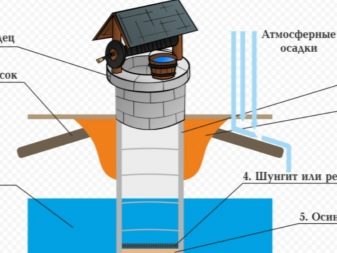

Importantly, there are ways to clean wells in stages without pumping water. This is not possible with all types of pollution, of course. So, the fight against microscopic algae, giving the water a greenish shade, is best carried out with the help of chlorine. In a few days the tank will be completely clean and ready to use. Natural sorbents, such as zeolite and shungite, effectively fight with the ingress of foreign substances. For an optimal effect, several kilograms of these reagents will have to be used at once. Another method is the use of dosing units.

The capacity of such a cartridge varies from 250 to 1000 cm3. But despite the presence of special developments, all the same, professionals recommend that you completely pump out the water and clean up the sludge by 100%. Then you need to fill the well with clean water, defending it at least a week.

Purification without pumping using open chlorine or dosing charges helps mainly against microbiological agents. But given the danger of the substance used, it is necessary to strictly follow the instructions of the manufacturers and do not apply doses higher than recommended.

It is important to resolve another issue - when is it best to carry out the scheduled cleaning of the well - in the fall or spring. Timely cleaning prevents the need for extra work of this kind and allows you to use fresh water all the time. Regardless of the schedules, you need to start work if:

sticks, stones, leaves and branches of trees, various birds and animals got into the well;

detected the presence of metals and their compounds;

water is clogged at depth with sand or clay.

Contamination with both metal and sand can be triggered by ground movement. They lead to the displacement of the rings and penetration into the extraneous mass. In this situation, it is necessary not only to clean, but also to repair the water source. Prevention of clogging is the regular rise of water to the top. Even when there is no obvious need for it, it turns out to be a very useful affair.

Before cleaning, always remove all interfering objects from the well, including pumping equipment.

After removing the water, it is necessary to inspect the structure and look for signs of visible destruction. In the absence of such problems, change the bottom filter. Sand, gravel and crushed stone located there must be pulled out and a completely new mound should be made. The freed walls are especially cleaned, for this purpose not only brushes, but also antiseptic preparations are used. After completing the formation of the bottom filter, return to the place of pumps and stationary output filters.

It has to be borne in mind that the water obtained during the first injection is not yet ready even for technical use. High-quality liquid is always transparent, without foreign smells or tastes. Sometimes such success is achieved only from the third bay. If the filters do not change, they are cleaned as prescribed by the manufacturer’s instructions - mainly by strong water pressure.

A different approach should be to the tube wells. In them, as well as in wells, it is possible to use only pumps and filters. Water pumping is also required, as well as checking the liquid obtained after cleaning in a specialized laboratory. Covering lids or canopies helps reduce the need for cleaning wells and wells.As for the time of regular purification, for wells, used only in summer, the time comes in spring and autumn. Toward winter, water has to be pumped out to prevent contamination of filters and pumps. In the spring months, special attention is paid to cleaning the walls of structures or replacing natural filters.

Even if the water seems clean all the time, it is recommended to check it four times a year in the laboratory.

Regardless of the conclusions of experts, cleaning the water source is required. It is necessary to carry it out in the case when the ground melts when the snow melts. Important: independent cleaning of the sewer well, as opposed to the water supply, is practically impossible. For this purpose, you will have to use special equipment, the purchase of which is not justified. Before using any reagent of natural or artificial origin, it is better to immediately check whether it is environmentally safe.

Installation of the bottom filter

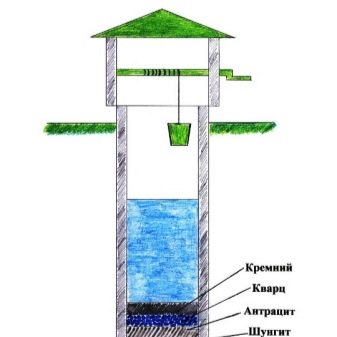

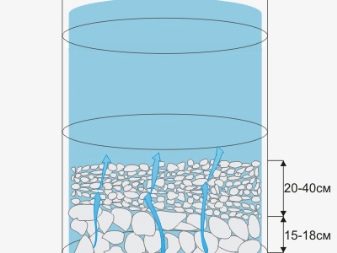

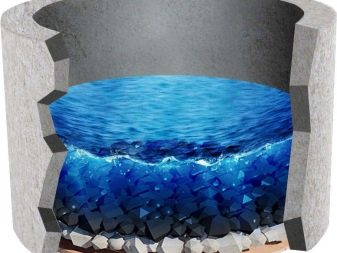

Properly installed bottom filter is an essential element of coarse cleaning, stops the invasion of sand and clay.For the formation of this protection using only natural materials that are not blurred by water. Be sure to put them in several layers to ensure complete safety using well water. WITHIt should be noted that in dense soils of clay origin with the production of water from underground springs, a filter is not required. But when the bottom is folded with soft clay and the water comes with considerable pressure, the fight against muddy suspension is very relevant.

Large crushed stone or pebble rocks lined with a layer of 0.15-0.2 m will help prevent the bottom blurring. If the foundation of the pit is made of sand and the water flows in even portions, you will need to install the filter yourself. It is also required in cases where there is a quicksand below.

The direct type of bottom filter is applied where the inflow is relatively small, as well as on top of the quicksand. First, the material of large fractions is laid out, then medium and small (each layer is 5-6 times smaller than the previous one).

The upper filtering surface in such a system is made of quartz sand or pebbles. If the bottom is already sandy, apply reverse filters.Their main task is to keep dirt from entering the water at the well bottom. At the same time, the owners are insured against fluid clogging with grains of sand rising in the flow of spring water. The difference from the direct scheme is that the sequence of layers is reversed; the thickness of each layer is a maximum of 150 mm.

Water disinfection

To clean the well is purely mechanical - very good. But it does not allow to protect yourself from:

bacteria;

viruses;

fungi;

amoebae;

parasitic organisms.

Meanwhile, all these species of living beings are the terrible enemies of man. Bad smell is just a subjective problem, and health effects will be much worse. Disinfectants should be used every six months before the seasonal use of the well and in the fall. Special cases when such a measure is needed urgently are:

mine flooding with flood or sediment, sewage;

infiltration of untreated groundwater;

clogging with any pesticides and industrial, household waste;

hit by land animals and birds;

the collapse of the material;

the presence of garbage;

bottom subsidence;

detection of excessive concentrations of microbes in the study of samples.

To make water suitable for drinking, you can use bleach in powder form.

Attention: it is necessary to carry out an accurate calculation of its quantity and not try to exceed the dosage "for greater efficiency." Precautions are carefully observed when handling this substance!

In some cases it is better to use potassium permanganate - this tool works quickly and is not dangerous. The disadvantage of it is relatively low efficiency.

30 g of the reagent is mixed with 10 liters of warm water. After waiting from 30 minutes to an hour, you need to pump out the water several times. Then dry walls are washed with the same solution, and a grid with 3-5 g of potassium permanganate or silicon chips is put on the bottom. Ready-made tablets based on chlorine compounds can be used only in accordance with proprietary instructions!

To accurately calculate the amount of reagents consumed, you must first calculate the volume of the well, starting from the depth and diameter. It is best to apply the solutions to the walls with a spray gun.

Important: all disinfectant solutions must be prepared in clean dishes,which previously rinsed.

After all, it is impossible to predict how a particular reagent will behave when interacting with foreign substances. Applying chlorine water, you need about 10 minutes to thoroughly mix it with long poles or scoop a bucket and a sharp spill back.

It is much easier to do this using an overhead pump. After such chlorination, in any case, it is necessary to cover the well with a thick cloth or polyethylene. Be sure to ensure that the mine was cool and did not fall the sun's rays. Otherwise, the chlorine will evaporate too quickly and will not produce the desired result. The walls will need to be washed with clean water. Pumping out the well after chlorination is repeated until even the faintest chemical odor disappears.

Note: any work with chlorine and its compounds can be carried out only when wearing a gas mask or respirator. Be sure to wear safety glasses and impermeable gloves.

Dosing cartridges should usually be applied for 30 days (unless otherwise specified by the manufacturer). The choice of the appropriate type of cartridges is better coordinated with the SES.When preparing the mixture on the basis of tablets, use plastic or enameled containers that can hold from 10 liters.

Precautionary measures

If on the surface of at least one of the concrete rings there are signs of pollution, raids, the color has changed - you need to clean it soon. This can be done at any time of the year, even in winter. But it is important to remember that the cleaning of wells is a much more serious procedure than going to the store or riding a bike. At least three people should start working at the same time. When descending into the well must be tied safety rope.

Before descending, it is worth checking whether dangerous gases have accumulated below. This is done by lowering a bucket with a burning candle; the deviation of its flame to the side, extinction or change in the color of the fire indicate danger. Experienced experts always go down in a helmet and rubber boots. Suffering from diseases of the heart and blood vessels, periodic dizziness in the wells is better not to climb, especially if the depth exceeds 3 m. You should definitely get a rope or a simple ladder, after making sure of their reliability.

Important: if the candle has not gone out, but has given a bright flash, this indicates the accumulation of combustible gas.

In such a situation, as with the saturation of the well with carbon dioxide and toxic fumes, it is better not to try to do the work on your own. Where it is more correct to call qualified specialists. It is not recommended to stand at one point for a long time, this may result in suction of the legs. It is recommended to lay a wooden platform in the case of silt or waterlogged soil, this will help to evenly distribute the weight.

When working in a well, it is worthwhile to periodically exchange remarks with those who are at the top. If no answer is heard, you should immediately lift the workers upstairs.

Without the most urgent need it is better to refrain from cleaning the well in the dark. Having noticed the objects falling from above, including the tool, it is better to nestle on the wall. Staying below can only be alone.

It is advisable to limit the work time at the bottom to 15 minutes with a rest at the top for at least as much time. If it is necessary to light something, only special lights are made in the well, which are made according to the explosion-proof scheme. To light and turn them off you need to strictly before the descent and after it. Categorically it is impossible to smoke below, drink water. Do not trust the cleaning of the well to minors.

For details on how to clean the well with your own hands, see the next video.