How to choose plastic wells?

In the sewer there are many elements, one of which is a well for the maintenance of the plumbing system. Today, modern models are presented in the form of light polymer structures, simple to install and operate. Why modern plastic products more profitable than traditional reinforced concrete, what are the types and sizes of structures we consider in this material.

Special features

Regardless of the type and purpose, almost all wells are of a similar design: a cylindrical shaft with trays for several sewers and a bottom (kinet). The length of the structure can be adjusted using extension cords and sliding shafts. To achieve the desired length, they are connected to each other.

Tight connection provides durability and reliability of the well. In some cases, sliding extender models are used that perform two functions at once - connecting parts of the structure together and acting as walls. The upper part must be closed with a hatch, which is also made of plastic.

Previously, water wells produced from reinforced concrete. But over time, the insulating layer of such structures is subjected to severe damage, reducing tightness. Today, plastic well-inserts can solve the problem of long and trouble-free use. Choosing modern products, you should pay attention to their functionality. Conventionally, they are divided into four categories such as:

- A15 it is intended for installation on a green zone and walking paths;

- B125 it is particularly durable, therefore it is suitable for installation on pavements and in park areas;

- S250 apply at arrangement of the sewerage which laying is carried out under roads;

- D400 considered the most durable, designed for use on the territory of highways.

At the same time, the hatches of the A15 standard can be mounted directly on the shaft of the well,but designs for products of other categories are mounted on the discharge ring or on a telescopic retractable tube.

There is a transitional element between the manhole and the mine itself - this is the neck. It is needed to receive the load and to compensate for the weight in order to prevent damage to the structure and the pipes suitable for it. The neck is a corrugated or telescopic design. The latter can be advanced, thereby opening the place for inspection or repair of walls, and therefore is considered more convenient to use.

The tightness of the design due to the presence of the discharge ring with thread. On the walls of the well there are holes for the inlet or outlet pipe. The range of models is represented by products with single and double walls. For a tighter opposition to the ground products equip stiffening ribs.

Purpose

Plastic wells are more often used as independent products, for example, when arranging water wells. But in some cases they can be used as an addition to ready-made concrete mines to protect the soil from the seepage of sewage.The main purpose of products can be called the function of interconnecting sewer lines. The special construction of wells provides the following conditions:

- the ability to control the technical condition of the pipeline in places nodal connections;

- changing the direction or diameter of the pipe;

- laying of branches of the sewer pipeline;

- changing the flow rate of wastewater;

- quick access to the sewer for maintenance and repair.

Plastic wells are widely used in the industrial field, as well as for the construction of drainage, household, stormwater networks. Today, plastic wells can be used in the following areas:

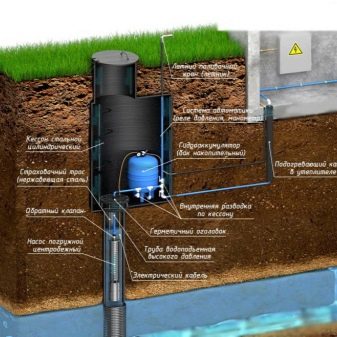

- in central and local water supply networks;

- for arrangement of the stormwater drainage system;

- to create drainage systems;

- in the autonomous sewer;

- in the industrial field;

- for deepening or strengthening of already established mine wells.

Advantages and disadvantages

Judging by consumer reviews, the popularity of these wells is due to a number of advantages, namely:

- affordable cost of products;

- small weight of all designs;

- resistance to decay, so that water pollution does not occur;

- low thermal conductivity, so the water in them does not freeze even in winter;

- high strength and reliability of products due to high-quality plastic and stiffeners;

- a wide range of products will allow you to choose the optimal design;

- high level of tightness. The walls of the well are protected from the penetration of microorganisms into the structure;

- with proper operation, the product will last for many years;

- wells are easy to install and use.

If we talk about significant shortcomings, they simply do not. All factors say only that plastic wells are incredibly convenient and practical.

The only thing is that the products should be cleaned from time to time and the pump should be prevented. To ensure that the quality of drinking water is always high, the well must be equipped with a lid.

Species

There are several types of water wells, each of which has its own characteristics.

- Inspection or inspection well. These models are designed to control the technical condition of the sewer system.Often they are used to place special equipment in hazardous areas. There are such wells in each sewage system in the places where the main line, branch junction, slope and pipe diameter change. One such manhole is able to combine several traffic flows at once. The distance between wells is calculated according to standard indicators. The larger the diameter of hydraulic structures, the greater the distance between the wells.

- Manifold wells. Most often used in various floatable systems, including drainage, household and storm. They are necessary to connect several pipelines into one. Depending on the particular design, they can be equipped with differential pipes, hydraulic locks, non-return valves.

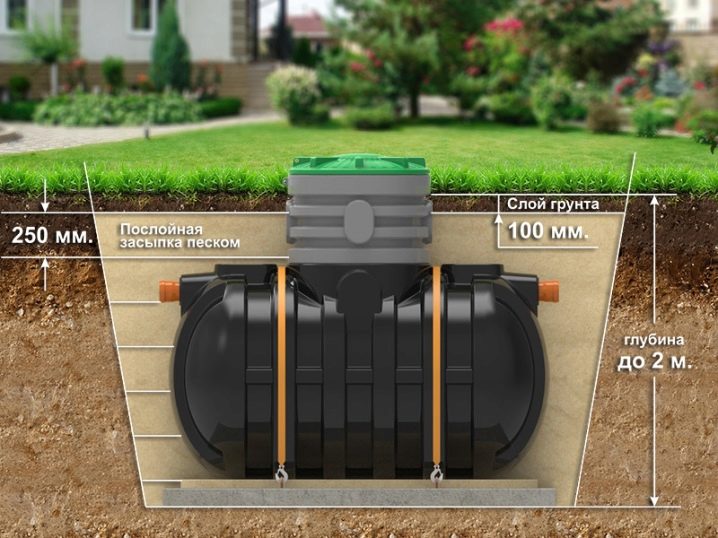

- Absorption wells. Installation of these models is carried out in those places where there is no possibility of another removal of wastewater. Absorption structures are plastic structures up to 2 m in depth and 1.5 m in diameter. The bottom is equipped with drainage: gravel, crushed stone, crushed brick are poured. The same materials are sprinkled for external walls of wells.Inset drainage pipes in the design should be performed at least at a height of 40 cm from the bottom. Such an approach turns the structures of wells into certain sand traps: microparticles of sand and other materials simply sink to the bottom.

- Water intake structures. These models are designed to accumulate wastewater before they are pumped out, removed or sent to wastewater treatment plants. The end result depends on the level of contamination of the water. Water receiving models have impressive size, as they must withstand up to several tons of liquid. Their walls, bottom and lid are absolutely tight, so even the loss of heavy precipitation can not affect the occupancy of the structure.

- Storage wells They are large tanks in which all the sewage and drains are collected. As a rule, they are mounted near residential buildings in the lowest part of the site. The design is as tight as possible, without a single gap or gap. The liquid entering into such wells is divided into fractions: heavy particles settle to the bottom, and the liquid along with light particles enters the next filtration well.

- Filtration. The volume of such structures is somewhat less than the previous ones. They are necessary to remove the liquid that enters the soil through the bottom. Due to partial disposal of sewage, cleaning the well is rarely done. Their feature is the absence of bottom: the well is simply filled with filtering materials (rubble, sand).

- Swivel installed in places where there are branches of sewer pipes. In some cases it is used in places where it is not possible to lay a continuous straight line from the house to the cumulative septic tank. It can be used as a manhole: through it you can easily clean the section of the water pipe.

- Stormwater wells used to transport wastewater accumulated in drainage pipes and trenches. May be open, closed or mixed. If moisture will be used in the future, then the well must be airtight. Otherwise, filtering or drainage is established. It is worth noting that in well-water pipelines a well-damper of sewage pressure is often used, which is necessary to reduce the flow rate.This reduces the high pressure on the walls of the pipes and improves the transport of water.

- Cable Such wells are used to locate cable network nodes, to pull cables, repair communications, and place telecommunications wells or power cables.

Materials

For the manufacture of plastic sewer wells used several types of plastic:

- PVC - This is the most common option. PVC wells are lightweight, durable, resistant to external stimuli. However, they do not tolerate temperature fluctuations and can be deformed under the influence of soil masses. The advantages of the material can be attributed to another significant factor - it is resistance to chemicals. PVC is a thermoplastic material that is practically non-flammable in open space.

- Rubber - This is the second most popular material used for the manufacture of manholes. As a rule, they are placed in special metal covers to protect the tanks from pressure and the effects of soil.

- Polyethylene. Constructions of this material also need protective covers.They are mainly used as drinking water, since ethylene polymer is used in production. Polyethylene is a fairly durable material, so the structures are well tolerated by the influence of aggressive environment and do not react with chemicals.

Dimensions

All structures can be divided into two categories, such as:

- a well with a diameter of less than one meter with an unattended shaft, which is compact in size and is installed at a shallow depth;

- A well with a diameter of more than one meter is suitable for system monitoring and maintenance.

Accessories

Plastic wells may have different equipment, but in general, their design consists of the following elements:

- top part;

- body;

- bottom.

Each of the parts can be represented by one or several products.

Top of the structure

The execution of the upper part is influenced by several factors such as:

- diameter;

- loads during operation;

- appearance;

- functionality.

The product can have a removable or deaf cover. Some models are equipped with a special hatch for collecting rainwater.On sale are designs with decorative covers that look beautiful on the background of the lawn.

And for industrial sites fit the usual products with plastic or cast iron hatches that can withstand higher loads.

Body products

The body of any well is a plastic pipe with corrugations. It is the presence of a corrugated profile that allows you to properly interact with the ground. In winter, the upper layer of soil freezes, covering the upper part of the well. Corrugation is able to change, preserving the integrity and functionality of the structure. Large diameter wells in the middle part of the structure have additional plastic rings with rigid ribs, which increase the level of reliability, allowing you to install products to a greater depth.

Bottom

The bottom can be open, closed or combined. In addition, the bottom can unite pipes of household and common-sewer large diameter. In the manholes, the bottom is designed in such a way that the structure can be easily combined with a domestic or common-sewage system. In this case, it is realistic to combine up to three traffic flows.

Large-diameter wells are most often equipped with a bell, which is connected to the pipe with a swivel. This allows you to deflect the connected pipe in any direction from the axis by 7.5 degrees.

Useful recommendations

Plastic wells are lightweight, which makes it possible to carry out the installation without special lifting equipment. There are two ways to install the mine, depending on the type of soil.

- Open installation method involves digging a large diameter mine. A layer of fine gravel is poured at the bottom, having previously been tamped with a layer of geotextile. The assembly of the shaft is carried out using diagonal rings, the threads of which should be pre-lubricated with a waterproof polyurethane sealant. After the pipe is lowered into the ground, it is carefully leveled along the plumb line. The gap from the pit wall to the mine is filled with fine gravel. At the bottom of the pipe, bottom filters are mounted or the column is wrapped with geotextiles using polymer-insulated wire. Before that, many holes with a diameter of 6–7 mm are made in the pipe. The top of the mine is insulated with foam or any other insulating material.

- Closed way it is applied on friable sites where soil fall is possible. The pit is dug out according to the size of one plastic ring, so that its upper part remains above the ground. Initially, they are mounting the first element, screwing the second element onto it, while not forgetting about sampling the earth from the inside. Continuing such manipulations, the structure will gradually settle down. The thread must also be lubricated with sealant.

The procedure is repeated until the structure reaches the aquifer. After that, the bottom of the ram and settle the bottom filter.

From time to time plastic wells need to be repaired and cleaned. The procedure for the reconstruction of the old mine is carried out as follows:

- pump out water from the tank;

- dismantle the valve;

- re-strengthen the bottom;

- mount well column;

- fill the space between two columns with gravel and sand;

- equip the new bottom filter;

- carry out pumping water submersible pump.

For information on how to choose the plastic wells, see the next video.