How to choose a well ring?

Not a single building can do without reinforced concrete rings. Previously, materials such as logs and stone were used to build well shafts. With the development of technology, the mechanism for creating objects of autonomous water supply has become much simpler. To date, to strengthen the walls of wells in the factory make special rings. They are made of plastic and reinforced concrete.

Special features

The well on the site is not only a water-providing functional element, but also a decorative element of the exterior. High hygiene requirements are applied to such structures. To create a wellbore and neck, elements of buried structures are traditionally used. The sewer system of a country house includes a pipeline and a well, where everything is interconnected. First of all, the well must be durable. Therefore, reinforced concrete well rings have long established themselves from the good side.

Modern rings for wells are presented in the market in wide assortment with various sizes and according to state standard specification. The process of producing well rings is not easy. For the manufacture of using only high-quality concrete fine-grained fraction. A prerequisite is the installation of a reinforcing cage inside the form, which allows you to distribute the load evenly over the product. Reinforced concrete structures are made from materials such as:

- permeable concrete solution for manholes and tunnels;

- concrete of low permeability, the scope of use of which is unlimited.

Their exploitation is allowed below or above the groundwater level. Depending on the conditions of use, select the desired product. There are two options for well rings: straight and with a groove. The second option is more hermetic and reliable. Rings form between themselves a depth trunk and a mouth of a well. The seams between the rings are sealed with cement, and gravel is poured at the bottom of the well to filter the water.

The advantages of reinforced concrete rings are as follows:

- a huge variety of sizes, which allows you to choose the right option for any site;

- comfortable round shape;

- low cost;

- terms of operation reach several decades;

- rings are used for all types of soil, while the lifetime is not reduced even under aggressive conditions;

- ease of installation does not require special knowledge;

- simplicity in the care and cleaning of the well itself, which is much easier to produce than with structures made of logs or bricks;

- For use in drinking wells, rings are treated with a special wax emulsion, which is absolutely environmentally friendly and harmless to humans.

The disadvantages of well-reinforced concrete rings are the following:

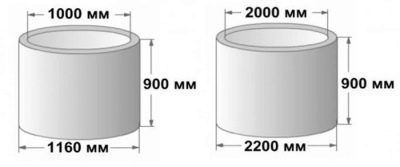

- heavy weight, sometimes reaching up to 3000 kg. In view of this, installation is possible only with special equipment, as well as outside help;

- transportation of reinforced concrete elements costs a considerable amount, due to the fact that you have to hire movers and a car.

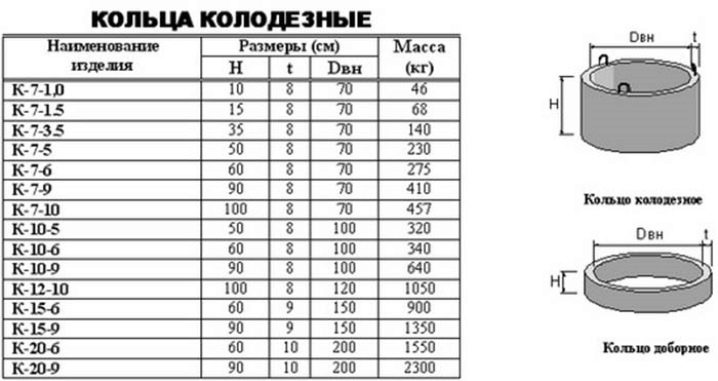

For the production of rings usually used concrete brand M200, as well as steel fittings. Well rings have such basic parameters as:

- diameter varies from 70 to 200 mm;

- height - from 10 to 100 cm;

- wall thickness - from 8 to 12 cm;

- weight up to 3000 kg.

Today, popularity is growing around plastic rings. They have a number of advantages over concrete, namely:

- high corrosion resistance;

- tightness that will not be lost even during shrinkage or frost;

- joint stiffness;

- installation of plastic rings is possible in any weather;

- tightness;

- plastic can be cut under any well, giving any architectural form;

- because of the small weight, it is not necessary to involve special equipment;

- All models are made according to GOST.

The diameter range of plastic rings ranges from 600 to 1500 mm, and the wall thickness is 50 mm. This type of rings is widely used for sewage systems, wells and drainage systems.

Kinds

Reinforced concrete products are widely used for the construction of water, inspection, candle and sewer wells. After the material is selected, the next step is to choose the type of rings, which differ in the design. Since the rings are used for a variety of purposes, there are several types adapted for a particular task.

- Wall. The CS mark designates end-to-end (wall) reinforced concrete products for wells. Typical standard rings representing hollow concrete cylinders are internally reinforced iron rods. These models are produced according to GOST of concrete brand M200, are used for the walls of the inspection and sewer manholes.

- Doborny. This type has non-standard dimensions and is used only in the case when wall for some reason does not fit, for example, it is necessary to bring the well to a certain height or the shaft deviates from the design depth. Manufacturing technology of high-quality models is simple, and installation is possible only if there are lifting equipment and a team of workers.

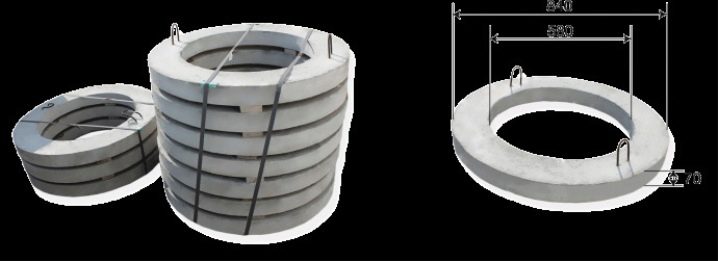

- Support or adjustment rings designed to increase the level of installation of the hatch on the amount of increasing the roadway, that is, this type of ring is necessary to regulate the height of the well. Rings are issued with the KO marking, are used to create the foundation part of the well and are installed in the neck.

- Hob rings overlap used in the construction of deep wells with a hole for the pipe, which can be placed both in the center and along the edges of the plate. Products with a plate - this is the uppermost element of precast concrete wells. They are designated by PC marking, their design provides special strength and tightness.

- Quarter Well Rings guarantee the strength and integrity of the design. Moisture that disappears into the well, eroding backfill, can create a dangerous situation. Reliable sealing rings increases the strength of the entire engineering system. As well as reliable joints of reinforced concrete structures prevent soil contamination.

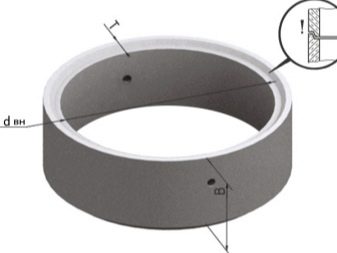

- Lock rings used in the construction of drinking wells. This model differs from the usual wall structure by the presence of a folded joint at the ends. The peculiarity lies in the fact that a protrusion is located on one ring and a recess on the other. When connecting the rings are joined so that the protruding part fell into the hole, the gaps at the same time are fixed with the help of cement or tow. Thus, such a well ring connection is securely fixed.Another big plus of rings with a lock is a better sealing compared to other models, since they exclude the mobility of the rings. The price of such a product, respectively, will be higher. Such options are considered the highest quality, reliable and safe.

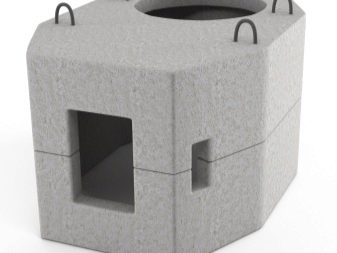

- Rings with the bottom. Reinforced concrete products with a bottom are represented by the labeling KCD. They are presented in the form of monolithic wall structures with a bottom. This type is used as the basis of the well mechanism and is a stove in which there is no hatch. They have standard sizes that will allow to avoid discrepancies of rings in the future, and also such dimensions provide water tightness. This type is used in the construction of septic tanks and septic tanks. Installation is simple in the absence of work on the construction of a concrete platform for the installation of rings. This option will protect the well from silting.

- Flat end models, having a smooth surface, are used for arrangement of wells with narrow mouths, as well as under conditions of danger of displacement of the soil.

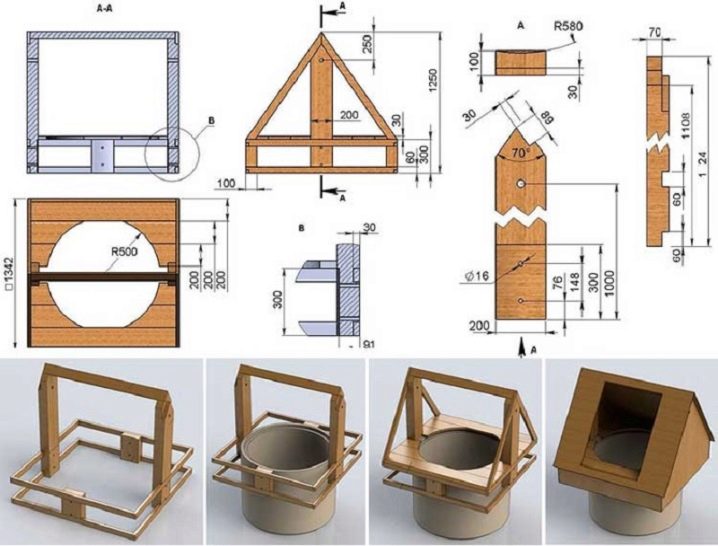

If you wish, you can make rings with your own hands.The cost of such a ring will be about 700 rubles. For manufacturing, you will need the following: a concrete mixer, sand, crushed stone and high-quality cement, containers and forms for pouring.

Depending on the purpose, there are several types of wells, such as:

- drinking, which are intended for the abstraction of water suitable for drinking or domestic needs;

- inspection wells are suitable for monitoring sewage;

- drainage structures are used to control and flush the drainage system;

- telephone wells are needed for the construction of communication networks;

- gas wells - for gas equipment;

- storm showers - to divert rainwater;

- water wells are used for water flow, respectively.

Dimensions

Before choosing a place for the future well, first of all, you should decide on the required volume. To make calculations, you will need the following indicators:

- the number of residents in the house;

- the amount of water that one person consumes;

- the number of days during which the well will be filled.

The volume will directly depend on the needs of water consumption.The average daily rate per person is without a bath from 150 to 250 liters. For a standard family of 4 people, water consumption can vary from 600 to 1000 liters. To ensure a certain reserve, the volume is calculated as three times the daily rate, that is, an average family will need a three-cubic pit.

Knowing the required volume, you can calculate the size of the future well. Depth is usually done 2-3 meters. The area of the well is calculated by the formula S = πR2.

Sewerage is always digging with the calculation of additional width, depth and length due to the fact that the protective wall in the form of formwork is being constructed. According to the technology, the elements of the submerged structures should be installed in a prepared pit and tightly fitted to each other. Without taking into account the weight and volume they can not be properly installed and transported. Weight and volume are also important when calculating construction work. The typical weight of concrete rings is different for each brand.

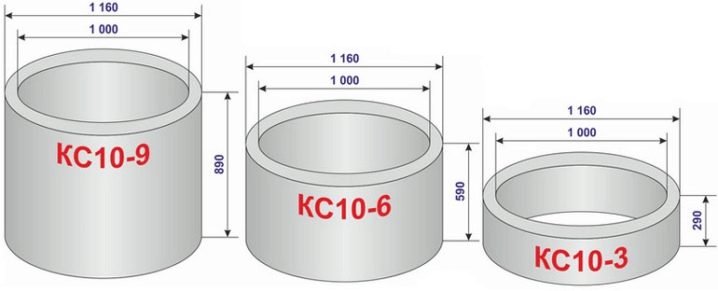

The sizes for reinforced concrete rings, which are regulated in accordance with GOST, are different. Products for well constructions are marked with a COP, followed by numbers indicating their diameter and height.The most common standard models are KC10, KC15, KC20 (height 90 cm). The cost of these models starts from 2500 rubles. Of great importance is also the thickness of the walls, which is selected taking into account the soil. The higher it is, the stronger the product, and the cost is correspondingly greater.

Well more than two meters are unprofitable at financial costs, and less than a meter - they are very difficult to install manually.

Installation

Installation work on the installation of reinforced concrete rings is a responsible procedure. You can order the installation from the professionals, but then the installation will not come cheap. Modern technologies allow for the installation of reinforced concrete rings with their own hands. The installation of well rings can be made with the help of special equipment into a ready-made foundation pit or with your own hands using the digging method. This method is a first installation of the first ring, which deepens by digging, then after the removal of the earth is established the second ring, and so on.

To begin with, it will be necessary to determine the place for the future construction. But before that it is necessary to get complete information about the quality of water and soil in the geological survey organizations of a city or region.And it is also possible to take water for testing from neighbors, and the analysis to perform in any SES.

Since water quality affects human health, this question should not be ignored. If the water is clean and lies at a depth of six meters, then you can proceed to the choice of location on the site for the well.

It is worth noting that the hole should be dug no closer than 20 meters to the stay of animals. The composition of the soil is also necessary to know before the earthmoving works. If it includes clay or stones, the installation will result in a rather difficult process. After the preparatory work, you can proceed to earthmoving. The ideal option is from August to October.

When using the first option, you should dig a hole where the ring is later inserted. The pit is made with a reserve depth of 10–15 cm, and in diameter it must be 10% larger than the diameter of the ring to be installed. The bottom of the pit can be reinforced and self-poured with concrete, or you can buy a ring with a bottom.

When self-assembly after pouring the bottom you need to wait 3-4 days, until it is completely solidified. If the bottom is not supposed, then a cushion of rubble falls.In addition to financial benefits, self-installation of elements of the buried structures has another advantage - the entire structure can be mounted in one day.

However, you need a special technique to install the ring, due to the fact that its weight sometimes reaches 3000 kg. It is necessary to take care of the free passage to the installation site in advance.

When choosing the second option, you should dig a hole in the right place and install the first ring. Further, when digging the pit begins to gradually deepen. In the course of the action and increase the depth on top of the first product put the second, then the next, and so on, as long as it is necessary. The pit is rummaged with shovels, and to seal the joints between the rings, they use cement solution and bitumen-based products. It is also necessary to build a waterproofing using a hydraulic lock to prevent harmful substances from the soil from leaking into the well.

The gaps between the rings can also be carefully sealed with rubber sealing materials, which are placed in the grooves for better tightness. Such materials must have medical certificates. When mounting rings with a lock, it is worth checking the reliability of the seal so that the rings will not further disperse.To avoid unpleasant odors, cover the well with a special stove with a hatch.

The absence of protrusions on the surface of reinforced concrete products allows them to be used in the repair work of already existing wells. In order to install concrete products, you need the following tools: tamper, bucket, ruler, hammer, chisel, water barrel, trowel and mortar box.

Tips

When choosing and installing well rings should follow the advice of experts.

- Many professionals advise not to use asbestos-cement or rubber rings for wells, as this is fraught with the appearance of a specific taste in water. For technical purposes or watering the garden, such models are suitable, but there is no man for domestic consumption. And also do not advise to cover the ring with bitumen or tar, if water is planned to be consumed by a person for cooking.

- Restoration of the old well by lowering reinforced concrete rings is quite possible, but under certain conditions. To do this, you need to choose the right diameter in order not to turn the crown logs.

- The position of the rings during installation must be constantly checked so that they do not go away. Otherwise, the mine may turn out to be bent in one direction. Walls should be combined as much as possible.

- To improve the slip rings when lowering, it is necessary to shed the outer walls with ordinary water.

- If reinforced concrete wedges during installation, it is possible to use shaped boards along the walls.

- When self-fabricating concrete rings, it is necessary to install a force to fill on a flat clean surface.

- It is necessary to pour concrete into the form in small doses, constantly ramming with a metal bar.

- Reinforced concrete well product, made by hand, should be left to solidify for 3-4 days.

- For strength, PVA glue is poured into the concrete mixture.

- The temperature outside when cooking the mixture for a future product must be at least + 8ºС and not higher than + 20ºС. The higher the temperature, the stronger the concrete will be.

- The depth of the pit for the well must be at least one meter.

- It is recommended to install waterproofing outside the well rings. A small layer of soil is removed around the perimeter of the well, then the cavity is covered with sand and covered with waterproofing material. At the end of gravel.

- The elevation of the rings above the soil level must be at least one meter.

- There are a number of limitations when installing well structures for organizing sewers. Thus, the wells must be located at least 30 meters from the natural reservoir, three meters from the trees in order to avoid damage by the roots. The minimum distance from the house can not be less than 5 meters.

- Part of the work is done in advance, for example, digging a well, buying reinforced concrete elements so as not to waste time on rented equipment.

- The installation of wells is not recommended at groundwater levels above 1.5 meters.

- The well must be installed in the free access for the aspener machine.

- Additional plastic rings can also be a good protection for the well.

How to choose a well ring, see the following video.