Inspection well: what is it?

The sewage system provides for the presence of many elements, each of which is designed to ensure the smooth operation of the network. One of the main elements of this system is the manhole. It is designed to verify the performance and operability of the mechanisms and structures of the sewer network, as well as to clean the sewer. This indicates that this component of the system is one of the leading, and it is worth dwelling on it in more detail.

Appointment of underground observation chambers

In more critical areas of the sewer network, viewing cameras are arranged. This is done, as a rule, on fairly long sections that have a large number of nodes, intersections, turns, as well as level differences.With the help of control points, it is possible to carry out checks on the performance of the pipeline lying at depths of up to two meters and, in case of detection of faults, carry out repairs in a timely manner. Shut-off and control valves, which are part of the inspection chambers, are located in full view, so it will not be difficult to track and replace structural elements that have served their own.

It is difficult to overestimate the role of the manhole, because if the accident occurs on a site not equipped with them, you will have to remove a large layer of soil, while the viewing chambers will allow you to quite accurately determine the location of the leak.

Nowadays there are many documents that normalize the construction of similar facilities., and their features are reflected in documents of the type SNiP or GOST. The requirements set forth in them are dictated by the experience of previous generations since the advent of the first communication systems for moving water. As an example of regulating the construction of a regulatory framework, point 2.04.03-85 (SNIP) called “Sewerage. Outdoor Networks and Structures ”, which contains the rules for the construction of manholes.Cable transitional manhole for plumbing and sewage can be done by hand and independently inspect the condition of the systems. You can choose a typical project, which consists of a specific scheme. And also it is necessary to designate such parameters as height, water dimensions and distance of double-wall constructions.

Construction features and device

Each of the elements of sewage have specific structural features. The inspection well is not an exception, so it is worthwhile to dwell on this point in more detail.

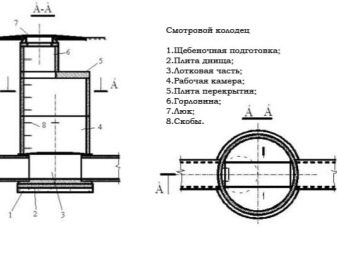

For a start it is worth noting that all types of manholes, of course, have such integral elements as:

- tray;

- bottom;

- Luke;

- neck;

- mine.

Other structural elements may vary depending on the purpose. Requirements for manholes, the legislator reflected in GOST 2080-90, which includes requirements for reinforced concrete prefabricated structures, as well as technical requirements for products, their characteristics and labeling.

Prefabricated buildings have several advantages over monolithic. One of the main ones is the low weight of individual structural parts, which allows their transportation and installation without the involvement of special equipment.In addition, the delivery of individual parts is much easier to implement than the delivery of an integral structure. Performing the necessary earthworks requires less effort in the case of collecting the construction in parts.

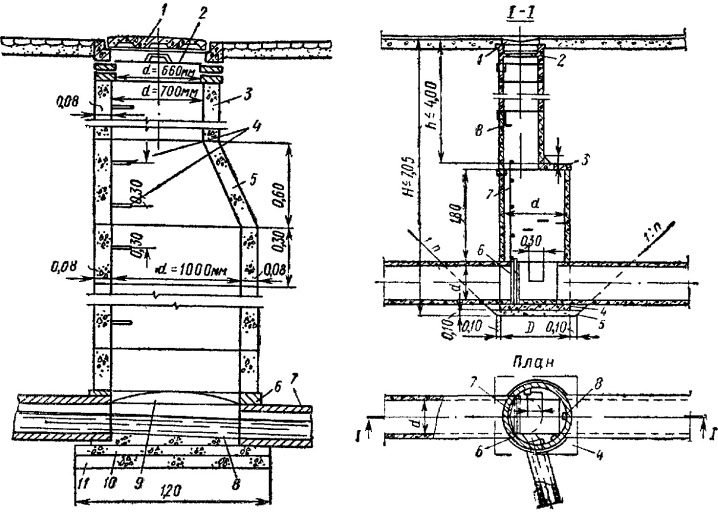

The lower part of the structure is a concrete slab placed on a previously prepared basehorizontally placed on a layer of rubble. This is done to give the structure additional stability and to ensure the outflow of groundwater. The lower part is called the tray. As a rule, it is equipped with holes for the installation of the pipeline, the location of which directly depends on the purpose of the well. Due to its specificity, the main working chamber has the largest dimensions. It is into it that they descend to check the wear of the structures and mechanisms of the well. The wall of the working chamber is equipped with a special ladder for more convenient descent.

The upper part of the working chamber includes a slab designed to close it, and a mouth of a narrower diameter located in the slab than the main part. It is covered with a special hatch, performing two main tasks - it is protection from unwanted guests,as well as protection from debris and precipitation. In order to impede penetration into the chamber, hatches are made of heavy metals, such as cast iron. When using hatches on chambers in suburban areas, it is more expedient to use more comfortable and aesthetically attractive variations of polymer covers.

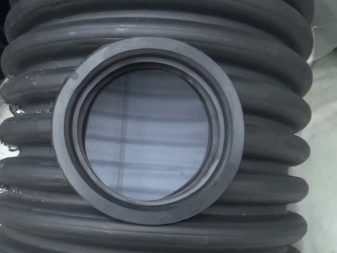

The specific requirements are imposed to designs of polymeric productsset out in GOST-R No0260760. As a result of the use of modern production technologies (extrusion welding), polyethylene has become the most common production material. Such products are considered quite reliable. They are not amenable to chemicals present in the soil, in addition, they are durable, environmentally friendly and airtight. Such cameras are purchased and installed in finished form. They are adapted to the rapid installation and connection of pipes, which is why owners of suburban areas often prefer them.

Kinds

The classification of inspection wells are based on two main features, such as:

- main function and place of installation;

- material of manufacture.

Based on the first factor, linear, nodal, rotary and differential views are distinguished., each of which is equally applicable to both household and industrial communication systems, which makes it possible to install any of the selected species in its suburban area. Linear manholes should be organized on fairly long terrain (from 35 to 300 meters). Moreover, according to the SNiP, they are necessary, even if the site has no prerequisites for the occurrence of accidents.

If the pipeline turns to the side, then the place of the bend requires the installation of a rotary type manhole. Here, the construction is subject to the general rule, which prohibits exceeding the angle of 90 degrees.

At the intersection of two or more pipelines it is necessary to install node models of wells. Structurally, this type is characterized by the presence of additional pipes (holes), which are mainly on the same level. If you need to increase or decrease the flow, you should use the drop-down view of manholes, where the nozzles are located at different levels. And also drop wells are used to lower the flow level.Contrary to the fact that the designs and functionality of wells look different, all types are very similar. At first, the wells were made of stone or brick, but later they came to the use of practical and lighter concrete counterparts, and the most modern variations are made from polymer.

Installation

Of concrete rings

Before starting work at the planning stage, you should plan the future installation site, as well as carry out the following activities:

- accurate marking of the site for digging the pit;

- cleaning the area;

- construction of a temporary entrance for equipment.

As soon as the area becomes free, you can begin to dig a pit. It is necessary to extract the soil from the ground to the required depth.

Next, you should level the bottom and cover it with a layer of 20 cm crushed stone. After that, you need to tamp the filter layer, which, if necessary, will need to be sealed with mastic from bitumen.

Further actions should be carried out according to the following plan:

- need to lay the base;

- equip the tray - to form the lower part of concrete M100, reinforce the grid of galvanized steel;

- seal the ends of the pipes with layers of cement and bitumen;

- after 2–3 days we need to process the concrete rings from the inside with bitumen and install them on the trough part;

- to carry out the installation of the floor plate and the neck, then seal everything;

- wipe the joints with cement mortar and bitumen;

- plaster tray;

- to build a clay castle at the bottom of the well;

- check the quality of waterproofing by filling the well with water and leaving it for a day.

Having received successful test results, it is necessary to backfill. In the upper part you need to make a blind area and leave it open. On the hatch you need to install a locking mechanism and close all the polymer cover.

From plastic

Preparation for the installation of a polyethylene chamber is carried out according to the same plan as for the installation of a concrete structure. But the work itself is carried out much faster and easier.

The entire installation process can be divided into the following steps:

- digging of the pit by excavation to the required depth;

- arrangement of the basis - filling of the filtering layer of rubble, and also the leveling layer of sand;

- installation of a plastic well on the prepared basis;

- sewer connection;

- backfilling with interval tamping.

There are certain types of cameras that have too little weight. In such cases, to ensure stability during the movement of groundwater, the structure is supplied with a submersible chamber filled with concrete.

There are nuances when installing a polyethylene well under the pavement or road. The walls of the chamber can simply not withstand the load and collapse, in order to avoid what you need to install the reinforced concrete plates, which will allow the well to remain in its original position during deformation of the roadway due to the displacement of the covering plates.

For these purposes, use two reinforced concrete slabs. In the center of the bottom a hole is made 1.5–2 cm above the diameter of the chamber. Then the well is lowered into the hole so that it is 9 cm above the bottom of the plastic product. The top slab is used as a regular ceiling with a hole for the hatch. The use of polymer wells in tandem with plastic pipes as a result provides a reliable, wear-resistant system that can last more than a dozen years.

Tips and tricks

The process of installing manholes may seem similar to the construction of other types of sewers. However, there are specific features and nuances that should be read before starting work. And in order not to be mistaken with the choice of products and installation technologies, it is worth referring to the prompts of the relevant regulatory documents and consultations with professionals. Depending on the construction, there are different types of wells, each of which is optimally suited in one case or another. Therefore, at the planning stage of the manhole device, it is necessary to study their classification in order to determine which type will work best or seek help from a specialist.

The construction of the manhole is a process that requires significant costs, which may be due to the involvement of special equipment, massive structures and considerable time and effort, so it is better to entrust the organization of this process to specialists.

For how to install the manhole, see the video below.