Technical characteristics of sewer plastic wells

Sewer wells are necessary structures to ensure comfort and good operation of the drainage system. They are offered on the market in a wide range and differ in scope, technical and operational characteristics, as well as the material from which they are made. Therefore, before buying, you need to study the full information and make sure that you have found exactly what is required. If you are interested in plastic sewer wells, then they are presented in several versions, each of which has its own advantages.

Special features

The main purpose of sewer wells isto connect with each other different parts of the highway. In addition, they serve to change the direction of a pipe. The task of some models is to reduce or increase the flow rate of waste liquid.

Wells are also designed for pressure testing and placement of pumping or shut-off and control devices. Plastic products are used in the form of tee, rotary and straight-pass wells. They are installed in places where the direction of the route changes or additional pipelines are connected.

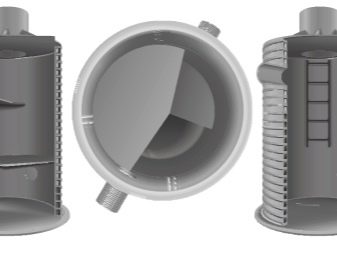

Wells sewer consist of such elements as mine, a tray and a mouth with a cover. The vertical shaft has a cylindrical shape. Inside it is fixed tray where wastewater is collected. The tray can be curved, have one or more branches.

All elements are interconnected due to cuffs, sealing rings, in some cases extruder welding is used. Thus, the product is sealed, the design is able to serve for many years, coping with its direct task. On the market, you can find any sizes and shapes of the elements of the well, so everyone can choose the appropriate option for a particular purpose.

The sewage plant has an inlet and an outlet for incoming and outgoing drains. It is equipped with a special hatch that overlaps the shaft. Due to the design features of the components, you can adjust the length of the well and reduce the load on it, which positively affects the service life. Special extension allows you to adjust the height of the mine. Such facilities are used for the arrangement of storm, industrial or domestic sewage.

Consider the function of each component of the sewer well.

- The lid is located on the neck, to which external communication lines are connected. It can be channels and ventilation gaps, it all depends on the system.

- The neck connects with the main shaft, fits its size and outer diameter of the cover.

- The mine, in turn, is an element that allows access to the tray and its dimensions are different. The wider the diameter, the easier it is to carry out service and place technological units.

- The main function is performed by the tray. But if we are talking about centralized or domestic sewage, special channels are used, as well as entries for pipes that will be connected from the outside.For inspection or other types of communications, thanks to a tray, it is possible to place and fix shut-off valves, as well as additional equipment, automation equipment and sensors.

Constructions by size are divided into two varieties. The first type is produced with a diameter that does not exceed one meter, therefore such a mine is not serviced. These are compact inspection wells and they are often installed shallowly. If the construction has a diameter of more than one meter, it is much easier to maintain it, the same applies to repairs.

Now let's talk about the benefits of plastic products.

- The designs are lightweight, which simplifies their transportation and installation. At the same time, the material is rather strong, resistant to corrosion and aggressive media, and is not exposed to mechanical damage.

- The product is flexible, therefore it may contract or expand somewhat.

- Products are offered at affordable prices.

- Another advantage of the design is that plastic products are practically not inferior to concrete in reliability and durability.

- If we talk about the service life in more detail, then we can confidently say that these products are able to be used for twenty-five years, or even more.But it is necessary to take into account the conditions in which the well is used, as well as the recommendations of the manufacturer. Dimensions of construction should correspond to the volume of wastewater and sewage throughput.

With all the many advantages of sewage structures there are downsides that are also important to consider. At installation of products it is necessary to observe accuracy as the product can be deformed. Often it is necessary to engage in the repair design. If there is even a small crack or spall, the product must be disposed of immediately, so before buying it is important to ensure the strength and quality of the material.

Species

Plastic sewer wells today are presented in several versions. Engineering networks are of different types, so for each of them their own types of wells are used. Such designs open access to measuring fittings, as well as locking and adjusting installations, waste channels

Tray revision structures

For branching and turning networks, this PVC product is most suitable. This type is used in cases when it is necessary to make installation of pipeline connections,as well as for their maintenance and inspection. The well tray is made with a slight bias to divert accumulated stock. The internal diameter of the product can be from 600 to 700 mm, the maximum depth of the well is up to thirteen meters, the diameter of the pipes varies from 100 to 300 mm. Wall thickness in different versions can be 20, 25 or 30 mm.

Sedimentary

This option is ideal for non-pressure manifolds. The well is a tank, from the walls of which are sewer pipes. The bottom of the structure is located below the level of the supplied pipelines. This allows the sediment to accumulate at the bottom of the well.

Such a model is installed on the turns and ramifications of the sewer system, as well as on straight sections of the highway through a certain distance. The main technical characteristics of the design coincide with the parameters of the audit products.

Inspection

Such wells are also called manholes. If it is necessary to install special sensors and locking and regulating devices in the pipeline, then the choice falls on such wells. The chamber is made completely sealed, the necessary fittings are located inside.

Usually fiberglass wells or plastic products are equipped with ladders to provide access to masters for repair. The internal diameter of the product can reach 2.2 meters, depending on the application. Accordingly, the larger this parameter, the thicker the walls of the structure.

Drop drops

These extinguishing chambers are operated on gravity sewer systems. The main task of the design is to reduce the flow rate in order to direct it to other collectors. Wells of this type also perform the functions of a sediment chamber. Such wells are used in cases where it is necessary to reduce the depth of the pipeline or there is a risk of increasing the flow rate, etc.

PVC drop wells are made in a standard size range, but can also be made in individual dimensions. To ensure the strength and tightness of the structure, all internal and external joints are boiled.

Cable

These designs meet the highest standards and requirements. They have high strength, tightness, resistance to temperature extremes and light weight.The product can last more than forty years with proper use.

Such wells are used on departmental and urban communication networks. The outer diameter of the shaft can be from 80 cm to 250 cm, the diameter of the hatch - 60 cm. It is possible to install the structure at any depth.

How to choose?

First you need to decide on the scope of the design, as well as carefully examine the conditions of the area where the installation will take place. It is recommended that you familiarize yourself with the technical and operational characteristics of the product, throughput, service life, etc.

When choosing a suitable option, it is recommended to pay attention to the thickness of the walls of the well (the thicker, the more durable and stronger), the dimensions of the product, the number of nozzles, etc. The market today presents both monolithic and modular models. The second option is preferable if it is necessary to install a well with adjustable height.

Prefabricated versions consist of several parts, each of which is equipped with seals, so that the finished design will have no less tightness than a monolith. At the time of purchase it is necessary to pay attention to the degree of load that the selected well can withstand.Usually, all technical information is placed in the accompanying documentation (nominal load, total weight, as well as the recommended installation location).

Tips and tricks

- The main indicator that speaks about the quality of any model of a plastic well is its resistance to the effects of an aggressive environment. During operation, the structure will be regularly exposed to organic solvents, which are destructive for some types of plastic. Therefore, for aggressive environments it is better to choose models made of polyvinyl chloride.

- If you need to achieve high tightness and install a sewer well in a place with significant temperature changes, it is better to opt for polyethylene products, as it withstands the pressure of the soil in the cold season. For weak soil, where the probability of loading is high, it is better to choose polypropylene. It has high ductility and wear resistance. In addition, such structures are easy to weld if necessary.

- It is not recommended to save and purchase the cheapest models.because it can adversely affect the performance of the entire sewer system, and soon you will have to not only do repairs, but also spend a lot of money to fix problems and replace parts that have failed.

The process of making plastic sewer wells and a good example in the next video.