Drainage wells: what are they intended for and how are they arranged?

To increase the durability of buildings, it is important to ensure maximum protection from the effects of external environmental factors, which sometimes adversely affect building materials. Drainage wells are an integral part of the system, which allows to avoid excessive accumulation of moisture, which contributes to the safety and integrity of buildings located in a certain area.

Device and system functions

Quite often, after heavy rainfall and melting of snow, a lot of water accumulates on the site, which stagnates and does not go into the ground.In this case, the soil is eroded, as well as the destruction of the foundation of existing residential or other buildings. If you do not take any measures to prevent such situations, a high level of humidity will lead to the collapse of all buildings located in the area.

To protect the site and buildings from the accumulation of moisture, regardless of what kind of building is located on the ground, it is first necessary to equip a reliable drainage system. The excess of moisture and wastewater gradually destroys even the highest quality buildings.

Competently planned construction of water drainage will ensure and maintain the required balance in the local area, as a result, eliminate the risk of over-wetting of the soil and waterlogging of the whole plot.

An important nuance is the choice of the location of the collection point for water. It will be selected on the basis of what will be the removal of excess moisture.

There are several options for solving this problem:

- ground drainage system;

- a nearby body of water of any type;

- various ravines;

- private autonomous sewer system.

It is necessary to highlight the main functional tasks that the drainage system solves:

- minimizes the load and pressure that groundwater exerts on the foundation and walls of the building;

- eliminates the risk of flooding the basement;

- drains the local area.

The most important place in this design is reserved for drainage wells.

Experts recommend that the arrangement of the system be carried out even before the excavation work is carried out to lay the foundation of the future building. In this case, it will be possible to avoid damage to the landscape design, as well as possible redevelopment and transfer of household or other buildings located on the site.

To install the drainage wells, a trench is dug along the perimeter of the house, into which a closed-type pipeline is laid and wells are installed. Their number is determined individually in each specific case based on the area of the territory, the type of soil and the depth of the groundwater.

The well in the drainage system, regardless of the type of construction, is a glass without a bottom, to the walls of which drainage, in some cases, sewer pipes are connected. The method of its installation involves the deepening of the product in the ground.The design is carried out in such a way that, if necessary, you can have access to the internal device, for example, to clean or replace pipes, clean the container from debris and control the process of water movement.

Capacity consists of the following parts:

- Luke;

- plastic shaft or body for the device.

It should be noted that before starting the construction of the drainage system, it is required to study the building codes that govern the arrangement and technology of work. Based on the specifics of the functional tasks that the installed drainage well will solve, the products can be classified into the following types: inspection, accumulative, absorption.

Types: purpose and features

Viewpoints

Similar elements in the drainage system are needed to inspect and control the level of moisture through the pipes. In addition, in some cases, a revision or a storm-receiving well is used to prevent possible problems associated with climatic conditions and an excess of moisture. Sometimes using such structures is carried out cleaning and flushing pipes.

The main feature of manholes is their size, thanks to which a specialist can easily go down and inspect the system.Based on this, the minimum diameter of the mine should be about one meter. There are constructions additionally equipped with sand receivers. Such devices are installed to collect the soil that enters the system.

Typically, conical inspection grooves are installed at the junction of pipes or in straight sections. The most popular is considered to be a device having the following dimensions - 400x1000 mm and 315x1000 mm.

Cumulative

The function of the collector wells is to collect drainage water. As a rule, the installation of such products on the site is relevant during irrigation. However, it is worth highlighting cases in which installation of accumulative drainage wells is also necessary - this applies to cases where, for one reason or another, it is not possible to divert moisture into the soil. According to their design, such receiving recesses are sealed end components for the entire drainage system.

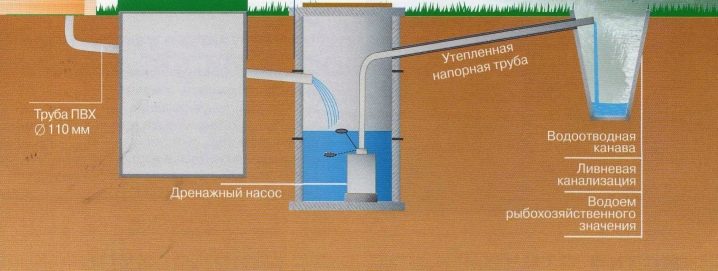

It is very important to competently approach the choice of such products, since their volume should be equal to the amount of water that fits on the site. Corrugated pipes with a large diameter, as well as a submersible pump are most often used for arranging the structure.Such wells must be made of sealed containers, so for the installation of demanded eurocubes.

Absorbing

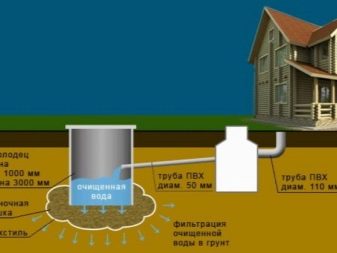

The challenge facing absorption wells is to divert accumulated water to the lower layers of the soil. The structures have no bottom and are supplemented by wells.

They are arranged by the following technology:

- first of all a hole is dug, the depth of which should be about two meters;

- the bottom of the well is filled with rubble, the installation of a plastic pipe;

- work is being done to fill the pit with gravel and broken bricks, this is necessary to ensure the filtration properties of the future well;

- The filtering material is covered with geotextile, after which it is filled with earth.

Such a well will allow water to flow out of the drainage system into the soil. Selection of the design occurs when assessing the size of the desired product and the material used for manufacturing. The cost of the product directly depends on these factors.

The challenge facing absorption wells is to divert accumulated water to the lower layers of the soil. Structures have no bottom and additional equip

Materials: construction and characteristics

Most often, drainage wells are made of two types of raw materials.

Concrete

This design is equipped with concrete pipes having different lengths and diameters. The most common designs for the drainage system are products made of reinforced concrete rings.

Concrete wells are distinguished by the following positive features.

- High strength - prefabricated concrete rings provide similar properties to the entire structure due to the specific qualities of the raw materials.

- Big operational term, which is determined by the resistance of the material to environmental factors. That is why, despite the large selection of various building materials of the latest generation, concrete remains a popular and sought-after raw material for the creation of drainage wells.

But work on the arrangement of the well of concrete elements differ in a number of difficulties. This is due to the impressive mass of structures, as a result of which the help of specialized equipment may be needed. Therefore, such works with their own hands will be quite difficult to do.

To create a concrete drainage well, two technologies are used to carry out the work: in the first case, the master is inside the ring and digs a hole, the product gradually sinks during the work.

Or, if the dimensions of the well are small, then the first step is to prepare the foundation pit, and then, using a crane or manipulator, the installation of the structure to its destination is carried out.

Plastic

The drainage well from plastic (KDN) differs in a number of positive features, among which it is worth highlighting the following:

- simple installation, the design does not require the involvement of trucks to perform work;

- the cost of plastic products is several times less than the price of reinforced concrete rings;

- the design already contains all the necessary distribution elements for the drainage of water, including rainwater, as well as the necessary branches for storm sewer;

- the service life of wells for drainage of plastic is about half a century.

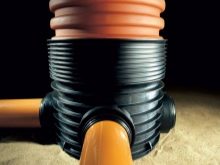

Experts identify the main distinguishing characteristic of such wells - the design includes perforated pipes, which ensure the stability and rigidity of the structure in the ground.For the manufacture of drainage wells from plastic manufacturers use the following types of raw materials: polyvinyl chloride, polyethylene, polypropylene.

In some cases, in order to save money on arranging the drainage system in the local area, structures of the combined type are used. For example, for revision and rotary wells, containers made of plastic are used, and the filtering and accumulative tank is made of concrete.

Septic tank

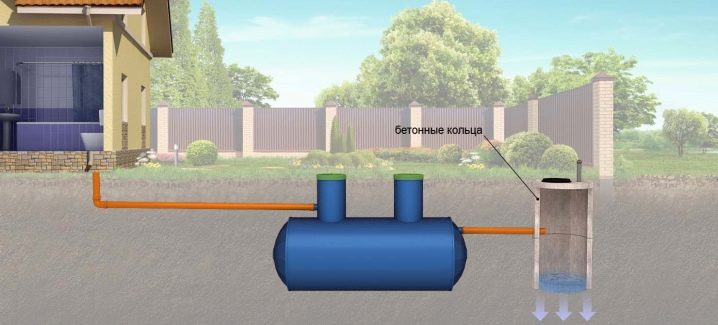

Installing a septic tank on the site is advisable in the event that there is a shortage of water, and the issue of excessive liquid consumption is also relevant, which is associated with additional expenses.

What is it needed for?

Installing a septic tank is a task that almost every site owner can solve. The device can be made from improvised means, so that the water entering the tank will be filtered. In addition, the design can be used to clean the drainage water and filter sewage.

Thanks to the septic tank, homeowners receive the following benefits:

- availability of water for irrigation, but there will be no need to pay extra for this water;

- In the first compartment of the septic tank, organic fertilizer is naturally formed, which can be used everywhere;

- the presence of a cleaning tank will serve as a solution to possible problems with the sanitary epidemiological station.

How does it work?

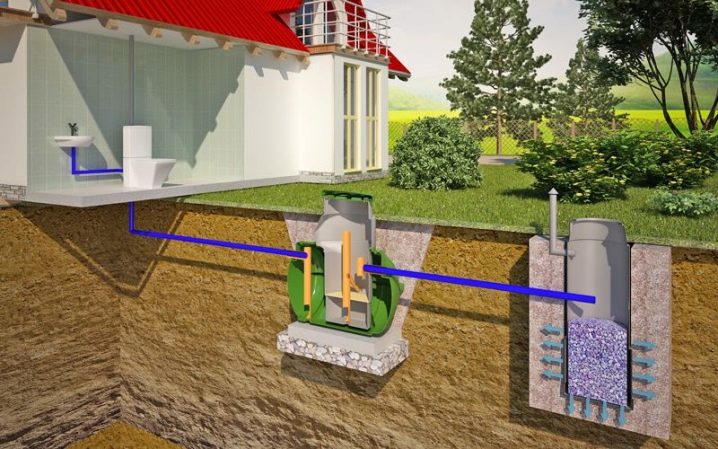

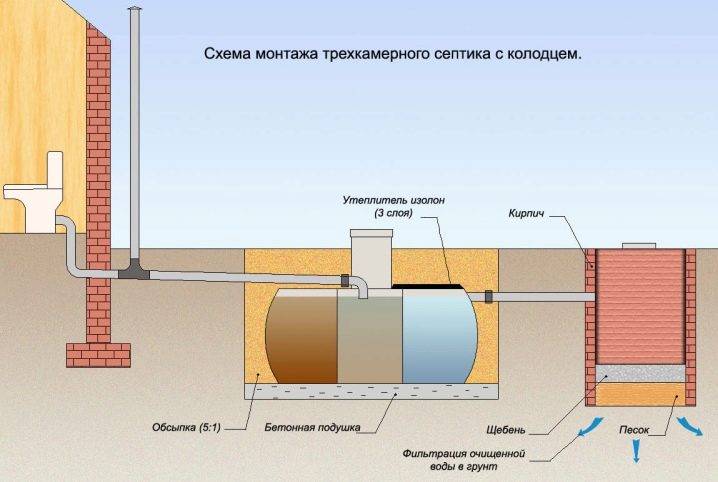

The principle of functioning of the device is quite simple: in the first compartment water is collected from the drainage system and sewage from sewage. In the process of entering the liquid sludge settles to the bottom, and water, filling the first section of the tank to the limit, freely flows into the second chamber. That is, in fact, the first section serves for the mechanical cleaning of the liquid from sludge and other inclusions.

Subsequent compartments carry out biological purification of the ingested liquid, thanks to the available microorganisms. They are specially purchased in supermarkets. When pumping liquid from the last section of the septic tank, the owners of the structure receive purified water, which can be safely used for household needs, especially for irrigation.

Installation steps

For the construction of a septic tank will need a pit that can fit three plastic or concrete pipes. After the pit is dug, products are installed into it at a distance of one meter from each other. The bottom of each product is concreted.This feature will help avoid water leaks and waste. At a height of about 10 centimeters from the top of the product, all three containers are interconnected by pipes.

After performing the above works, the structure is filled with gravel, rubble and brick, which will increase the strength of the septic tank. The final layer will be the ground, which must be carefully rammed. At the final stage, the installation of hatches for each tank. For their arrangement around each pipe is concreting the surface.

Installing other options

A popular and sought-after type of manhole are swivel models for drainage, which are usually located in the corners of the system where the pipes are connected. Such structures do not need to be installed at each turn, however, the decision on the number and location of such wells should be made in each individual case. First of all, it is necessary to take into account the constructive of the entire drainage system and install it so that all communications can be connected to the rotary wells.

The need to install such products is due to the fact that the corners in the overall water drainage system are the most vulnerable and susceptible to damage.In addition, garbage and dirt accumulate in these places, which leads to the formation of blockages, as a result - the whole system will not be able to function productively. It is thanks to the rotary structures that you can clean and eliminate contamination or drainage defects.

According to experts, wells of this type should be installed at every second turn according to the standard installation scheme of spillway type structures.

Cleaning

Timely maintenance of the entire drainage system, including pipes and wells, is an important task, extending the service life of the entire structure, as well as the structures located in the territory. For such work, you may need to pump out the accumulated water from the wells.

What can pump water?

In order to extract water from drainage wells as quickly as possible, you should resort to using a pump. Typically, for such work is used submersible electrical device. The device has an acceptable cost, therefore it is available for purchase.

If the device is planned to be used only for work with the drainage system, there is no need to purchase an especially powerful pump. The optimal power rating is 100-200 liters per minute.Submersible pumps with more power are needed for industrial use only.

There are cases when there is no need to use a pump for pumping water. This option is possible if the stock has a differential slope, directed into a reservoir.

Sequence of work

The specifics of the drainage system requires a special approach to its maintenance. To carry out the cleaning of any drainage well with his own hand, it is necessary to conduct a series of consecutive measures. A method consists in gradual siphoning of water by about 50 centimeters, accompanying pumping by washing and cleaning the walls of the tank.

- To clean the bases, it is best to use a large sponge or a soft brush designed for processing metal products. Care should be taken not to deform the surface and structure of the well.

- During the cleaning process, contamination from the walls can get into the water. This is not to be feared, since the existing liquid will be completely pumped out later.

- The use of any chemical detergents or cleaning products is strictly prohibited, as they may cause harm to humans.

- Reaching the bottom of the well, you should completely pump out the remaining water and begin work on the major cleaning of the bottom of the tank.

- The only disinfectant that can be safely used for washing is a 10% bleach solution. This composition needs to treat the base of the well, as well as pour a small amount of the substance on the bottom in the presence of water. Then close the lid tightly, additionally wrapping it with a tarpaulin, in order to prevent chlorine from evaporating.

- In this state it is necessary to leave the capacity for at least two days. After a time, the cover and material can be removed and completely filled twice and drained well to wash off the chlorine residues and protect themselves from possible contact with hazardous substances.

For details on how to clean the drainage well, see the next video.

On the need to install drainage on the site, see below.